Patents

Literature

31results about How to "Avoid Operational Safety Hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for mutual redundancy of train display screens

ActiveCN102765396AAvoid Operational Safety HazardsLocomotivesControl systemHuman–computer interaction

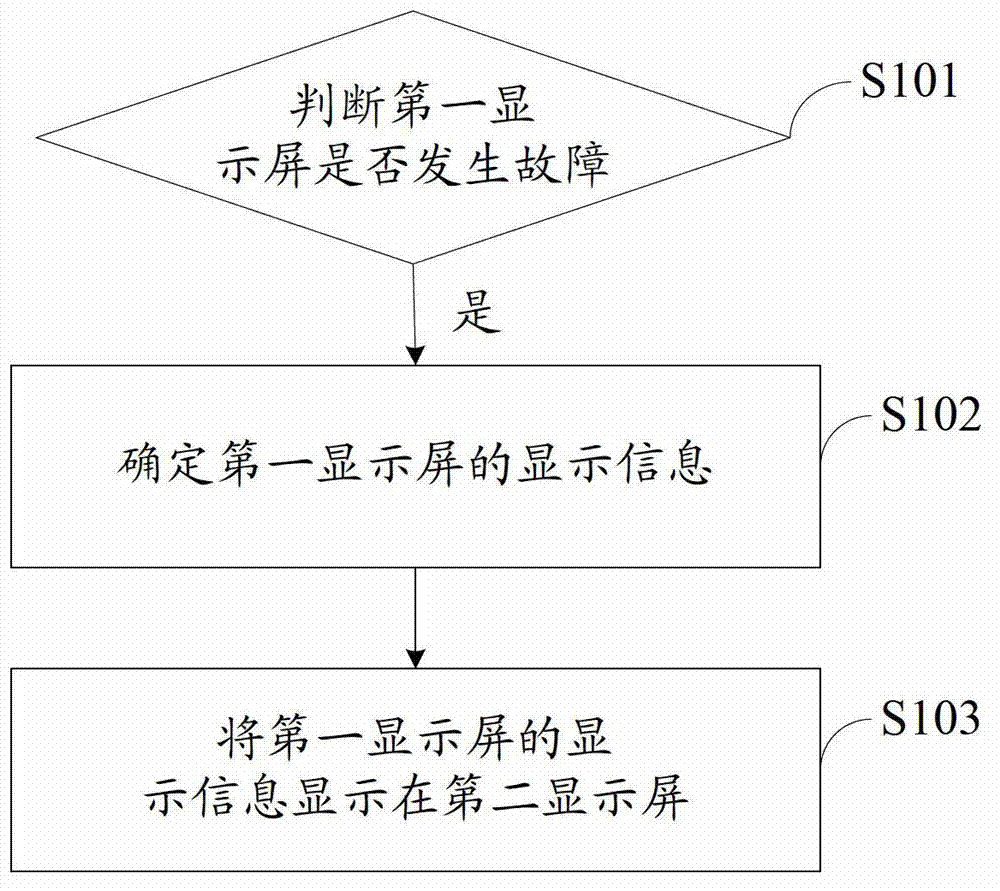

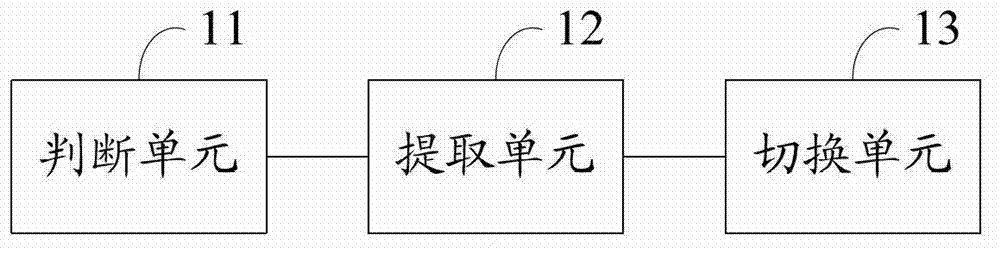

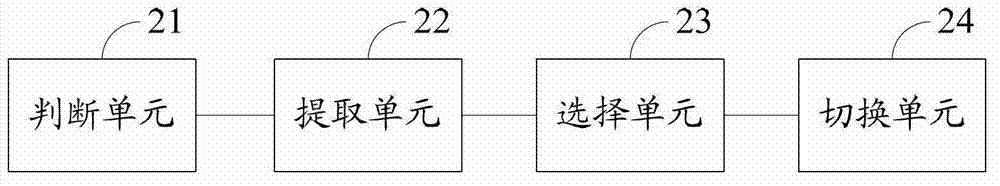

The invention discloses a method for mutual redundancy of train display screens. The method includes: judging whether a first display screen fails or not; if yes, determining display information of the first display screen; and displaying the display information of the first display screen on a second display screen. The first display screen serves as a train control system display screen or a network system display screen; when the first display screen serves as the train control system display screen, the second display screen serves as the network system display screen; and when the first display screen serves as the network system display screen, the second display screen serves as the train control system display screen. Mutual display of the train control system display screen and the network system display screen in a train can be realized, and the safety factor in the running process of the train can be further increased.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

