Automatic pressing production line of large explosive column

A production line and explosive technology, which is applied in the field of large-scale explosive column automatic pressing production line, can solve the problems of difficulty in ensuring the vacuum degree of workpieces, unable to meet the fully automatic explosive column production line, unable to realize automatic vacuuming of explosive column, etc., and achieves improved operation. Working conditions, ensuring vacuum degree, and avoiding the effect of hidden dangers of operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

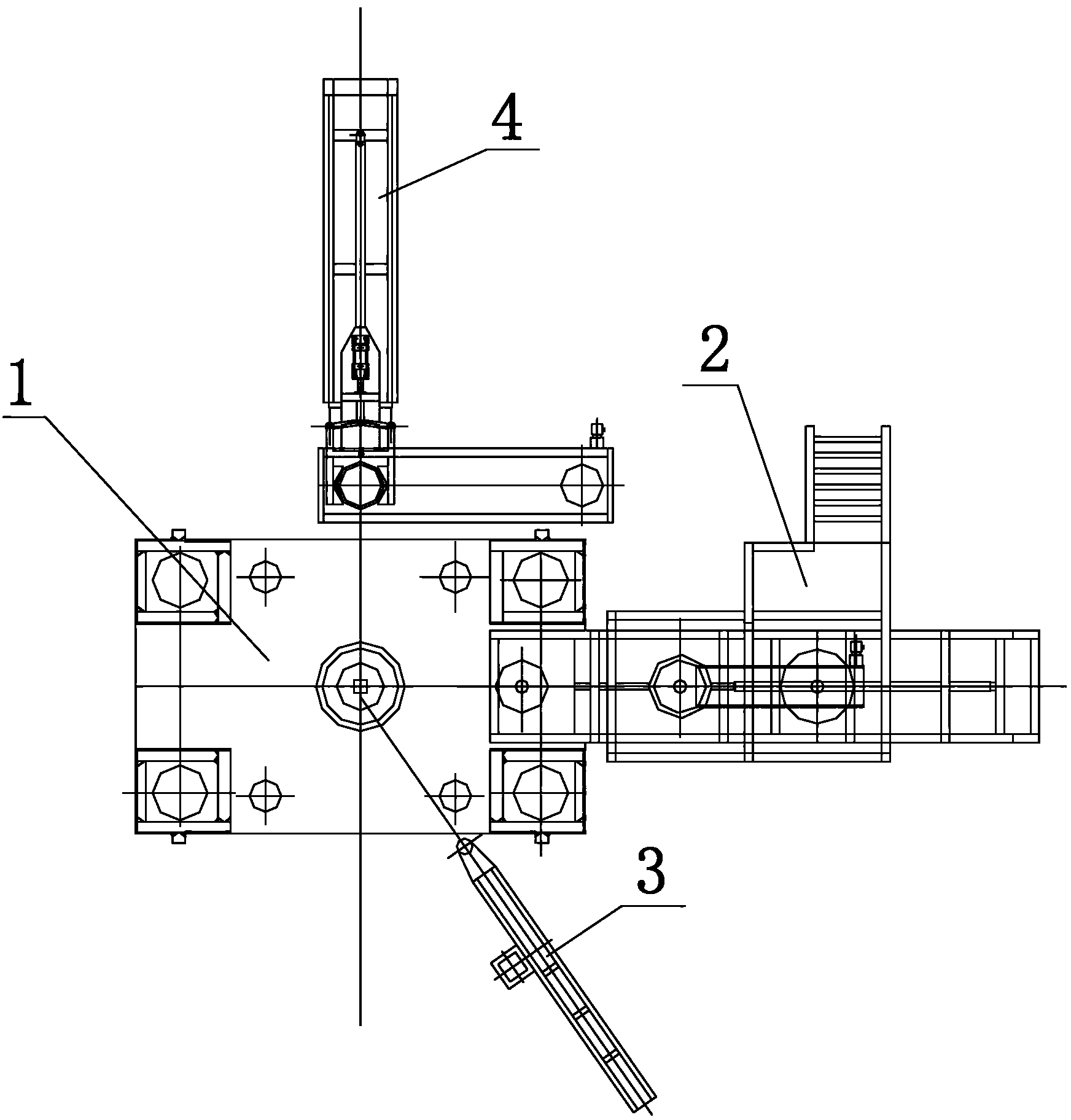

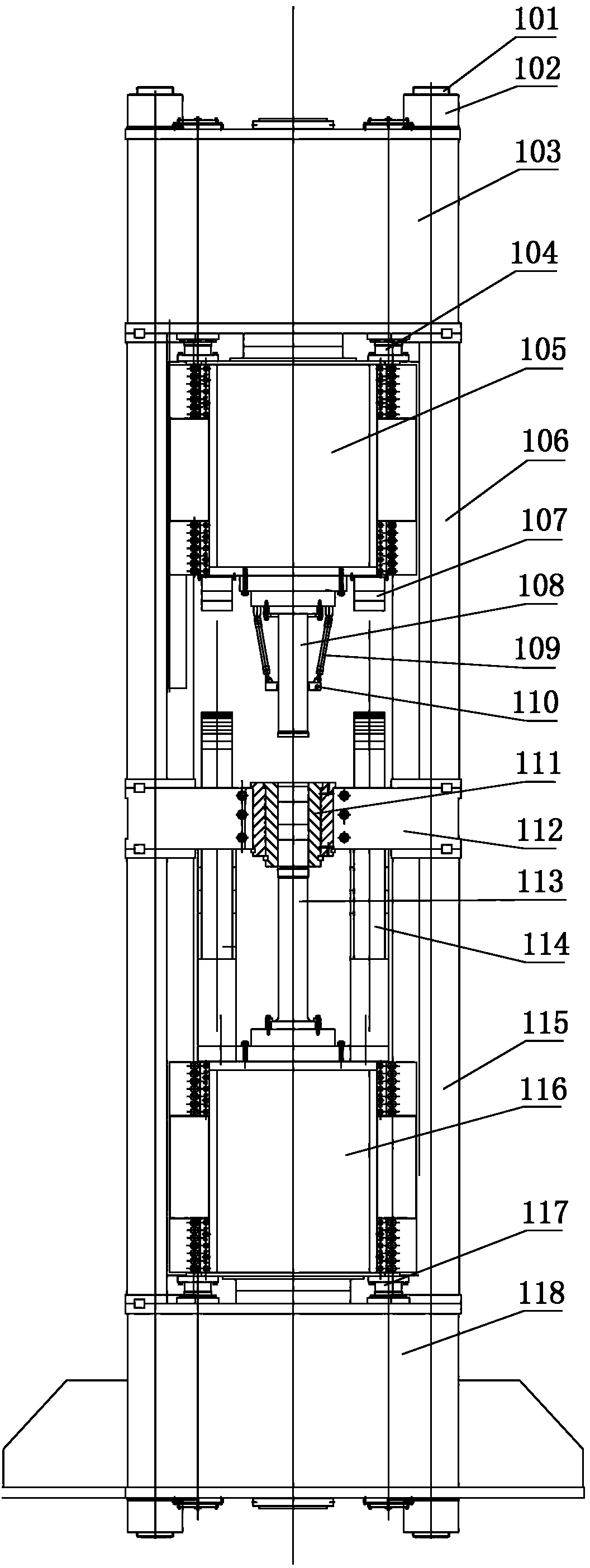

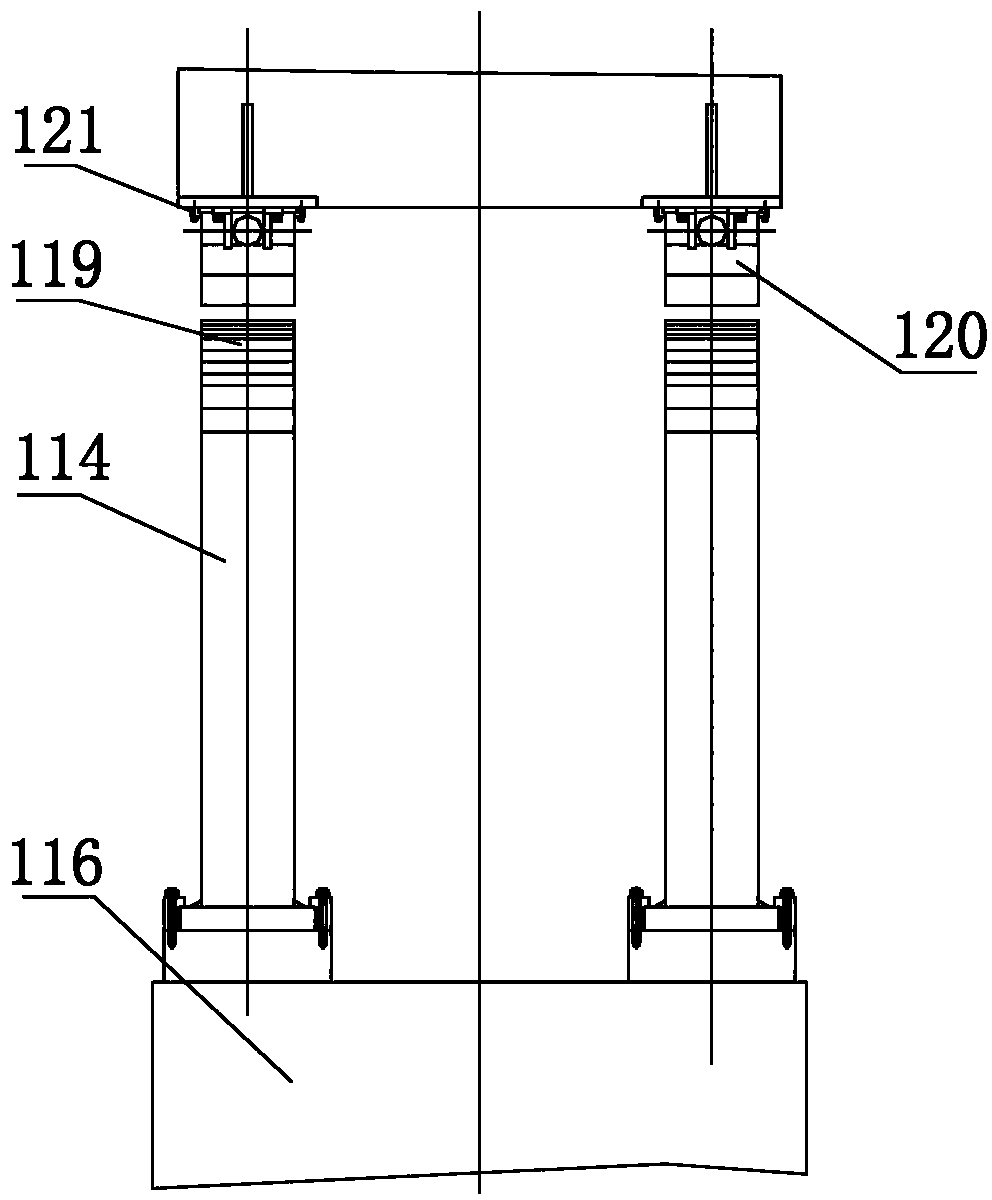

[0042] see Figure 1-Figure 11 , a large-scale explosive column automatic pressing production line, including the fixed connection between the upper beam 103 and the middle beam 112 through the upper pillar 106, the connection between the lower beam 118 and the middle beam through the lower pillar 115, and through the lock nut 102 and the tie rod 101 The press fuselage is fixed; the upper return cylinder 104 is installed on the lower part of the upper beam, the lower part of the upper return cylinder is connected with the upper belt cylinder slider 105, and the lower part of the upper belt cylinder slider is provided with an upper punch 108. A mold cover 111 is installed on the middle beam; it also includes an automatic weighing and feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com