High-density integrated circuit packages for improved solder strength and reflow methods thereof

An integrated circuit, welding strength technology, applied in the direction of circuits, electrical components, electrical solid devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

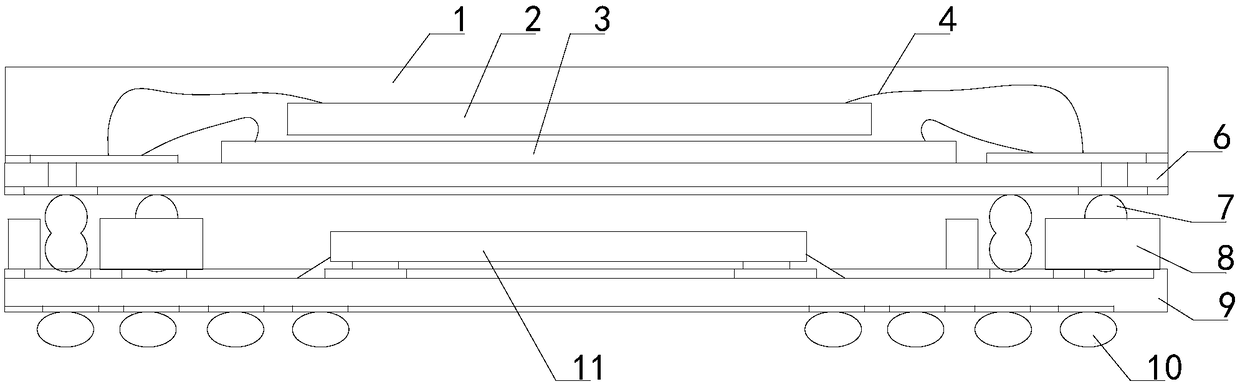

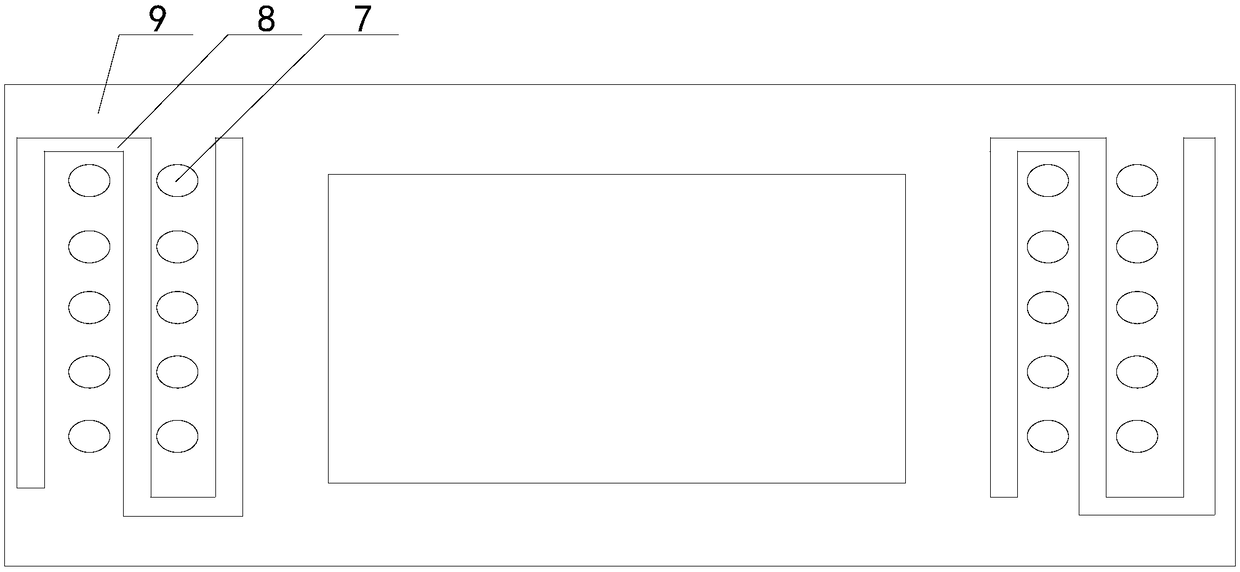

[0043] Such as figure 1 and figure 2 As shown, the high-density integrated circuit package for improving soldering strength includes a second base 6, a second solder ball 7, an S tube 81, a first base 9, and a first chip 11, and the second base 6 is stacked on the first On the upper side of the base 9, the second solder ball 7 is arranged between the second base 6 and the first base 9 so that there is no contact between the second base 6 and the first base 9; the first chip 11 is arranged between the second base 6 and the first base 9 Between the first substrate 9 and flip-chip on the upper surface of the first substrate 9; there are multiple second solder balls 7, which are evenly distributed between the first substrate 9 and the second substrate 6 and form a solder ball array; S tube 81 Including not less than three long tubes and not less than two short tubes, the long tubes and short tubes are connected at intervals to form an S shape, in which the long tubes are paralle...

Embodiment 2

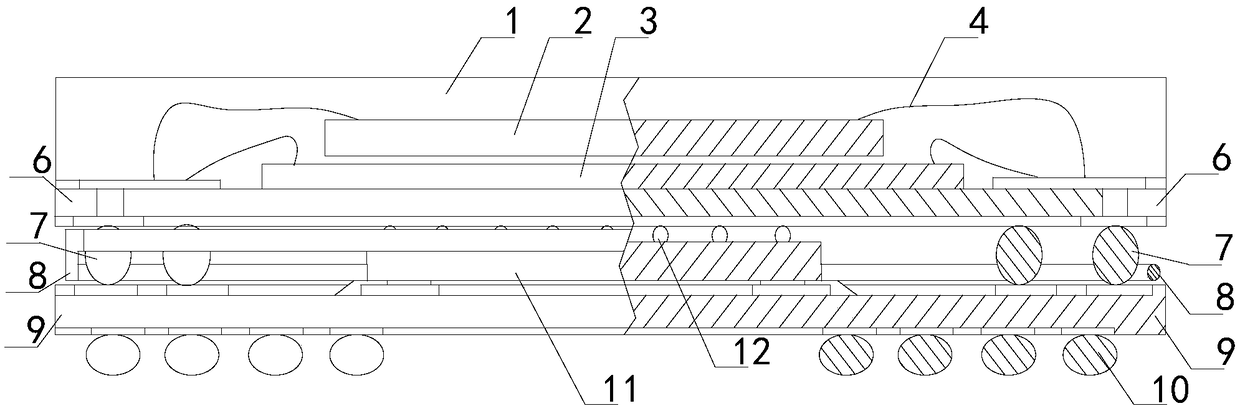

[0055] like Figure 3 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that an internal return pipe 12 is provided on the upper side of the first chip 11, and a communication pipe is provided on the upper side of the first substrate 9, and the communication pipe and the S pipe 81 are connected end to end to form The closed outer return pipe 8 ; the contact between the inner return pipe 12 and the outer return pipe 8 enables heat transfer between the inner return pipe 12 and the outer return pipe 8 . The second chip 3 and the third chip 2 are arranged on the upper surface of the second base 6, and the second chip 3 and the third chip 2 are stacked in a naked way, and are bonded through the wire 4; in order to fix the second chip 3 and the third chip 2 are fixed together by potting glue 1 . In this embodiment, the height of the first solder ball 10 is about 0.23 mm, the thickness of the first base 9 is about 0.3 mm, the thickness of the second ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com