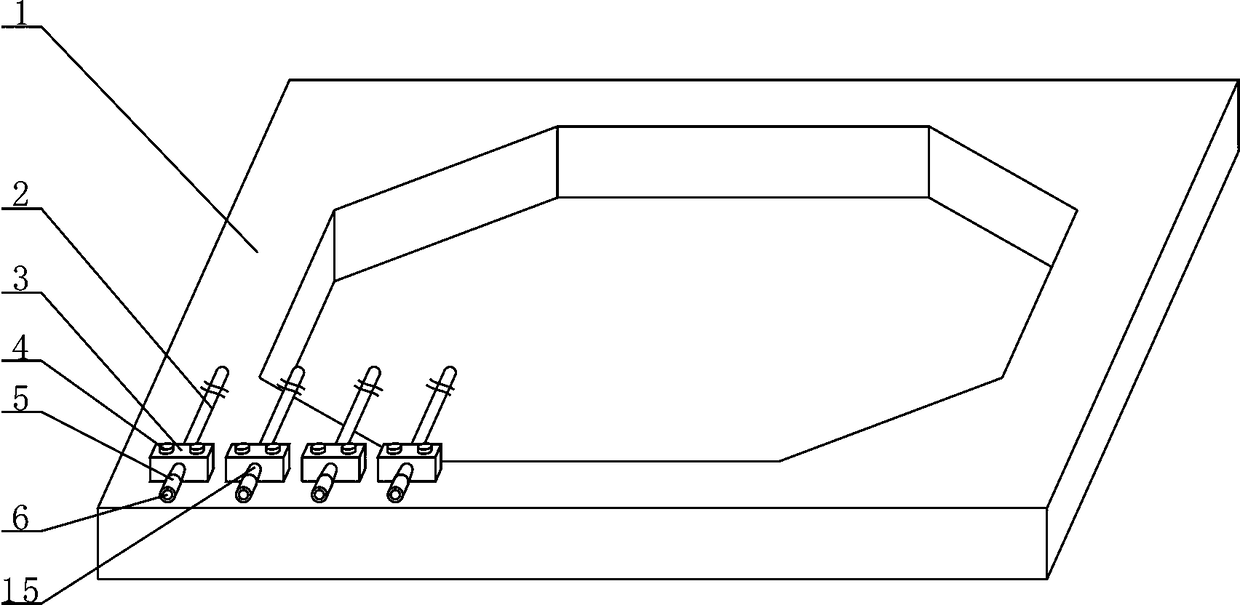

Intermediate frequency furnace plug dust preventing device

A technology of dust-proof devices and intermediate frequency furnaces, which is applied in the direction of coupling devices, parts of connecting devices, furnaces, etc., can solve the problems of unfavorable production safety of intermediate frequency furnaces, very high dust-proof requirements, and no dust-proof devices, etc., to achieve improvement Production safety guarantee and production efficiency, strong practicability, and high-efficiency dust-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

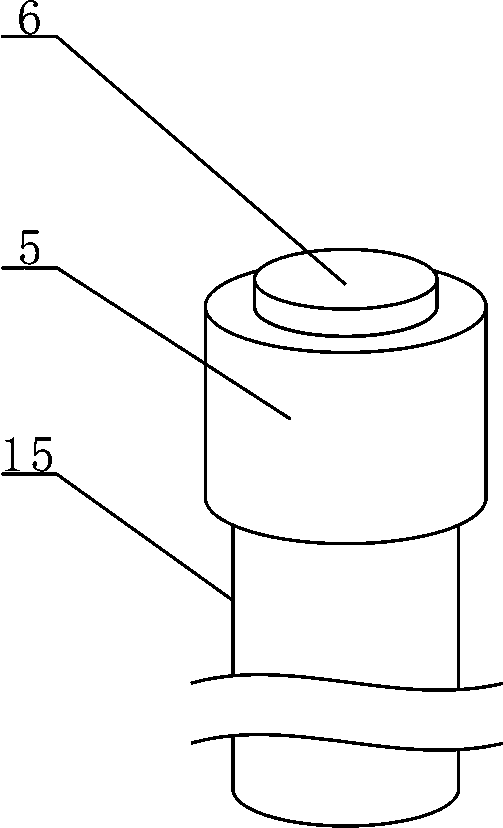

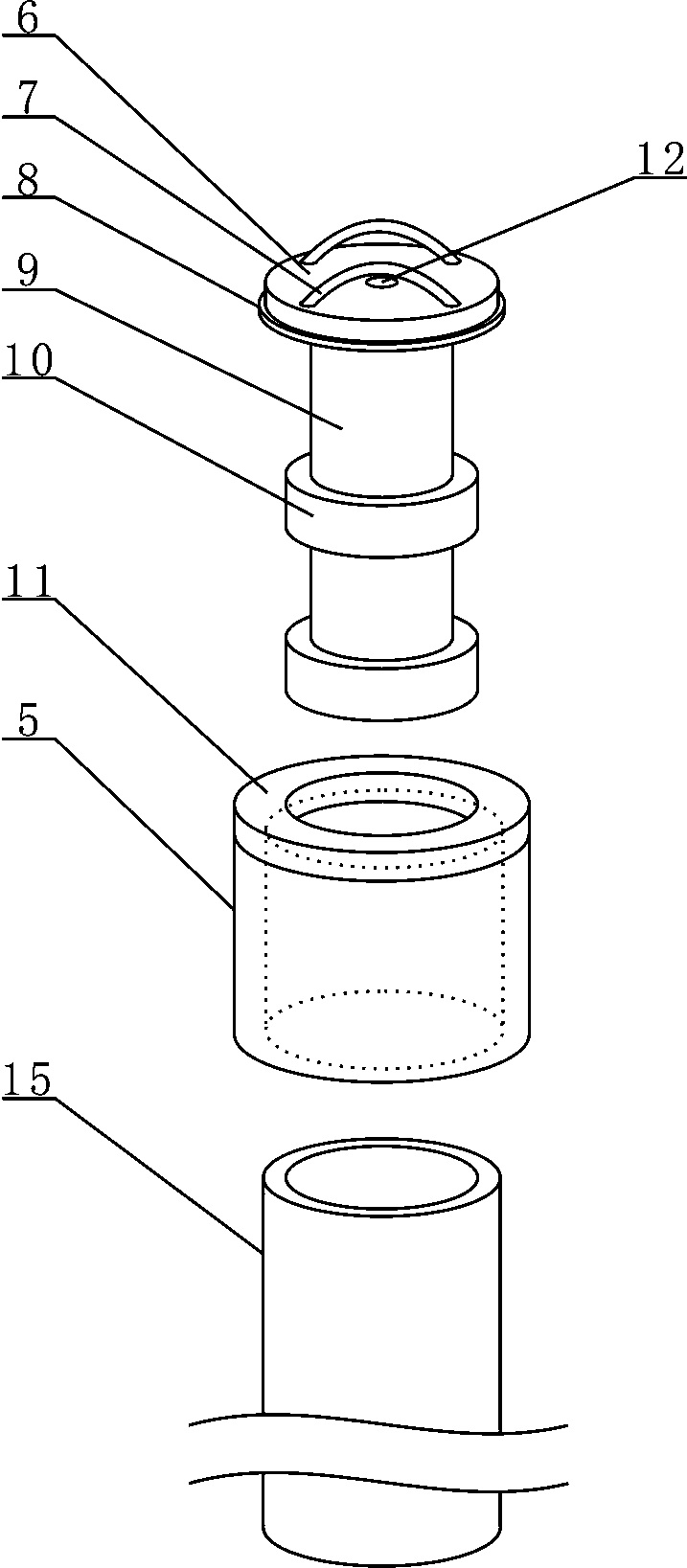

[0033]Embodiment 1, the dust-proof device for a plug of an intermediate frequency furnace, when in use, set the fixing block 11 on the casing 5, and then set the handle 7 and the liquid injection hole 12 on one end surface of the cover plate 6 , and then set the plug on the liquid injection hole 12, and set the sealing ring 8 on the outer surface of the cover plate 6. The sealing ring 8 is made of materials with sealing properties such as silicone rubber and polyurethane, and then a part of the connecting rod 9 The liquid inlet 14 is set on the end face, and at least two dust removal blocks 10 are arranged equally on the outer surface of the connecting rod 9, and the liquid outlet hole 13 is arranged on the outer surface of the dust removal block 10, and then the connecting rod 9 is placed on the One end face provided with a liquid inlet 14 is fixedly connected with the cover plate 6, and the liquid injection hole 12 on the cover plate 6 is correspondingly connected with the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com