Oil spray nozzle

A technology of fuel injectors and fuel injection holes, which is applied in the field of anti-carbon deposition nozzles, which can solve problems such as carbon deposits in fuel injectors, coking of fuel injection holes, and affecting spray effects, so as to reduce residues and reduce carbon deposits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

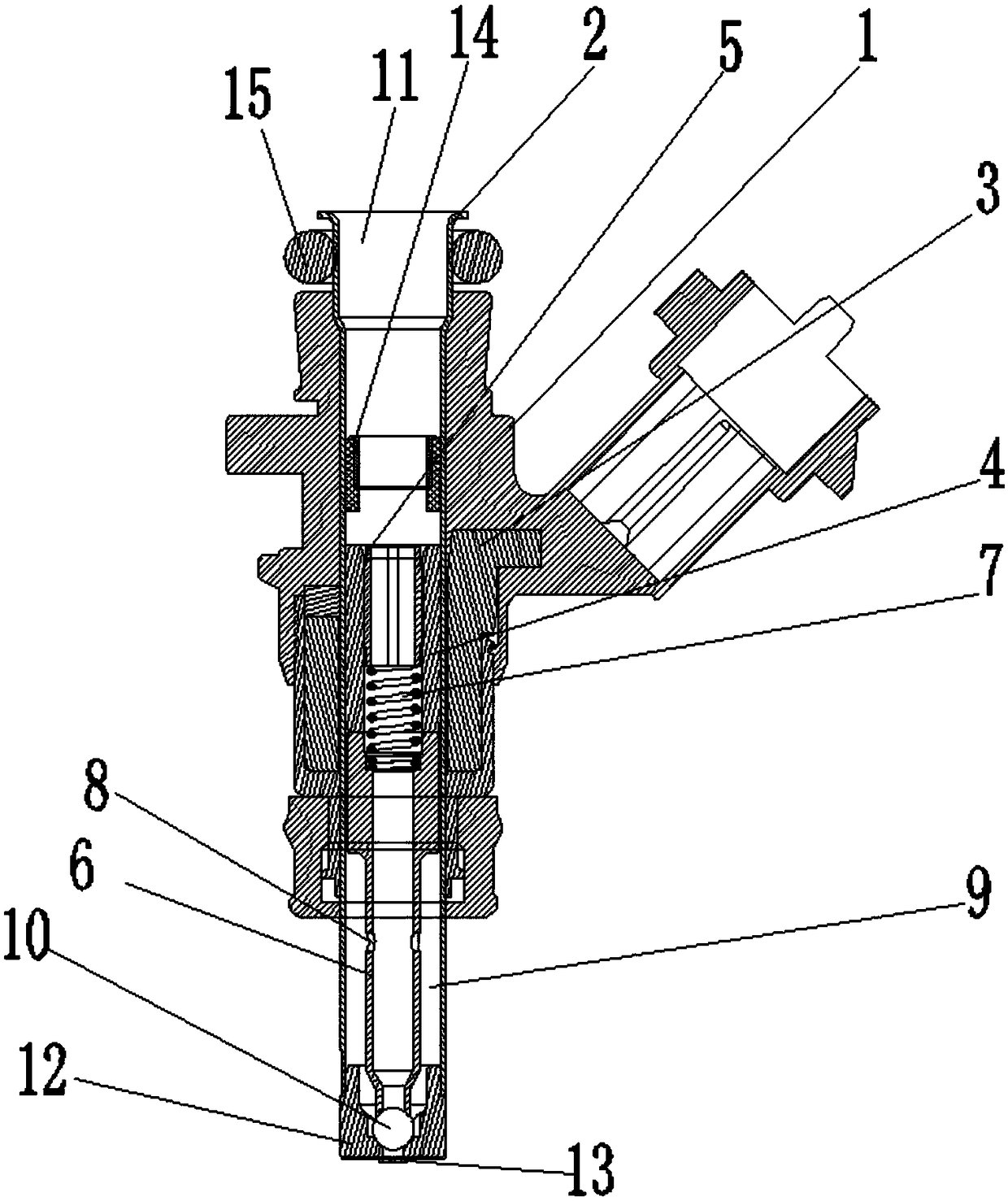

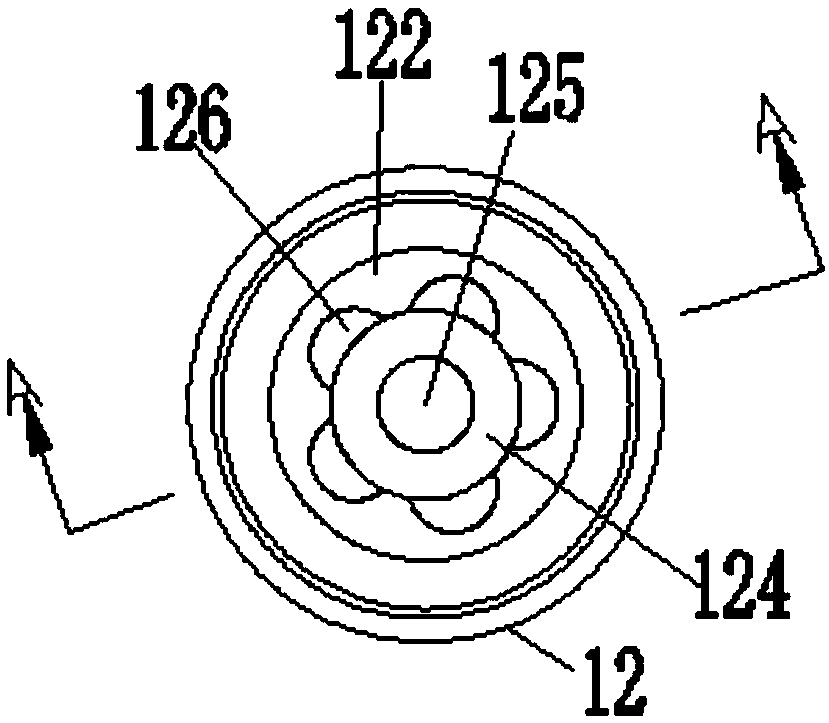

[0041] Such as Figure 1-12 As shown, this embodiment discloses a fuel injector, which can be a fuel injector, a gas injector or a urea injector. The fuel injection nozzle includes a housing 1. The housing 1 may be the housing of the fuel injection nozzle mentioned above in the prior art, and is usually composed of several matching structures; the housing 1 is provided with The valve body 2 can be the valve body structure of the above-mentioned fuel injection nozzle in the prior art; a coil assembly 3 is arranged between the housing 1 and the valve body 2, the coil assembly 3 It can be a combination of existing structures, such as a coil former arranged between the housing 1 and the valve body 2, a coil surrounding the coil former, a positive and negative electrode structure connecting the two poles of the coil, etc.; In order to set the structure for controlling the movement of the valve core 6 in the valve body 2 in a position that matches the coil assembly 3, an adjusting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com