Automatic feeding and multi-surface processing device for triaxial numerically-controlled machine tool

A CNC machine tool and multi-faceted processing technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as hidden safety hazards, high labor costs, manual replacement, etc., to reduce the number of operators and avoid safe operation. Hidden danger, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

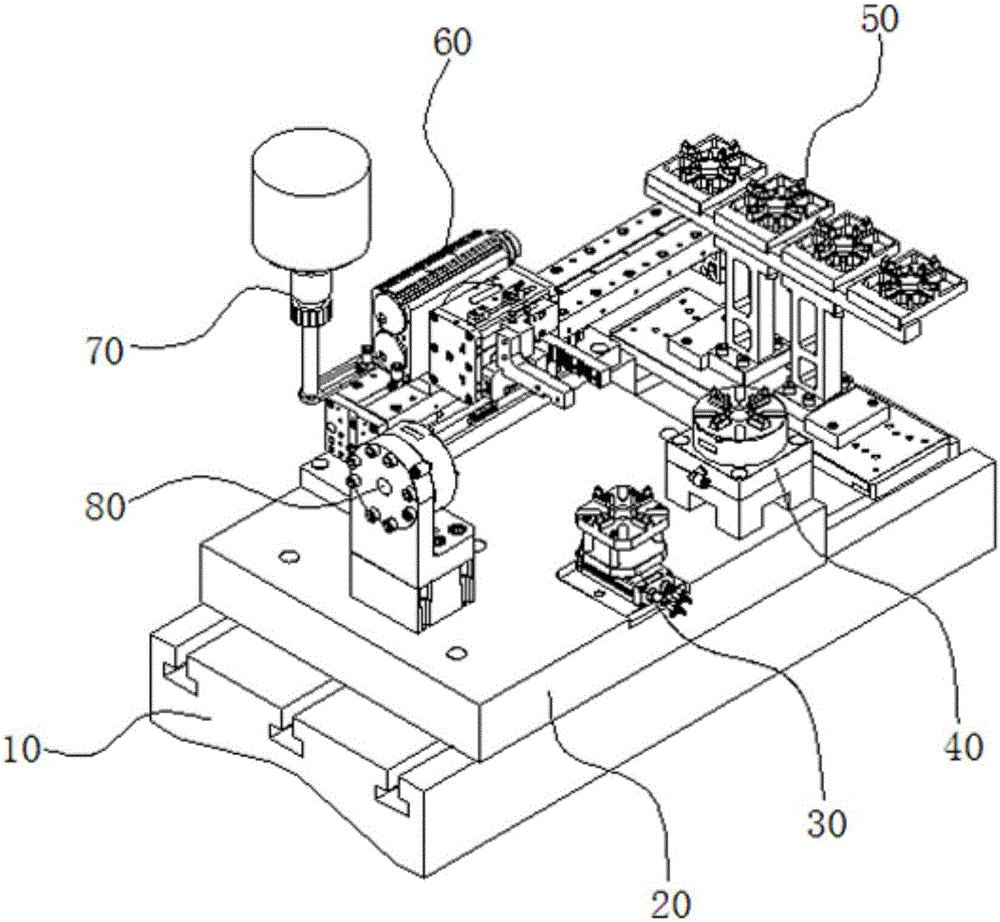

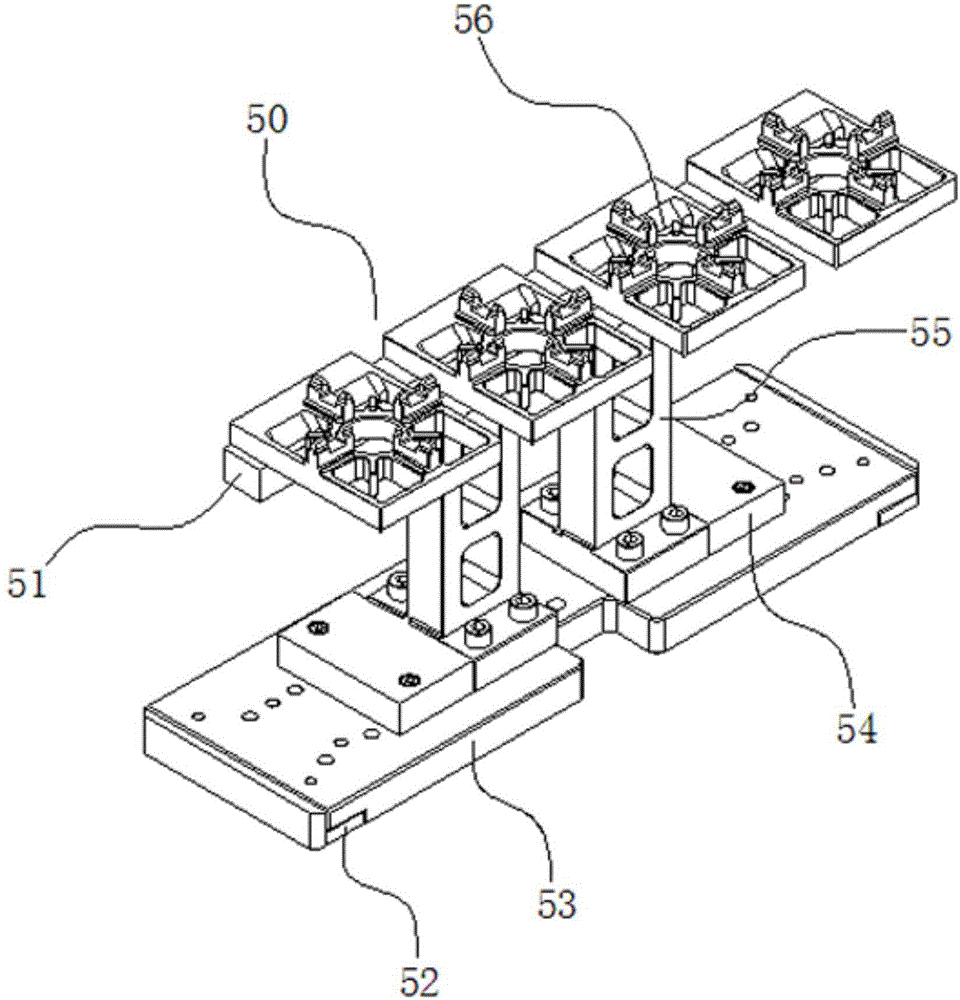

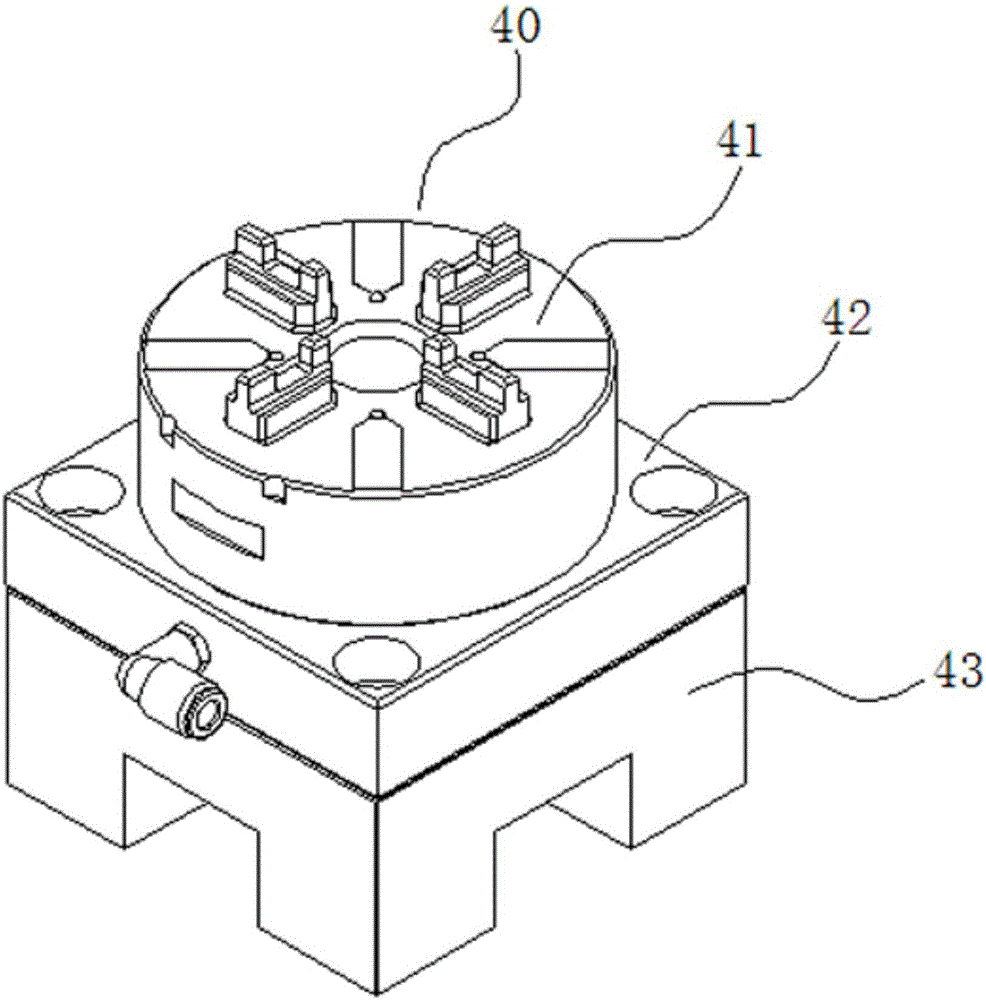

[0018] Such as figure 1 , Figure 8 and Figure 9 As shown, a three-axis CNC machine tool automatic feeding and multi-face processing device includes a CNC machine tool platform 10, a CNC machine tool workbench 20 is installed on the CNC machine tool platform 10, and one side of the CNC machine tool workbench 20 is externally installed. On the rack module 50 for placing a plurality of workpieces 90, the first pneumatic chuck module 40 for clamping the workpieces 90 is installed on the CNC machine table 20, and the horizontal rotation module 30 for driving the workpieces 90 to rotate horizontally. In the feeding module 60 that can rotate vertically and transmit the workpiece 90 horizontally, and the second pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com