Raised drilling machine large drill removing method, inverted basket and drill removing structure

A technology for drilling rigs and drilling rig power heads, which is applied to drilling equipment, drill pipes, drill pipes, etc. It can solve the problems of drill pipe disconnection, etc., and achieve the effect of improving safety factor and considerable safety benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

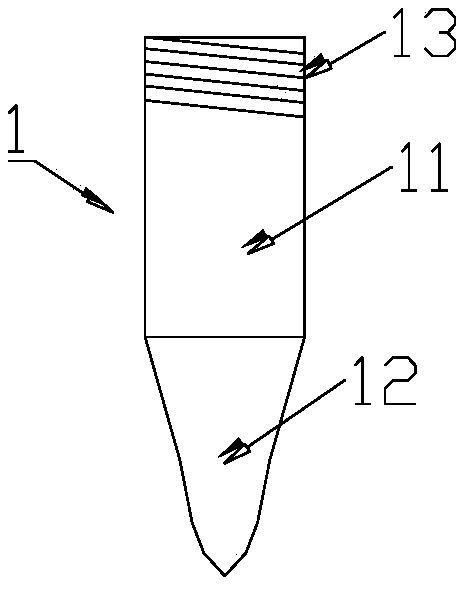

[0026] Such as figure 1 As shown, an inverted basket 1, the inverted basket 1 includes a basket body 11, the basket body 11 is a steel column, the bottom of the basket body 11 is welded and fixed with an inverted basket ring 12, and the upper end is provided with an external thread connected with a drill pipe 13. The inverted basket ring 12 is formed by bending steel bars and welding the basket body 11.

Embodiment 2

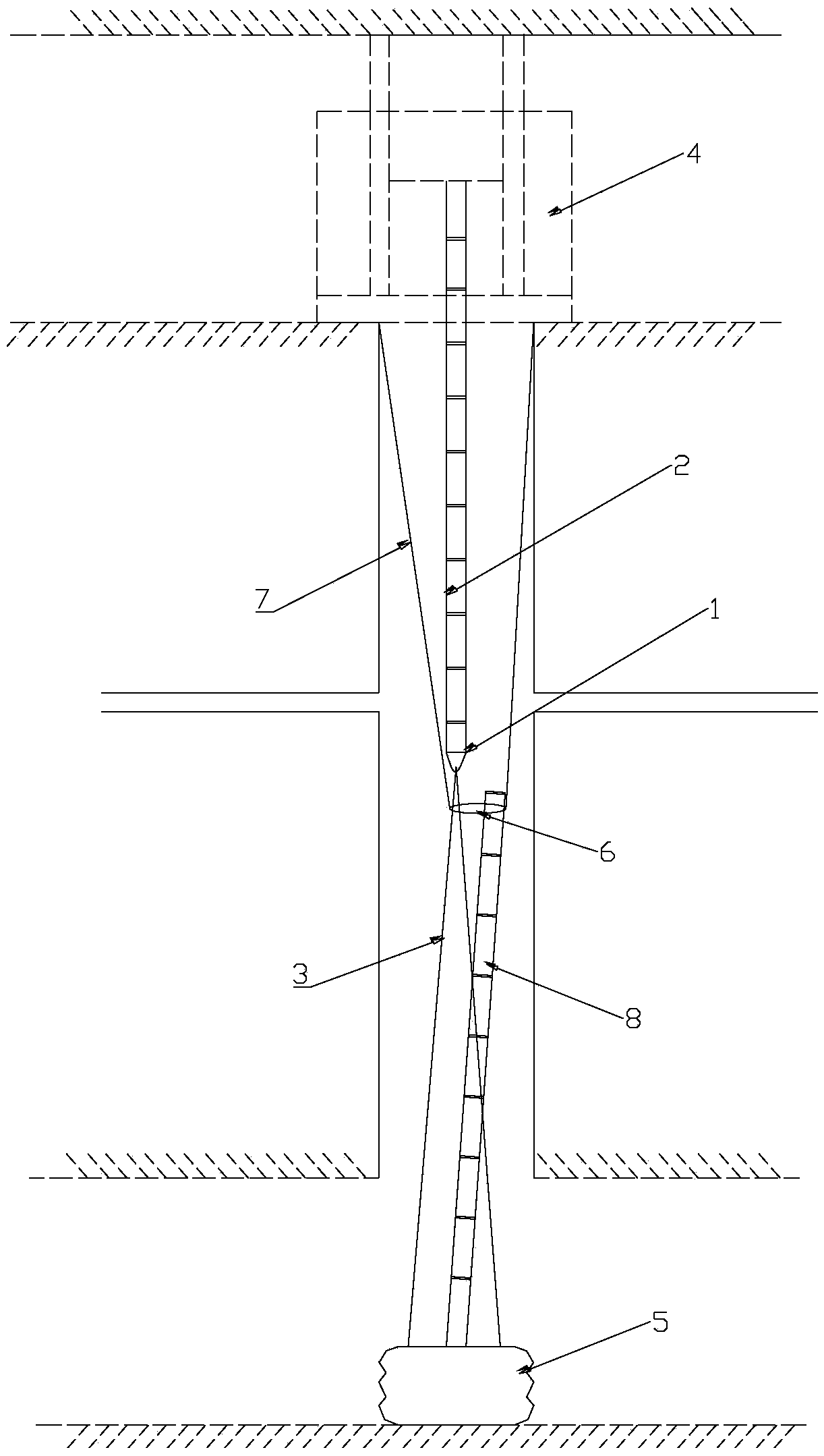

[0028] Such as figure 2 As shown, the anti-drilling machine large drill bit drop drilling method is characterized in that: comprising the following steps:

[0029] Step 1. First remove 19 of the 20 drill pipes 2 connected to the drilling rig 4, leaving only one drill pipe 2 to install the inverted basket 1;

[0030] Step 2. Thread a 90m-long φ18.5mm steel wire rope 3 inside the inverted basket ring 12 so that the two sides of the steel wire rope 3 are equal in length; fix the steel wire rope 3 with an ingot card at the bottom of the inverted basket ring 12;

[0031] Step 3. The drill rig 4 is connected to the 19 drill pipes 2 that were previously removed, and the basket 1 is turned upside down to the position where the drill pipes 2 are disconnected. The steel wire rope 3 stuck on the basket 1 is slowly dropped to the lower opening of the small eye;

[0032] Step 4. Go down to the lower opening of the small eye and use the ingot card to lock the big drill bit 5 with the ends...

Embodiment 3

[0039] A drill drop structure of a large drill bit 5 of an anti-drilling rig, comprising an inverted basket 1, a steel wire rope 3, and a limit ring 6; the inverted basket 1 is fixed on the drill pipe 2, and is gradually lowered to the lower opening of the small hole through the drilling machine 4; the inverted basket 1 includes an inverted basket ring 12, a steel wire rope 3 is worn inside the ring, and the two rope ends of the steel wire rope 3 are respectively fixed with the big drill bit 5; the big drill bit 5 is fixed with an indwelling drill pipe 8; the limit ring 6 is set on the two steel wire ropes 3 and Stay on the drilling rod 8, and carry it to the upper end of the drilling rod 8 by the traction rope, so that the upper end of the drilling rod 8 is in the middle position of the lower opening of the ommatidium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com