Coordinated control method of multi-point operation for driving mechanism of climbing ship lift

A driving mechanism and coordinated control technology, applied in the field of control, can solve problems such as inconvenient operation and incompatibility, and achieve the effect of avoiding hidden dangers in operation safety and solving complex software development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

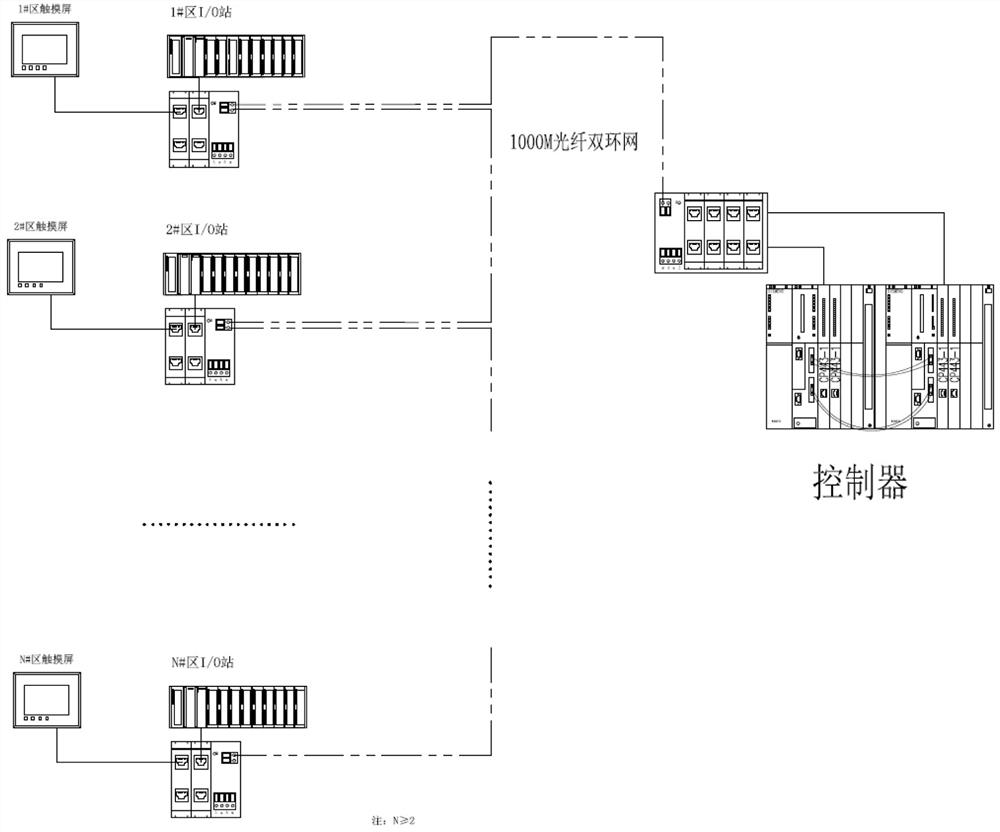

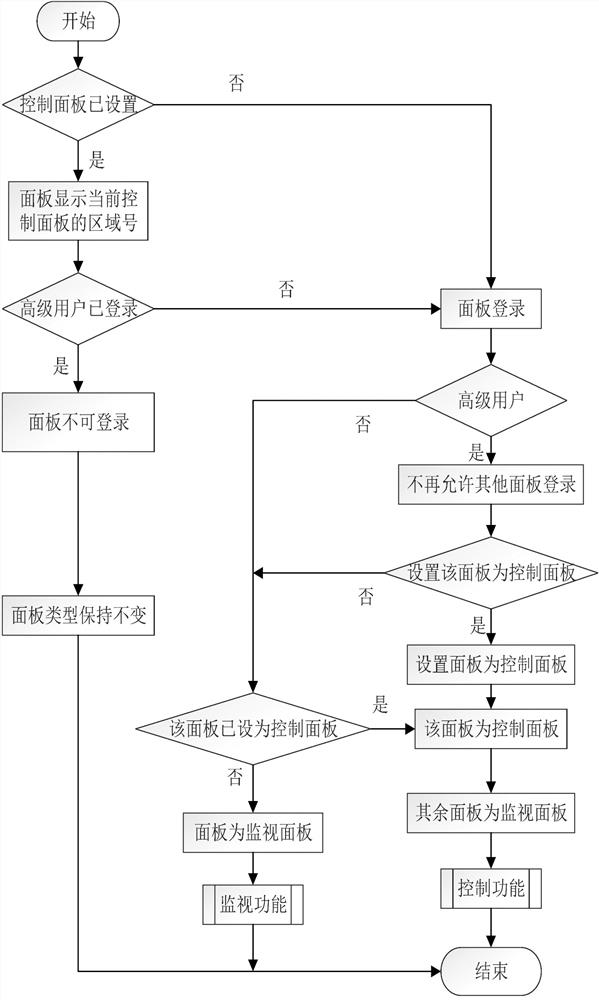

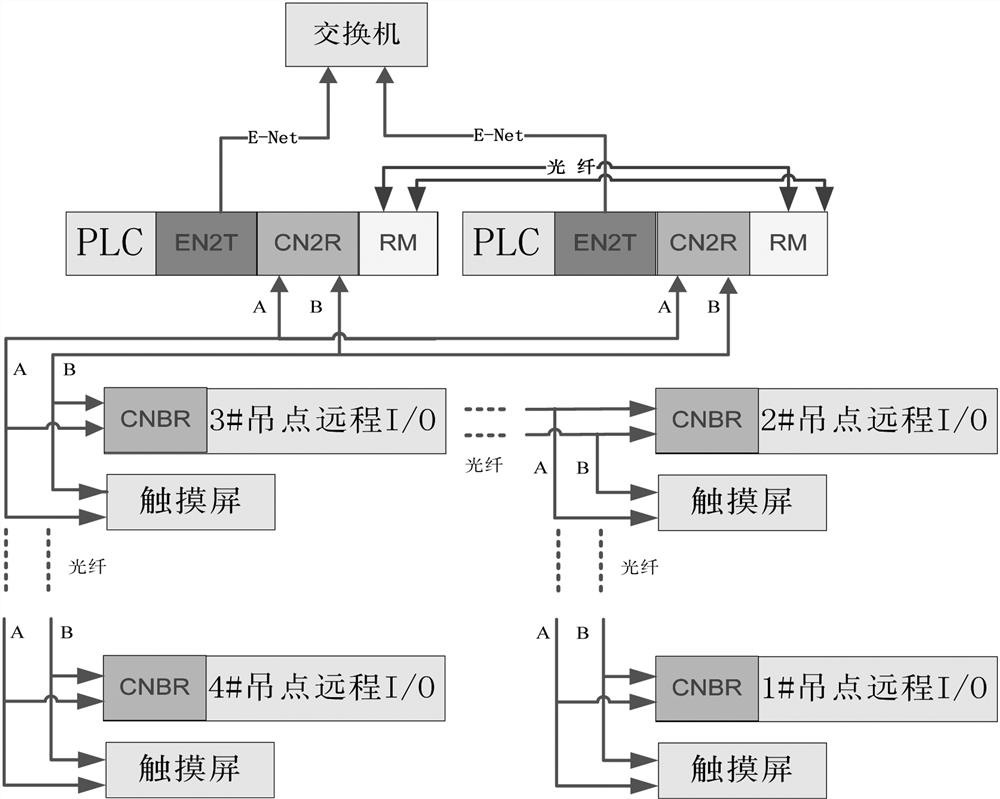

[0023] The invention relates to a multi-operation panel safety control technology in a control station of a ship lift monitoring station, which is suitable for occasions where multi-point simultaneous monitoring and multi-point control are required in a distributed control system such as a ship lift; The isolation of structural areas facilitates operators to realize multi-area operation and maintenance functions at any time. The present invention sets multiple operation panels in multiple equipment distribution areas of the ship lift driving mechanism monitoring system, and realizes multi-point operation coordination control.

[0024] Such as figure 1 As shown, the equipment layout of the driving mechanism of the climbing ship lift is scattered. In order to facilitate on-site monitoring and on-site debugging, it is often not enough to use one operation panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com