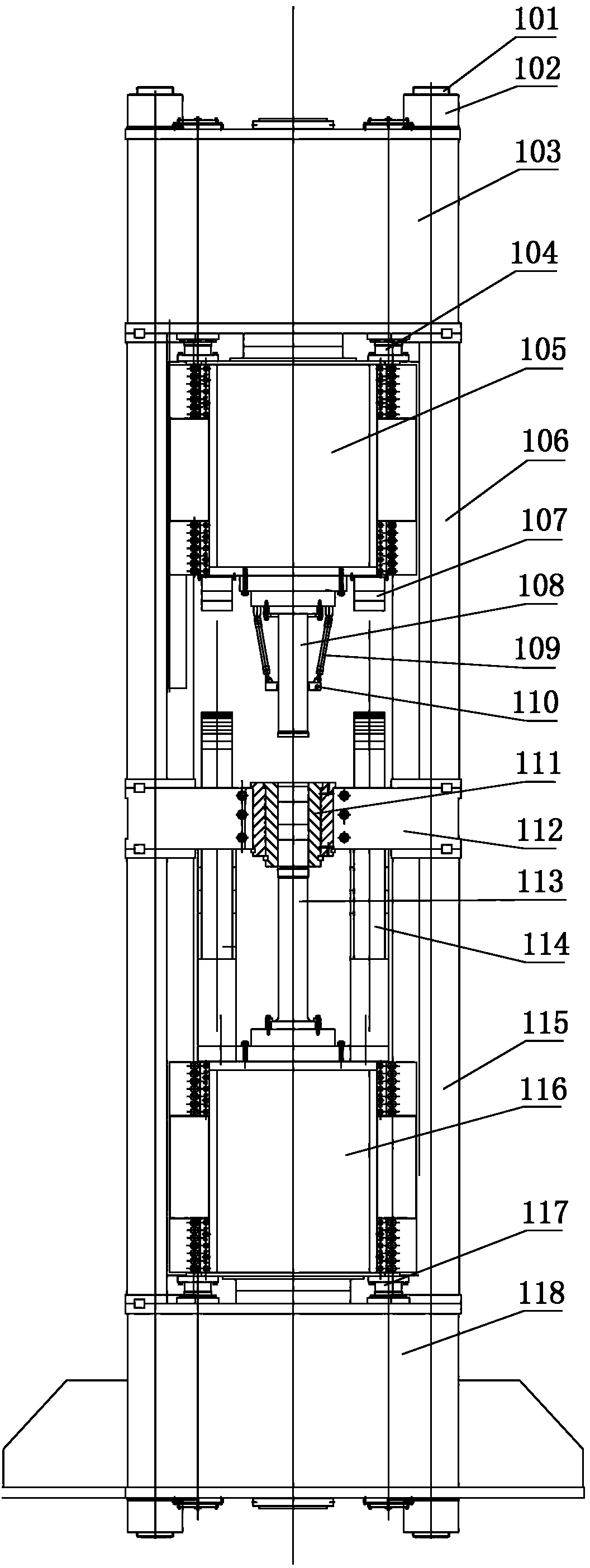

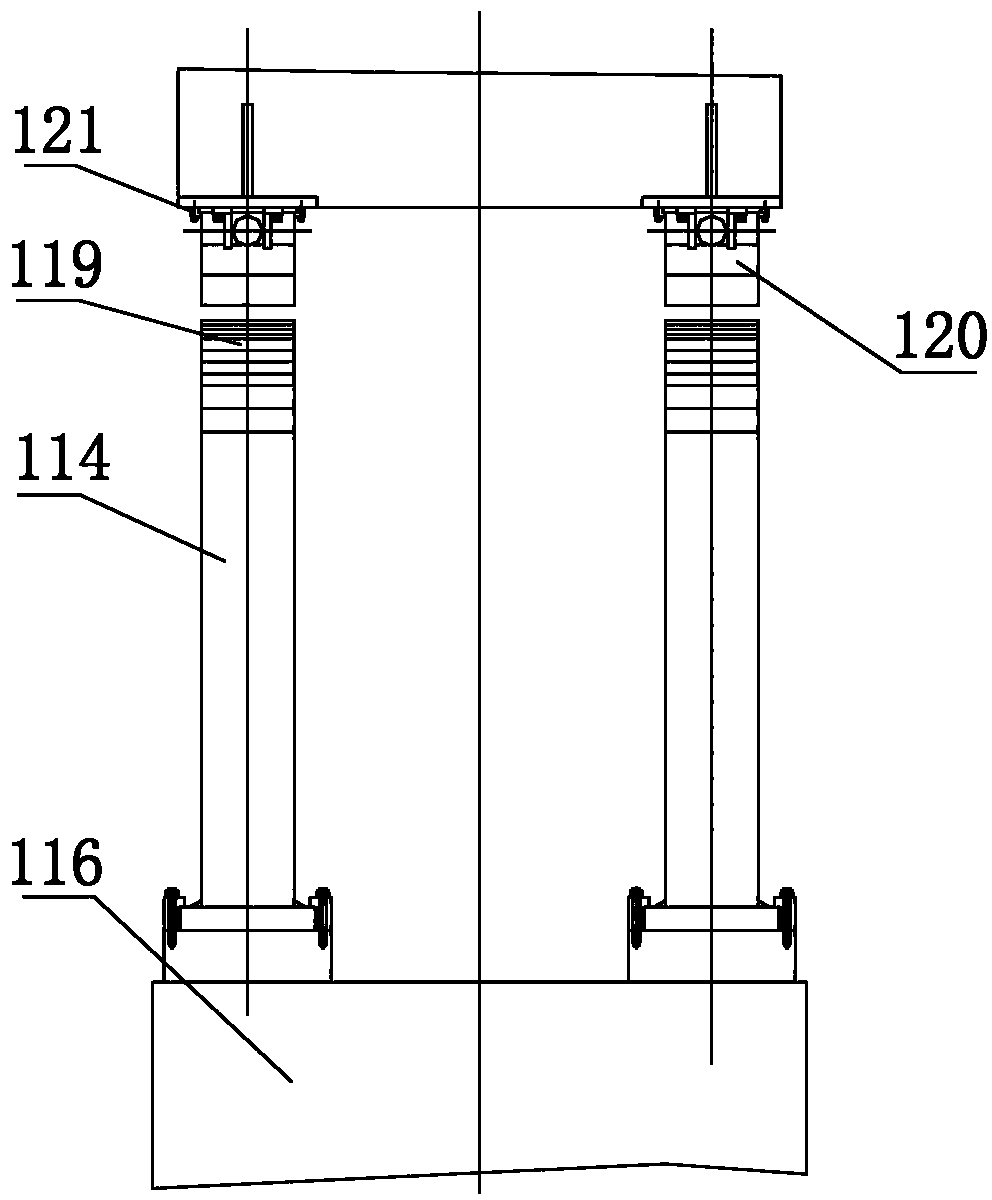

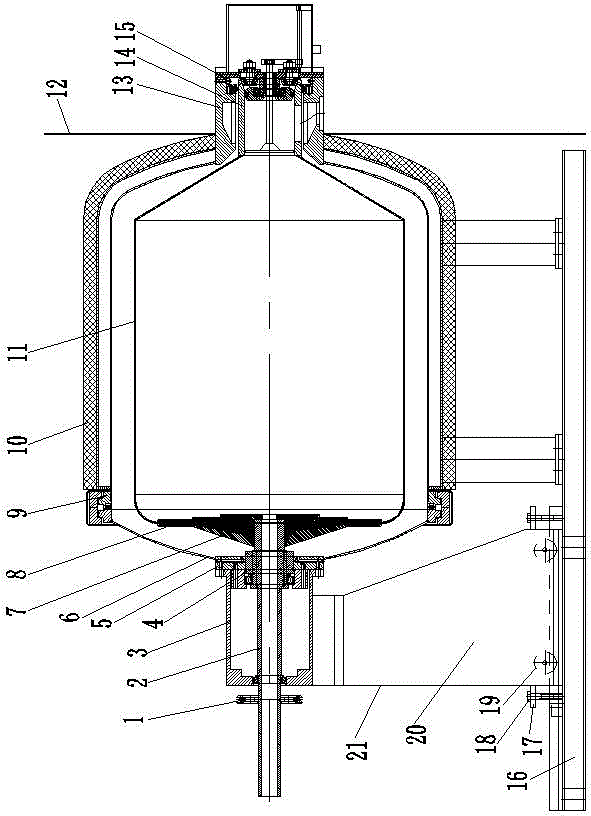

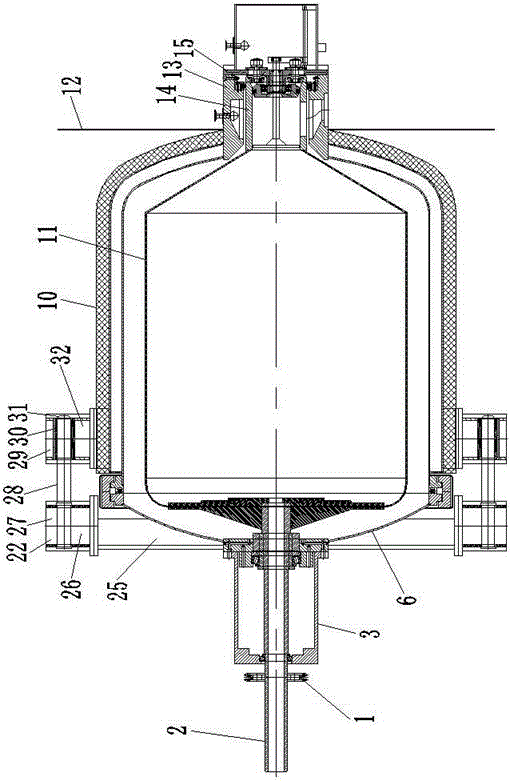

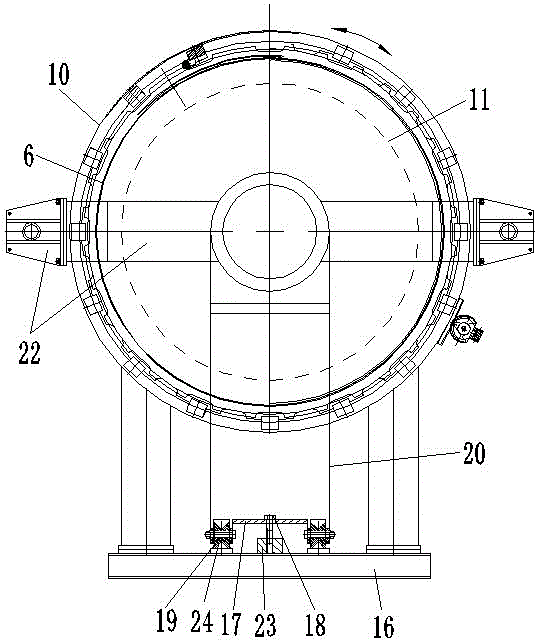

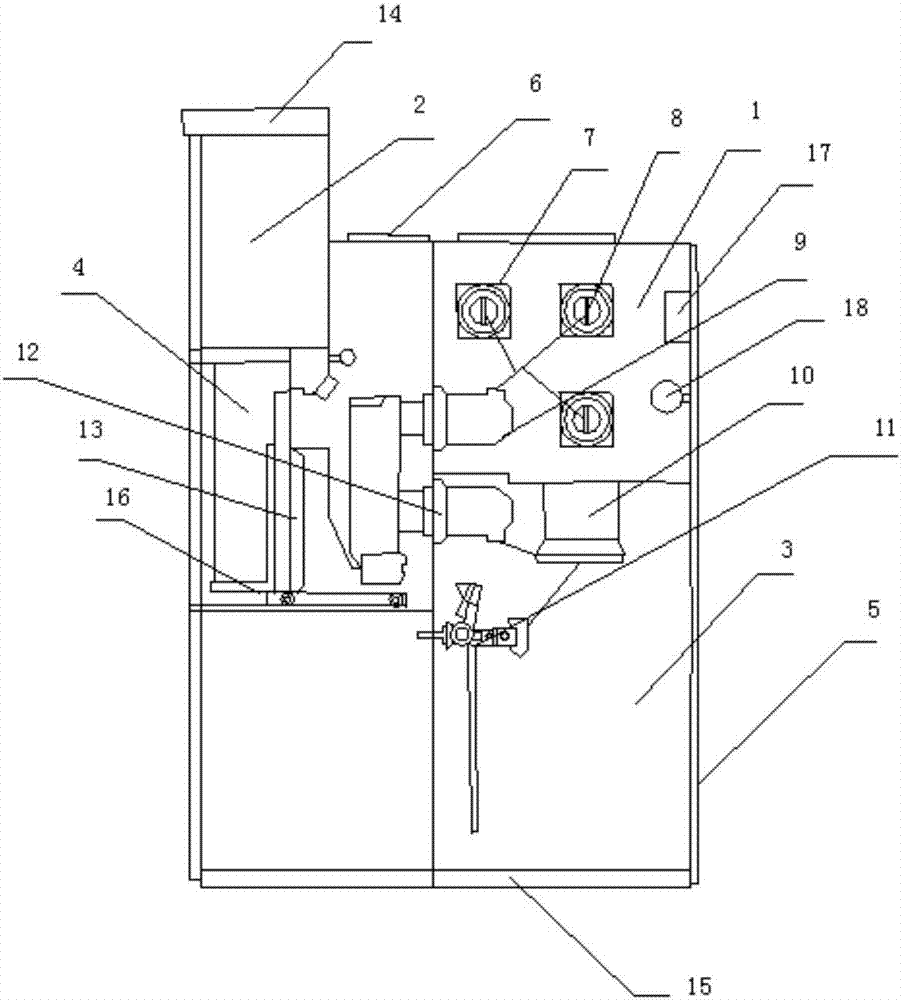

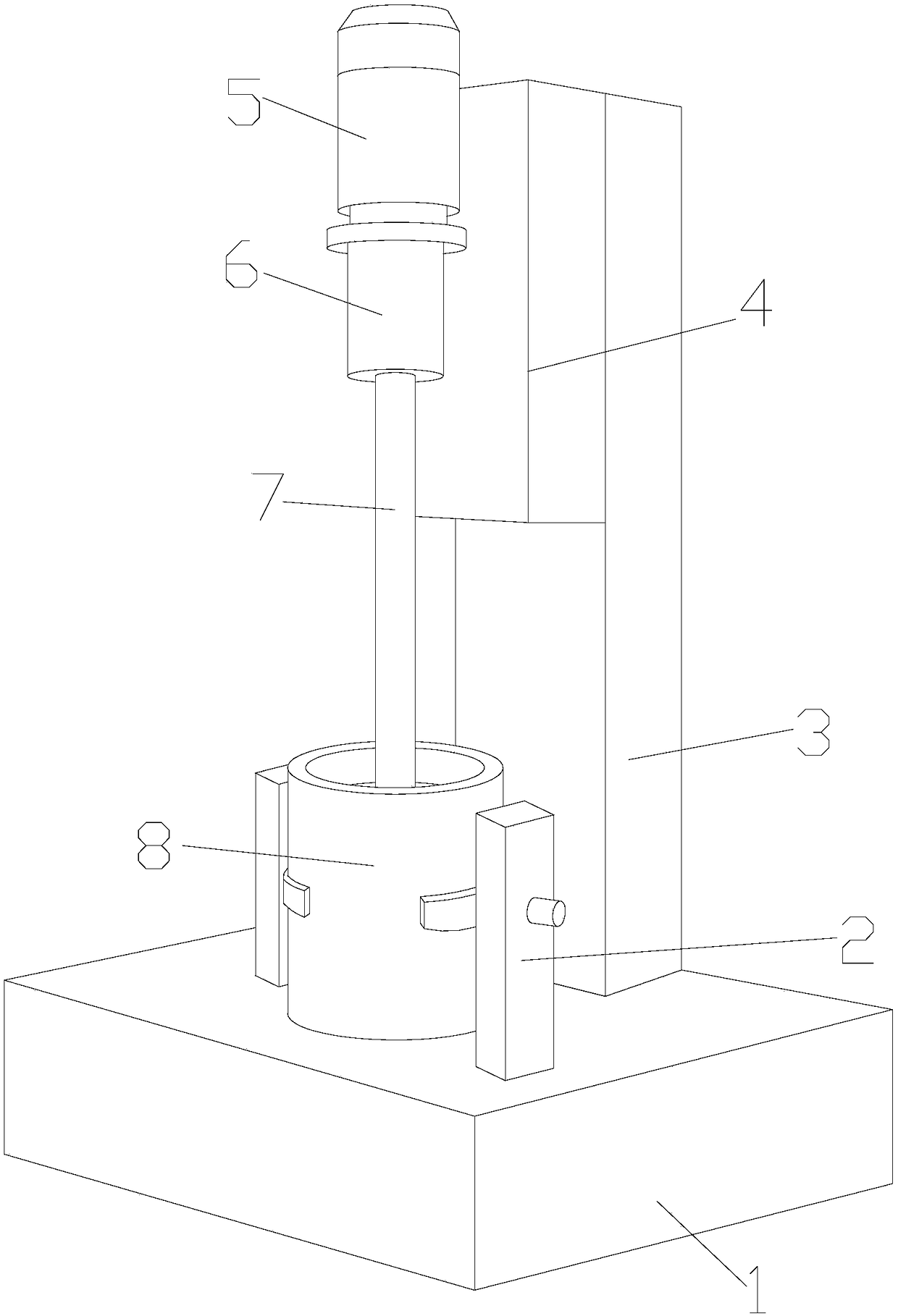

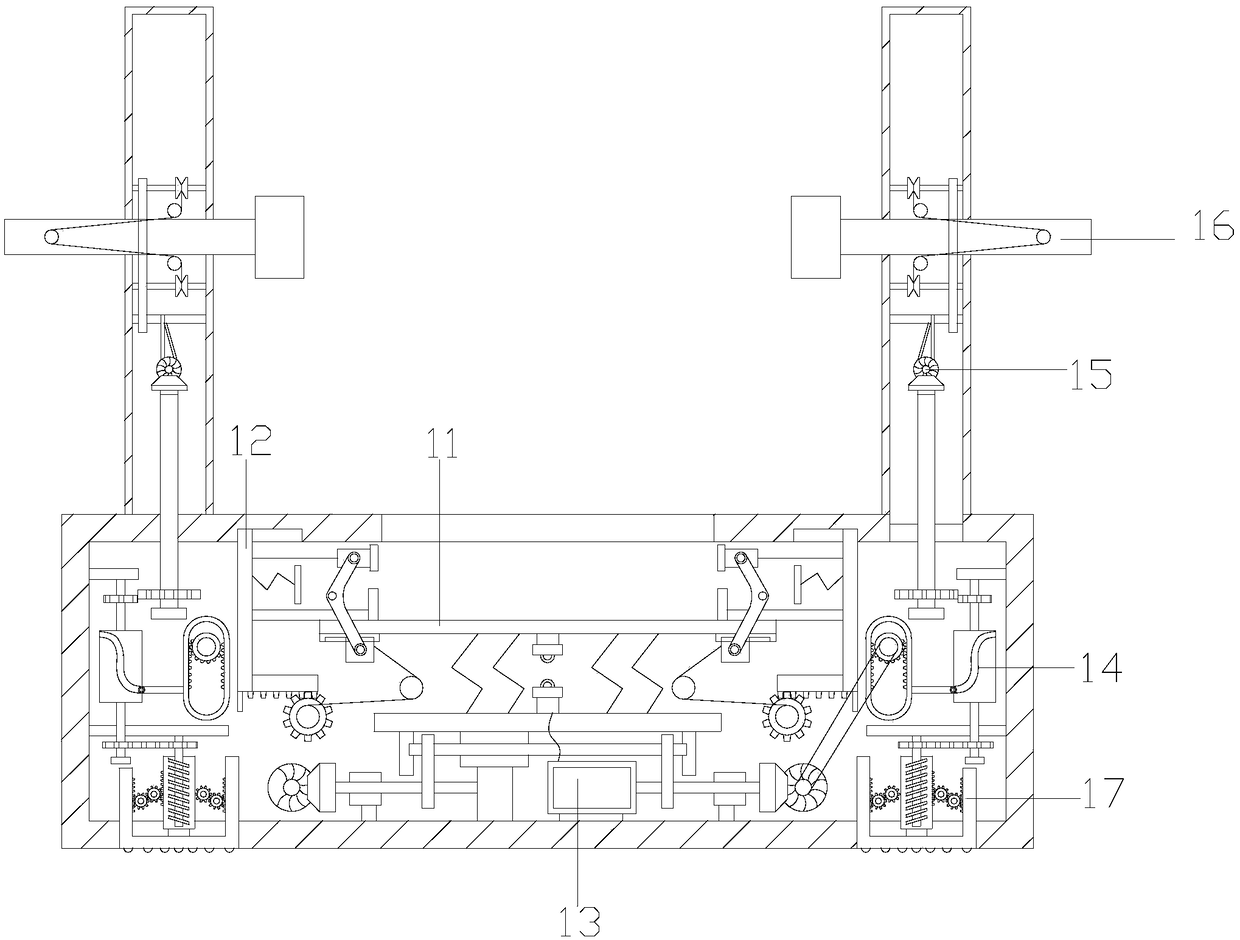

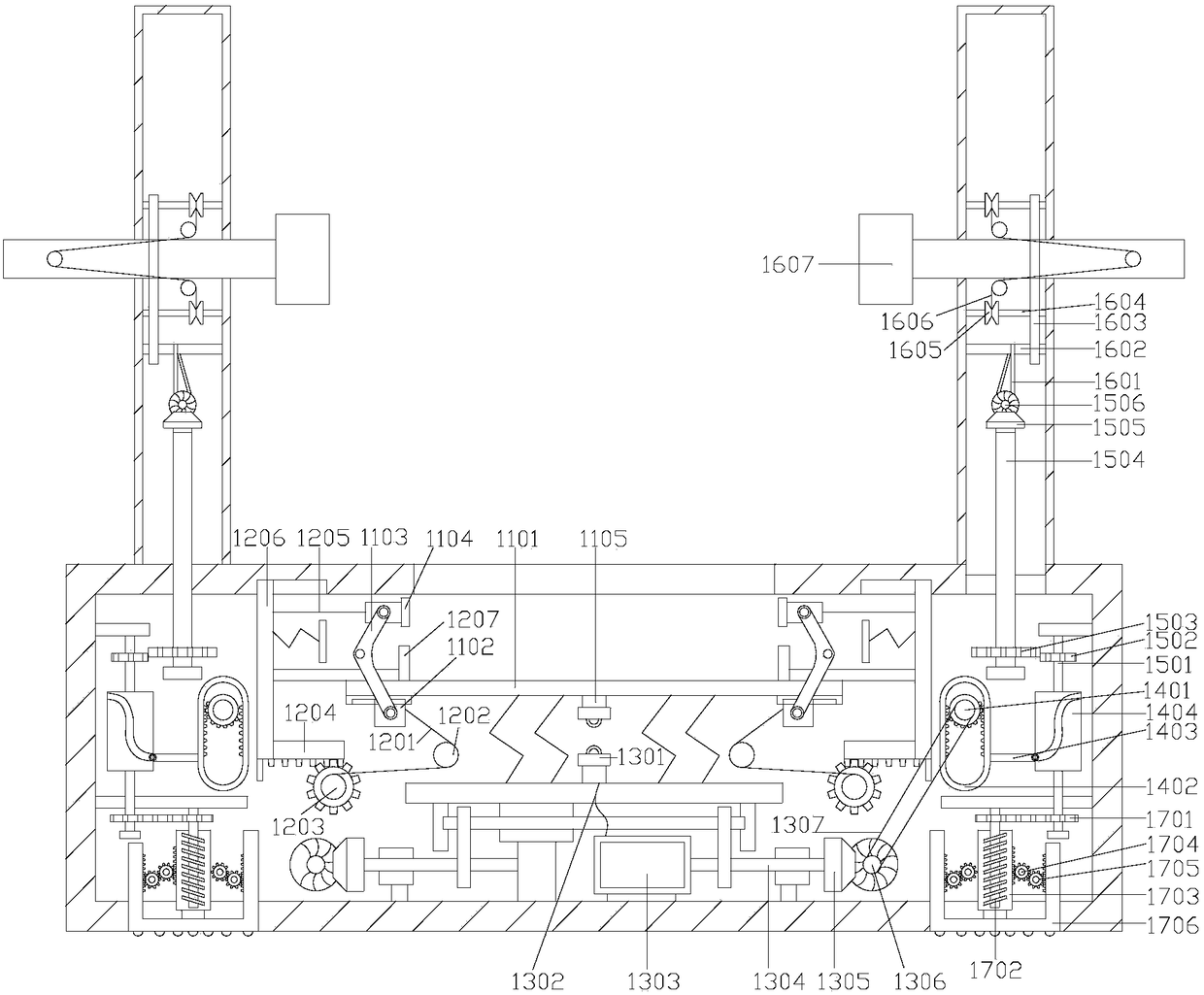

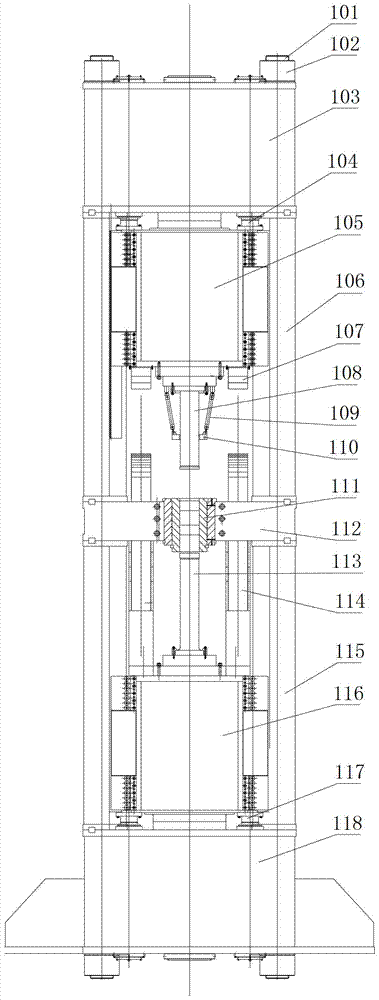

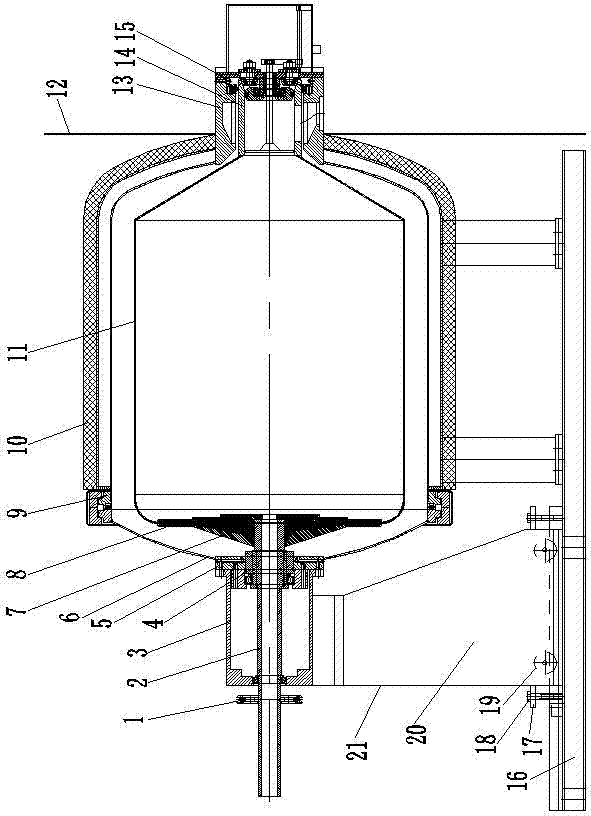

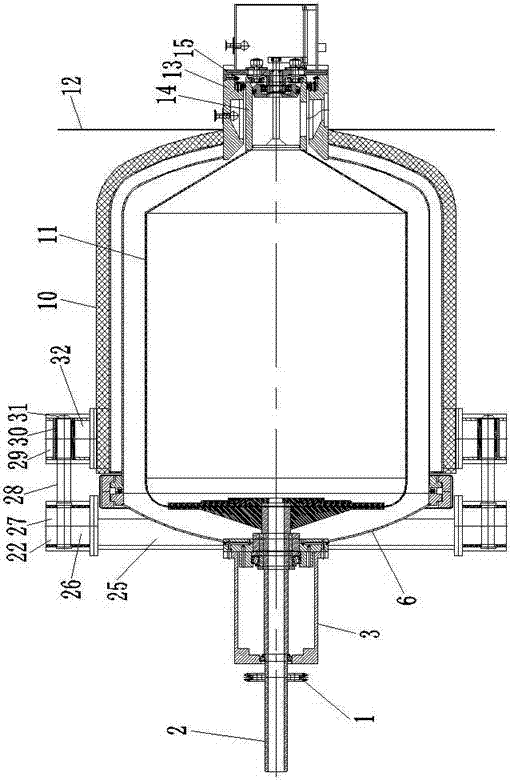

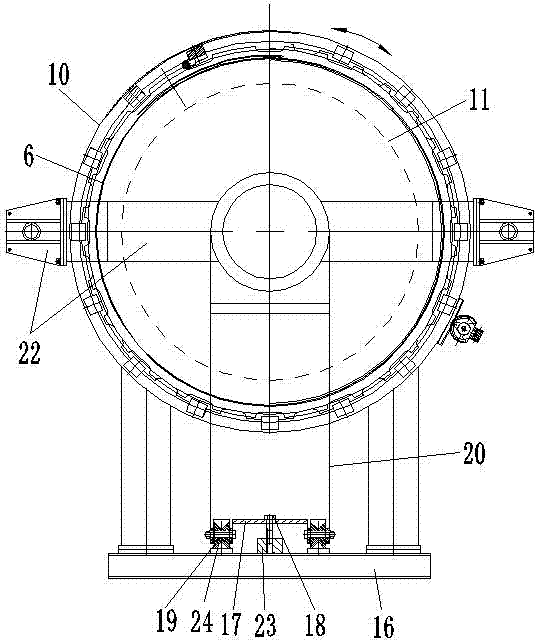

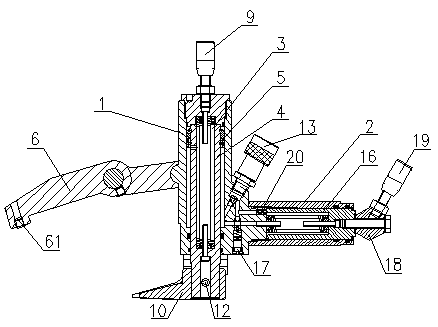

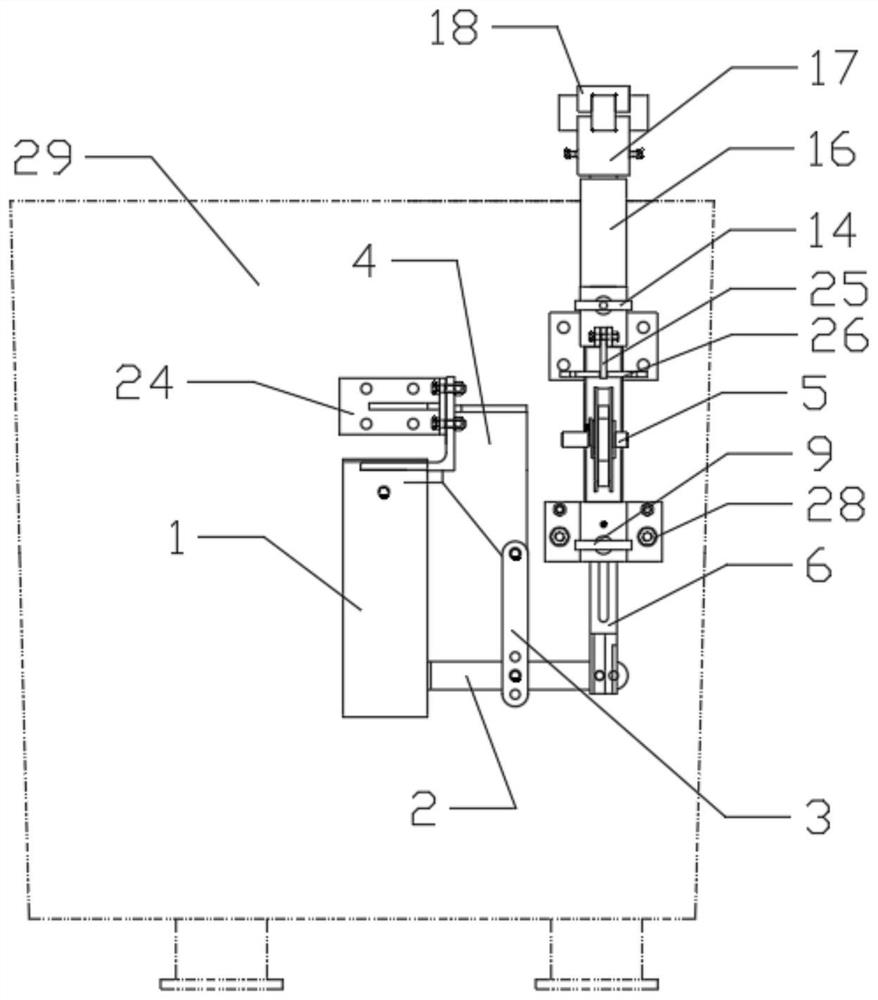

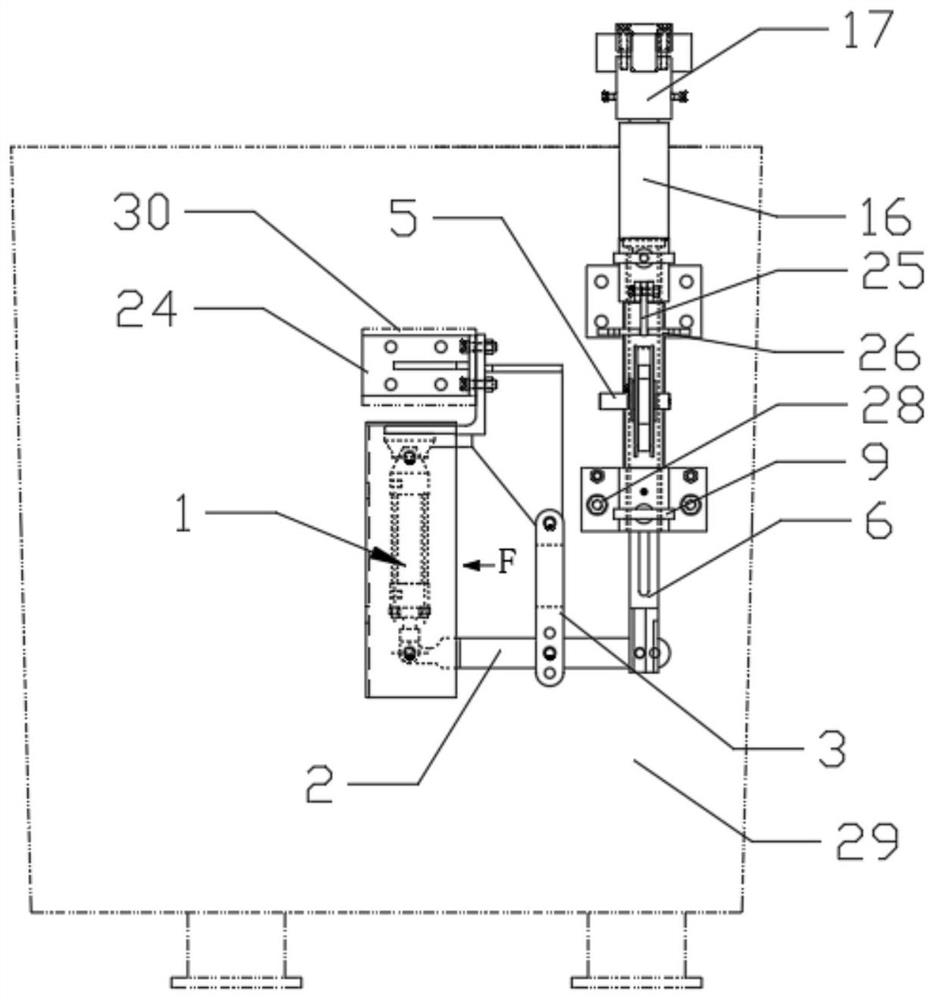

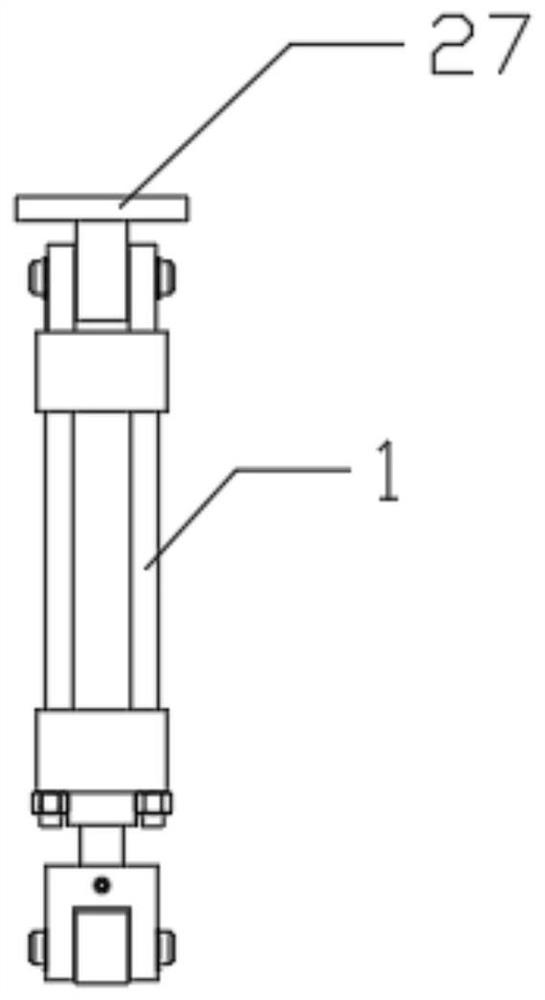

Automatic pressing production line of large explosive column

ActiveCN103265389AIncrease pressureHigh densityExplosive working-up apparatusProduction lineUltimate tensile strength

The invention relates to an automatic pressing production line of a large explosive column. The automatic pressing production line comprises a hydraulic press, which is composed of an upper beam, an upper return cylinder, an upper slide block with a cylinder, an upper punch, a middle girder with a die sleeve, and a lower beam. The automatic pressing production line is characterized by also comprising an automatic weighing and feeding device, a powder smoothing device and an automatic discharge device, which are arranged at the periphery of the hydraulic press; a lower return cylinder is arranged at the upper part of the lower beam; the lower return cylinder is connected with a lower slide block with a cylinder; a lower punch is arranged on the lower slide block with the cylinder; an automatic evacuating device is arranged at the lower part of the upper slide block with the cylinder; and mechanical limiting devices are arranged on the upper slide block with the cylinder and the lower slide block with the cylinder. The automatic pressing production line has the advantages that full-automatic operation of feeding, smoothing, two-way control and discharge of the explosive column can be achieved through the production line; the labor intensity of operating personnel can be greatly reduced; the production efficiency of a large-tonnage hydraulic press is improved; potential safety hazards are avoided; air bubbles of the explosive column in the pressing process can be reduced; the compact evenness and the accuracy of the explosive column are improved; and the product quality is also ensured.

Owner:TIANJIN TIANDUAN PRESS CO LTD

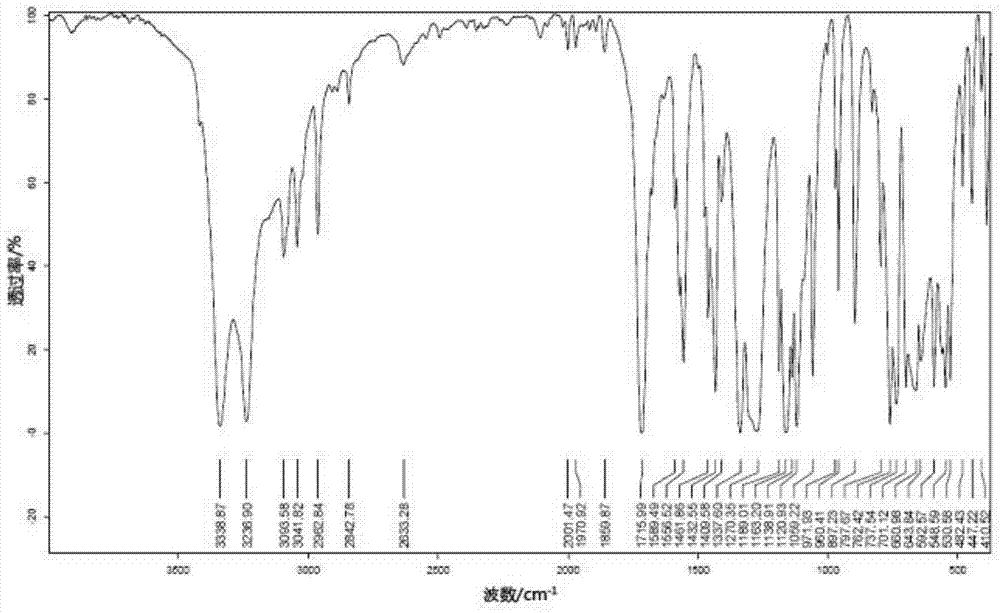

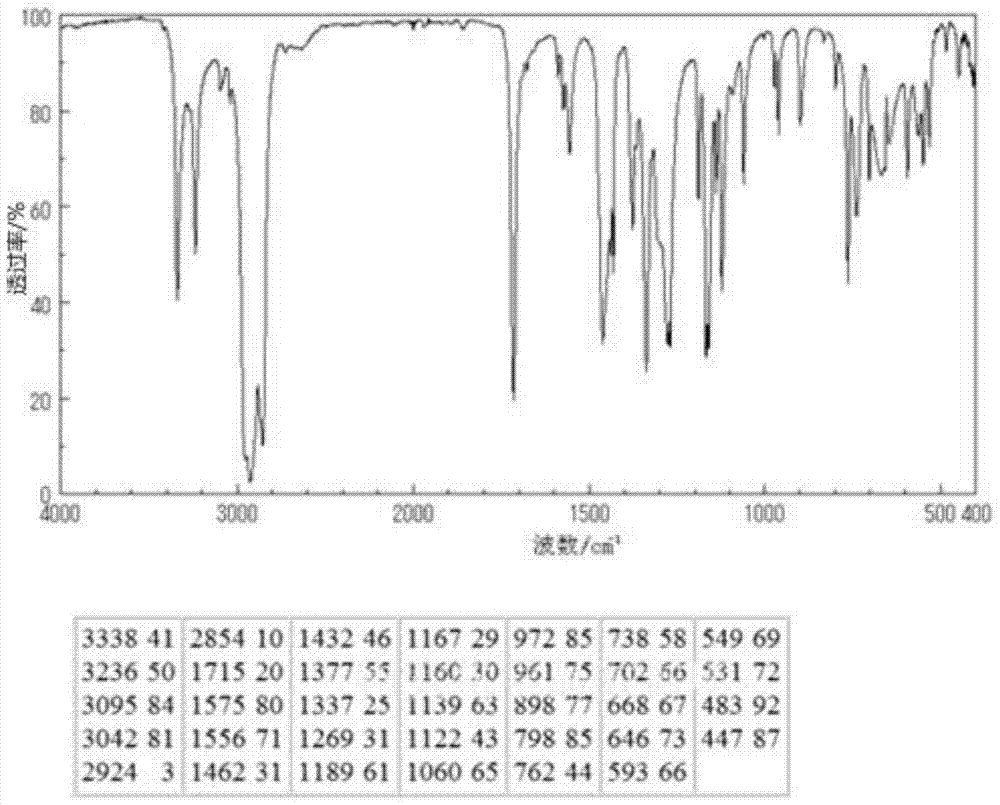

Cyanide leaching method for gold ores

ActiveCN101787442AAvoid Operational Safety HazardsImprove cyanide leaching rateLeaching ratePre treatment

The invention provides a cyanide leaching method for gold ores, and relates to a cyanide leaching method for refractory gold ores. The method is characterized by comprising the following steps: firstly crashing ores, grinding, adding potassium permanganate and sodium hydroxide and carrying out the heating and stirring pretreatment, then washing and filtering the treated ore pulp, and carrying out the cyanide leaching process. The method has the advantages of simple flow, easy operation, low investment, low operation cost and less environmental pollution, and can greatly improve the cyanide leaching rate of the gold ores difficult to leach.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

