Environment-friendly stamping and overturning mechanism for building board machining

A technology for building boards and turning mechanisms, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of inaccurate positioning, complex structure, and easy damage of stamping mechanisms, and achieve high mechanical structure reliability and structural design. Reasonable, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] For the convenience of explanation, figure 1 The middle right direction is front, front end, front part, forward direction, and the left side direction is rear, rear end, rear part, backward direction.

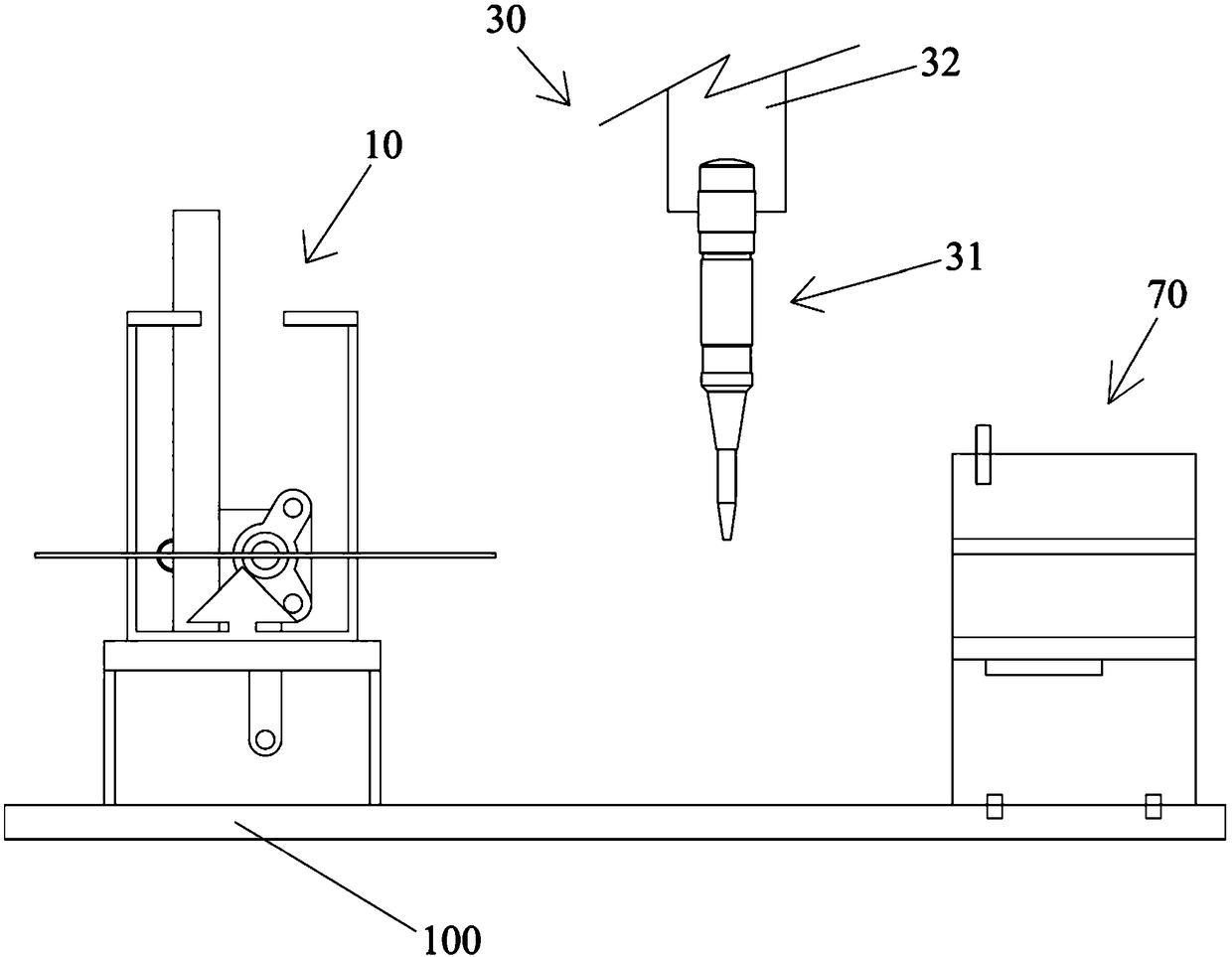

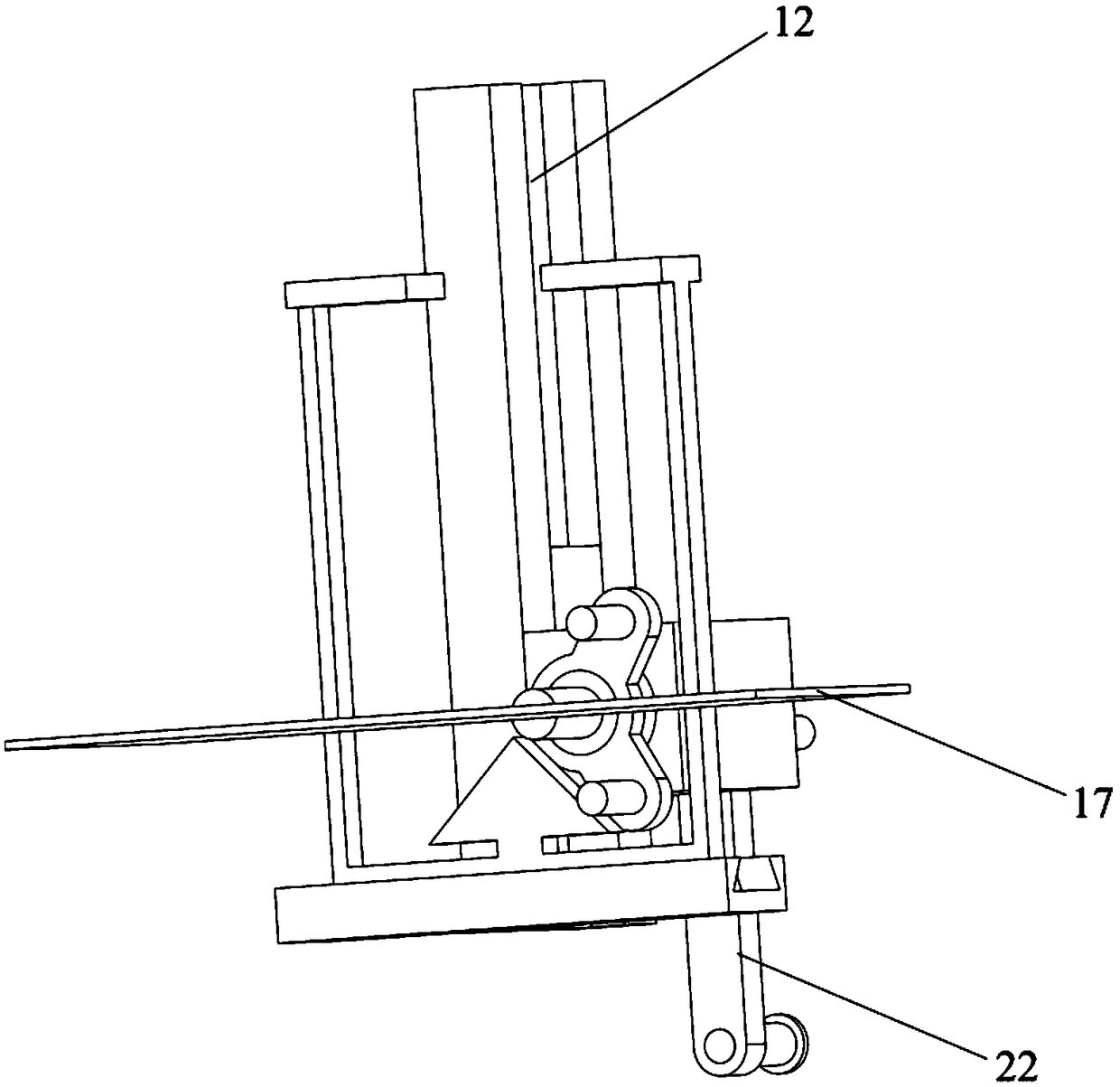

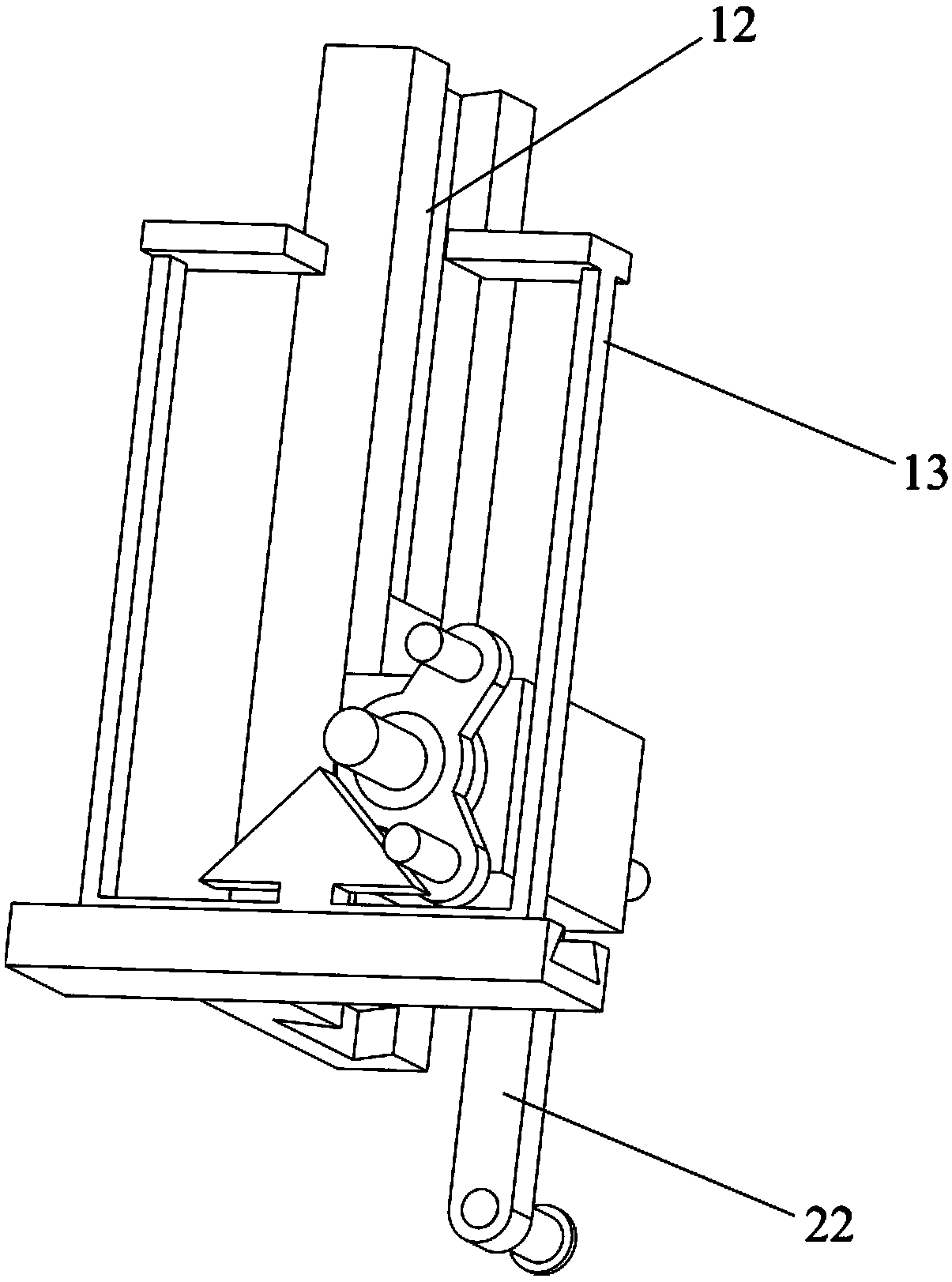

[0027] Such as Figure 1 to Figure 6 As shown, the embodiment of the present invention provides an environment-friendly stamping and turning mechanism for building board processing, including a frame 100, on which a turning device 10 is arranged, and the turning device 10 includes a frame fixed on the frame 100 The horizontal chute 11 and the vertical chute 12, the horizontal chute 11 is slidably provided with a guide bracket 13, the vertical chute 12 is provided with a first slider 14, and the first slider 14 is provided with A fourth axle fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com