The preparation method of methanesulfonamide

A technology of methanesulfonamide and amination reaction, which is applied in the preparation of sulfonamides and organic chemistry, can solve the problems of high water consumption and low efficiency in dehydration, and achieve the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems to be solved, technical solutions and beneficial effects clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] The concrete process step of production method of the present invention is as follows:

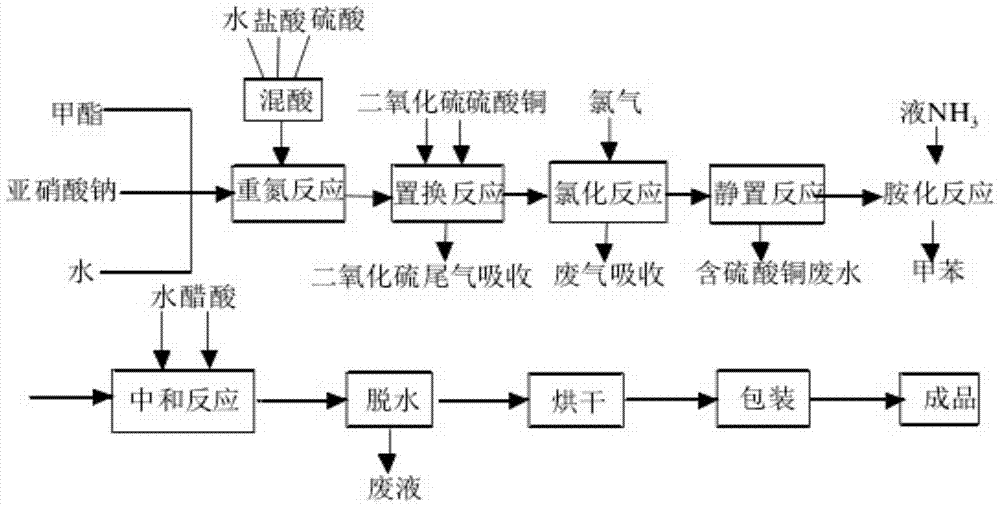

[0027] (1) Adopt the traditional method for producing methanesulfonamide from methyl o-formate benzenesulfonyl chloride to carry out steps such as diazonium reaction, displacement reaction, chlorination reaction, static reaction, amination reaction, neutralization reaction to raw material successively.

[0028] figure 1 Show the production process of methanesulfonamide from methyl o-formate benzenesulfonyl chloride. Now put the mixed acid prepared by water, hydrochloric acid and sulfuric acid in the diazo pot, and star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com