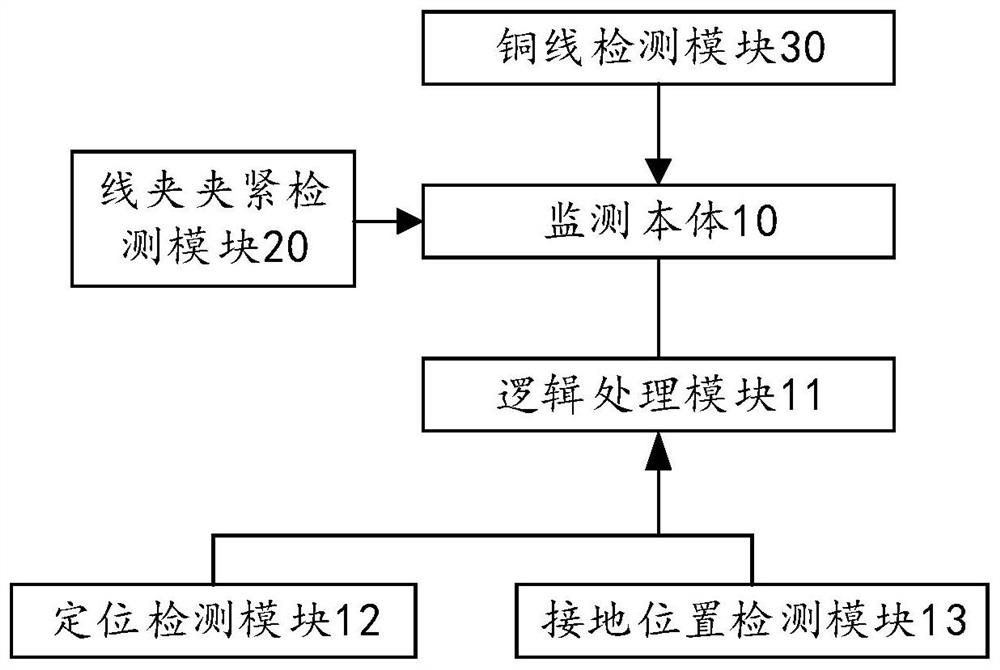

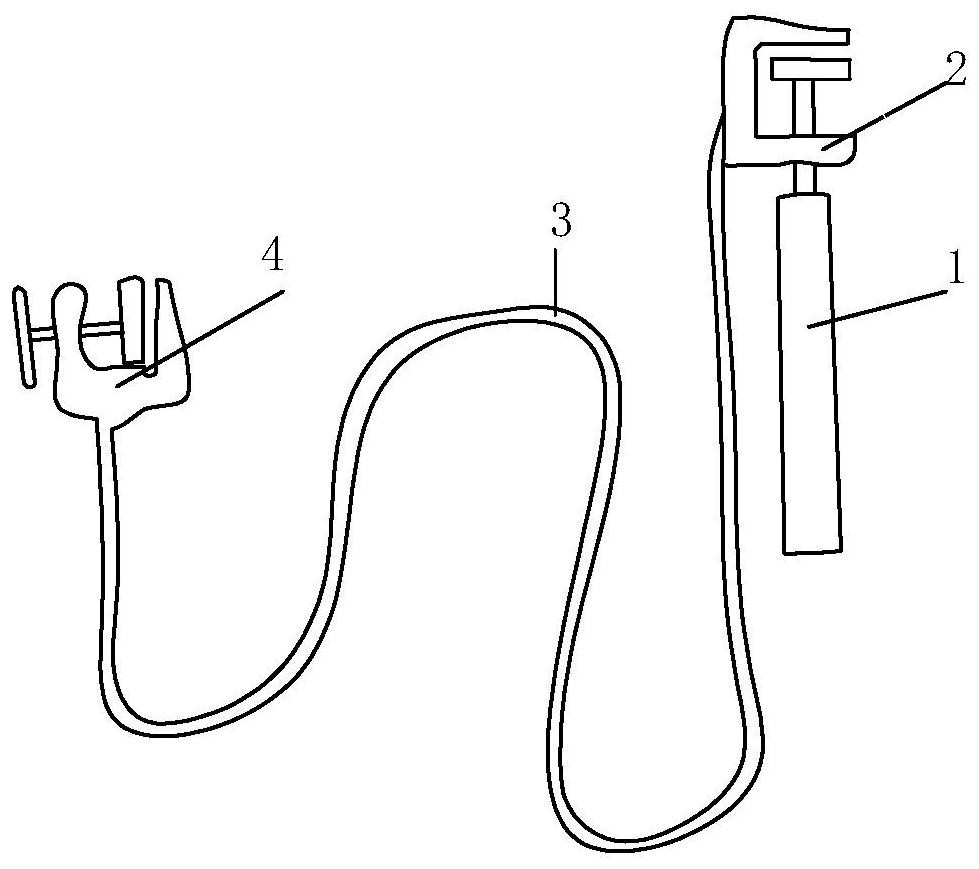

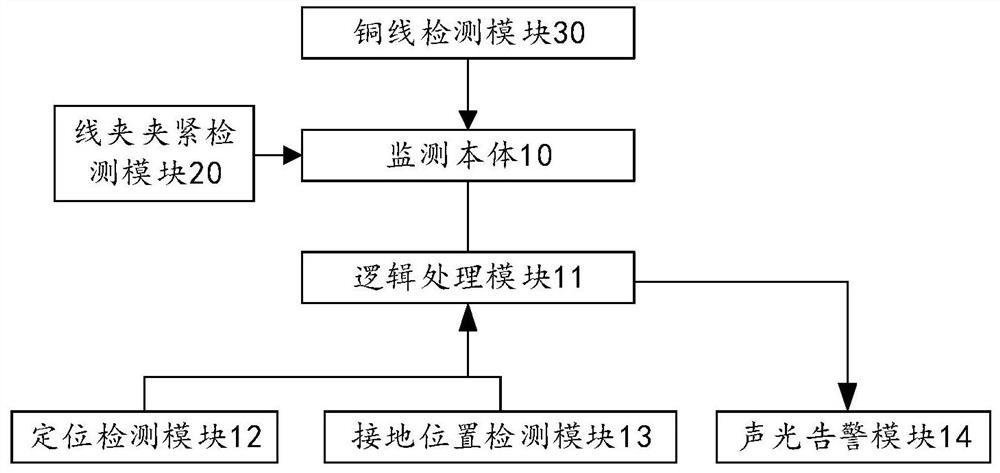

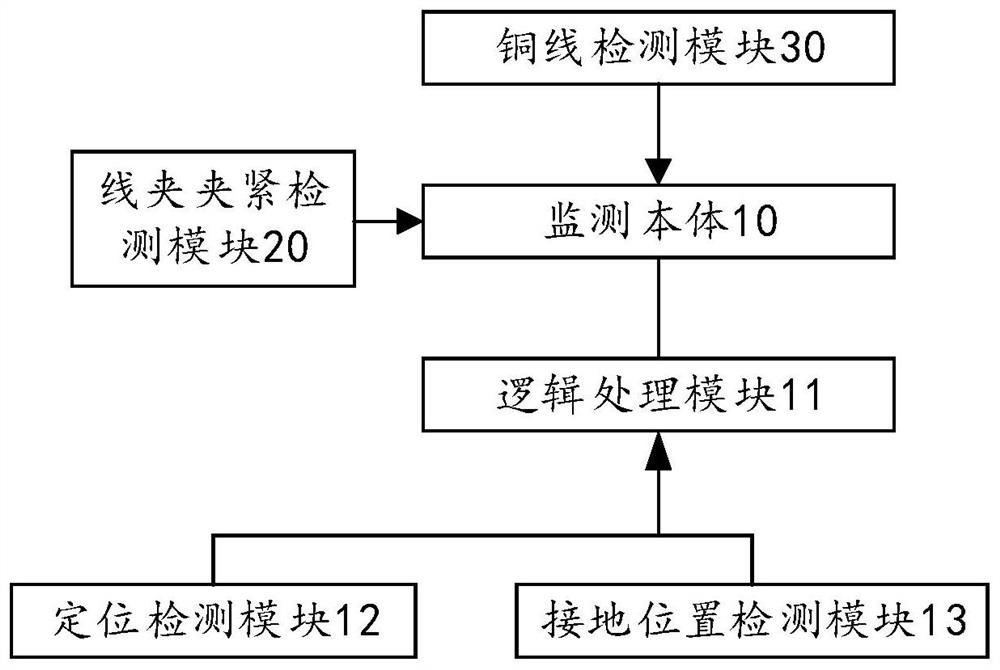

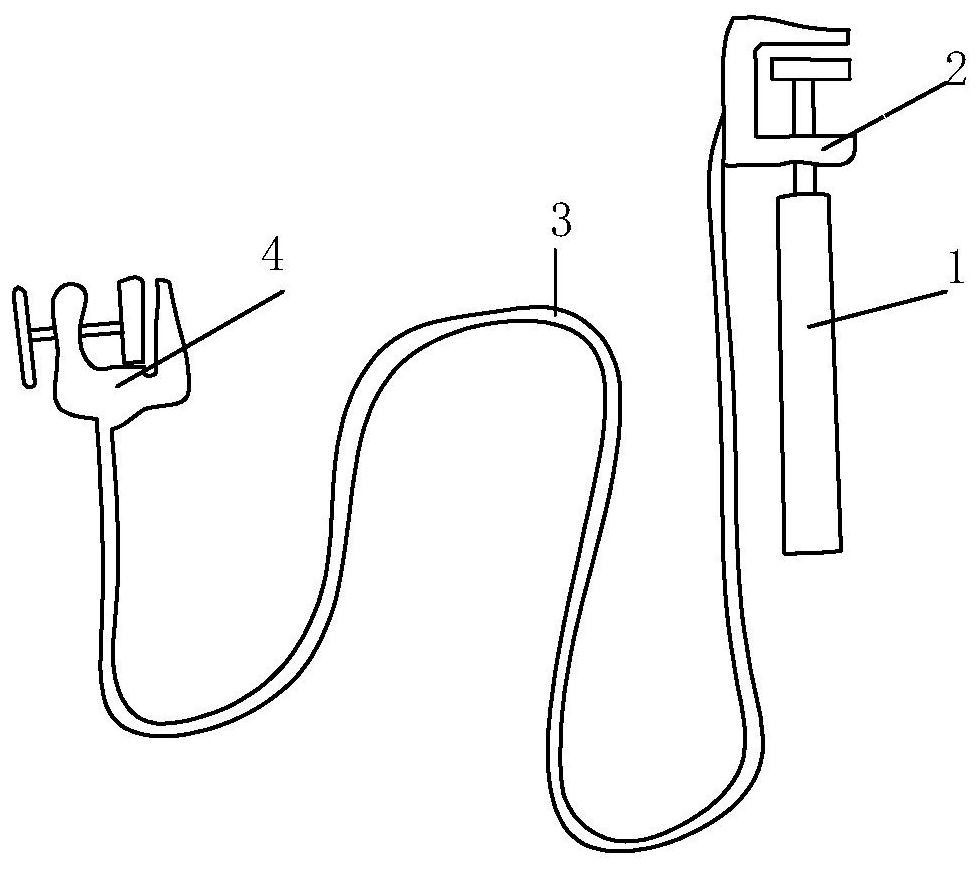

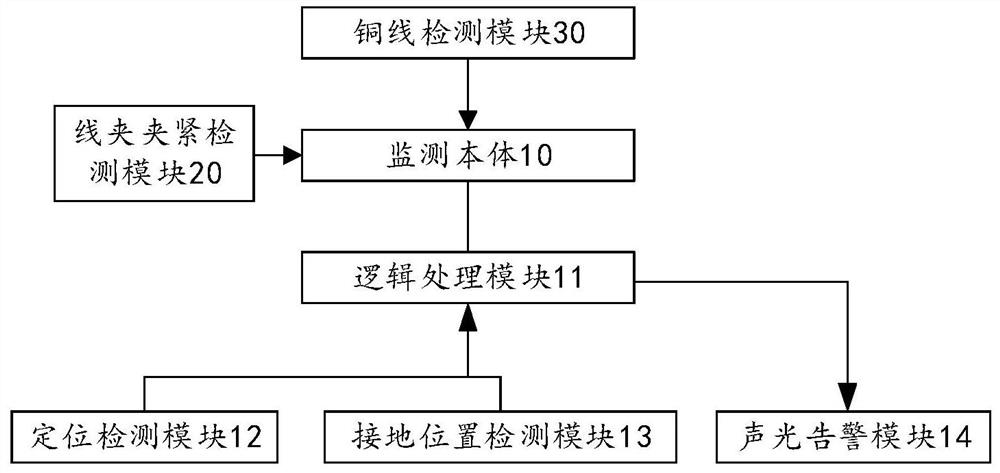

Portable ground wire state monitoring device and method

ActiveCN112713423ACan't solveResolution statusMeasurement devicesCoupling device detailsCopper wireControl engineering

The embodiment of the invention relates to a portable grounding wire state monitoring device and method. The device comprises a monitoring body, a wire clamp clamping detection module and a copper wire detection module, wherein the wire clamp clamping detection module and the copper wire detection module are connected with the monitoring body, and the monitoring body comprises a logic processing module, and a positioning detection module and a grounding position detection module which are connected with the logic processing module. According to the portable grounding wire state monitoring device, the logic processing module is adopted to analyze detection data and state information of the wire clamp clamping detection module, the copper wire detection module, the positioning detection module and the grounding position detection module and then judge a state of the portable grounding wire, and an operator can be assisted to confirm normal use of the grounding wire; potential hazards to personal safety of operators and operation safety of a power grid caused by incorrect hanging positions, loosening, missed dismounting and the like of the ground wire are avoided, and a technical problem that an existing ground wire monitoring platform cannot know the abnormal state of the ground wire in time is solved.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

