Center torsion bar type object mass center and rotational inertia measuring mechanism based on the knife edge support

A technology of knife-edge support and moment of inertia, applied in measuring devices, testing of machines/structural components, testing of static/dynamic balance, etc., can solve problems such as difficult operation at the center end of the rotating shaft, low efficiency, and low precision of the swing unit. Achieve the effect of saving time and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with embodiment (accompanying drawing):

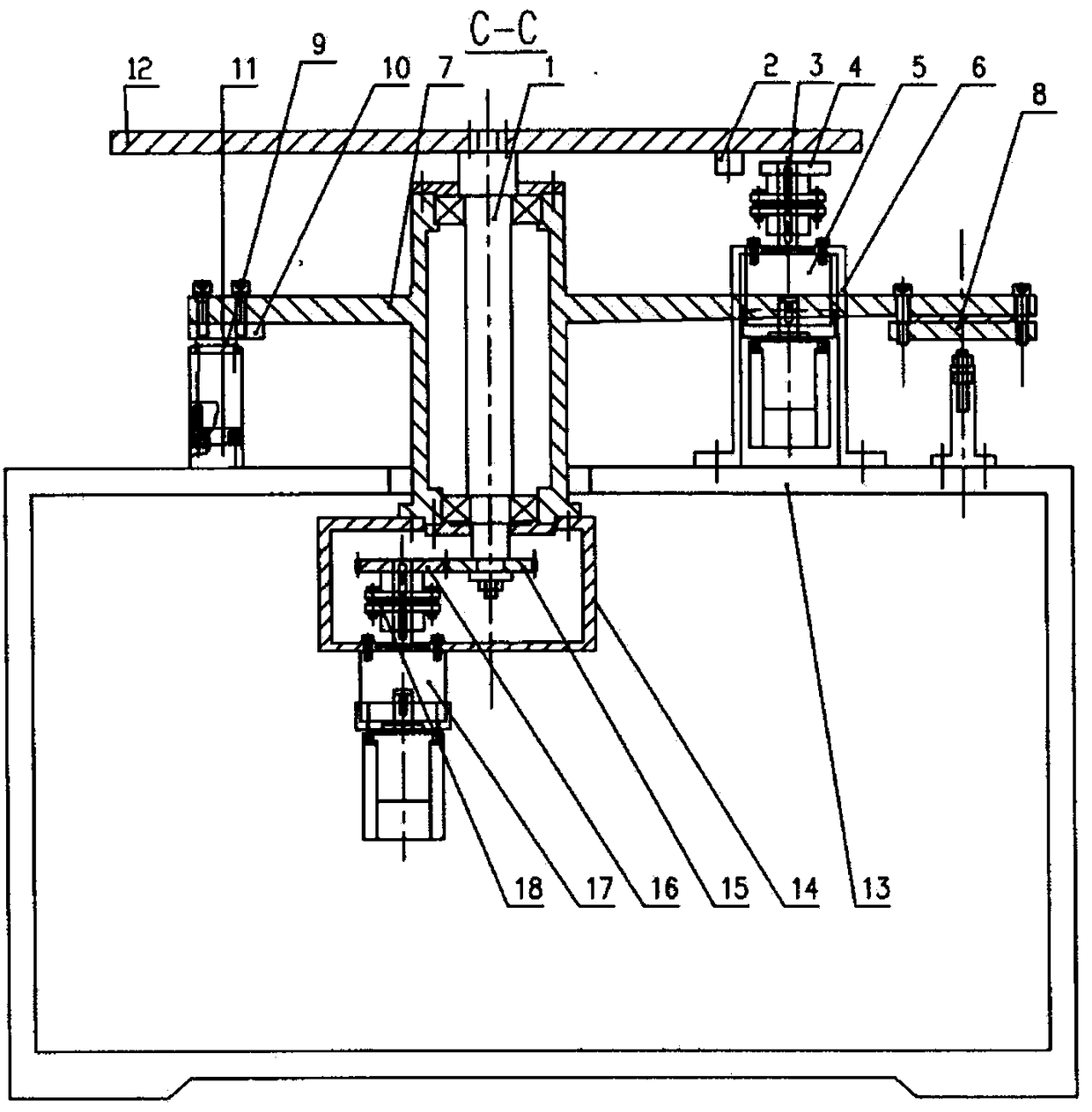

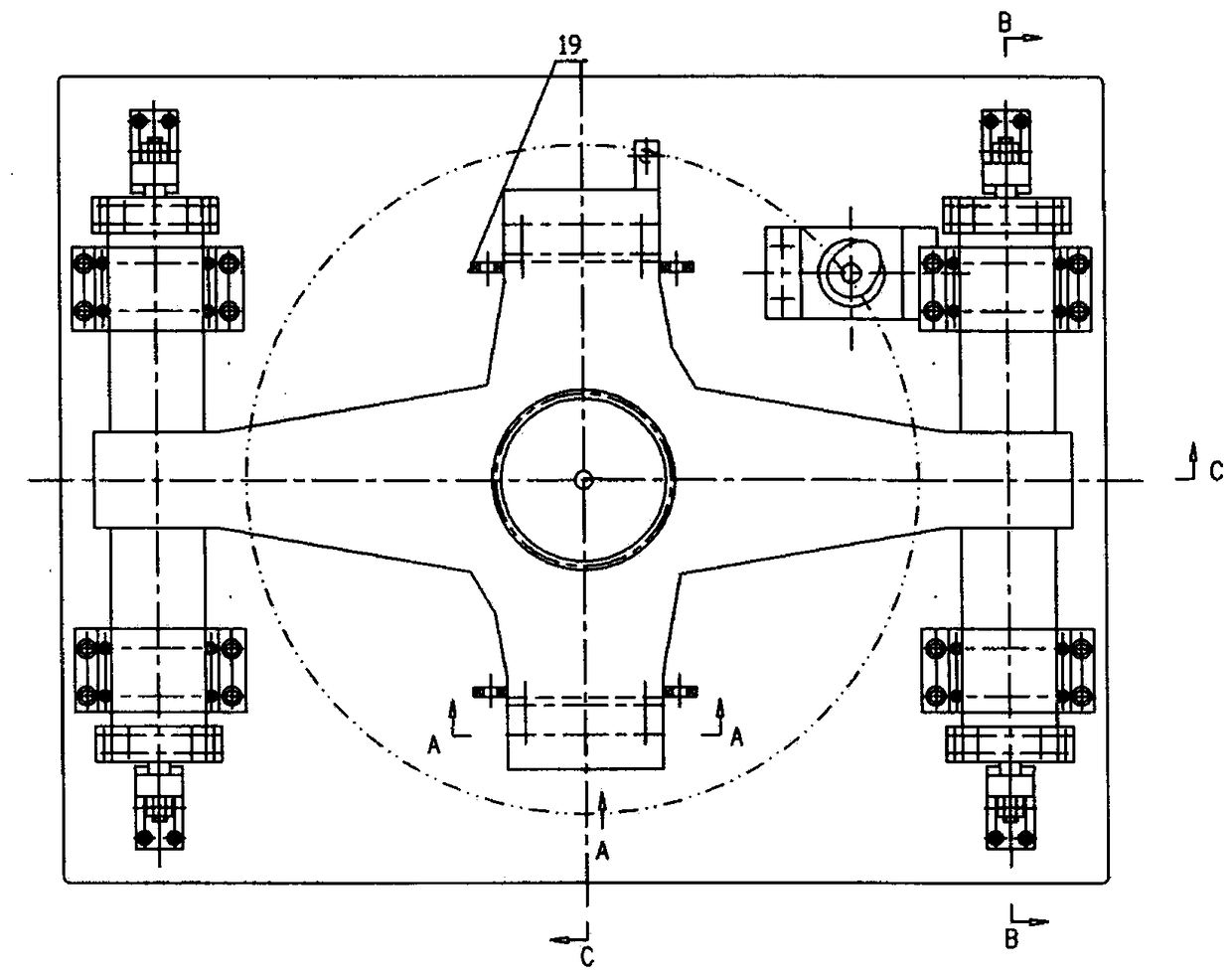

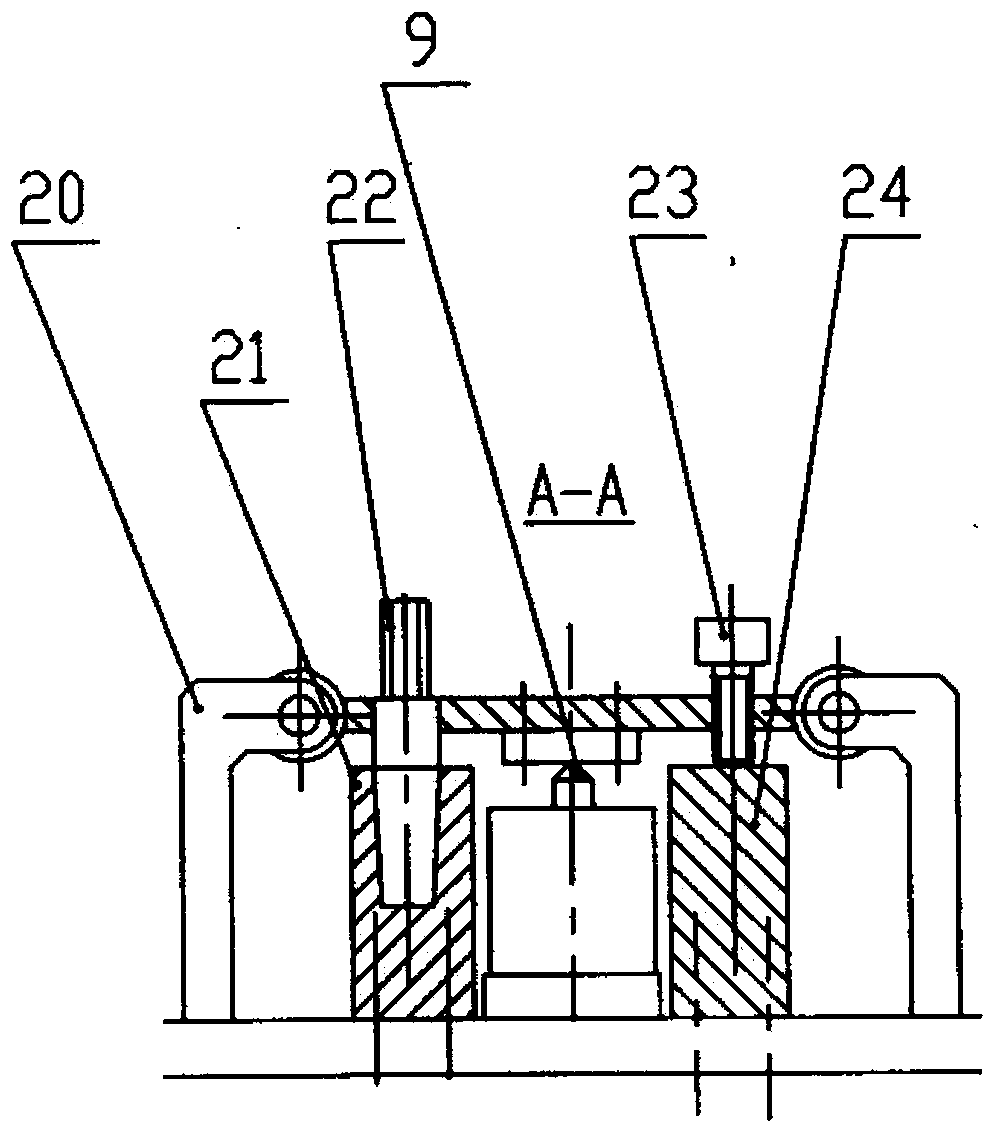

[0032] like figure 1 , 2As shown, the central torsion bar-type object center of mass and moment of inertia measurement mechanism based on the knife-edge support of the present invention includes a rotating shafting 1 that is vertically installed on the test bench through a shafting base 7 and has the function of a torsion bar. The rotating tray 12 on the top of the rotating shaft system; the front and rear lower blades 9 used to support the entire rotating system are coaxially arranged under the front and rear wings of the shafting frame 7, and are fixed on the test bench 13 through the connecting block 11 On the bottom surface of the front and rear wing plates of the shafting base 7 is fixedly connected with an upper plate 10 matched with the cutting edge of the lower knife edge, and the upper plate 10 is placed on the lower knife edge 9; on the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com