Paper box production and processing cutting forming device

A molding device and carton technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of unable to meet the daily production needs of enterprises, unable to clean up waste in time, and accumulation of production lines, etc., to increase the cutting effect and reduce cutting burrs. the appearance rate and ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

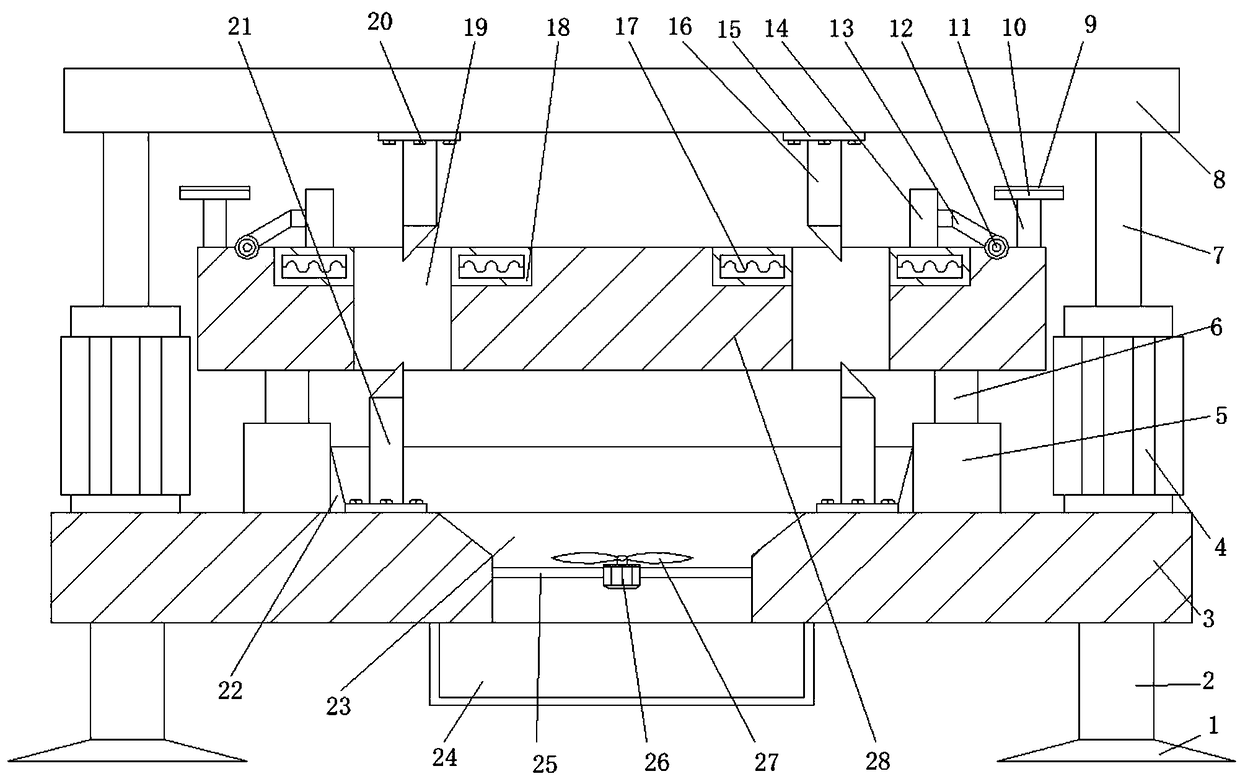

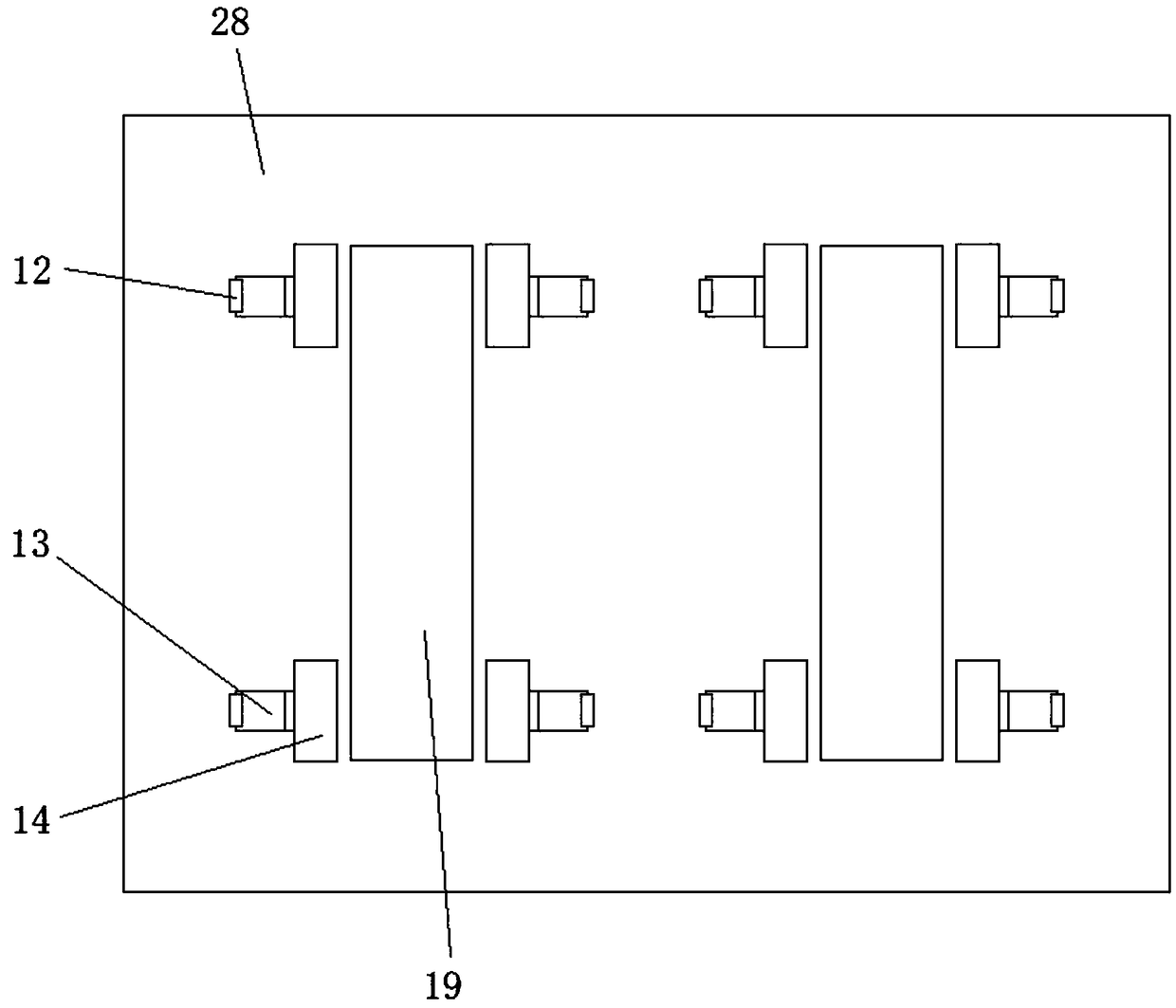