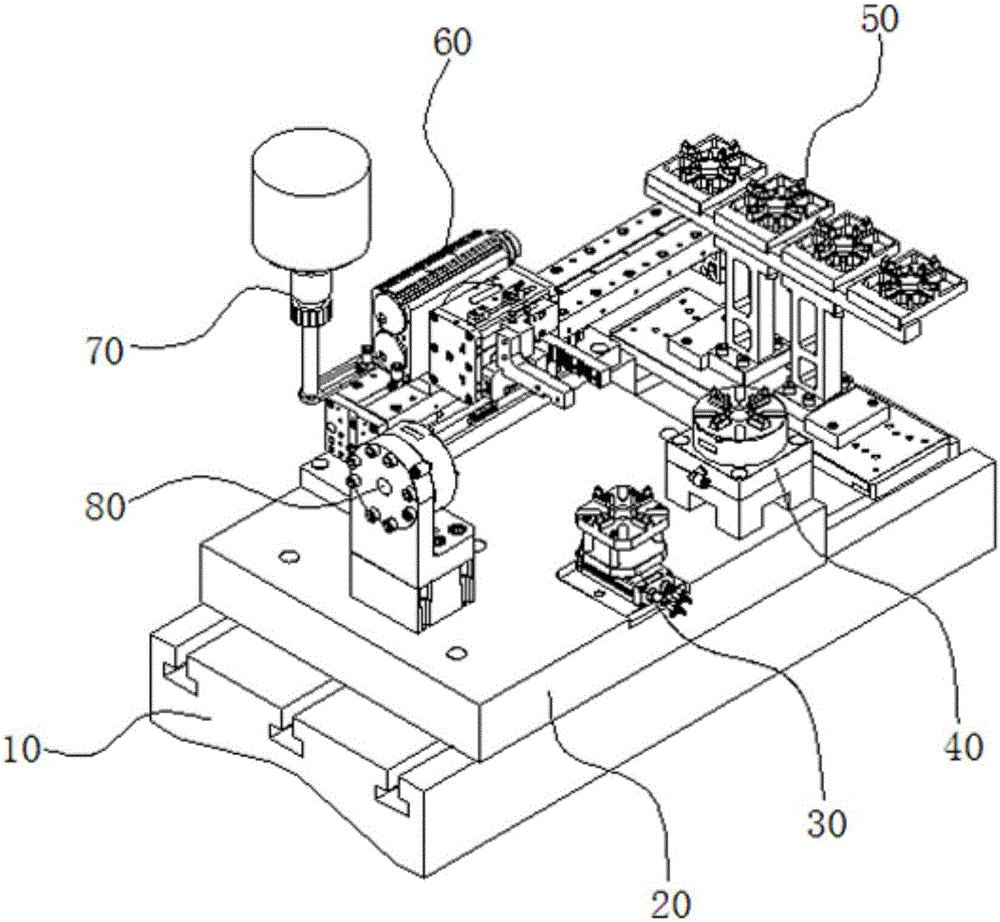

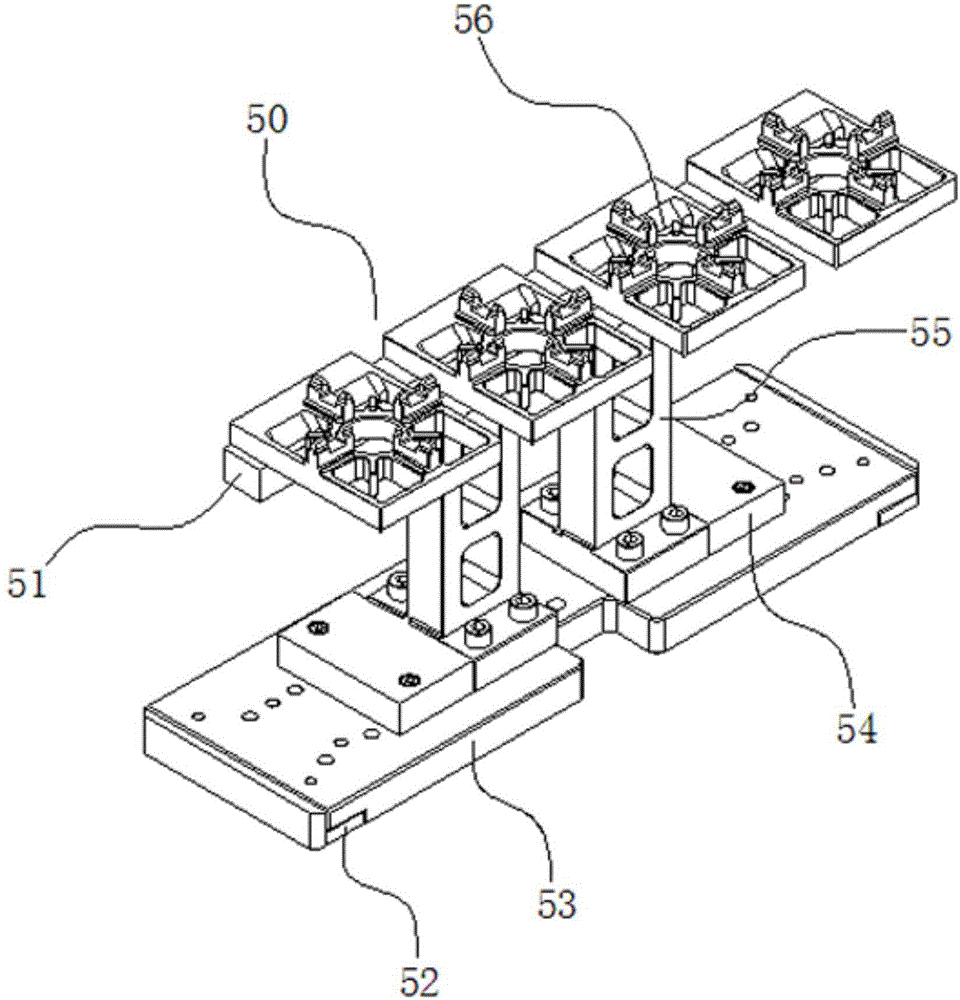

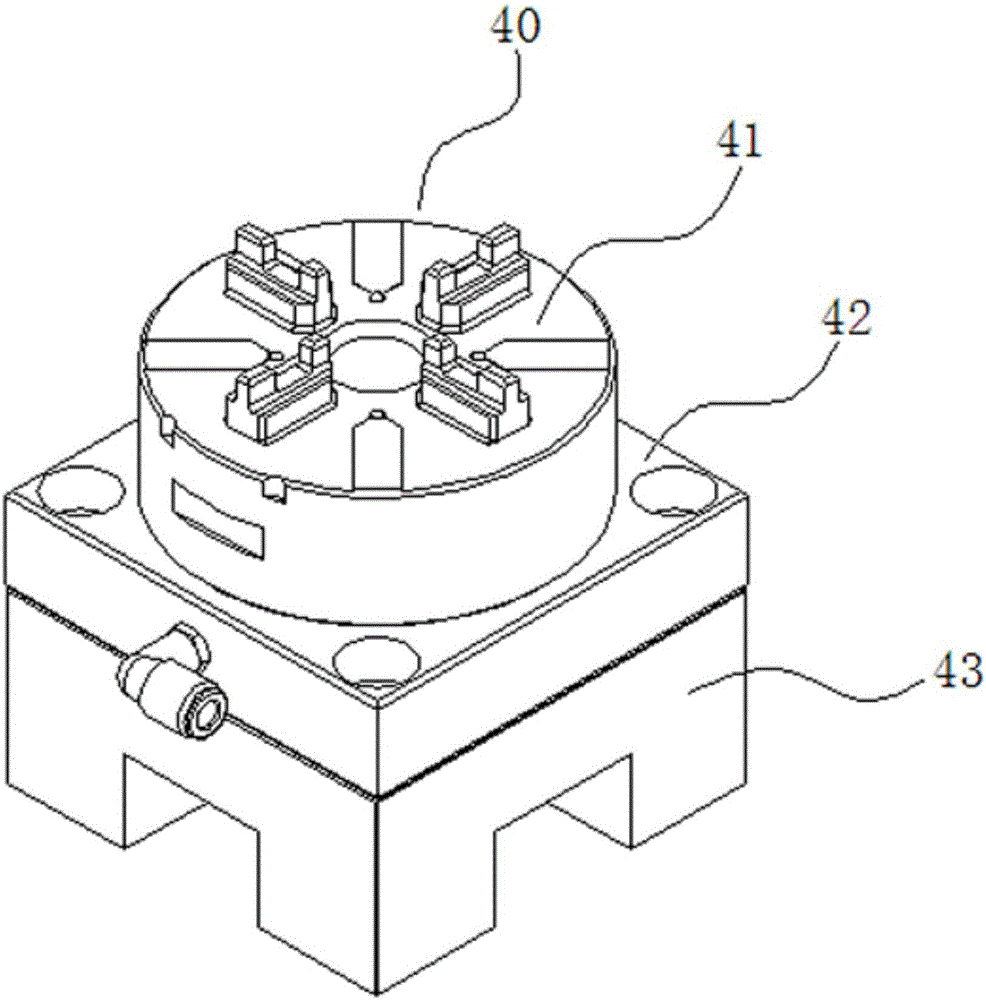

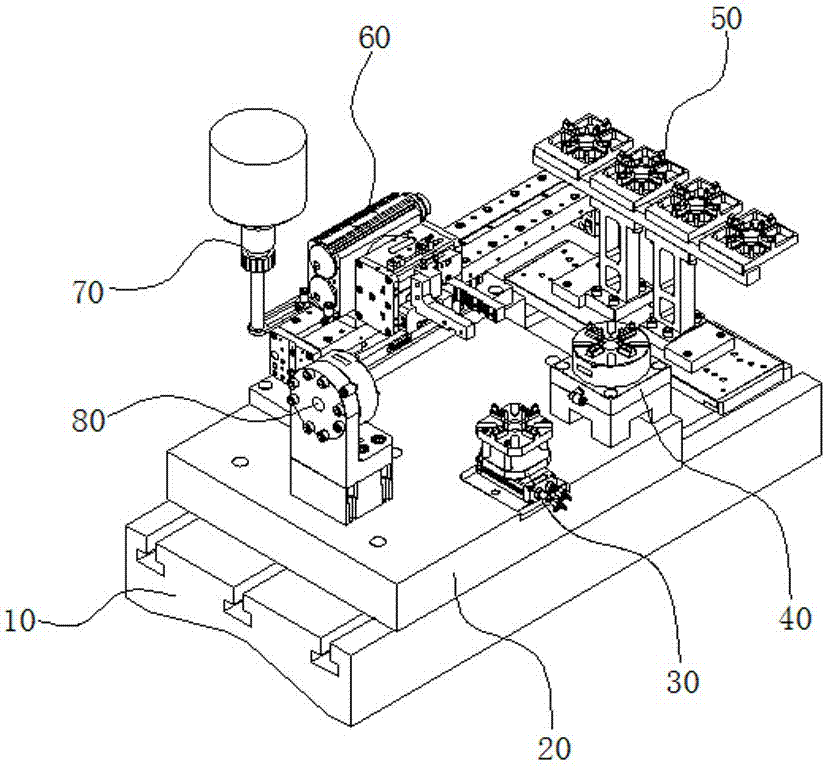

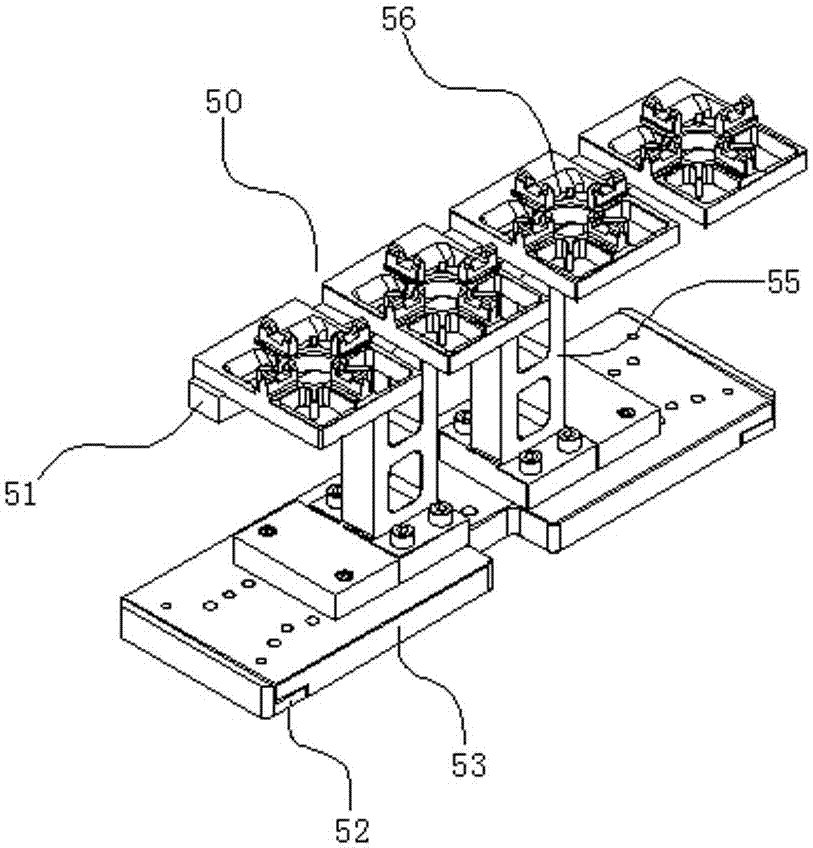

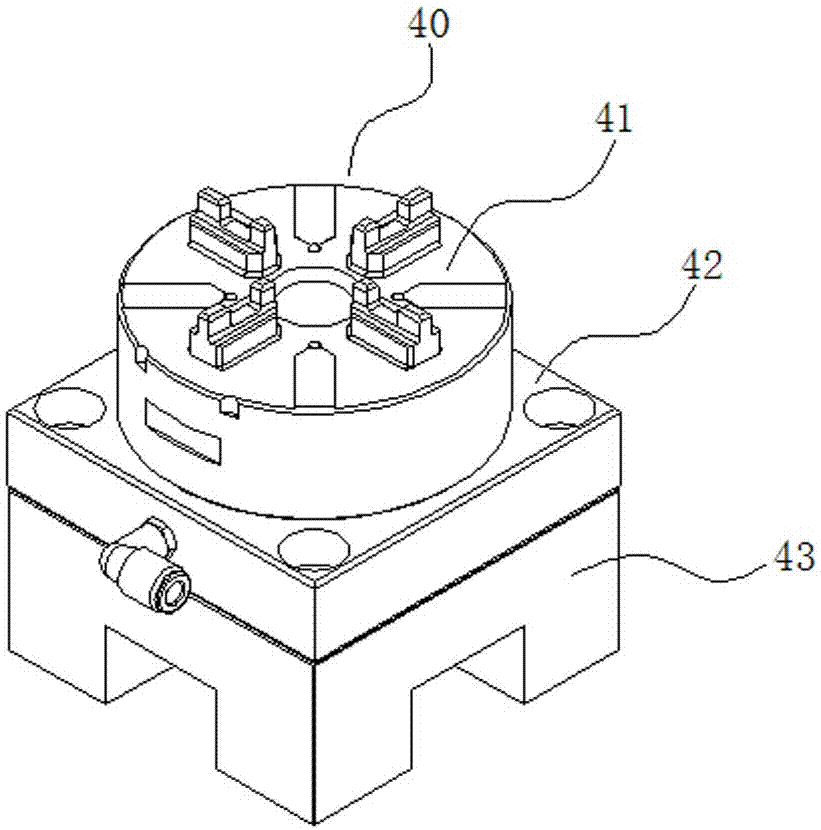

Automatic feeding and multi-surface processing device for triaxial numerically-controlled machine tool

InactiveCN106002304AWith multi-face cutting functionHigh degree of automationLarge fixed membersMetal working apparatusNumerical controlEngineering

The invention discloses an automatic material feeding and multi-face processing device for a three-axis numerical control machine tool, comprising a numerical control machine platform, on which a numerical control machine workbench is installed, and one side of the numerical control machine workbench is externally installed with a A material rack module for a workpiece, the first pneumatic chuck module for clamping the workpiece is installed on the workbench of the numerical control machine tool, the horizontal rotation module for driving the workpiece to rotate horizontally, and the feeding material for the workpiece that can rotate vertically and transmit the workpiece horizontally module, and a second pneumatic chuck module for clamping workpieces, and a spindle fork module for transporting workpieces between the above-mentioned modules is installed above the workbench of the CNC machine tool. The automatic feeding and multi-face processing device of the three-axis CNC machine tool of the present invention can make the three-axis CNC machine tool have the multi-face cutting function of the four-axis and five-axis CNC machine tools, and has the advantages of simple structure, convenient manufacture, low cost and high efficiency.

Owner:徐明

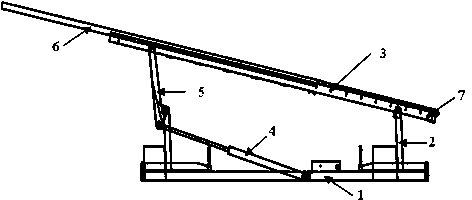

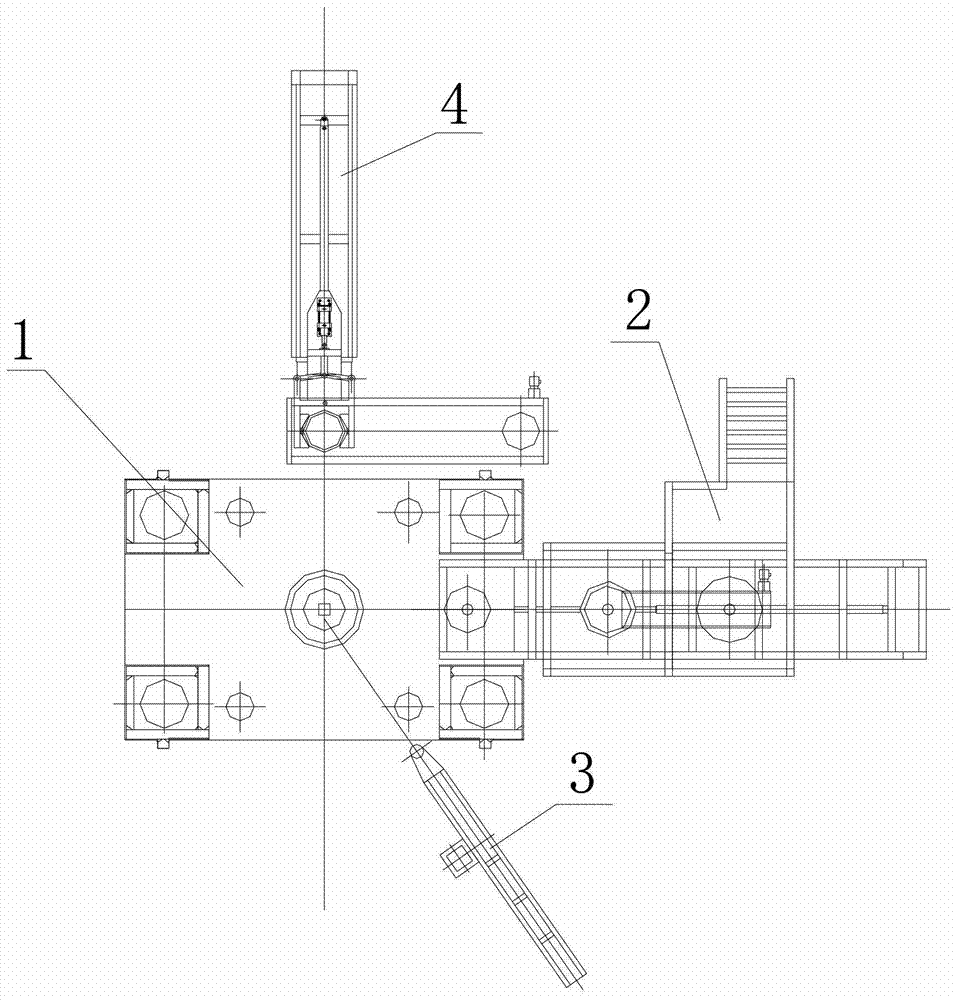

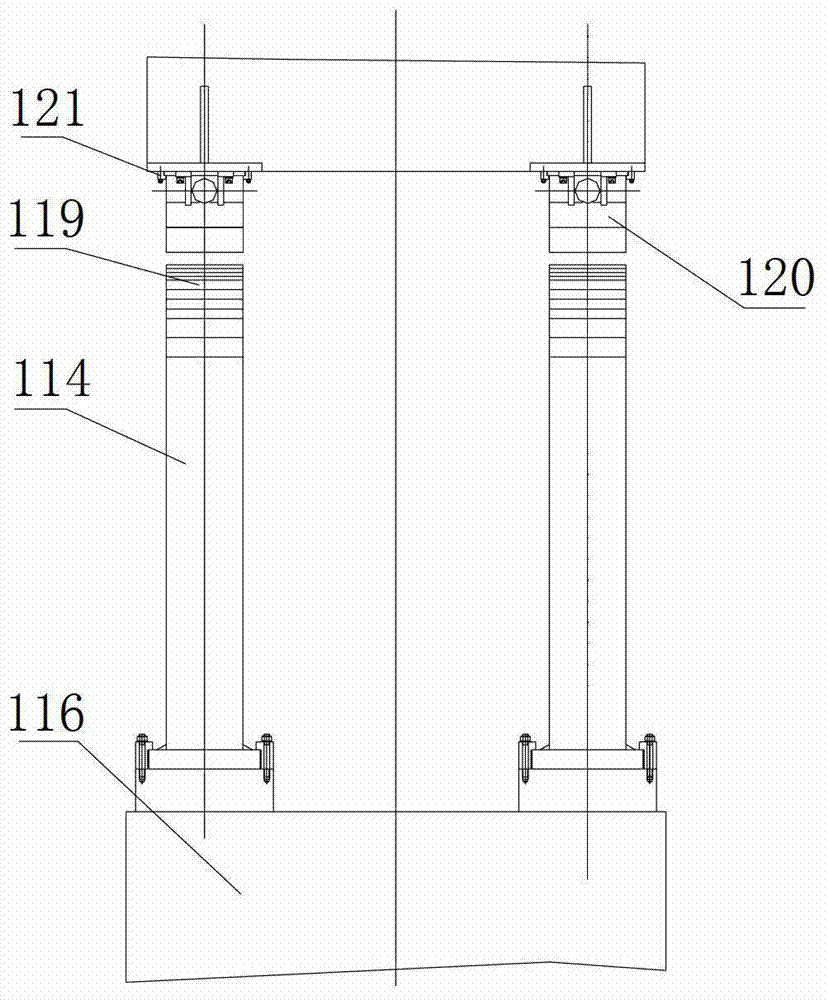

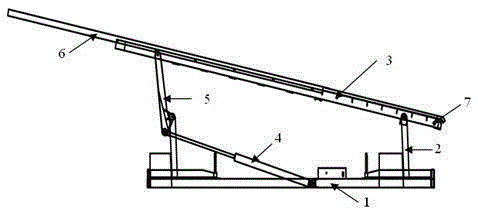

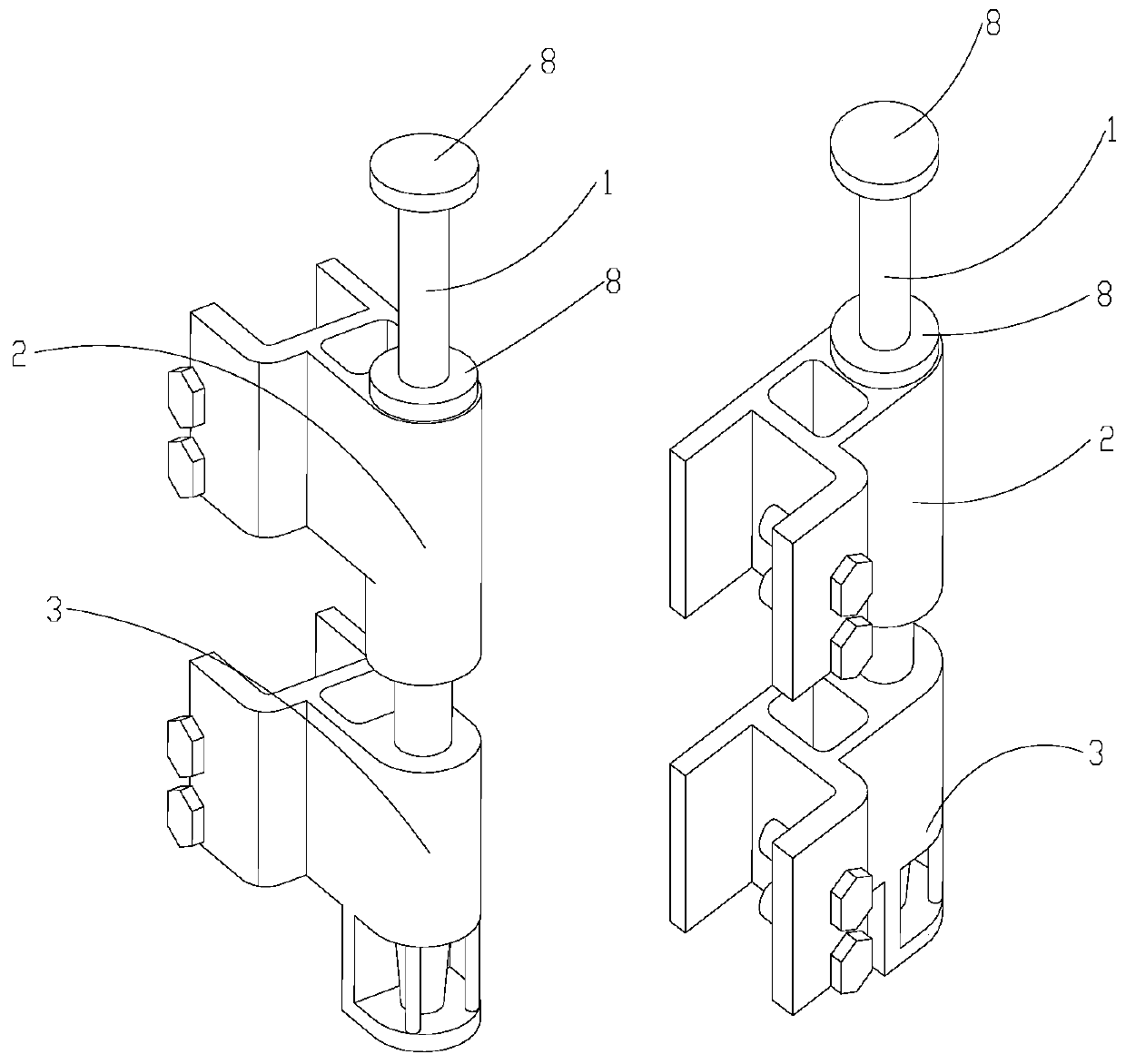

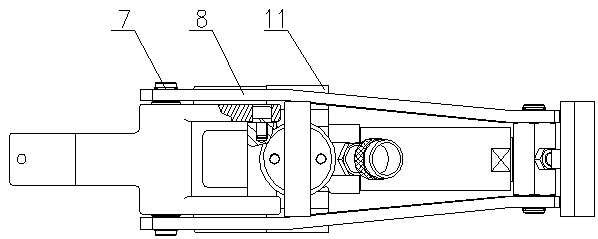

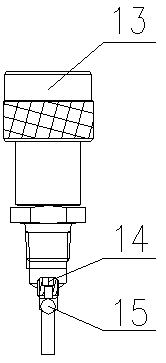

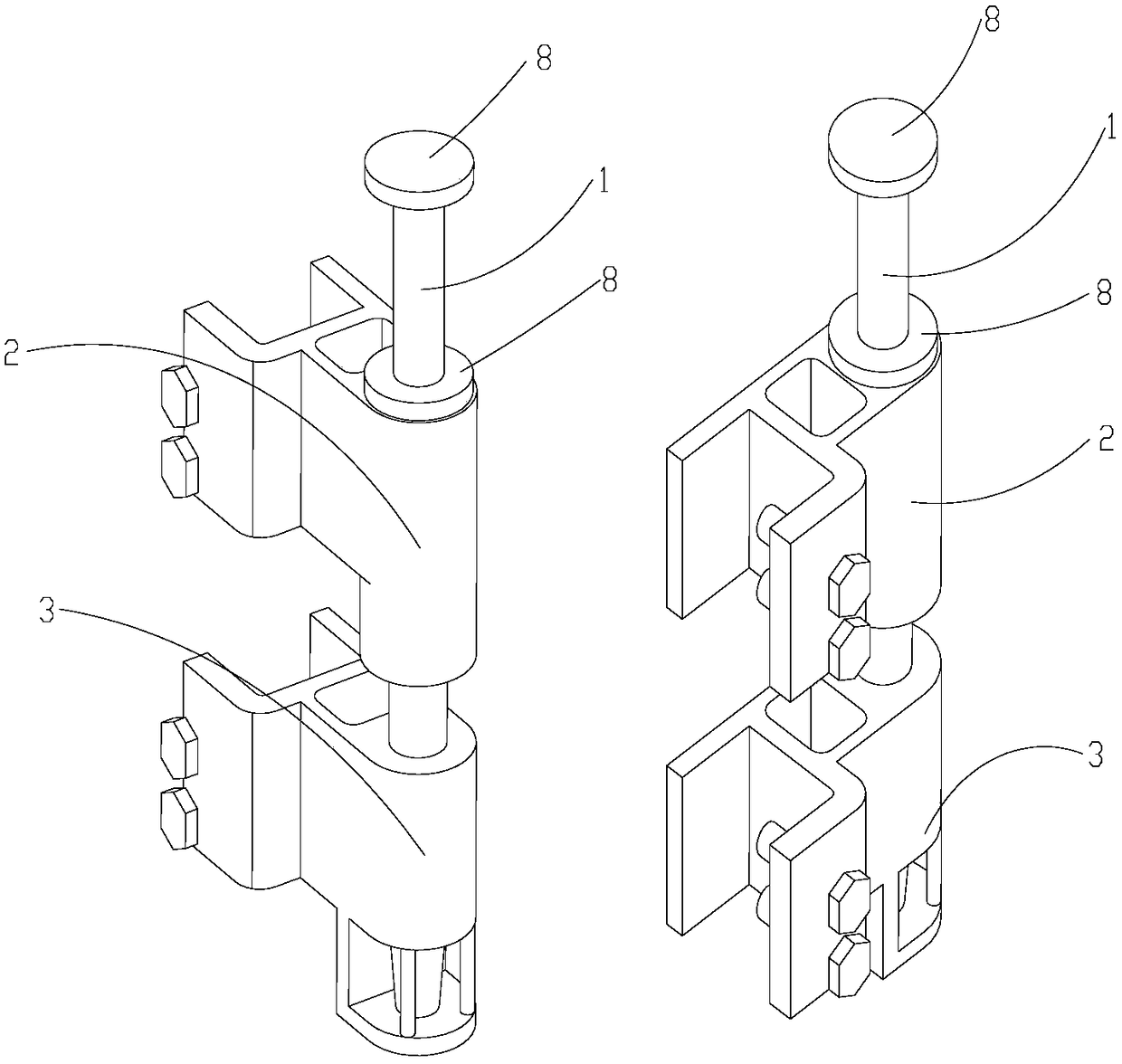

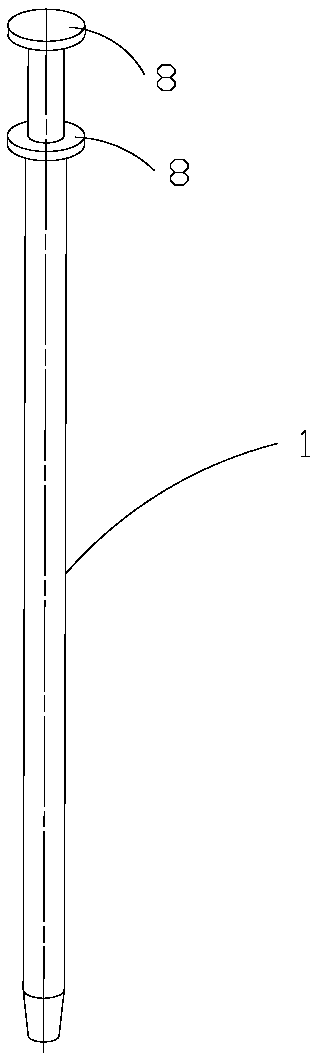

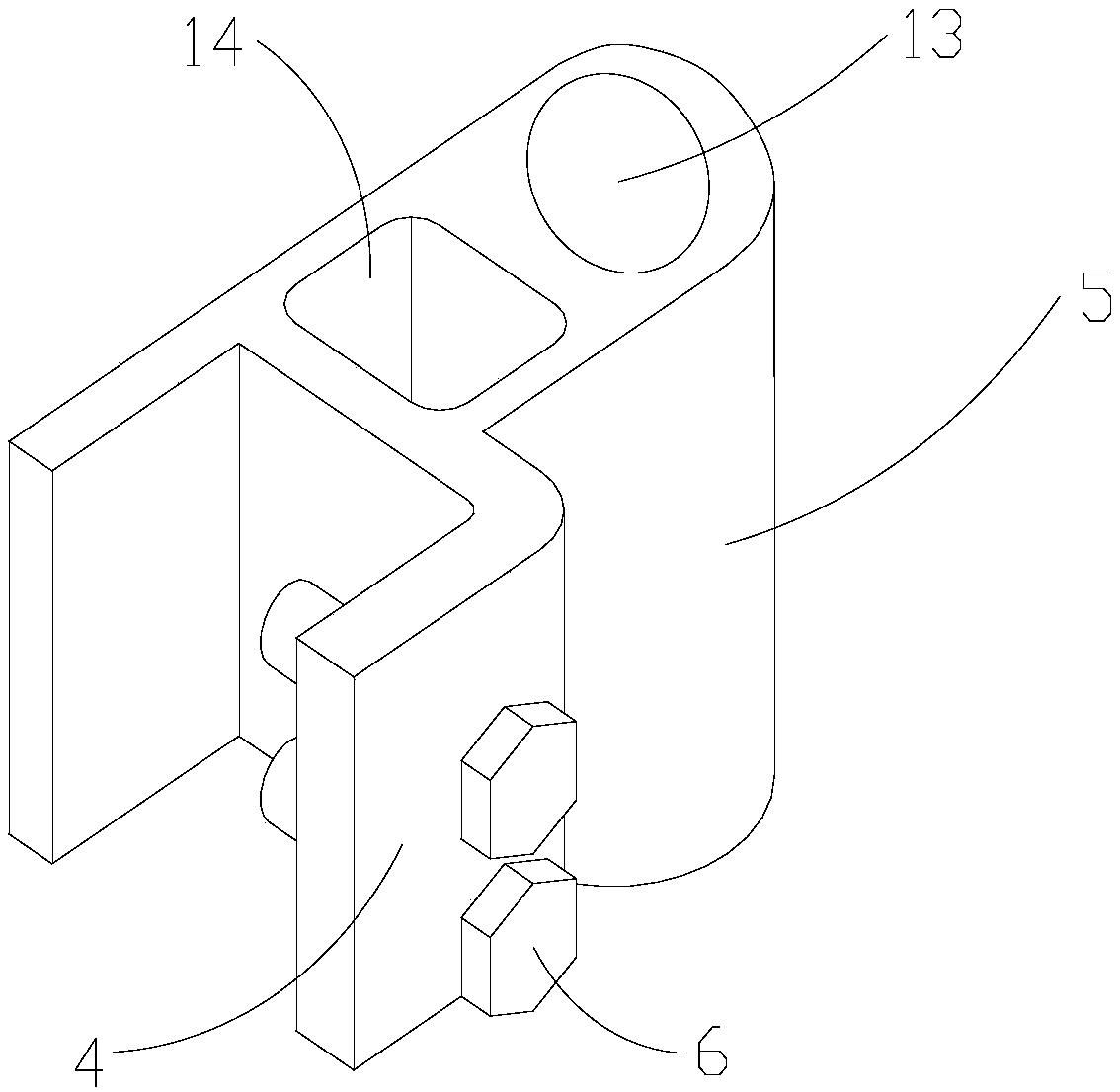

Swing arm type pipe rod spatial slideway

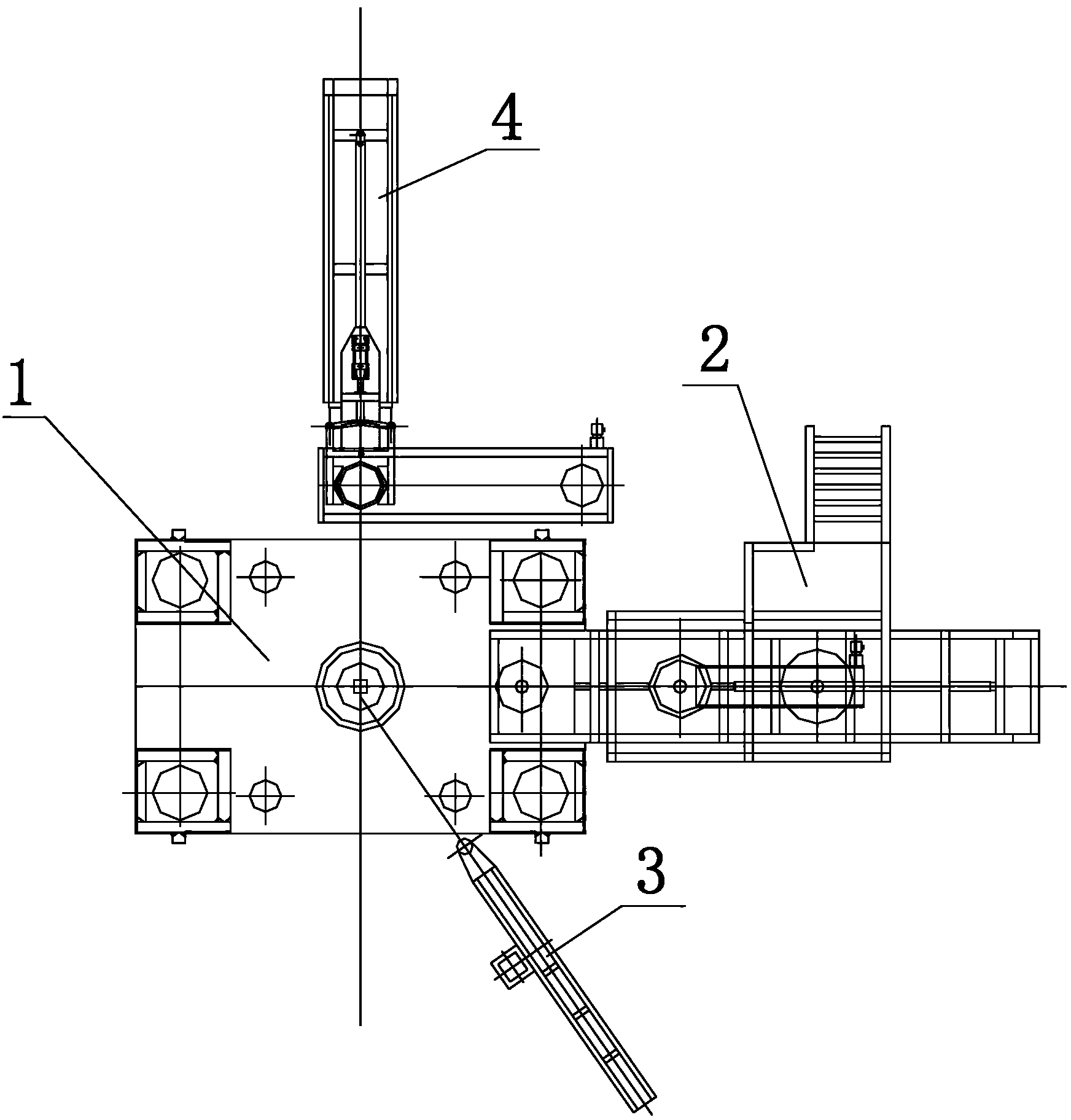

InactiveCN103899256AAvoid safety hazardsReduce labor intensityDrilling rodsDrilling casingsHydraulic cylinderClassical mechanics

