A power device and a preparation method thereof

A technology of power devices and epitaxial layers, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems that affect the performance of VDMOS devices, improve the on-resistance, and is not conducive to reducing the power loss of devices, so as to improve the impact resistance. The effect of breakdown voltage capability, reduction of on-resistance, and improvement of breakdown voltage capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

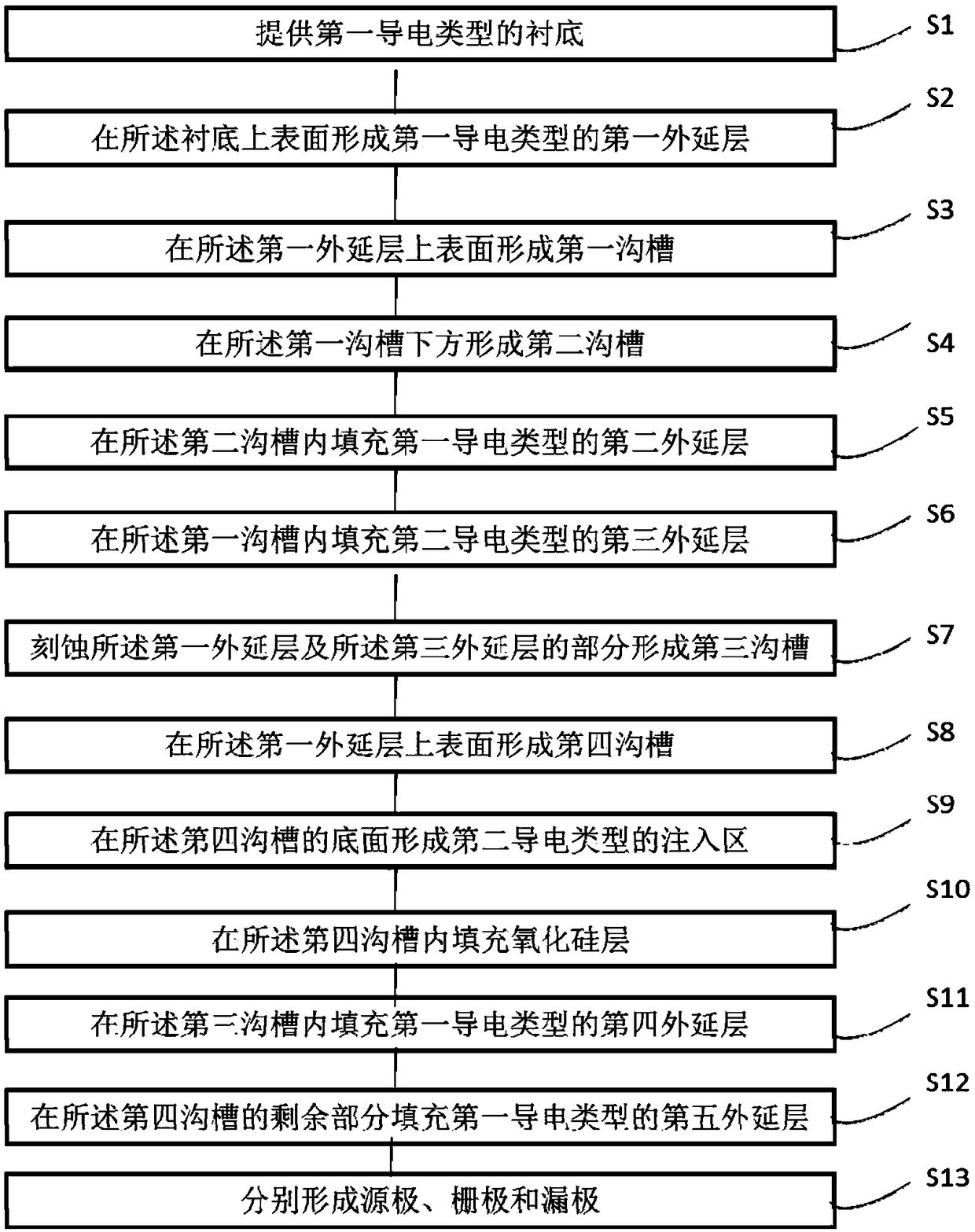

[0063] An embodiment of the present invention provides a method for preparing a power device, such as figure 1 A schematic flow chart of a method for preparing a power device provided by an embodiment shown, the method for preparing a power device includes:

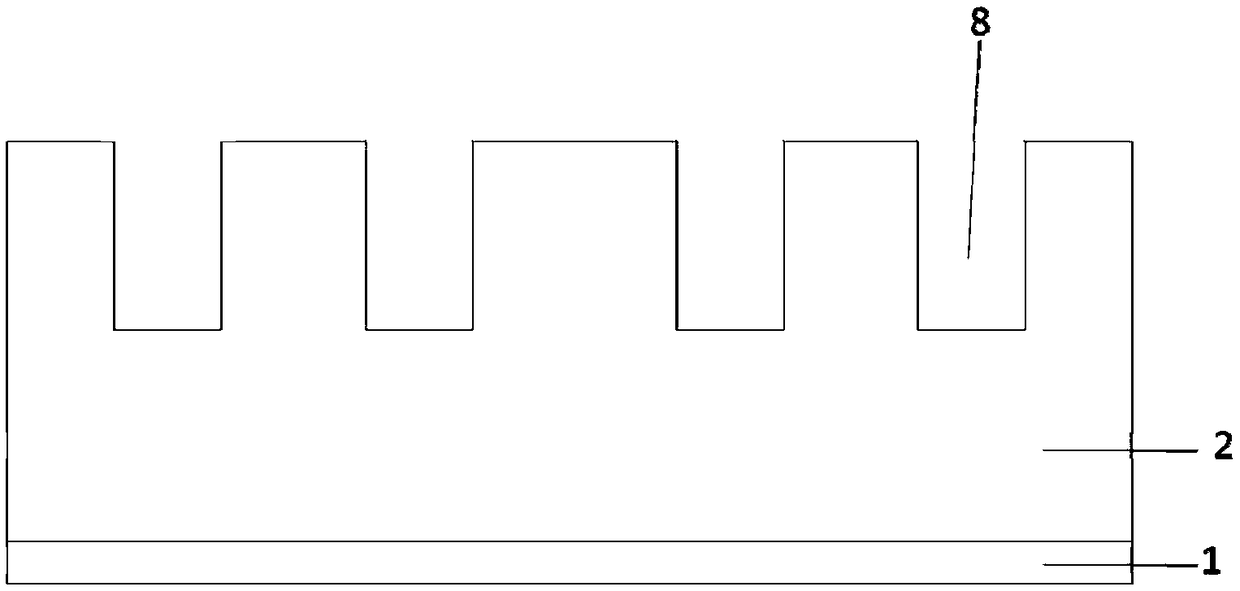

[0064] Step S1: providing a substrate 1 of the first conductivity type;

[0065] Step S2: forming a first epitaxial layer 2 of the first conductivity type on the upper surface of the substrate 1;

[0066] Step S3: forming first trenches 8 on the upper surface of the first epitaxial layer 2, the number of the first trenches 8 is at least two, and the number of the first trenches 8 is an even number;

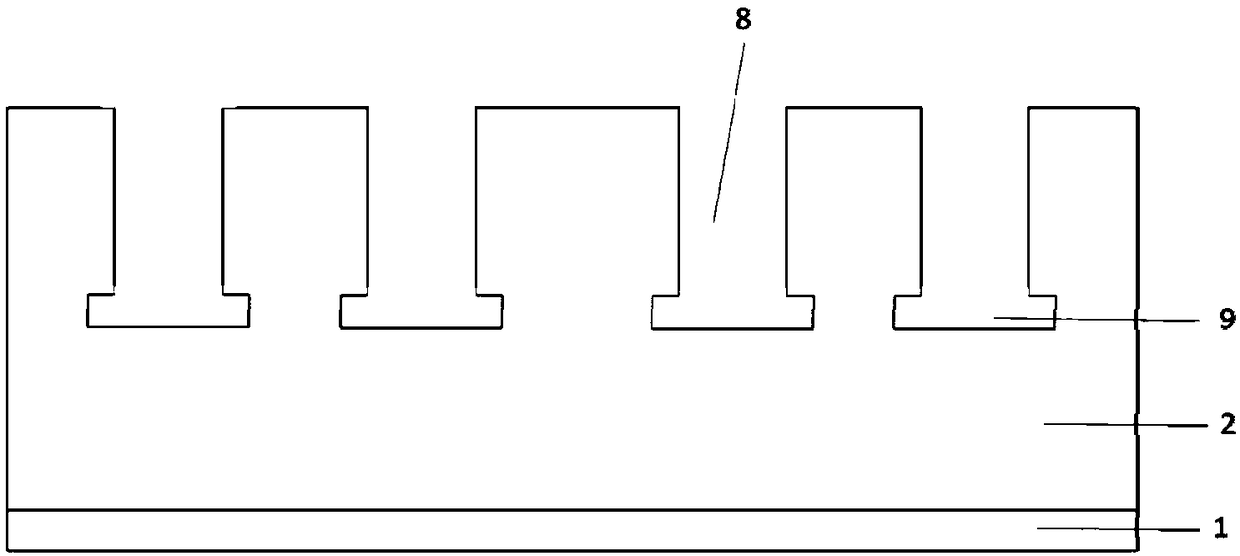

[0067] Step S4: forming a second groove 9 under the first groove 8, the second groove 9 is connected to the first groove 8, and the width of the second groove 9 is larger than that of the first groove 9. the width of the trench 8;

[0068] Step S5: filling the second trench 9 with a second epitaxial layer 3 of the first co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap