Overhauling device capable of treating lithium bromide solution in lithium bromide absorbing unit on site

A technology for on-site processing and medium lithium bromide, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as large economic losses, excluding time for purchasing solutions and transportation, and inability to conduct on-site processing, so as to save maintenance costs , significant economic benefits, and the effect of improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

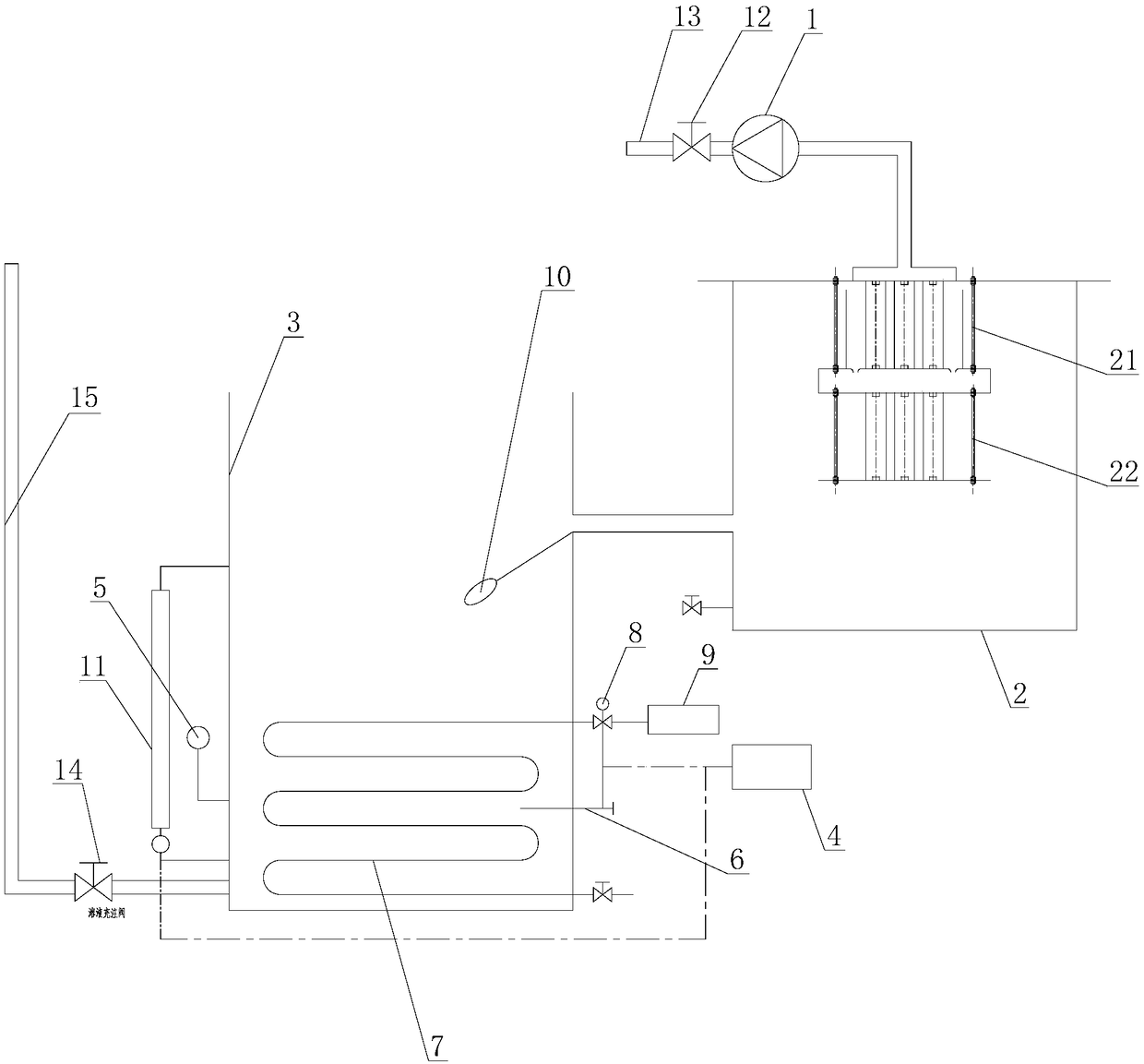

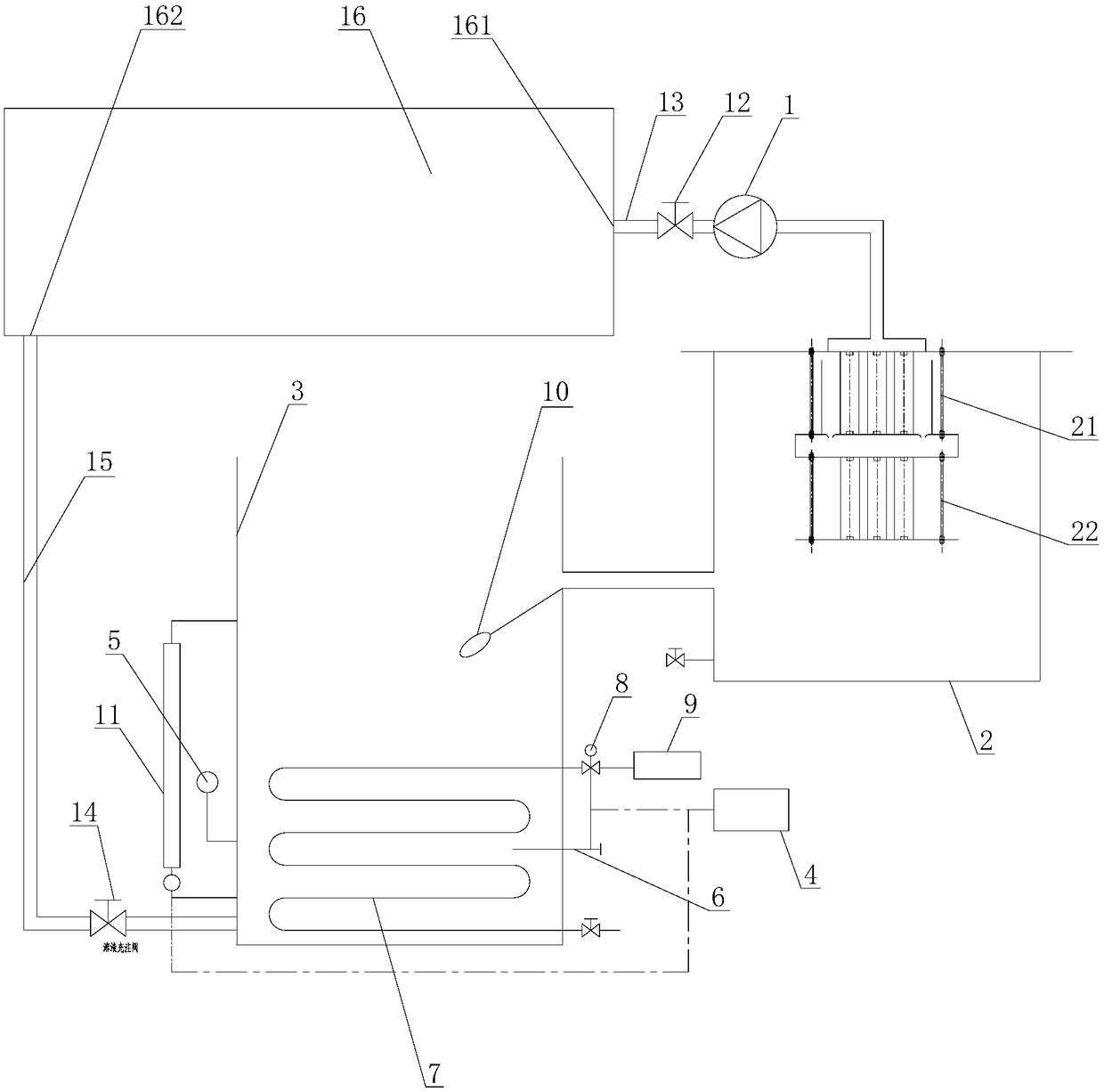

[0014] Such as figure 1 , figure 2 As shown, the described overhaul device that can handle the lithium bromide solution in the lithium bromide absorption unit on the spot includes a self-priming pump 1, a filter 2, a reaction kettle 3 and a thermostat 4, and the outlet of the self-priming pump 1 is connected to the filter The inlet of 2 is connected, the outlet of filter 2 is connected with the inlet of reactor 3, and the solution concentration meter 5 for real-time detection and displaying the concentration of solution in reactor 3 is arranged outside reactor 3, and is set in reactor 3 A solution thermometer 6 and a steam heat exchanger 7 are arranged, and the solution thermometer 5 is used to collect the temperature of the solution in the reactor 3 in real time and send the collected solution temperature signal to the thermostat 4 in real t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com