The invention relates to a swing arm type pipe rod spatial slideway. The swing arm type pipe rod spatial slideway is composed of a mechanical part, a hydraulic system and an electrical system. A base (1) is connected with swing arms (2), one of the swing arms (2) is connected with a platform (3), the other swing arm (2) is connected with a rotary arm (5), one end of the rotary arm (5) is connected with a main hydraulic cylinder (4), the other end of the rotary arm (5) can slide on the platform (3), a slideway (6) is mounted on the platform (3) and connected with a horizontal pushing hydraulic cylinder (7), and the slideway (6) is pushed to slide back and forth on the platform (3). Pipe rods can be directly taken and delivered to the working position from an oil pipe bridge or can be directly delivered to discharge on the related bridge. The swing arm type pipe rod spatial slideway has the advantages that potential safety hazards of hurt to people by pulling the pipe rods are eliminated, labor intensity is reduced by more than 80%, on-site severe working conditions are avoided, potential safety hazards of passing on the site are eliminated, the working position of an operator is fixed, safety and comfortability are achieved, and two persons are reduced to one for auxiliary operation.

Owner:东营市尚科石油装备有限公司

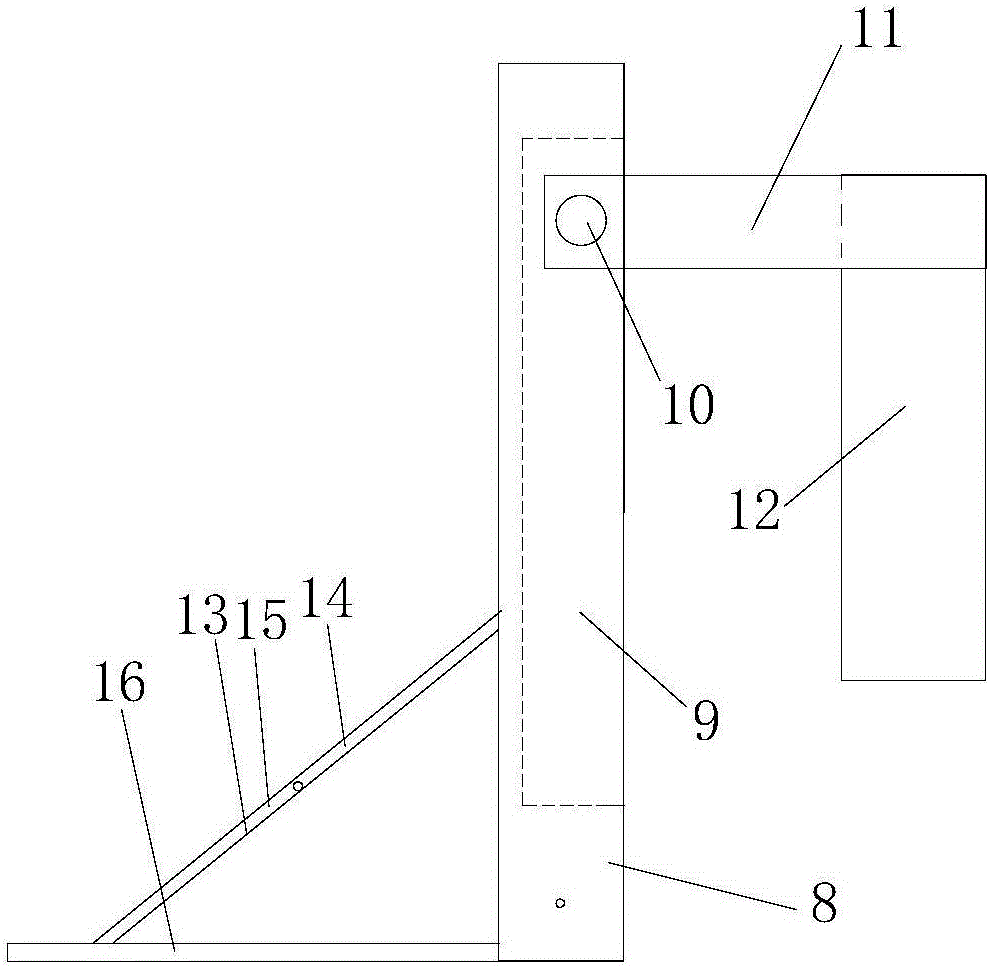

Guiding and supporting device for quick open door of cleaning machine

ActiveCN105127168AAvoid potential safety hazards in equipment operationAvoid damageCleaning processes and apparatusEngineeringMechanical engineering

The invention provides a guiding and supporting device for a quick open door of a cleaning machine. The guiding and supporting device comprises guiding devices and a sliding supporting device. The guiding devices are symmetrically arranged on the two sides of a loading box in the axial direction, one ends of the guiding devices are fixedly connected with the loading box, and the other ends of the guiding devices are fixedly connected with the quick open door. The upper end of the sliding supporting device is connected with a cleaning roller in the cleaning machine, and the lower end of the sliding supporting device is in sliding fit with ground rails. After cleaning and maintenance are carried out on the cleaning roller, the cleaning roller can slide to a preset matching position along the ground rails fast and accurately, and damage caused by rotation to a mechanical seal when the cleaning roller is assembled improperly is avoided. When the cleaning roller rotates, eccentric force can be generated by asymmetry of cleaning materials loaded in the cleaning roller and can be effectively offset by the guiding devices, and the situation that under the action of the eccentric force, the quick open door for supporting the cleaning roller through bearings vibrates along a quick open door clearance, and consequently the service lives of the supporting bearings at the two ends of the cleaning roller and the mechanical seal are influenced is avoided.

Owner:SHINVA MEDICAL INSTR CO LTD

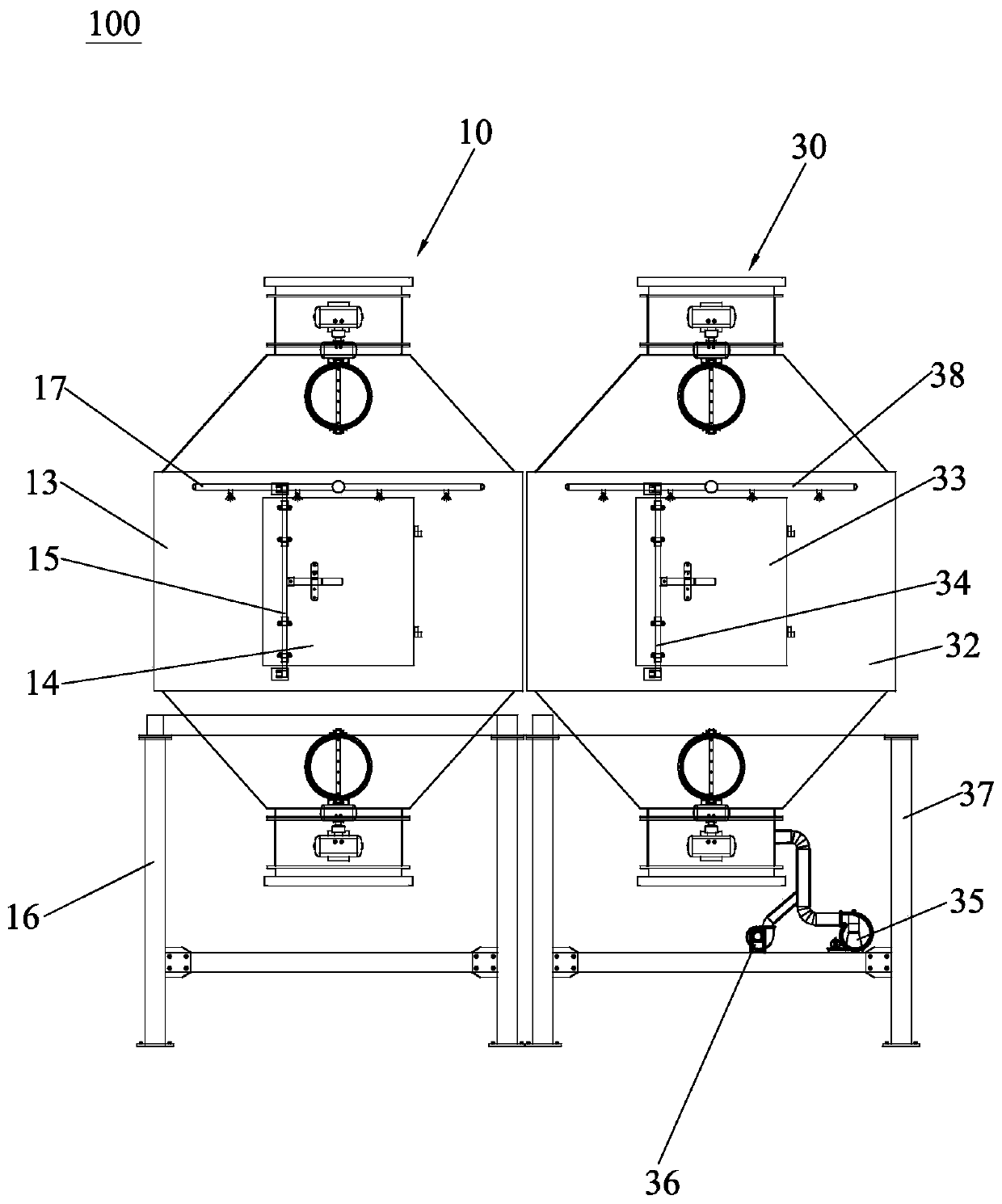

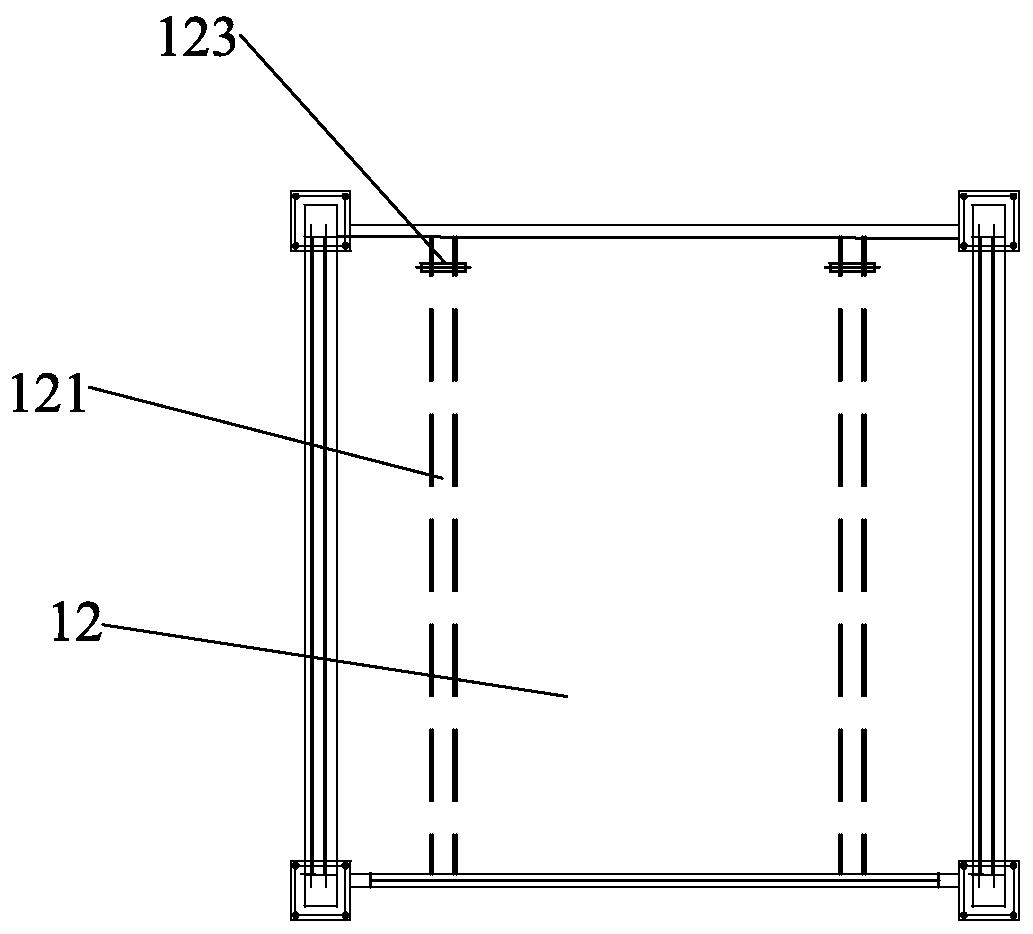

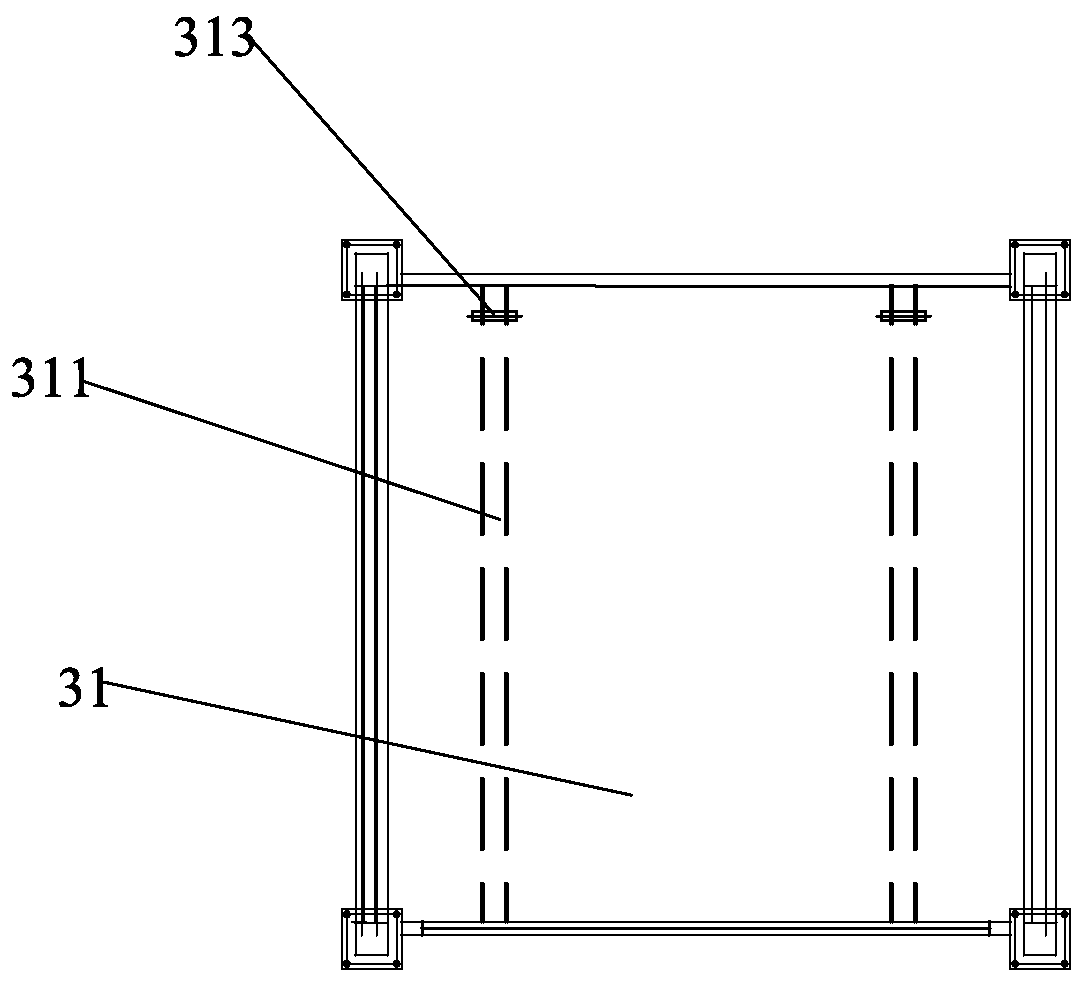

Activated carbon adsorption and catalytic combustion device for VOCs waste gas treatment

PendingCN111330406AReduce the number of installationsAvoid Operational Safety HazardsGas treatmentDispersed particle separationActivated carbonExhaust fumes

The invention discloses an activated carbon adsorption and catalytic combustion device for VOCs waste gas treatment. The device comprises an adsorption apparatus and a desorption apparatus, the adsorption apparatus comprises at least one movable activated carbon module, the adsorption apparatus is provided with a plurality of adsorption cavities, the activated carbon module can be taken out and installed relative to the adsorption cavities, and when installed in the adsorption cavities, the activated carbon module can be used for adsorbing organic components in VOCs waste gas; the desorption apparatus is provided with a plurality of desorption cavities, the activated carbon module can be taken out and installed relative to the adsorption cavities, and when the activated carbon module is installed in the adsorption cavities, the desorption apparatus is used for desorbing the activated carbon module for regeneration. The activated carbon adsorption and catalytic combustion device for VOCs waste gas treatment provided by the invention has the advantages of convenient use and operation, low cost, small floor area and wide application range.

Owner:深圳市瑞秋卡森环保科技有限公司

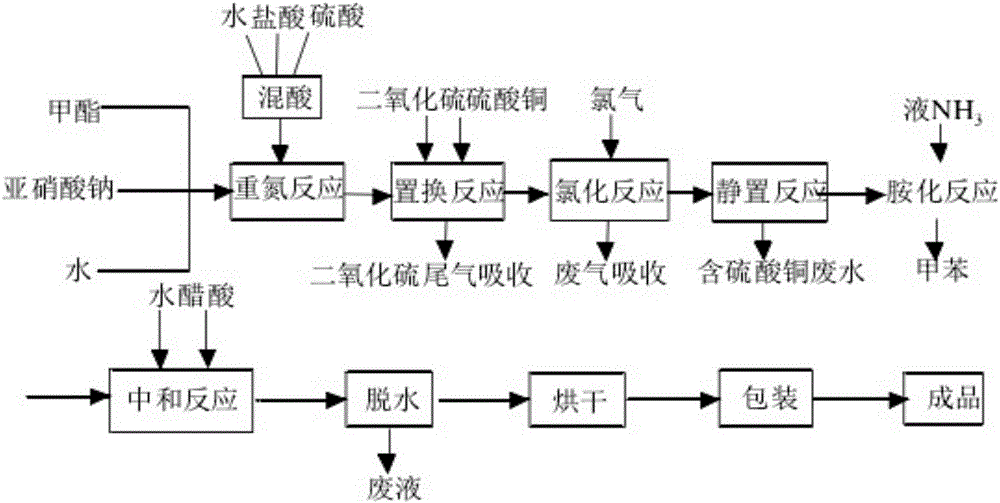

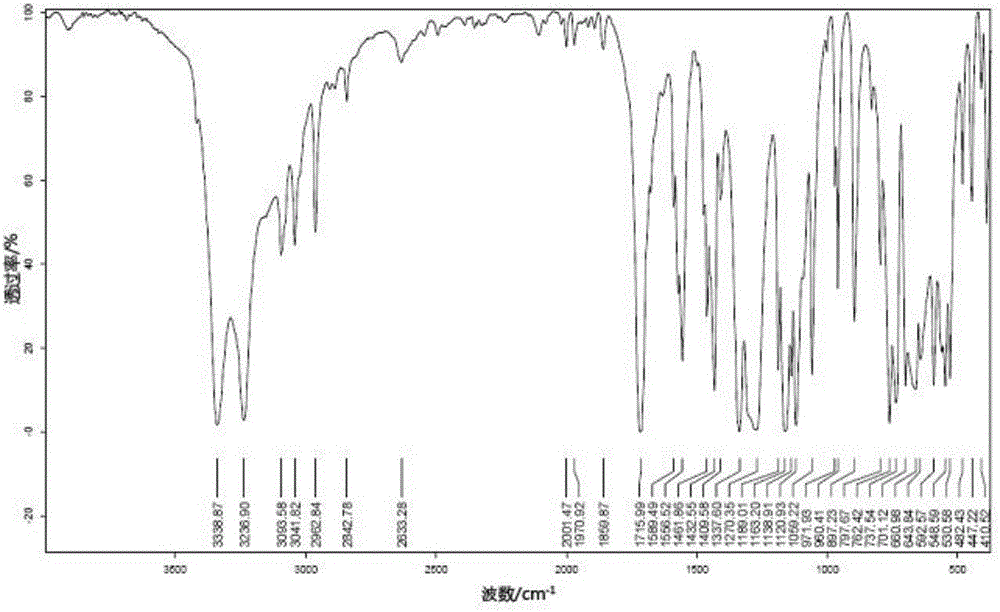

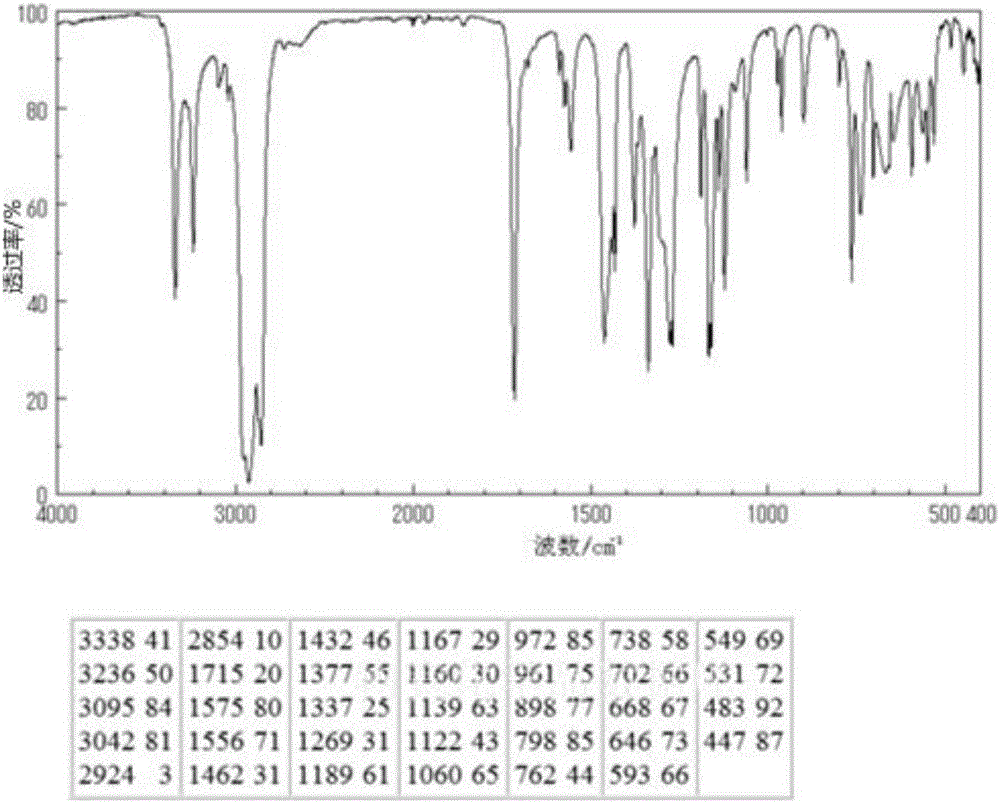

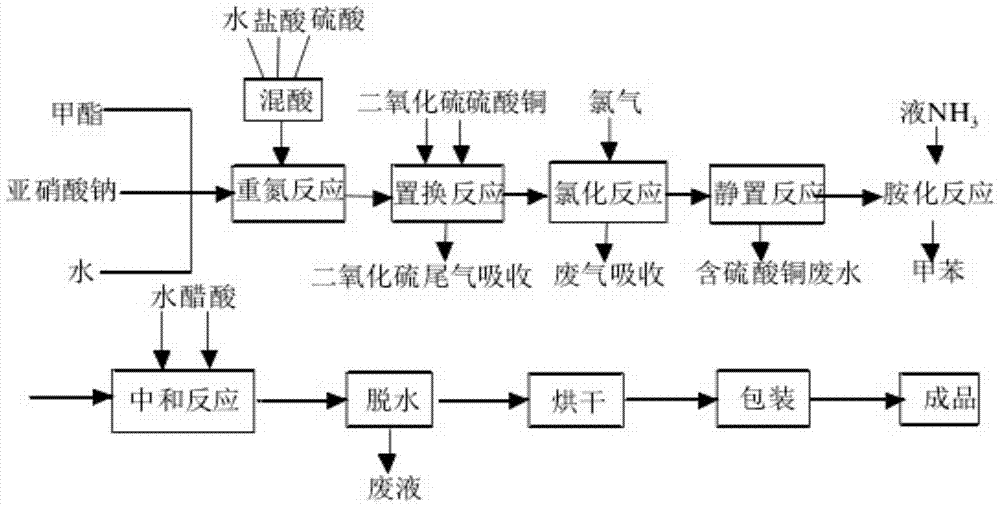

Preparation method of methyl o-sulphamoylbenzoate

ActiveCN105085333AIncreased energy consumption and production capacityReduce labor intensitySulfonic acid amide preparationElectricitySeparation technology

The invention relates to a preparation method of methyl o-sulphamoylbenzoate. The preparation method specifically includes the steps of conducting a diazo reaction, conducting a replacement reaction, conducting a chlorination reaction, conducting a standing reaction, conducting an amination reaction, conducting a neutralization reaction, dewatering, drying and packaging. In the dewatering step, mother liquid is placed in a diaphragm press filter to be subjected to extrusion and diaphragm bulging press and then subjected to re-extrusion and diaphragm bulging after being washed, a filter-press dehydration separation technology is initiated and replaces a traditional centrifugal dewatering separation technology, and then the dewatering purpose is achieved. Compared with the prior art, more electricity and water are saved through the method, the capacity under the equal energy consumption is greatly improved, the production environment is improved, and the labor intensity is relieved.

Owner:辉县市润得生物科技有限公司

Corrosion resisting insulation medium voltage switch cabinet

PendingCN107240865AReasonable distributionControl overhaulConjugated diene hydrocarbon coatingsSubstation/switching arrangement casingsEngineeringOperational safety

The invention discloses a corrosion resisting insulation medium voltage switch cabinet comprising a cabinet body, a bus room, a breaker room, a cable room, a relay meter room and a pedestal; the pedestal is arranged on the cabinet body bottom; the bus room, the breaker room, the cable room and the relay meter room are arranged in the cabinet body; the bus room is arranged on the upper portion in the cabinet body; the cable room is arranged below the bus room; the breaker room is arranged on one side of the bus room; the relay meter room is arranged above the breaker room; the corrosion resisting insulation medium voltage switch cabinet is simple in structure, reasonable in distribution, safe in operations, corrosion resisting, and long in life.

Owner:JIANGSU SHENFEI ELECTRICAL TECH CO LTD

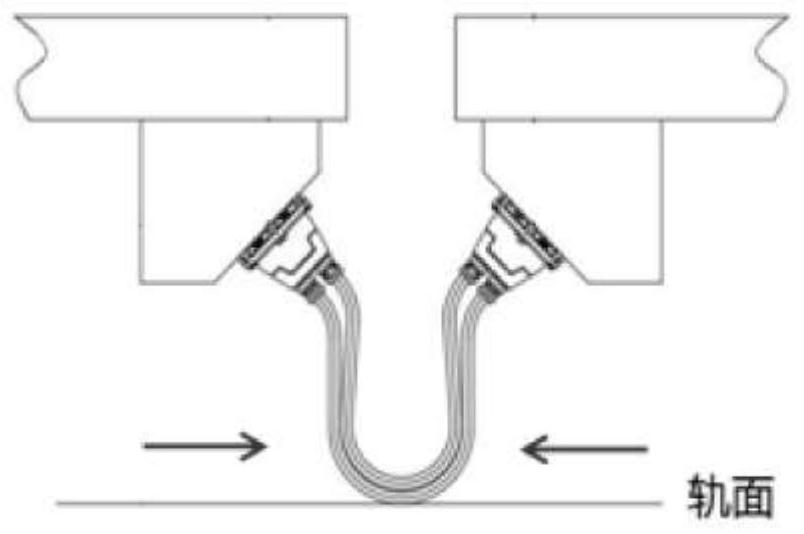

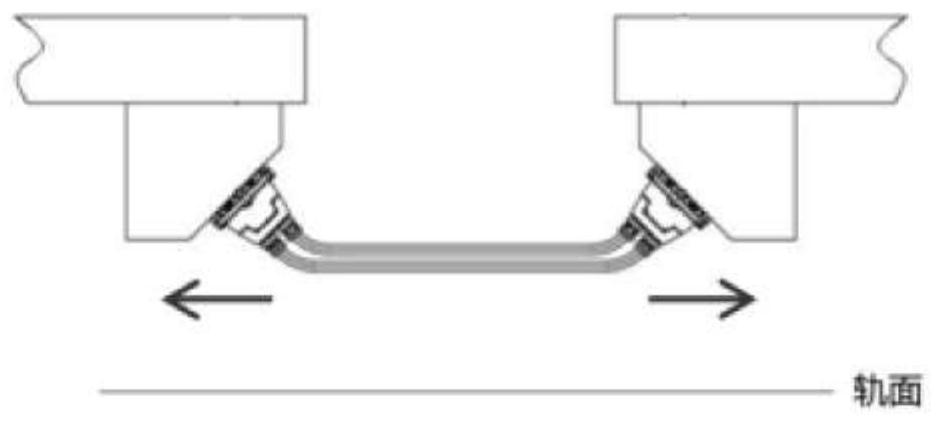

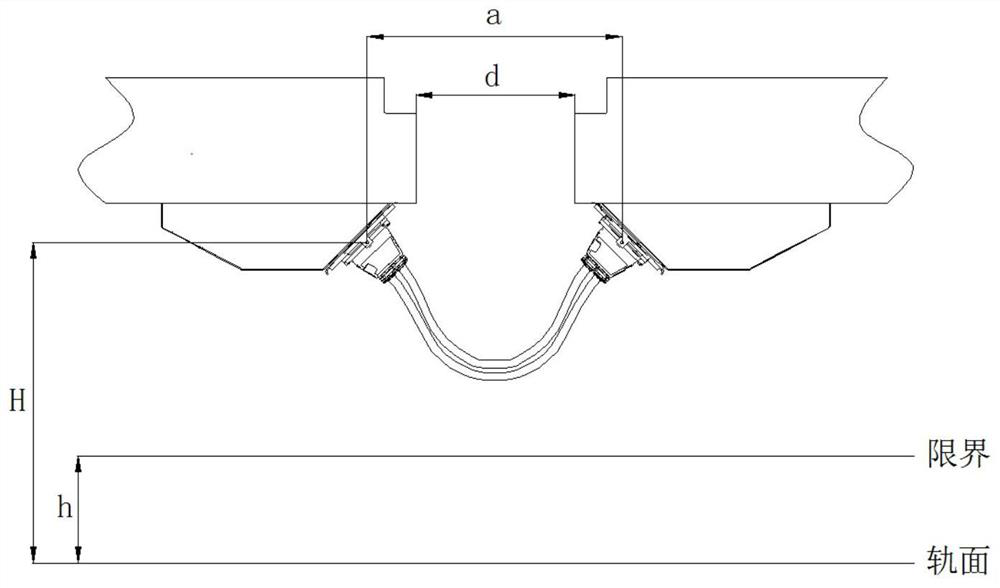

Rail transit vehicle and vehicle end jumper cable length calculation method thereof

PendingCN113806928AReduce operational safety hazardsReduce cost lossCable arrangements between relatively-moving partsDesign optimisation/simulationEngineeringElectric cables

The invention discloses a rail transit vehicle and a vehicle end jumper cable length calculation method thereof. The jumper cable length L meets the following relational expression: L is greater than L1 and less than L2; wherein L1 is the length of the jumper cable calculated according to the maximum linear distance Y of the mounting surfaces of the two vehicle end connectors, and L2 is the length of the jumper cable calculated according to the minimum linear distance y of the mounting surfaces of the two vehicle end connectors. The method can be suitable for various lines with different parameters and is high in universality and operability, the length value, calculated through the method, of the jumper cable is reliable and high in accuracy, potential safety hazards of vehicle operation caused by the improper length of the cable can be effectively avoided, and important reference and application value are provided for calculating the length of the jumper cable between rail transit vehicles.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Environment-friendly coating dispersing device

InactiveCN108607410AAvoid shaking position shiftAvoid Operational Safety HazardsRotary stirring mixersTransportation and packagingEnvironmental resistanceCoupling

The invention discloses an environment-friendly coating dispersing device which structurally comprises a supporting and stabilizing device, a fixing machine arm, a supporting frame, a connector, a driver, a coupling, a dispersing stirrer and a coating barrel. The upper surface of the supporting and stabilizing device and the lower surface of the fixing machine arm are welded and fixed to form an integrated structure, the outer surface of one end, close to the fixing machine arm, of the supporting frame is fitted with the outer surface of one end, far away from the driver, of the connector, thedriver is mechanically connected with the coupling, one end, far away from the coating barrel, of the dispersing stirrer is embedded into the coupling and rotatably connected with the coupling, the coating barrel is arranged on the lower portion of one end, far away from the coupling, of the dispersing stirrer, and the lower surface of the coating barrel is fitted with the upper surface of the supporting and stabilizing device. Potential safety hazards are eliminated by avoiding position deviation due to shaking of the coating barrel in dispersion, and the problem of operation potential safety hazards caused by easiness in shaking and position deviation of a disperser body is avoided by increasing the friction force of a disperser and the ground.

Owner:沈国强

Three-axis cnc automatic loading and unloading and multi-face cutting device

ActiveCN106112610BPrevent fallingHigh degree of automationWork clamping meansMetal working apparatusNumerical controlEngineering

The invention discloses an automatic feeding and discharging and multi-face cutting device of a three-axis computer numerical control (CNC) lathe. The automatic feeding and discharging and multi-face cutting device comprises a CNC platform. A CNC workbench is installed on the CNC platform. A rack module for containing a plurality of workpieces is installed outside one side of the CNC workbench. The CNC workbench is provided with a first pneumatic chuck module for clamping the workpieces, a horizontal rotation module for driving the workpieces to rotate horizontally, a feeding module for vertical rotation and horizontal delivery of the workpieces, and a second pneumatic chuck module for clamping the workpieces. A spindle forklift module for transporting the workpieces among the modules is installed above the CNC workbench. By means of the automatic feeding and discharging and multi-face cutting device of the three-axis CNC lathe, the three-axis CNC lathe can have the multi-face cutting function as a four-axis CNC lathe and a five-axis CNC lathe; and the automatic feeding and discharging and multi-face cutting device has the advantages of being simple in structure, convenient to manufacture, low in cost and high in efficiency.

Owner:先进科技(惠州)有限公司

Cyanide leaching method for gold ores

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Anticorrosive anti-interference switch cabinet

InactiveCN107880759AGood insulation and corrosion resistanceExtend your lifeFireproof paintsChloropene polymer coatingsIsophoroneHydroxypropylmethyl cellulose

The invention discloses an anticorrosive anti-interference switch cabinet. The anticorrosive anti-interference switch cabinet comprises a cabinet body, wherein the surface of the cabinet body is coated with an anticorrosive anti-interference layer, and the anticorrosive anti-interference layer is prepared from the following components in parts by mass: 60 to 70 parts of polyurethane resin, 30 to 40 parts of bisphenol A epoxy resin, 15 to 20 parts of chloroprene rubber, 11 to 13 parts of hydroxypropyl methyl cellulose, 2 to 3 parts of dibutyl phthalate, 1 to 3 parts of glass fibers, 1 to 2 parts of hexadecyl trimethyl ammonium bromide, 4 to 7 parts of water glass, 5 to 7 parts of lecithin, 10 to 13 parts of propylene carbonate, 6 to 10 parts of polyvinyl alcohol, 3 to 6 parts of montmorillonite powder, 2 to 7 parts of butyl acrylate, 1 to 3 parts of vinyl trimethoxy silane, 4 to 7 parts of methylacetamide, 2 to 3 parts of benzyl dimethyl ketal, 11 to 16 parts of expanded perlite, 9 to 13 parts of talcum powder, 2 to 6 parts of methylvinyldichlorosilane, 6 to 11 parts of sodium-base bentonite, 2 to 3 parts of isophorone, 10 to 13 parts of nano filler, 4 to 8 parts of lignin sodium sulfonate, 5 to 9 parts of curing agent, 1 to 3 parts of antirust agent, 8 to 12 parts of coupling agent, and 0.6 to 0.8 part of composite rare earth.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