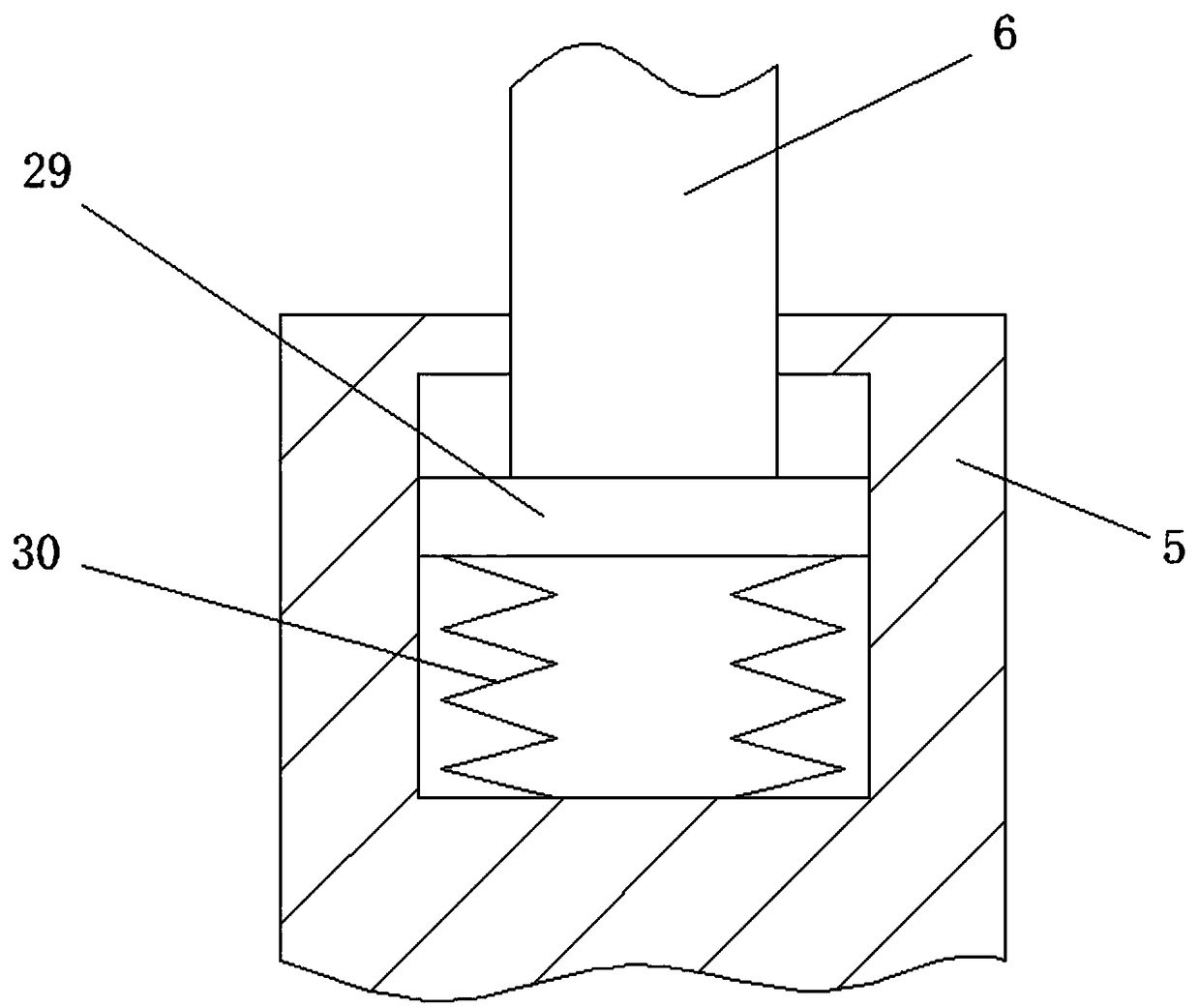

[0021] see Figure 1-4 , a carton production, processing, cutting and forming device, including a lower template 3; the lower template 3 is cuboid, made of steel plates, and its lower surface is left and right symmetrically welded legs 2; the lower end of the legs 2 is equipped with a leg 1 , used to support the lower formwork 3; the upper surface of the lower formwork 3 is symmetrically connected by bolts to fix the hydraulic lever 4; the upper part of the hydraulic lever 4 is connected to the hydraulic telescopic rod 7, which is used to provide power for up and down movement; The upper end of the hydraulic telescopic rod 7 is welded and fixed with an upper template 8, which is driven by the hydraulic cylinder 4 to move up and down; the lower surface of the upper template 8 is symmetrically connected to the fixed mounting plate 15 by connecting bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com