Design method for matching optical fiber composite overhead ground wires with common ground wire

An overhead ground wire and optical fiber composite technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problem that there is no unified design standard for optical fiber composite overhead ground wires and ordinary shunt ground wires, and the probability of lightning strikes for optical fiber composite overhead ground wires increases and decreases. Issues such as the service life of optical fiber composite overhead ground wires, to achieve the effect of enriching alternatives, saving cost and investment, and avoiding potential safety hazards in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

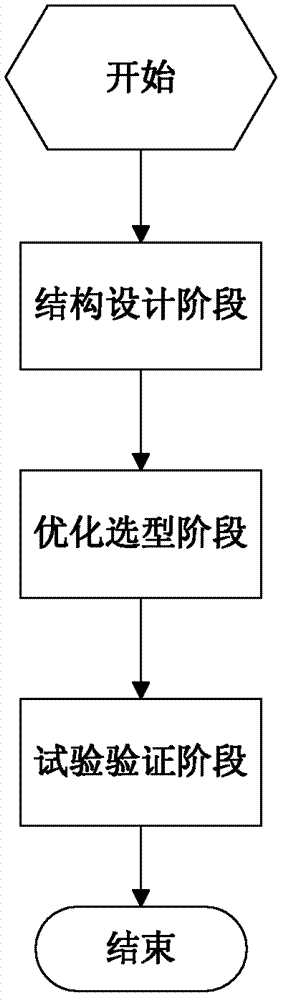

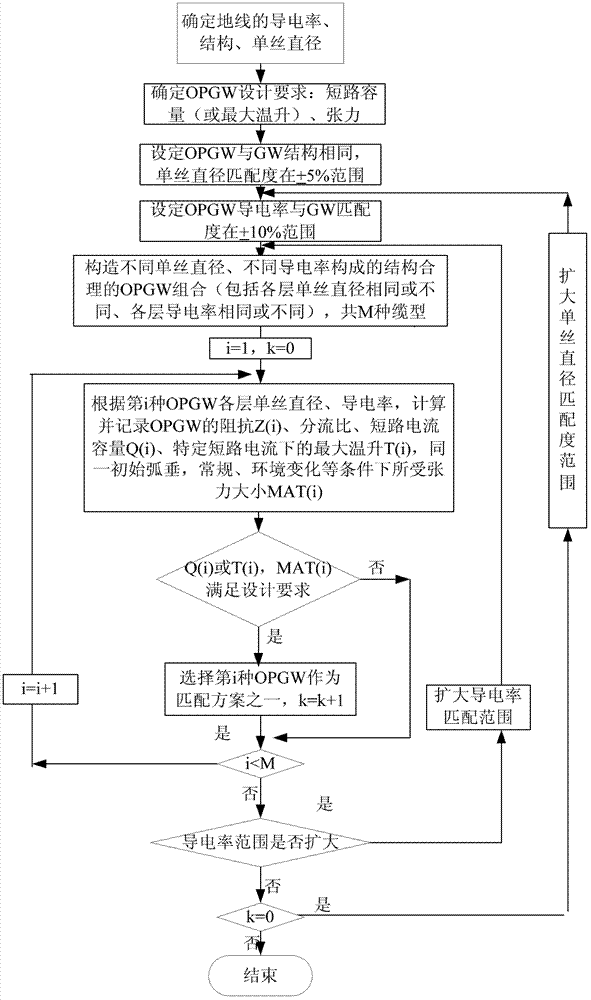

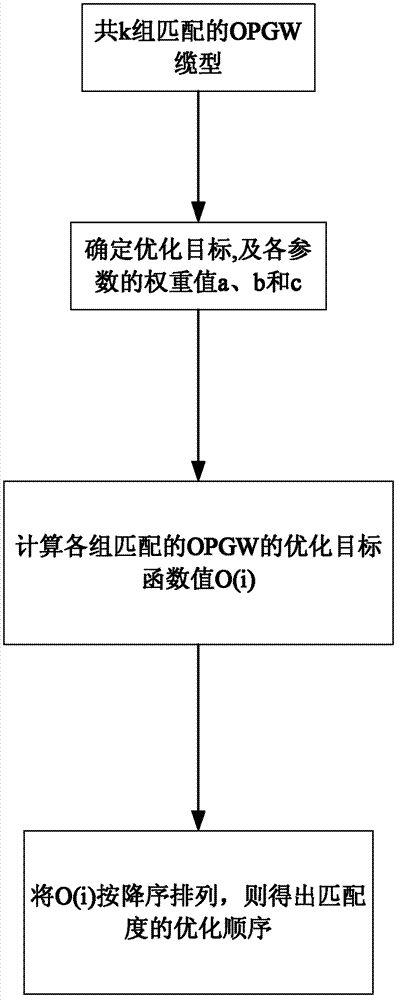

[0073] Such as figure 1 as shown, figure 1 It is a flow chart of the matching design method of optical fiber composite overhead ground wire (OPGW) and common shunt ground wire provided by the present invention. When the present invention selects the matching optical fiber composite overhead ground wire OPGW for the selected common shunt ground wire, there are structural design phases, optimization selection phases and test verification phases.

[0074] Each stage of the method of the present invention will be further described in detail below.

[0075] (1) Structural design stage:

[0076] The goal of the structural design stage: to select various optical fiber composite overhead ground wire OPGW combinations whose electrical performance parameters and mechanical performance parameters match with ordinary shunt ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com