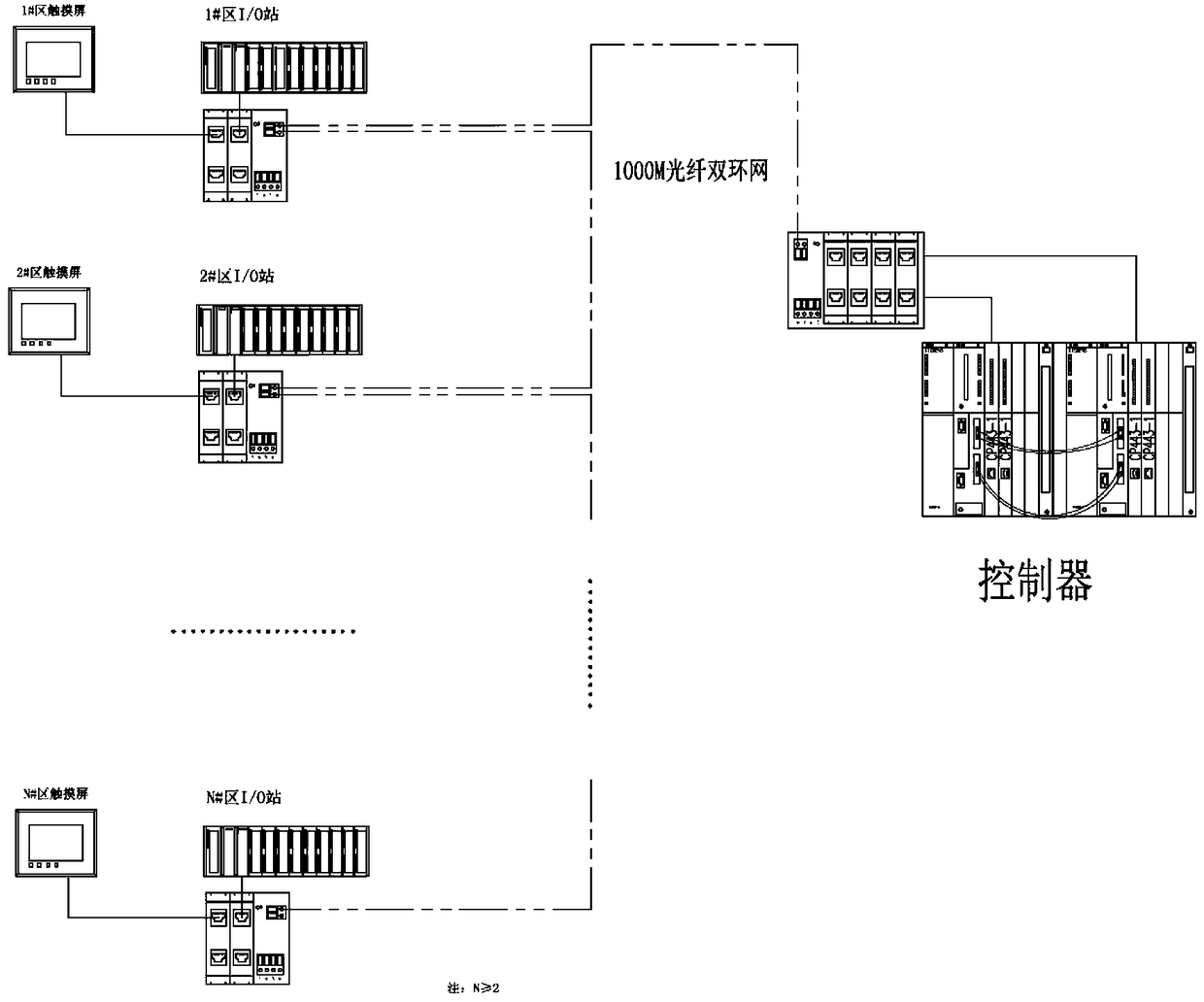

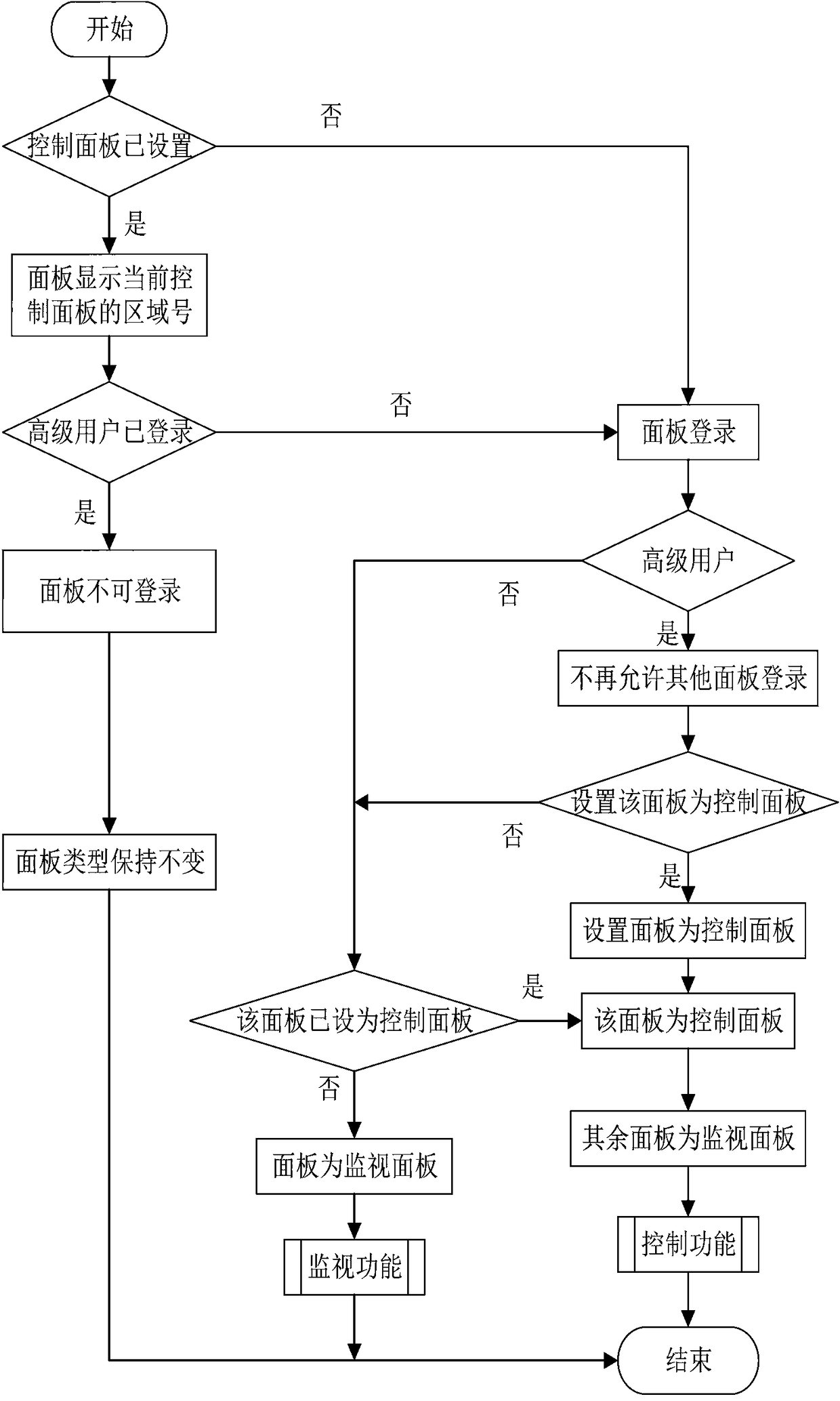

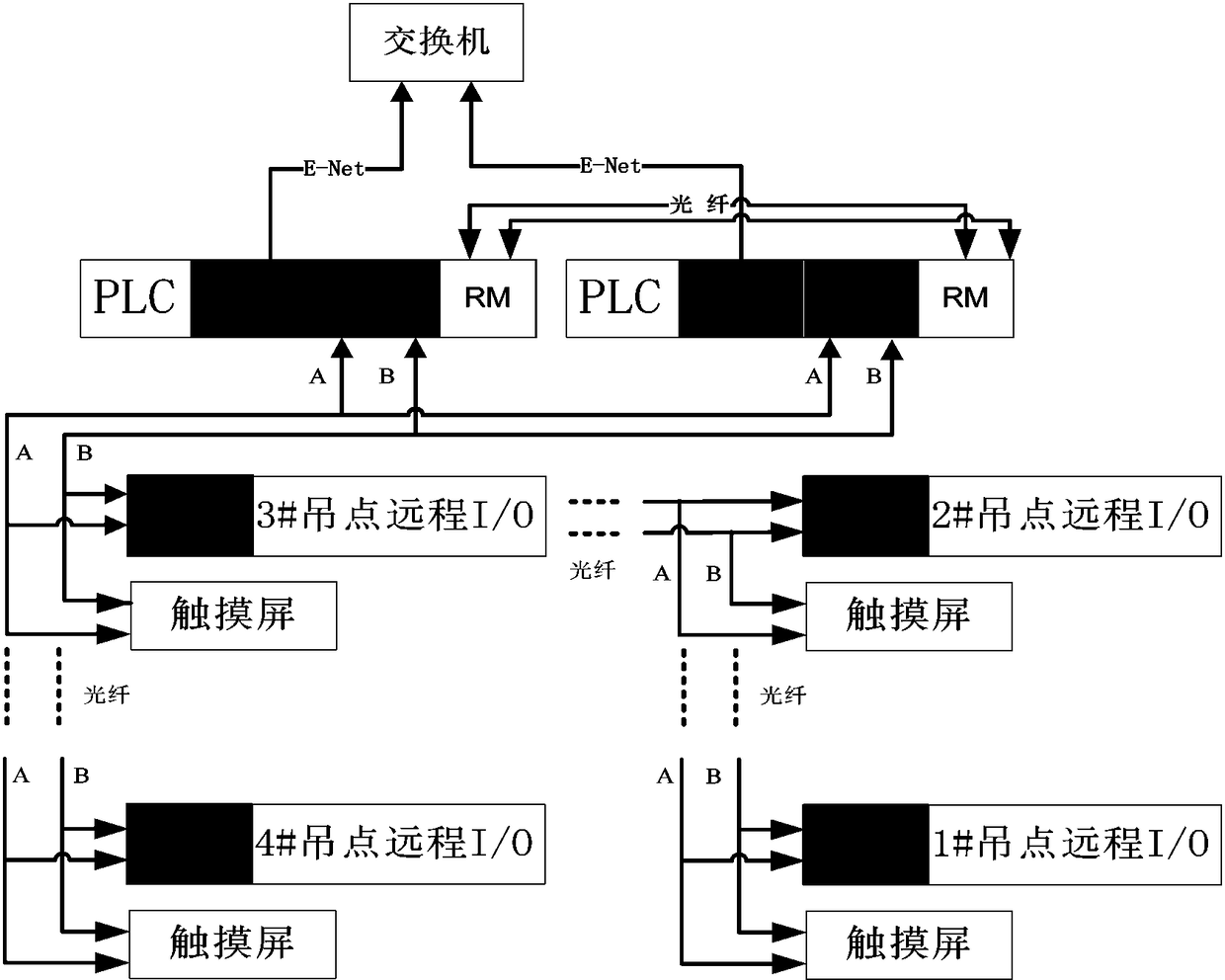

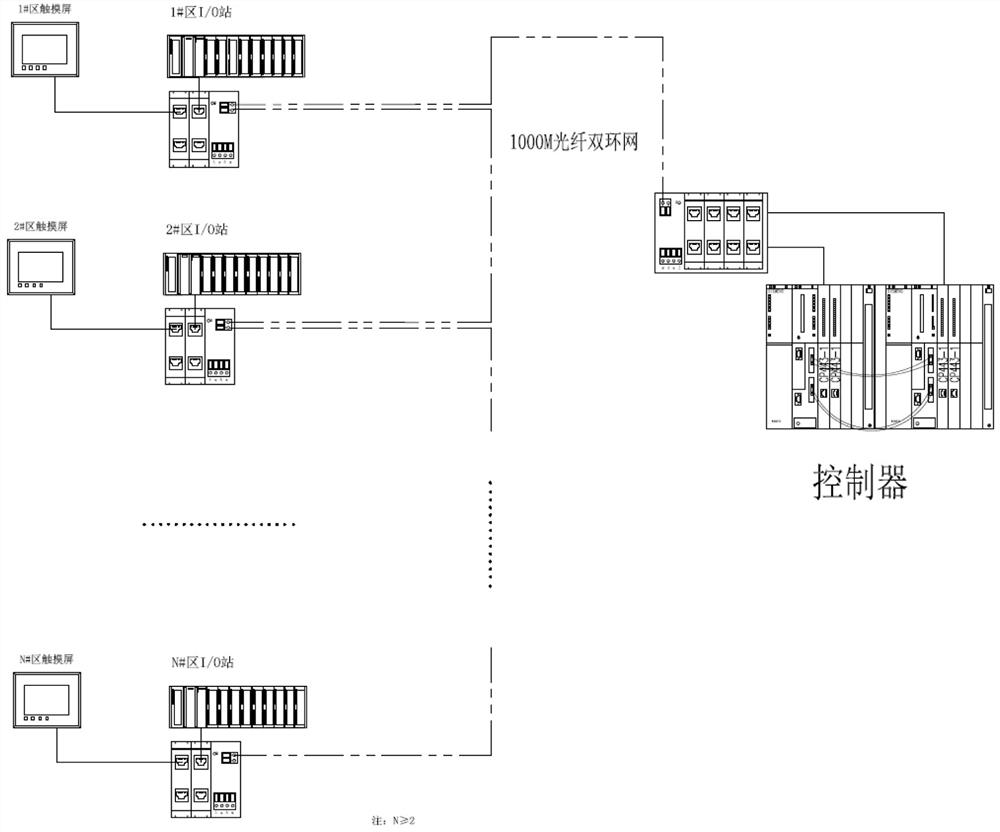

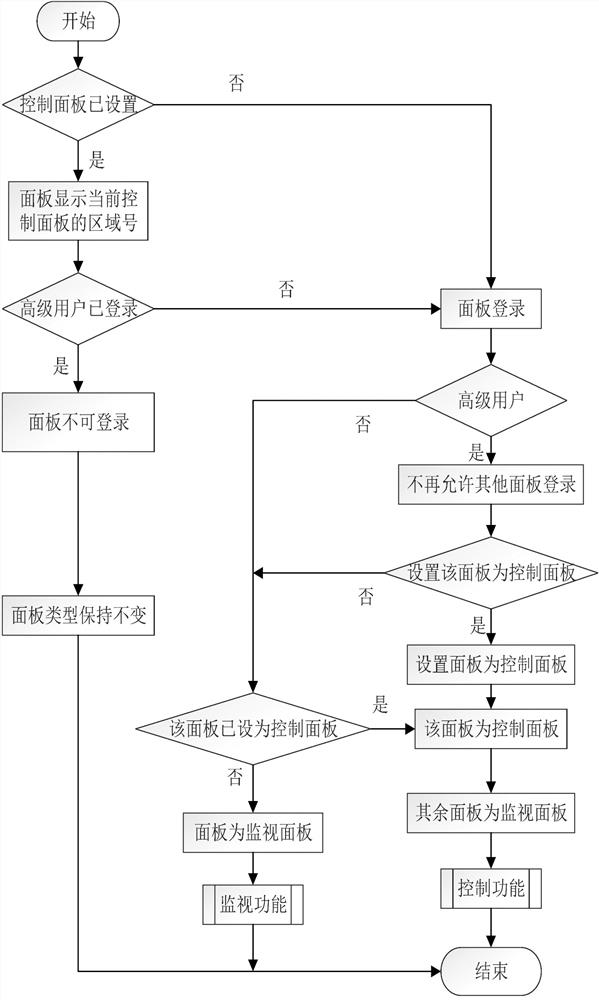

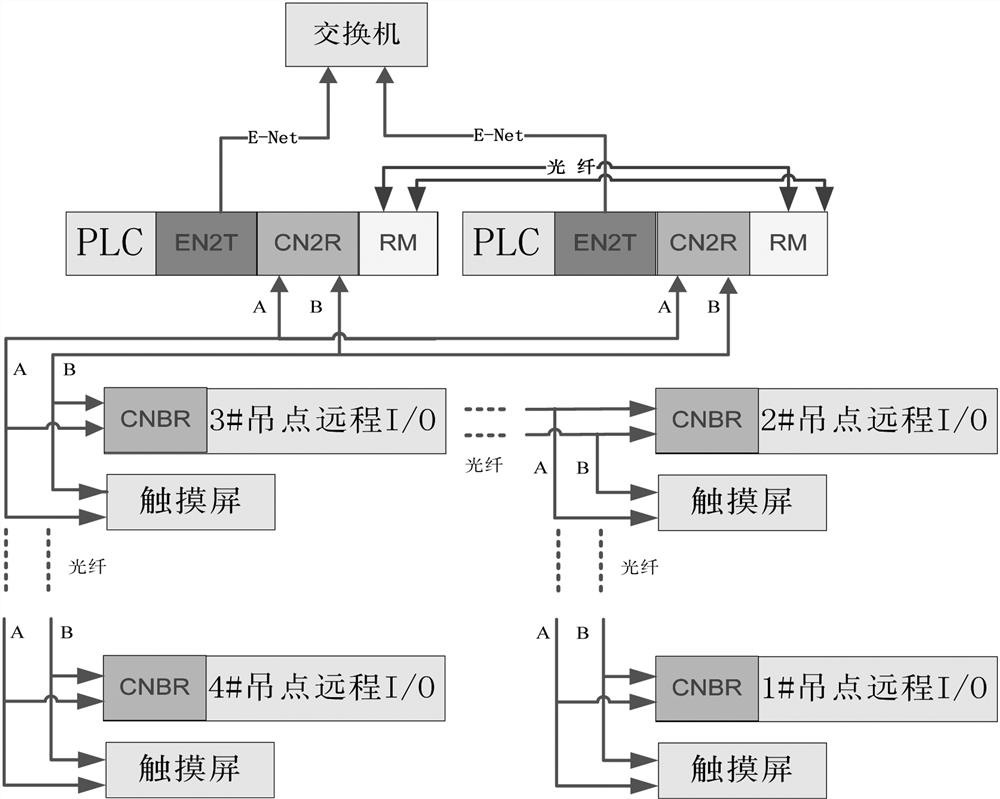

Multi-point operation coordinated control method of climbing ship lift driving mechanism

ActiveCN109162268AGuaranteed performanceTake security into considerationProgramme controlComputer controlMonitoring systemSoftware development

The invention discloses a multi-point operation coordinated control method of a climbing ship lift driving mechanism. Multiple operation panels are arranged in each equipment distribution area of a ship lift driving mechanism monitoring system; and except for one set of controller, the system adopts a remote IO station mode to form a system network in order to control equipment in each area. The multi-point operation coordinated control method of the climbing ship lift driving mechanism, disclosed by the invention, has the advantages that only one operation panel is used as a control panel tocarry out operation, the rest operation panels can only perform monitoring functions, and moreover, the control panel can be changed according to user demands, situations that the software developmentis complicated and the disorder is easy to cause in operation due to the adoptions of the multiple operation panels are completely eliminated, and safety hazards in the operation are avoided.

Owner:WUHAN GREAT SEA HI TECH

Automatic pressing production line for large explosive grains

ActiveCN103265389BIncrease pressureHigh densityExplosive working-up apparatusProduction lineEngineering

The invention relates to an automatic pressing production line for large-scale explosive powder columns, which includes a hydraulic press consisting of an upper beam, an upper return cylinder, an upper cylinder slider, an upper punch, a middle beam equipped with a die sleeve, and a lower beam. The characteristics are: It includes an automatic weighing and feeding device, a powder smoothing device and an automatic discharging device arranged on the side of the hydraulic press. The upper part of the lower beam is equipped with a lower return cylinder, which is connected with the slider of the lower belt cylinder, and the lower belt cylinder slides The block is equipped with a lower punch, an automatic vacuum device is provided at the lower part of the upper cylinder slider, and a mechanical limit device is provided on the upper cylinder slider and the lower cylinder slider. The advantages are: this production line can realize the fully automatic operation of explosive column feeding, smoothing, two-way pressing and discharging, which can not only greatly reduce the labor intensity of operators, improve the production efficiency of large-tonnage hydraulic presses, avoid potential safety hazards, and It can reduce the air bubbles in the powder column during the pressing process, improve the mass density uniformity and precision of the powder column, and ensure the product quality.

Owner:TIANJIN TIANDUAN PRESS CO LTD

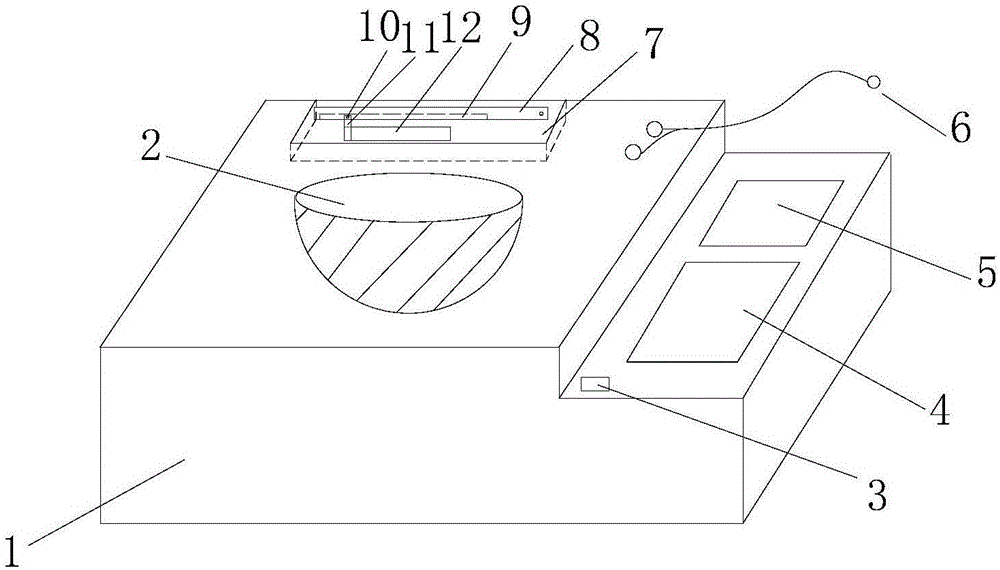

Masterbatch drying device

InactiveCN106346662AImprove the defect of inaccurate temperature measurementAvoid Operational Safety HazardsCoatingsTemperature controlMasterbatch

The invention provides a masterbatch drying device and belongs to the field of masterbatch drying. The masterbatch drying device comprises a housing, a cover core, a temperature control panel, a time control panel, a thermocouple and a fixing device, wherein the cover core, the temperature control panel, the time control panel, the thermocouple and the fixing device are mounted on the housing; the thermocouple measures the temperature of a masterbatch via the fixing device; the temperature control panel performs heating temperature control operation on the cover core; the time control panel sets a time period according to a temperature change. The device has the following advantages that the temperature can be measured more accurately and safely, a more convenient and quicker man-machine operation interface is added, and the energy of experiment personnel is saved.

Owner:天津市多彩塑料色母有限公司

A guide support device for quick-opening door of washing machine

ActiveCN105127168BAvoid damageSwipe quickly and accuratelyCleaning processes and apparatusMechanical engineering

The invention provides a guiding and supporting device for the quick-opening door of a cleaning machine. The other end is fixedly connected with the quick-opening door; the upper end of the sliding support device is connected with the cleaning drum in the cleaning machine, and the lower end is slidingly matched with the floor rail. After the cleaning drum is cleaned and maintained, it can quickly and accurately slide to the predetermined matching position along the ground rail, preventing damage to the mechanical seal caused by rotation of the cleaning drum due to improper assembly. When the cleaning drum rotates, an eccentric force will be generated due to the asymmetry of the cleaning materials loaded in the cleaning drum. The setting of the guide device can effectively counteract the eccentric force and prevent the bearing from supporting the quick-opening door of the cleaning drum under the action of the eccentric force. Vibrate along the gap of the quick-opening door, thereby affecting the service life of the support bearings and mechanical seals at both ends of the cleaning drum.

Owner:SHINVA MEDICAL INSTR CO LTD

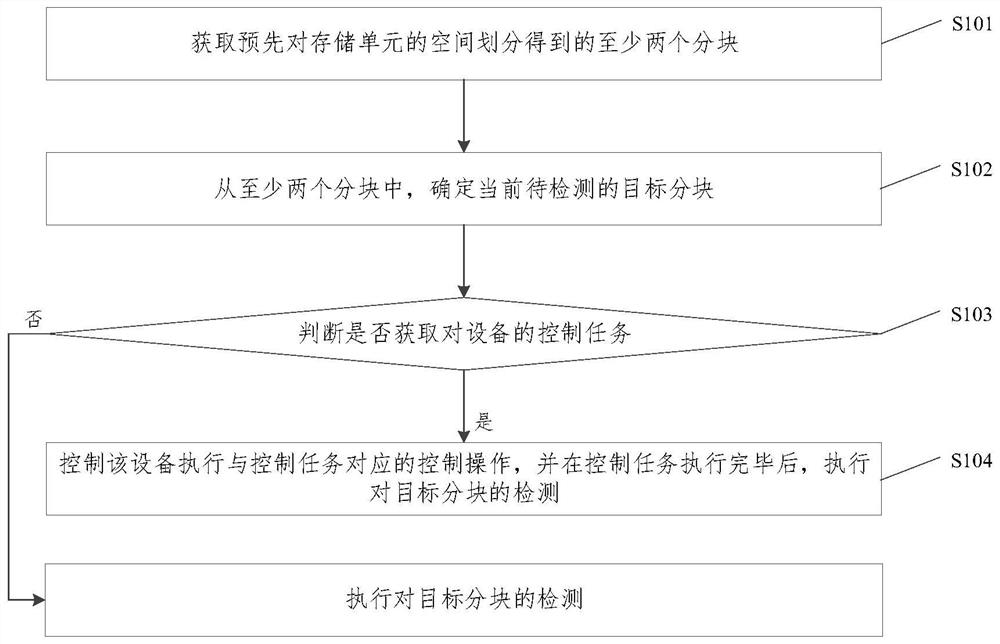

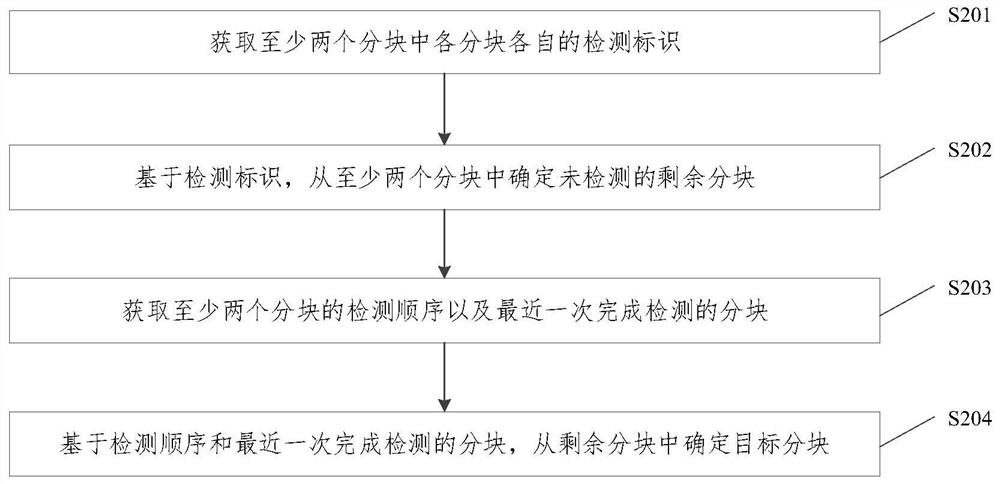

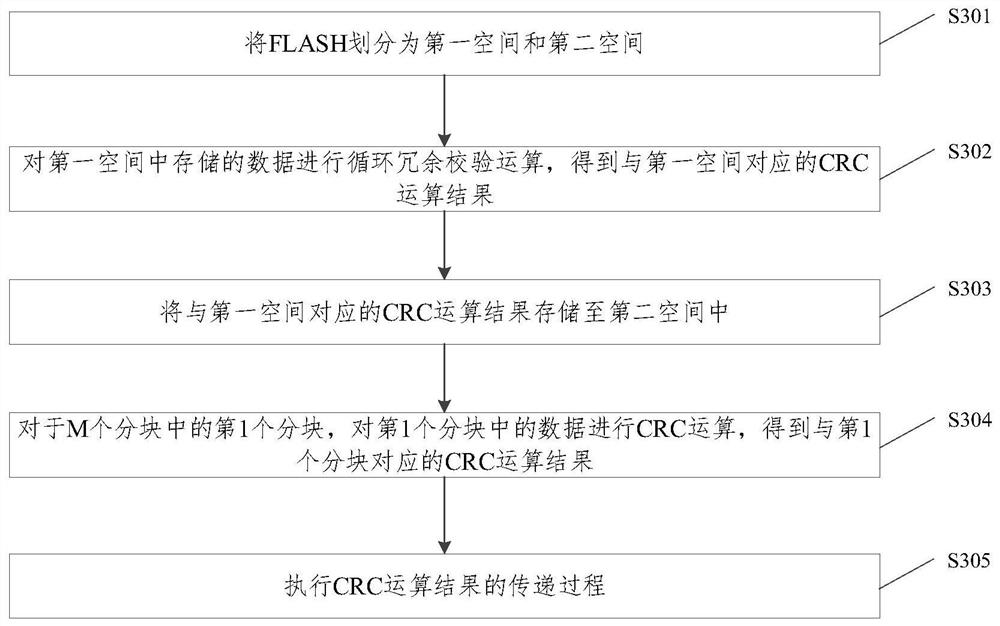

Safety controller detection method and device, equipment and storage medium

PendingCN113468008AAvoid Operational Safety HazardsFaulty hardware testing methodsTotal factory controlSpatial partitionControl engineering

