Multi-blade multipurpose mechanical scissors

A technology of machinery and scissors, applied in metal processing and other directions, can solve problems such as poor, time-consuming and labor-intensive cutting accuracy, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

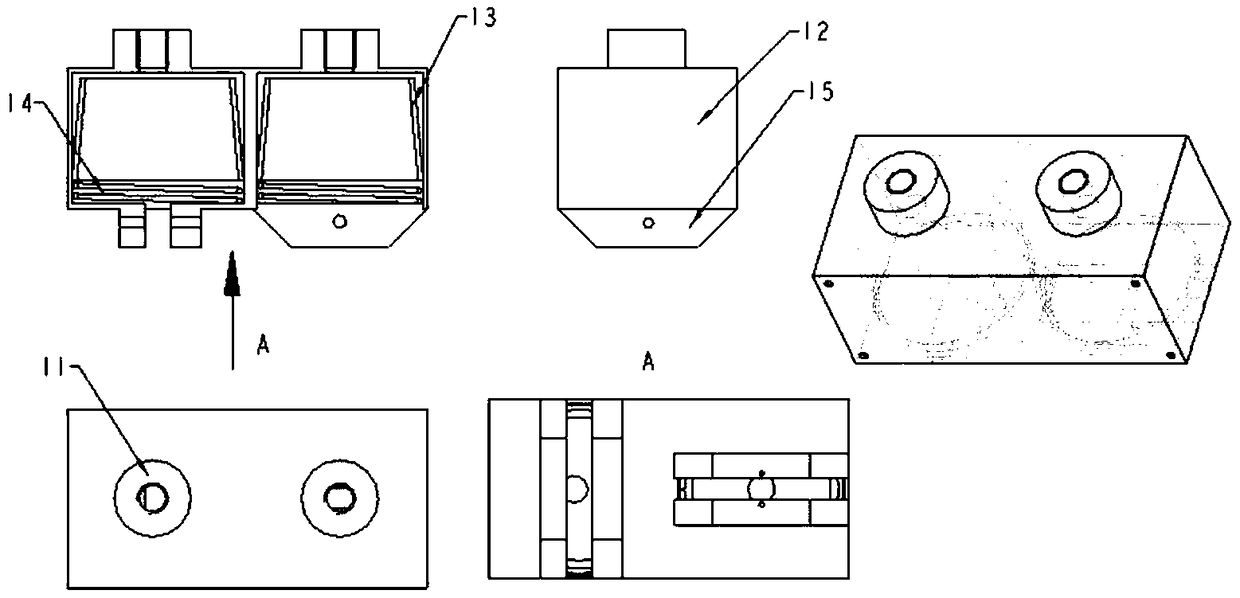

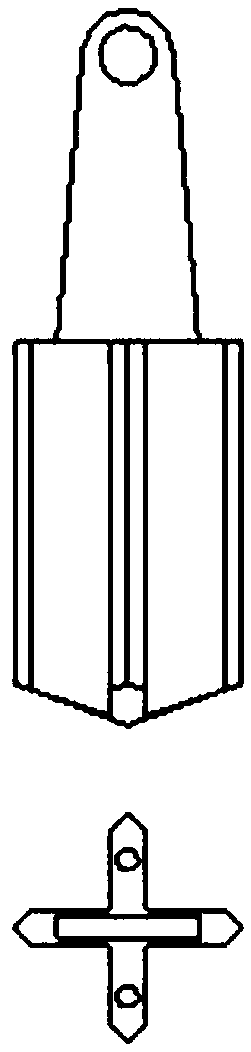

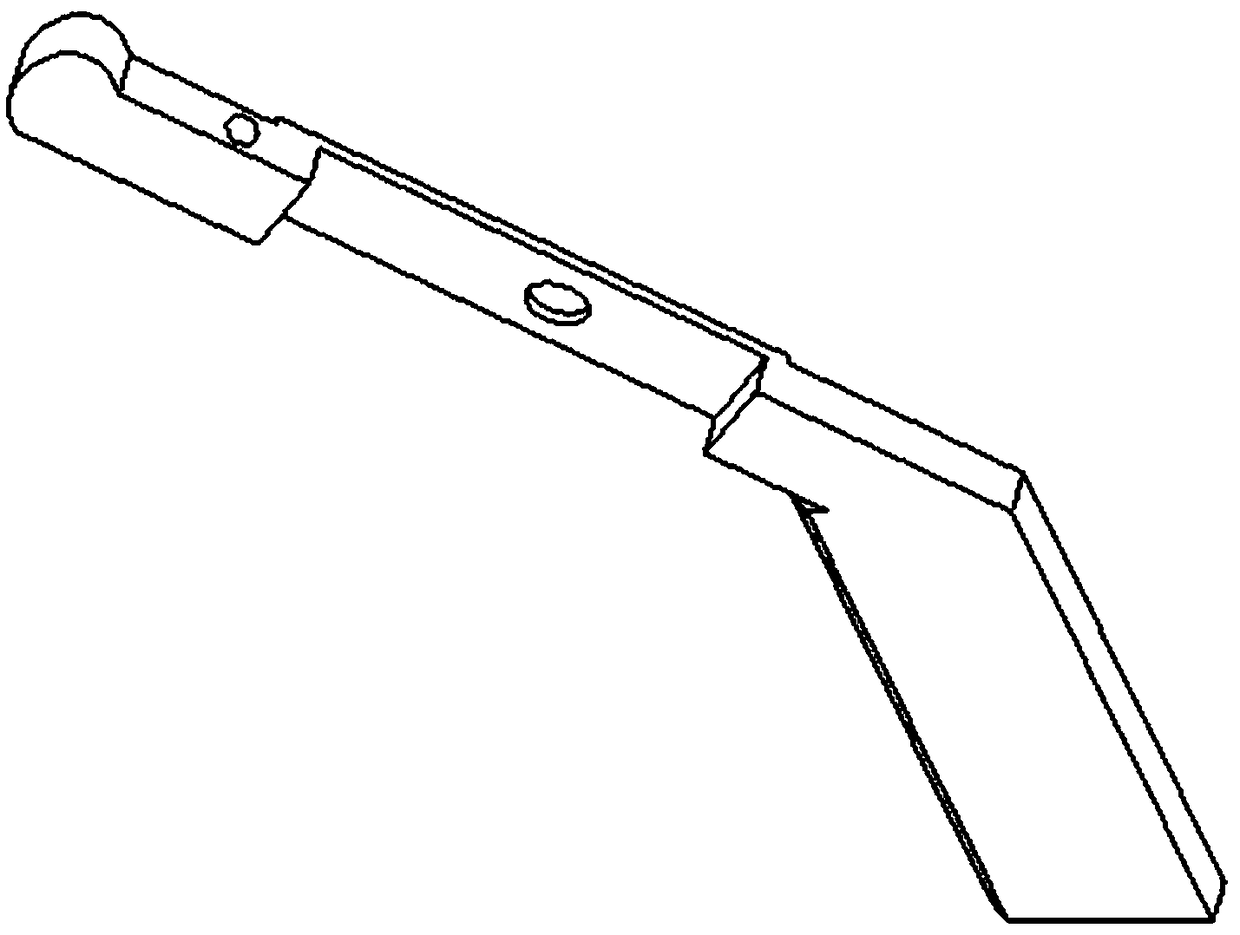

[0018] The following is a further description of the multi-blade multi-purpose mechanical scissors of the present invention with reference to the accompanying drawings.

[0019] Such as figure 1 , 2 , 3, 4, 5, and 6, a multi-blade and multi-purpose mechanical scissors, which is characterized by comprising: a mechanical body 1, a blade assembly 2, an object to be cut 3; the mechanical body 1 has a square structure and is fixed in On the assembly line frame that needs to be installed, the fixed blade 21 of the blade assembly 2 is connected to the bottom of the machine body 1, and the cut object 3 is a soft material and a rigid thin shell, and is placed on the front of the blade assembly 2. Below, the working cutting opening of the blade assembly 2 is cross-shaped, realizing the one-time forming of the cross-shaped opening of the cut object 3; the mechanical body 1 includes a base 11, a cylinder 12, a slider 13, and a return spring I14. Connecting block 15; the bottom of the base 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com