AMT intermediate shaft braking structure

An intermediate shaft and brake disc technology, applied in the direction of brake actuators, axial brakes, brake types, etc., can solve problems such as large size, harsh working environment, faults, etc., to achieve small influence of external factors and rich technical reserves , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

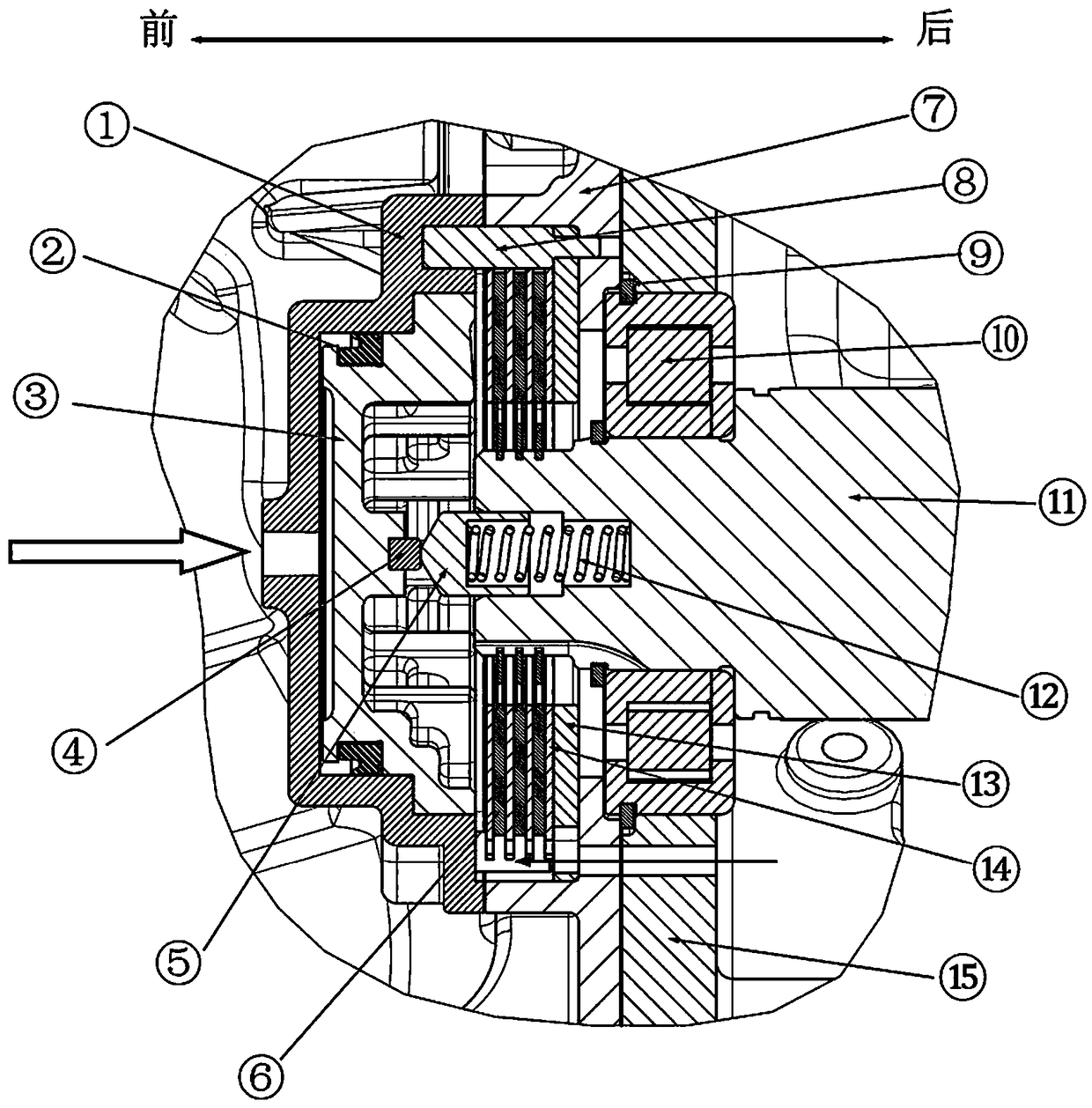

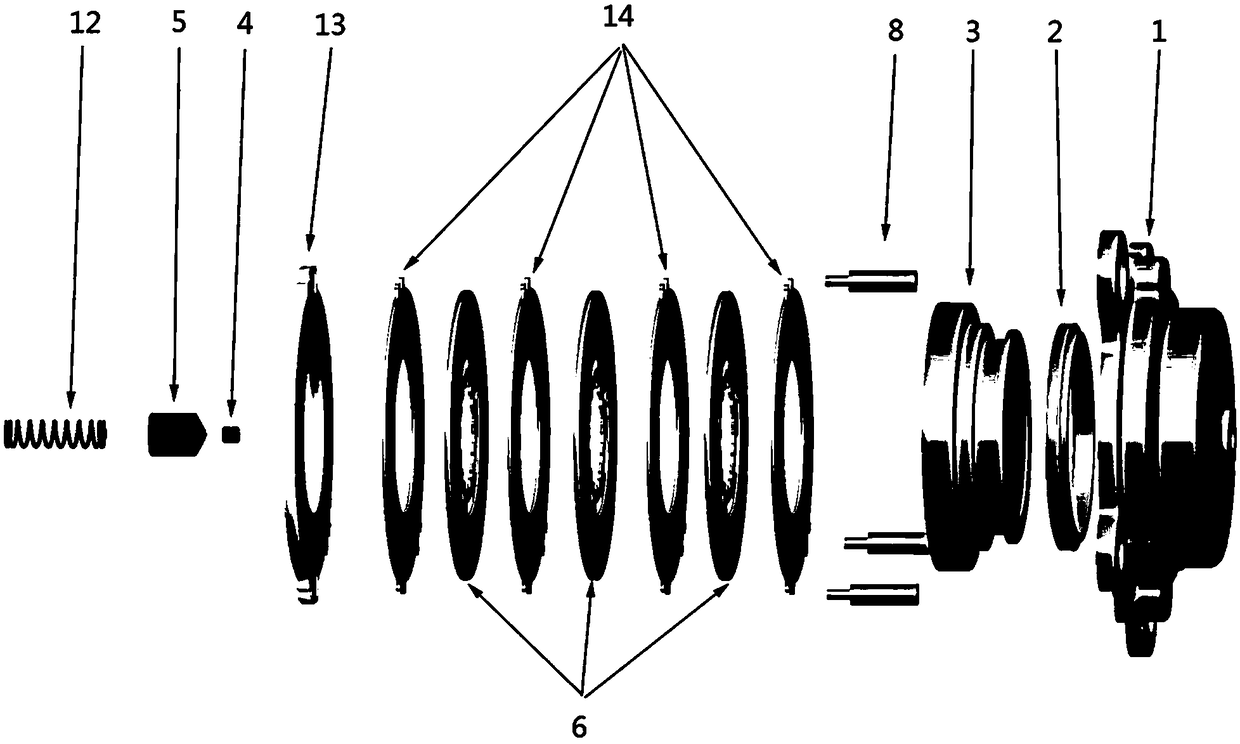

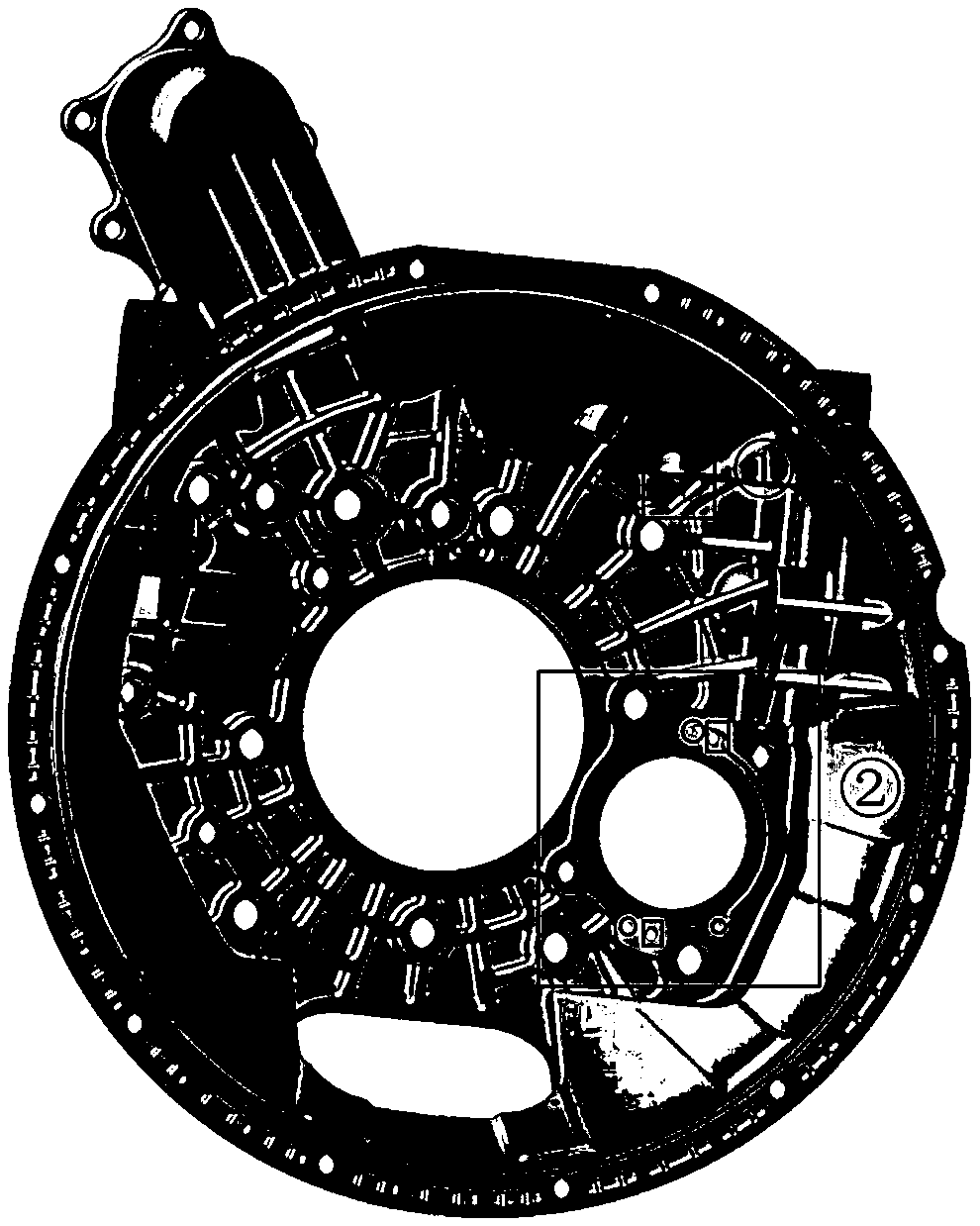

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] see Figure 1-2 The AMT intermediate shaft brake structure of the present invention includes an intermediate shaft 11 extending from the transmission housing 15 to the front end cover 1 of the clutch housing. A plurality of friction discs 6 rotating with the shaft are arranged at intervals on the outer circumference of the extension part of the intermediate shaft 11. The intermediate shaft The extension part of 11 is connected with the friction disc 6 through involute splines matched inside and outside. A brake disc 14 that does not rotate with the shaft is arranged between the friction discs 6, a piston 3 is arranged inside the front end cover 1 of the clutch housing, and a brake air inlet is opened on the front end cover 1 of the clutch housing, and the piston 3 and the front end of the clutch housing The inner walls of the cover 1 are sealed by a K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com