Owner:SHENZHEN YUEJIANG TECH CO LTD

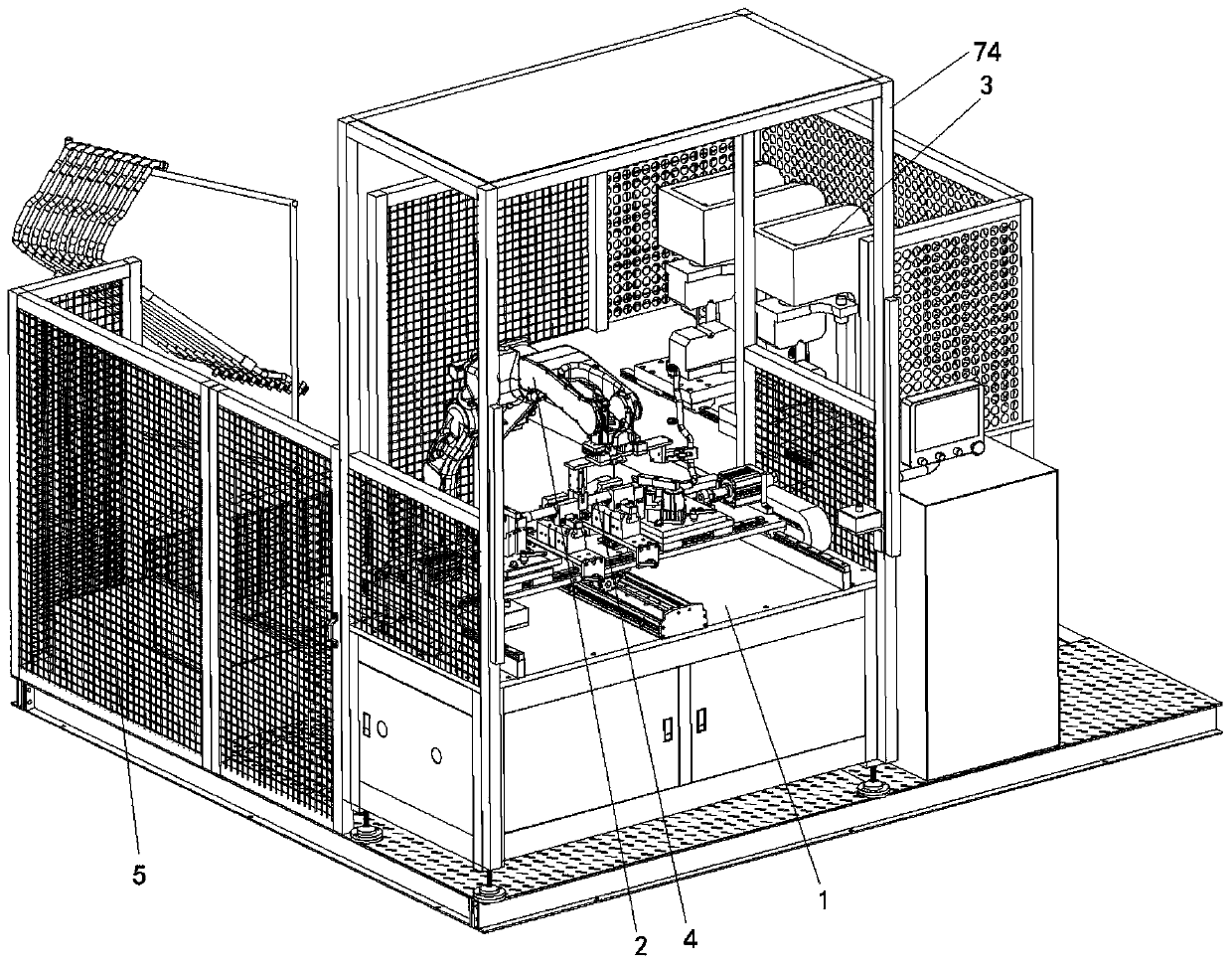

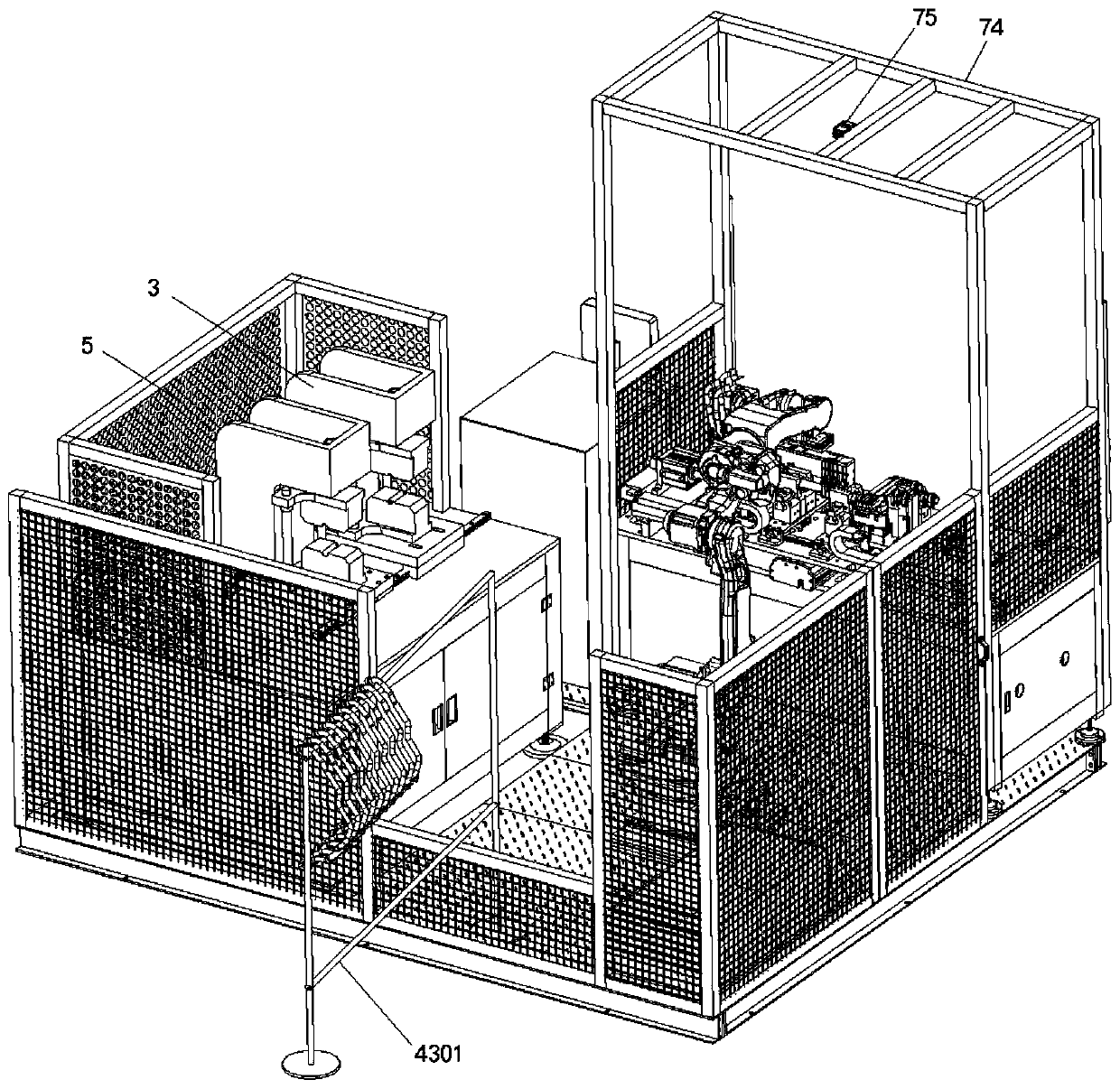

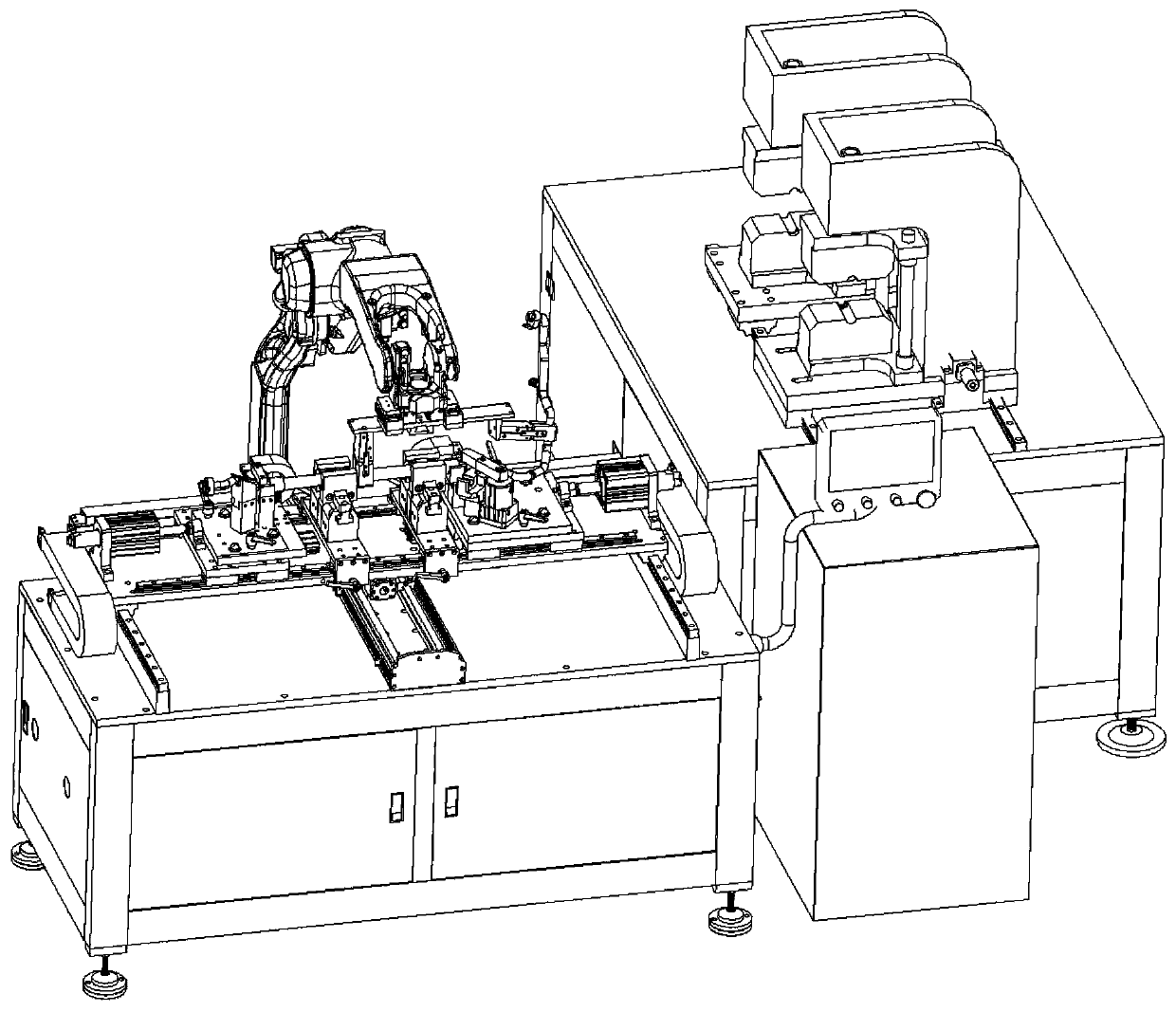

Automatic pipe buckling assembling production line for air conditioner pipeline

PendingCN110227933AReduce labor intensityEnsure consistencyGripping headsAssembly machinesProduction lineEngineering

The invention relates to an automatic pipe buckling assembling production line for an air conditioner pipeline. The automatic pipe buckling assembling production line comprises an assembling table, arobot and a pipe buckling machine. The assembling table assembles a to-be-buckled pipefitting, the robot grabs the to-be-buckled pipefitting on the assembling table and transfers the same to a pipe buckling station of the pipe buckling machine, the pipe buckling machine buckles the to-be-buckled pipefitting at the pipe buckling station, and the robot takes down the buckled pipefitting at the pipebuckling station of the pipe buckling machine and transfers the buckled pipefitting to a discharge position. The pipefitting needed to be buckled is placed to the assembling table to be assembled, thepipefitting is transferred to the pipe buckling station of the pipe buckling machine through the robot, the pipefitting is buckled by the pipe buckling machine, after pipe buckling, the robot transfers the pipefitting to the discharge position, and then the robot grabs the to-be-buckled pipefitting from the assembling table in cycles. According to the production line, the operating potential safety hazards as staff is in direct contact to the pipe buckling machine are avoided, and the staff only needs to assemble the pipefitting need to be buckled on the assembling table, so that the labor intensity of the staff is reduced, the work efficiency is enhanced, the pipe buckling consistency is guaranteed, and the automatic degree is improved.

Owner:常州市盛士达汽车空调有限公司

A swing arm type pipe rod space slideway

InactiveCN103899256BAvoid safety hazardsReduce labor intensityDrilling rodsDrilling casingsHydraulic cylinderEngineering

The invention relates to a swing arm type pipe rod spatial slideway. The swing arm type pipe rod spatial slideway is composed of a mechanical part, a hydraulic system and an electrical system. A base (1) is connected with swing arms (2), one of the swing arms (2) is connected with a platform (3), the other swing arm (2) is connected with a rotary arm (5), one end of the rotary arm (5) is connected with a main hydraulic cylinder (4), the other end of the rotary arm (5) can slide on the platform (3), a slideway (6) is mounted on the platform (3) and connected with a horizontal pushing hydraulic cylinder (7), and the slideway (6) is pushed to slide back and forth on the platform (3). Pipe rods can be directly taken and delivered to the working position from an oil pipe bridge or can be directly delivered to discharge on the related bridge. The swing arm type pipe rod spatial slideway has the advantages that potential safety hazards of hurt to people by pulling the pipe rods are eliminated, labor intensity is reduced by more than 80%, on-site severe working conditions are avoided, potential safety hazards of passing on the site are eliminated, the working position of an operator is fixed, safety and comfortability are achieved, and two persons are reduced to one for auxiliary operation.

Owner:东营市尚科石油装备有限公司

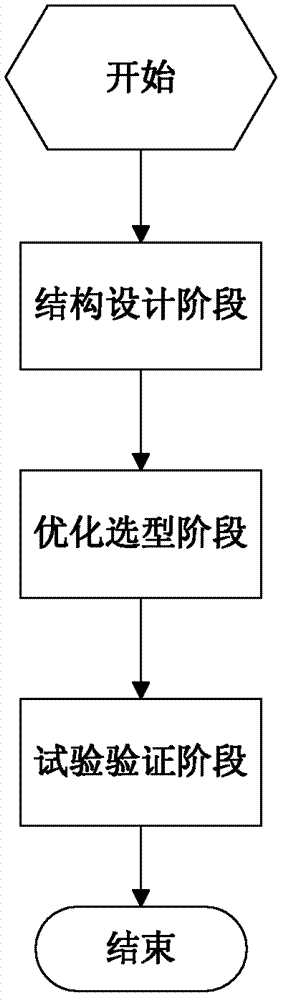

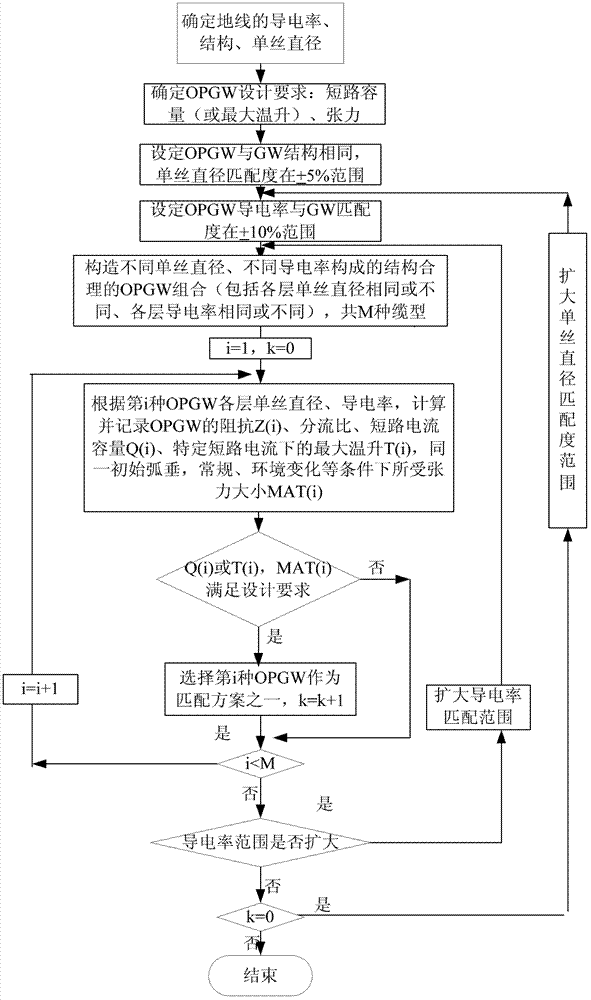

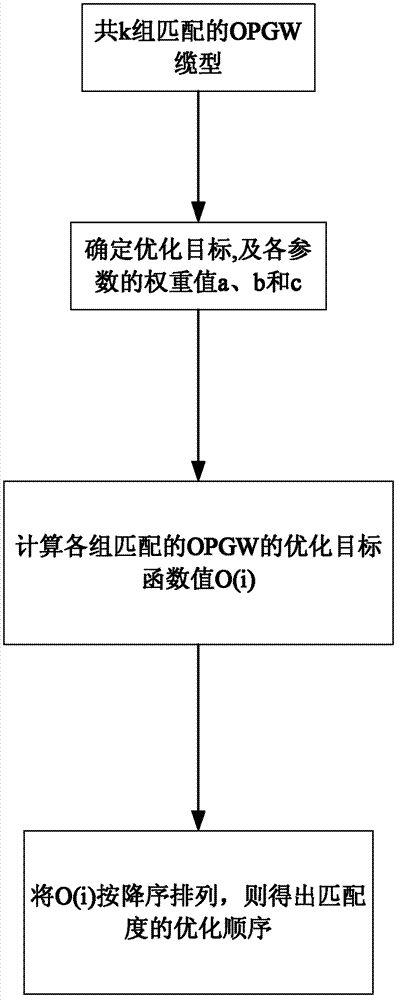

Design method for matching optical fiber composite overhead ground wires with common ground wire

ActiveCN102684105BAvoid missingImprove selection efficiencyApparatus for overhead lines/cablesTelecommunications networkElectrical performance

The invention relates to a design method for matching optical fiber composite overhead ground wires with a common ground wire. The method comprises the following steps: (1) a structure design stage of determining the optical fiber composite overhead ground wires, wherein the matching degree of electrical performance parameters and mechanical performance parameters of the optical fiber composite overhead ground wires and a shunt ground wire is in the matching range and the optical fiber composite overhead ground wires meet the circuit design requirement; (2) an optimizing and selecting stage of determining to sort the optical fiber composite overhead ground wires according to an optimization target and calculating dynamic sag difference verification in the thermal effect and engineering; and (3) a test verification stage of carrying out test verification on the optical fiber composite overhead ground wires which are sorted according to the optimization target. The method provided by the invention is beneficial for ensuring the operating quality of an OPGW (Optical Fiber Composite Overhead Ground Wire) cable, reducing the accident occurrence rate, prolonging the service life of the cable and regulating the OPGW design selection and engineering construction and has important significance on ensuring the safe and stable operation of a power telecommunication network.

Owner:CHINA ELECTRIC POWER RES INST +1

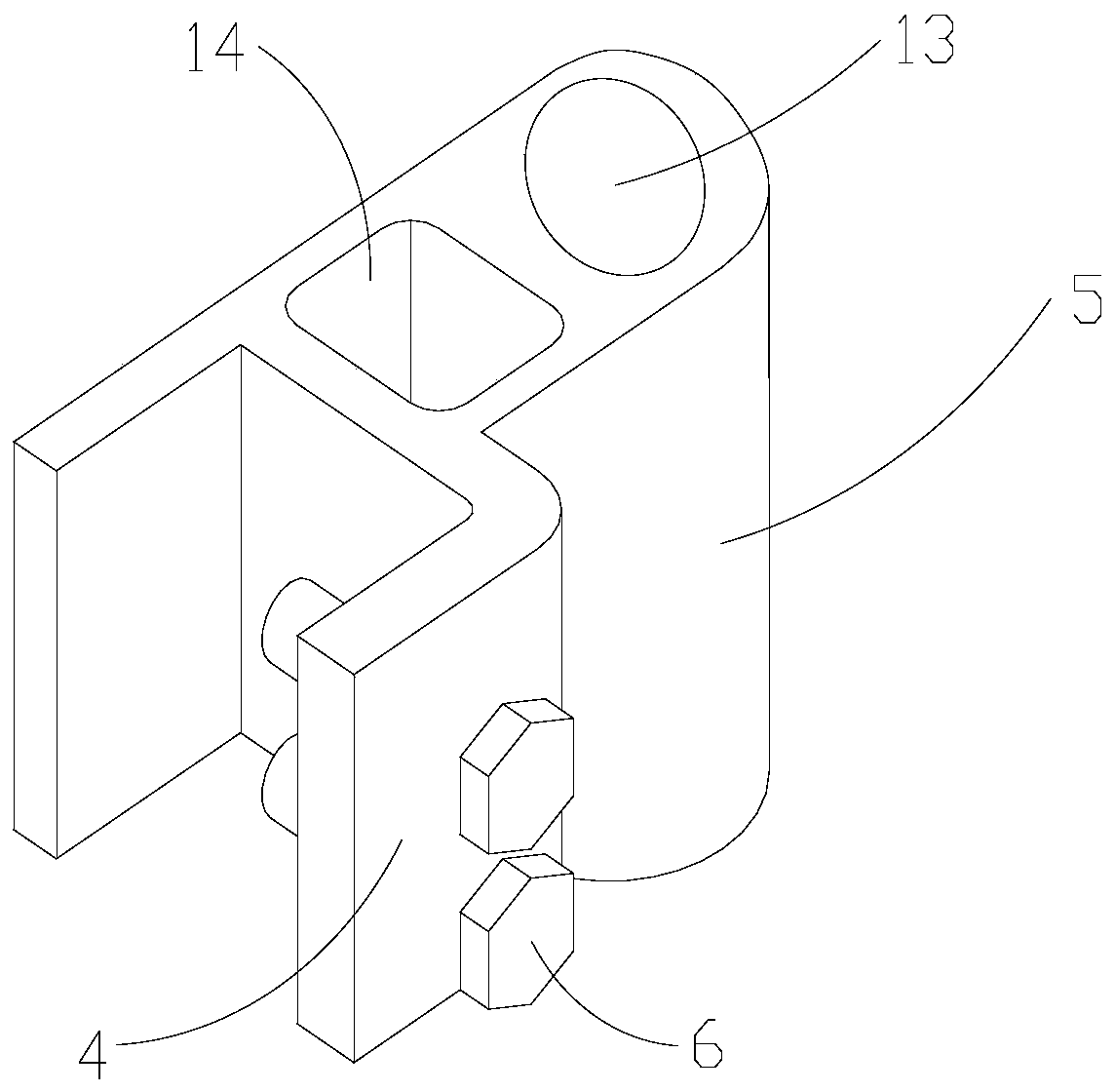

Box-closing guide device for large sand box

ActiveCN108515150BImprove applicable placesEasy to arrange side by sideMoulding flasksClassical mechanicsStructural engineering

The invention provides a box closing guiding device for a large sandbox. The device is used in the field of sand mold casting, and is used for solving the problems of large realization difficulty andhigh safety risk of inner box taper positioning in the molding or closing process of the large sandbox. The box closing guiding device for the large sandbox comprises a guiding rod, a first positioning piece and a second positioning piece, the first positioning piece is fixed on an upper sandbox, the guiding rod is inserted to the first positioning piece, and the second positioning piece is inserted to the guiding rod and is fixedly connected to the lower sandbox in order to realize ostensive box closing, so the safety risk of an operator in the box closing process is reduced, the efficiency of the box closing process is improved, the problem of uniform clamping of the sandbox, caused by nonalignment of positioning holes in the box edge due to torsion deformation of the upper sandbox and alower sandbox, is avoided, and the leak-out risk of metal from the sandbox is avoided.

Owner:KOCEL EQUIP

Portable tire disassembly device

The invention relates to the technical field of motor vehicle maintenance, and in particular to a portable tire disassembly device. The portable tire disassembly device comprises a cylinder body and an oil cylinder. A tension spring, an ejector rod and a limiting sleeve are arranged in the cylinder body, and a claw body is movably connected to the left side of the cylinder body. The cylinder bodyis fixedly connected with the oil cylinder. A quick coupling is arranged on the connecting position. A slotted screw is arranged at the bottom of the quick coupling. A steel ball is arranged below theslotted screw, and the steel ball is located at an inclined oil way opening in the cylinder body. A tension rod is arranged in the oil cylinder, a connecting head is arranged on the right side of thetension rod, and a fixed handle is arranged on the connecting head. A damping screw is arranged on an oil inlet and outlet passage in the oil cylinder. The portable tire disassembly device has the characteristics of simple structure, convenient carrying and safe use and is especially suitable for the disassembly of large and medium-sized engineering vehicle tires, the operation is simple, and thedisassembly efficiency is high.

Owner:杭州富阳荣鑫机械配件有限公司

The preparation method of methanesulfonamide

ActiveCN105085333BIncreased energy consumption and production capacityReduce labor intensitySulfonic acid amide preparationState of artSeparation technology

The invention relates to a preparation method of methyl o-sulphamoylbenzoate. The preparation method specifically includes the steps of conducting a diazo reaction, conducting a replacement reaction, conducting a chlorination reaction, conducting a standing reaction, conducting an amination reaction, conducting a neutralization reaction, dewatering, drying and packaging. In the dewatering step, mother liquid is placed in a diaphragm press filter to be subjected to extrusion and diaphragm bulging press and then subjected to re-extrusion and diaphragm bulging after being washed, a filter-press dehydration separation technology is initiated and replaces a traditional centrifugal dewatering separation technology, and then the dewatering purpose is achieved. Compared with the prior art, more electricity and water are saved through the method, the capacity under the equal energy consumption is greatly improved, the production environment is improved, and the labor intensity is relieved.

Owner:辉县市润得生物科技有限公司

Coordinated control method of multi-point operation for driving mechanism of climbing ship lift

ActiveCN109162268BGuaranteed performanceTake security into considerationProgramme controlComputer controlMarine engineeringControl engineering

The invention discloses a multi-point operation coordinated control method of a climbing ship lift driving mechanism. Multiple operation panels are arranged in each equipment distribution area of a ship lift driving mechanism monitoring system; and except for one set of controller, the system adopts a remote IO station mode to form a system network in order to control equipment in each area. The multi-point operation coordinated control method of the climbing ship lift driving mechanism, disclosed by the invention, has the advantages that only one operation panel is used as a control panel tocarry out operation, the rest operation panels can only perform monitoring functions, and moreover, the control panel can be changed according to user demands, situations that the software developmentis complicated and the disorder is easy to cause in operation due to the adoptions of the multiple operation panels are completely eliminated, and safety hazards in the operation are avoided.

Owner:WUHAN GREAT SEA HI TECH

Device and method for monitoring state of portable ground wire

ActiveCN112713423BAvoid Operational Safety HazardsPrevent leakageMeasurement devicesCoupling device detailsCopper wireControl engineering

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Automatically-controlled casting ladle plug rod opening and closing device

InactiveCN113333731AIngenious structural designStructural innovationMelt-holding vesselsHydraulic cylinderAutomatic control

The invention discloses an automatically-controlled casting ladle plug rod opening and closing device. The technical problems that in the prior art, a plug rod opening and closing device is manually operated, operation is dangerous, safety is poor, and the casting quality is affected are solved. The automatically-controlled casting ladle plug rod opening and closing device is arranged on a ladle body; a connecting rod mechanism comprises a vertical connecting rod and a transverse driving connecting rod; the bottom of the vertical connecting rod is hinged to the middle of the transverse driving connecting rod; a hydraulic system device comprises a vertically-fixedly-arranged hydraulic cylinder; a piston rod of the hydraulic cylinder stretches out of the bottom of the hydraulic cylinder, and the end of the piston rod is hinged to the left end of the transverse driving connecting rod; the bottom end of a vertical plug rod is hinged to the right side of the transverse driving connecting rod; the lower portion of the vertical plug rod is connected with a bottom water filling nozzle of the ladle body; and the hydraulic system device controls the piston rod of the hydraulic cylinder to stretch out and draw back, a vertical sliding rod is driven to move up and down through transmission of the transverse driving connecting rod, and finally the vertical plug rod is driven to move up and down through a transverse arm. The automatically-controlled casting ladle plug rod opening and closing device can be widely applied to the technical field of casting machines.

Owner:WEIHAI GONGYOU FOUNDRY MACHINERY CO LTD

Box closing guiding device for large sandbox

ActiveCN108515150AImprove applicable placesEasy to arrange side by sideMoulding flasksEngineeringSafety risk

The invention provides a box closing guiding device for a large sandbox. The device is used in the field of sand mold casting, and is used for solving the problems of large realization difficulty andhigh safety risk of inner box taper positioning in the molding or closing process of the large sandbox. The box closing guiding device for the large sandbox comprises a guiding rod, a first positioning piece and a second positioning piece, the first positioning piece is fixed on an upper sandbox, the guiding rod is inserted to the first positioning piece, and the second positioning piece is inserted to the guiding rod and is fixedly connected to the lower sandbox in order to realize ostensive box closing, so the safety risk of an operator in the box closing process is reduced, the efficiency of the box closing process is improved, the problem of uniform clamping of the sandbox, caused by nonalignment of positioning holes in the box edge due to torsion deformation of the upper sandbox and alower sandbox, is avoided, and the leak-out risk of metal from the sandbox is avoided.

Owner:KOCEL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com