High-power pulse field strength calibration system and high-power pulse field strength calibration method

A technology for calibrating systems and pulse fields, applied in measuring devices, instruments, measuring electrical variables, etc., can solve problems such as inability to measure and calibrate high-power pulse field strength, and achieve the effect of meeting the needs of measurement guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

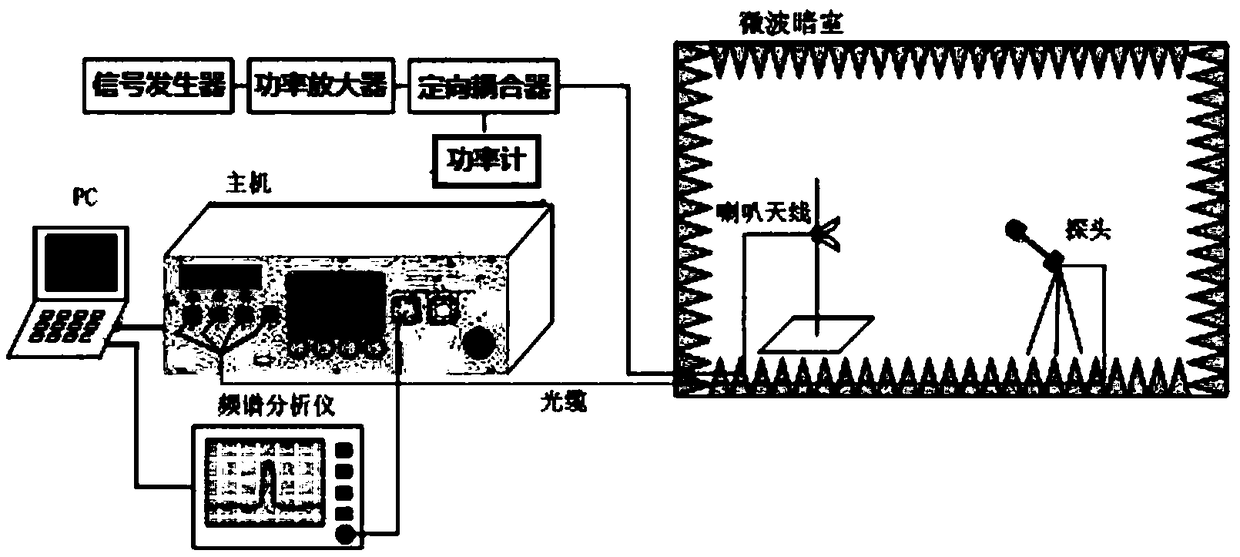

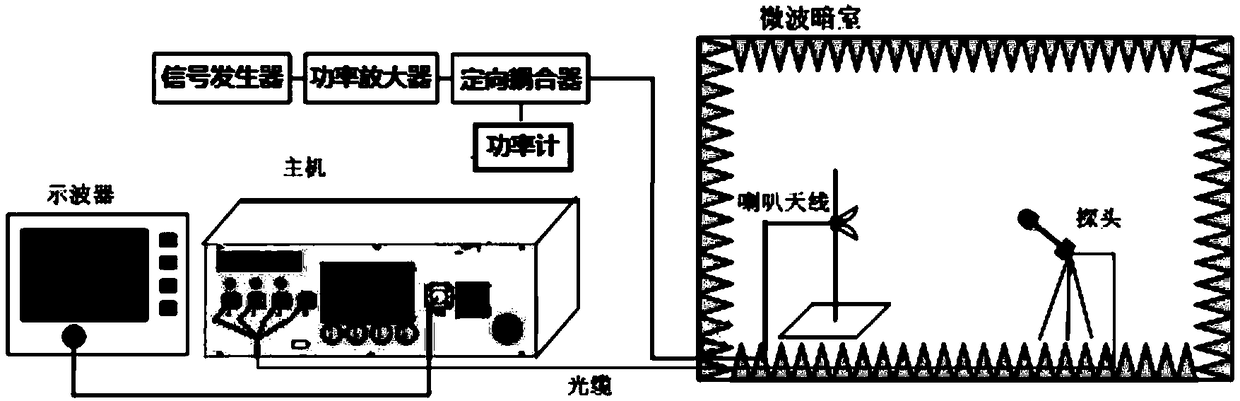

[0029] The proposal discloses a high-power pulse field strength calibration system, and the maximum amplitude that the system can calibrate can reach 3000V / m. The system includes: a horn antenna and an integrated optical electric field sensor arranged in a microwave anechoic chamber; the mouth surface of the horn antenna needs to face the integrated optical electric field sensor. The horn antenna emits a pulse field with a fixed duty ratio in the microwave anechoic chamber, and the integrated optical electric field sensor generates an induced voltage by sensing the pulse field strength. The system also includes an analysis module, which is placed outside the microwave anechoic chamber, and obtains calibration data of the pulse field strength based on the parameters of the pulse signal source and the induced voltage.

[0030] In this embodiment, the system may further include: a pulse signal source for generating a pulse field with a fixed duty ratio. The pulse signal source c...

Embodiment 2

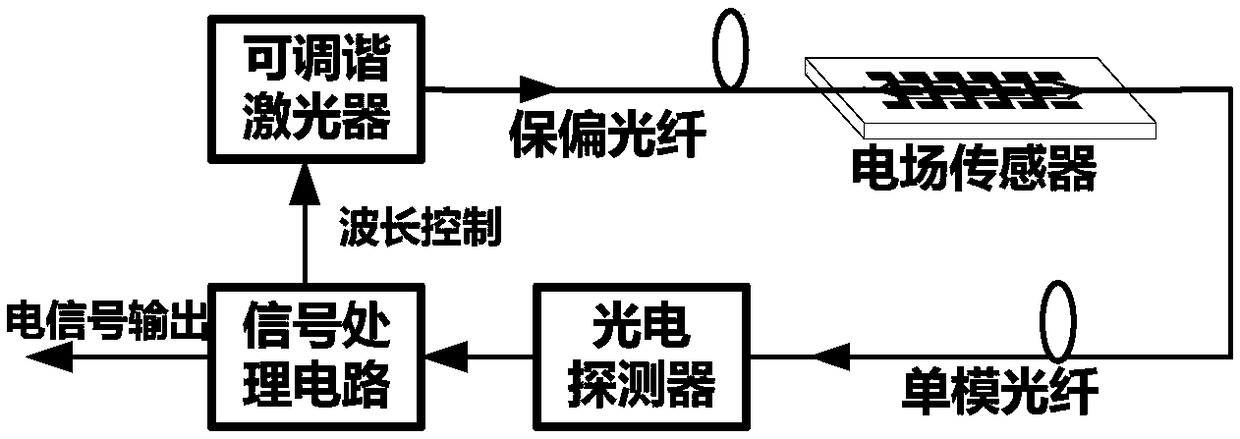

[0040] This embodiment discloses a high-power pulse field strength calibration method with a maximum amplitude of 3000V / m in the S-band (2GHz-4GHz), using an integrated optical electric field sensor (100MHz-18GHz) to calibrate the high-power pulse field strength. Among them, the integrated optical electric field sensor utilizes the electro-optic effect of the LiNbO3 crystal under the action of an external electric field to realize the measurement of the electromagnetic field. Because this kind of field sensor modulates the electrical signal onto the optical path, it is less disturbed by redundant interference objects and can be used for field strength measurement of up to tens of thousands of volts per meter. Such as image 3 As shown, the integrated optical electric field sensor includes a tunable laser, an optical fiber, an electric field sensor, a photodetector, and a signal processing circuit; the tunable laser is connected to the electric field sensor through a polarizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com