Environment-friendly coating dispersing device

A technology of dispersing device and environmental protection coating, applied in mixers with rotating stirring device, transportation and packaging, dissolving and other directions, can solve the problems of hidden dangers, hidden dangers of operation, and displacement of the shaking position of the disperser body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

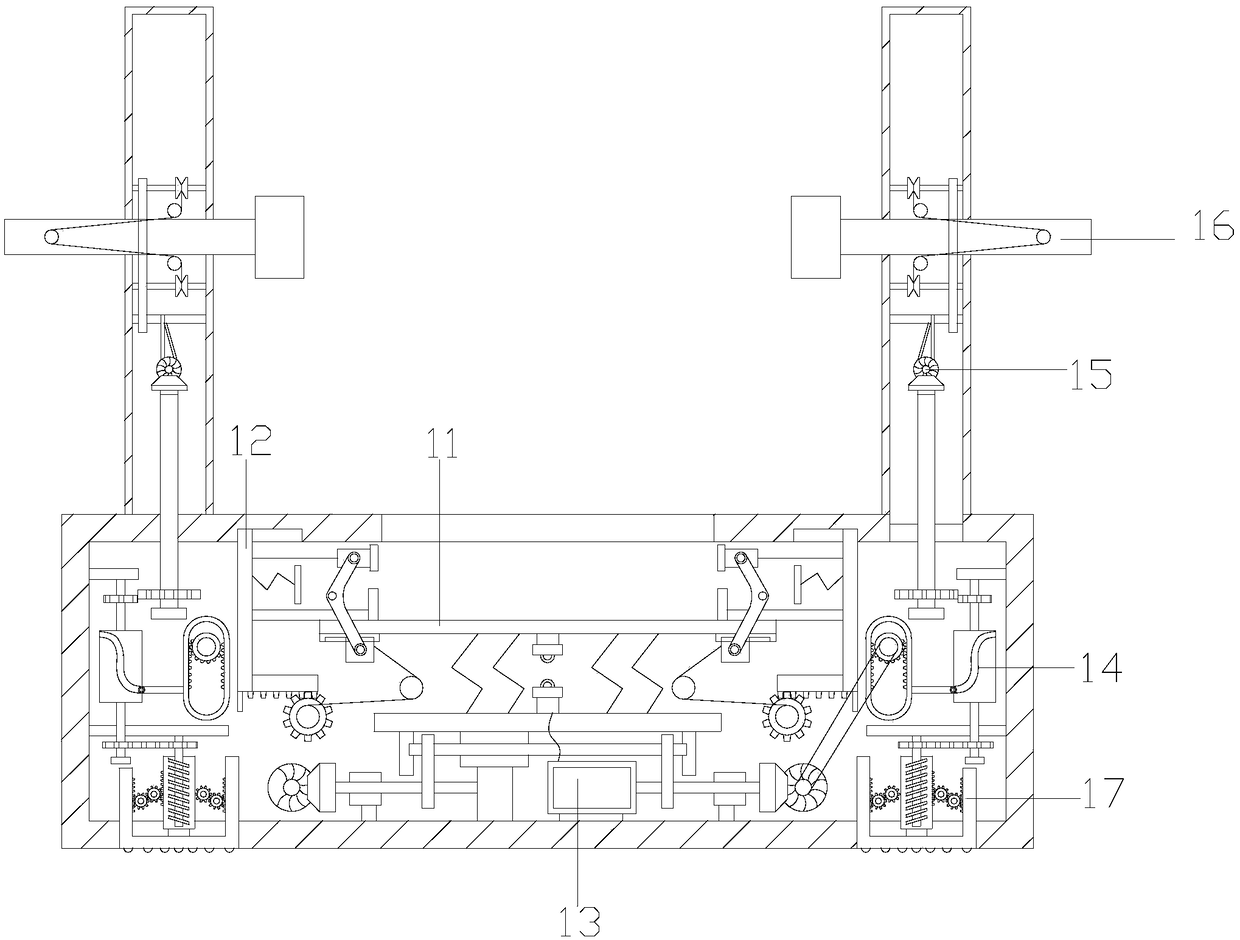

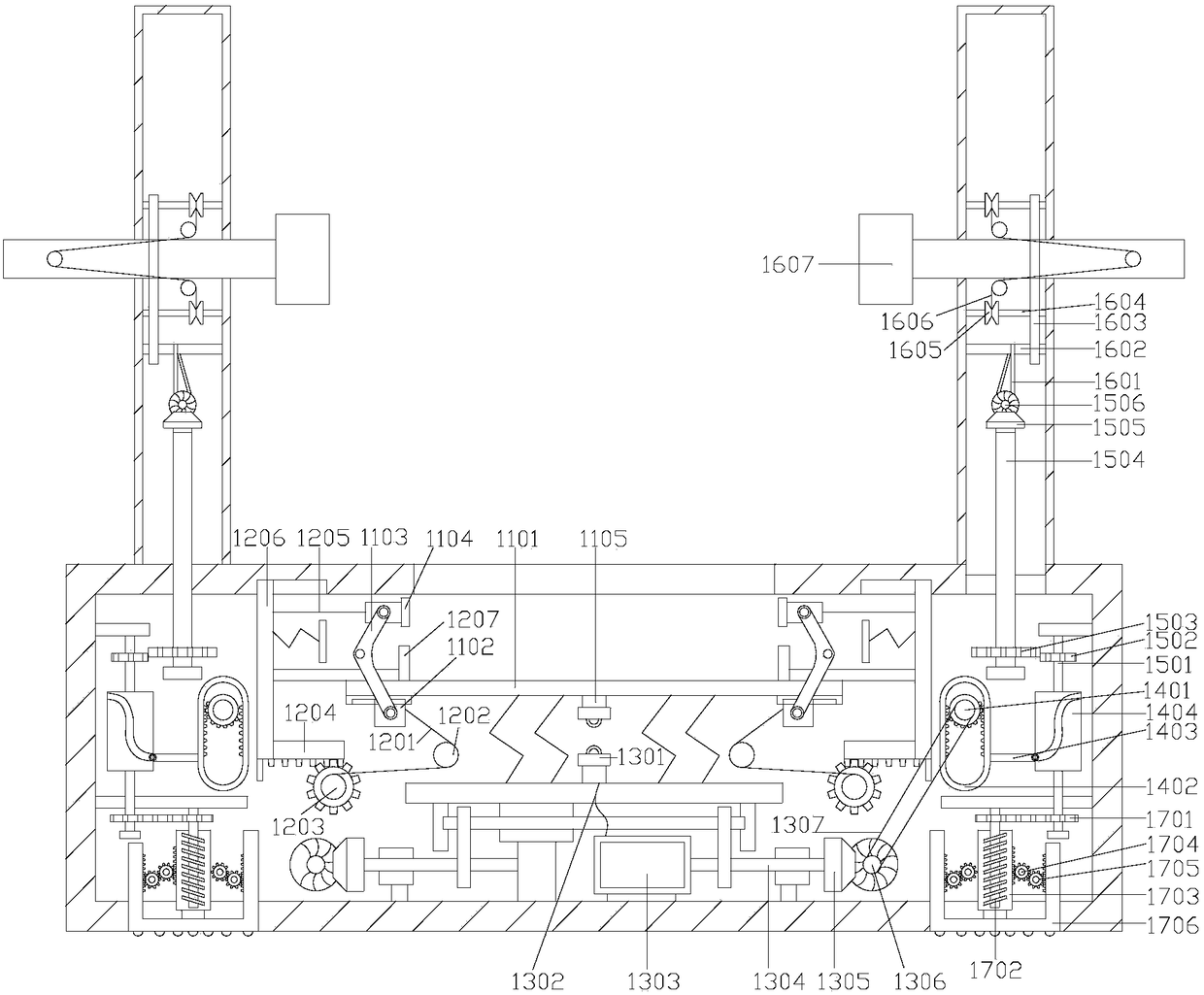

[0026] like Figure 1-Figure 4 Shown, the present invention provides a kind of technical scheme of environment-friendly paint dispersing device:

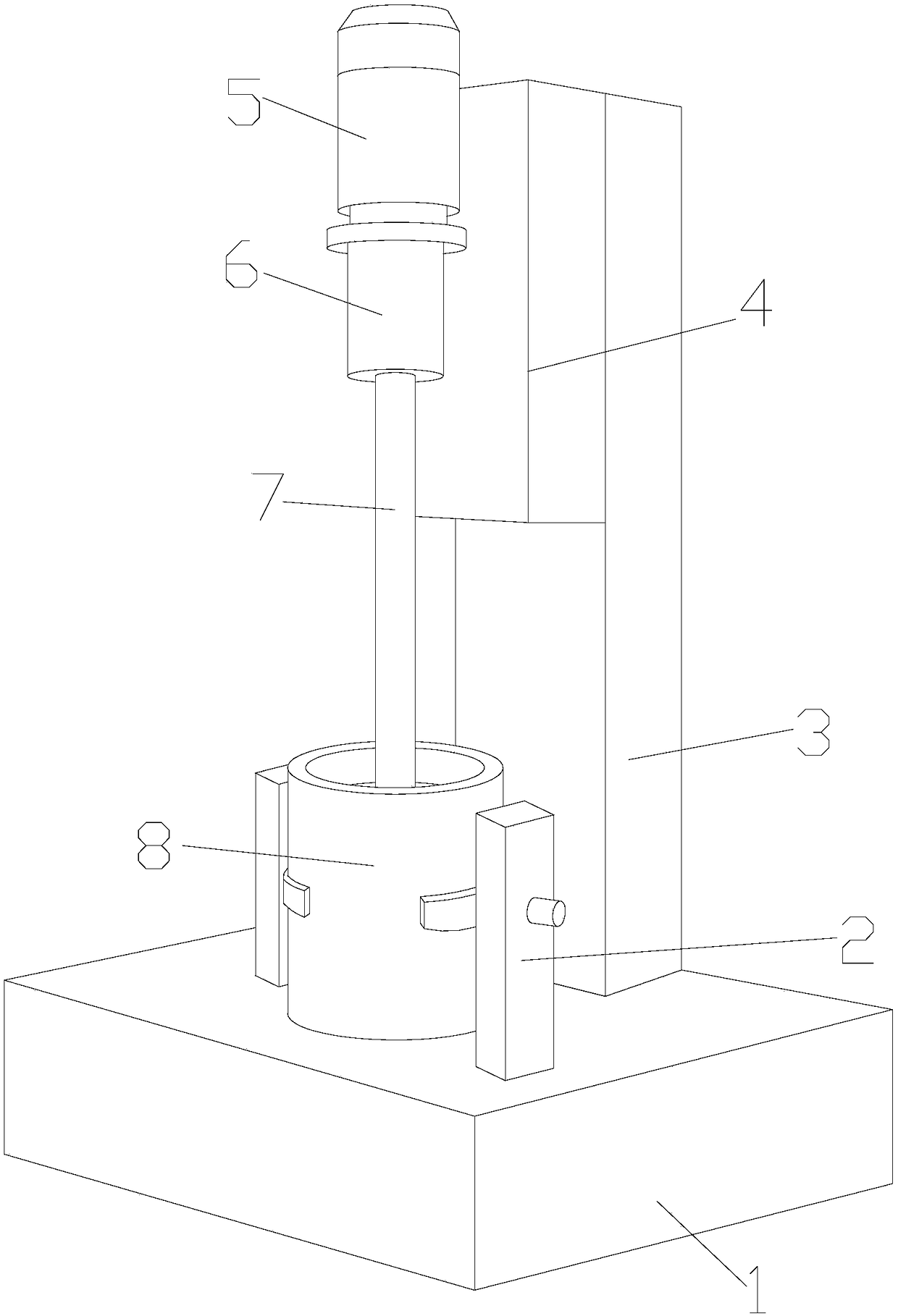

[0027] A kind of environmental protection paint dispersing device, its structure comprises supporting and stabilizing device 1, fixed machine arm 2, bracing frame 3, connector 4, driver 5, coupling 6, dispersing mixer 7, paint barrel 8, described supporting and stabilizing device The upper surface of 1 and the lower surface of the fixed arm 2 are welded and fixed to form an integrated structure, and the outer surface of the end of the support frame 3 close to the fixed arm 2 is attached to the outer surface of the end of the connector 4 away from the driver 5, so The end of the connector 4 away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com