Two-step method for preparing peroxide crosslinked polyethylene pipe

A technology of cross-linked polyethylene and di-tert-butyl peroxide, which is applied in the field of plastic product manufacturing, can solve the problems of poor hygienic performance, difficult operation, fire disaster prevention, etc., and achieve the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

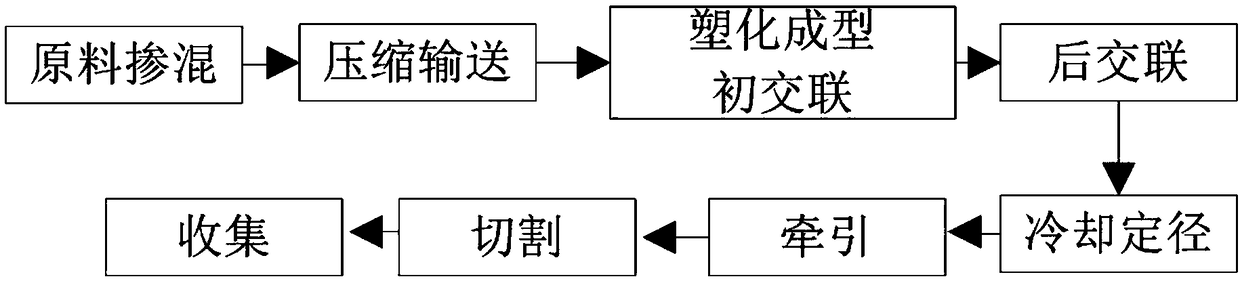

[0036] This embodiment example provides a kind of preparation method of peroxide crosslinked polyethylene pipe, such as figure 1 shown, including the following steps:

[0037] (1) Mix 100g of high-density polyethylene (HDPE), 0.40g of di-tert-butyl peroxide (DTBP), and 0.45g of antioxidant 1076 in a closed mixer at no more than 35°C at a stirring speed of 300rpm for 10min, to obtain a blend;

[0038] (2) Put the blend into the hopper of the extruder. In order to ensure that the crosslinking agent does not decompose prematurely and the HDPE does not melt, it is compressed and transported to the die (mold) at a temperature of 125 ° C. The temperature of the die is 230 ° C. , extruding, melting and plasticizing the blend and performing initial cross-linking, the cross-linking degree of the initial cross-linking is 20%;

[0039] (3) Put the blend after the primary crosslinking into a non-resistance, and the temperature is 250°C in a hot environment to complete the postcrosslinki...

Embodiment 2

[0042] The present embodiment provides a kind of preparation method of peroxide crosslinked polyethylene pipe, comprising the following steps:

[0043](1) Mix 100g of high-density polyethylene (HDPE), 0.37g of di-tert-butyl peroxide (DTBP), and 0.4g of antioxidant 1076 in a closed mixer at no more than 35°C at a stirring speed of 200rpm for 12min, to obtain a blend;

[0044] (2) Put the blend into the hopper of the extruder. In order to ensure that the crosslinking agent does not decompose prematurely and the HDPE does not melt, it is compressed and transported to the die (mold) at a temperature of 130°C. The temperature of the die is 220°C. Extrude, melt and plasticize the blend and carry out initial crosslinking, the degree of crosslinking of the initial crosslinking is 17%;

[0045] (3) The blend after the initial crosslinking is put into a non-resistance, and the temperature is 270 ° C in a hot environment to complete the postcrosslinking, and the crosslinking degree of t...

Embodiment 3

[0048] The present embodiment provides a kind of preparation method of peroxide crosslinked polyethylene pipe, comprising the following steps:

[0049] (1) Mix 100 g of high-density polyethylene (HDPE), 0.45 g of di-tert-butyl peroxide (DTBP), and 0.42 g of antioxidant 1076 in a closed mixer at no more than 35 ° C at a stirring speed of 250 rpm for 12 min, to obtain a blend;

[0050] (2) Put the blend into the hopper of the extruder. In order to ensure that the crosslinking agent does not decompose prematurely and the HDPE does not melt, it is compressed and transported to the die (mold) at a temperature of 128°C. The temperature of the die is 240°C. Extrude, melt and plasticize the blend and carry out initial crosslinking, the degree of crosslinking of the initial crosslinking is 23%;

[0051] (3) The blend after the initial crosslinking is put into a non-resistance, and the temperature is 250 ° C in a hot environment to complete the postcrosslinking, and the crosslinking de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cross-linking degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com