Thin film transistor, array substrate, and display device

A technology of thin-film transistors and drain electrodes, which is applied in the direction of transistors, semiconductor devices, electrical components, etc., can solve the problems of poor display effect, achieve the effects of reducing parasitic capacitance, reducing the facing area, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

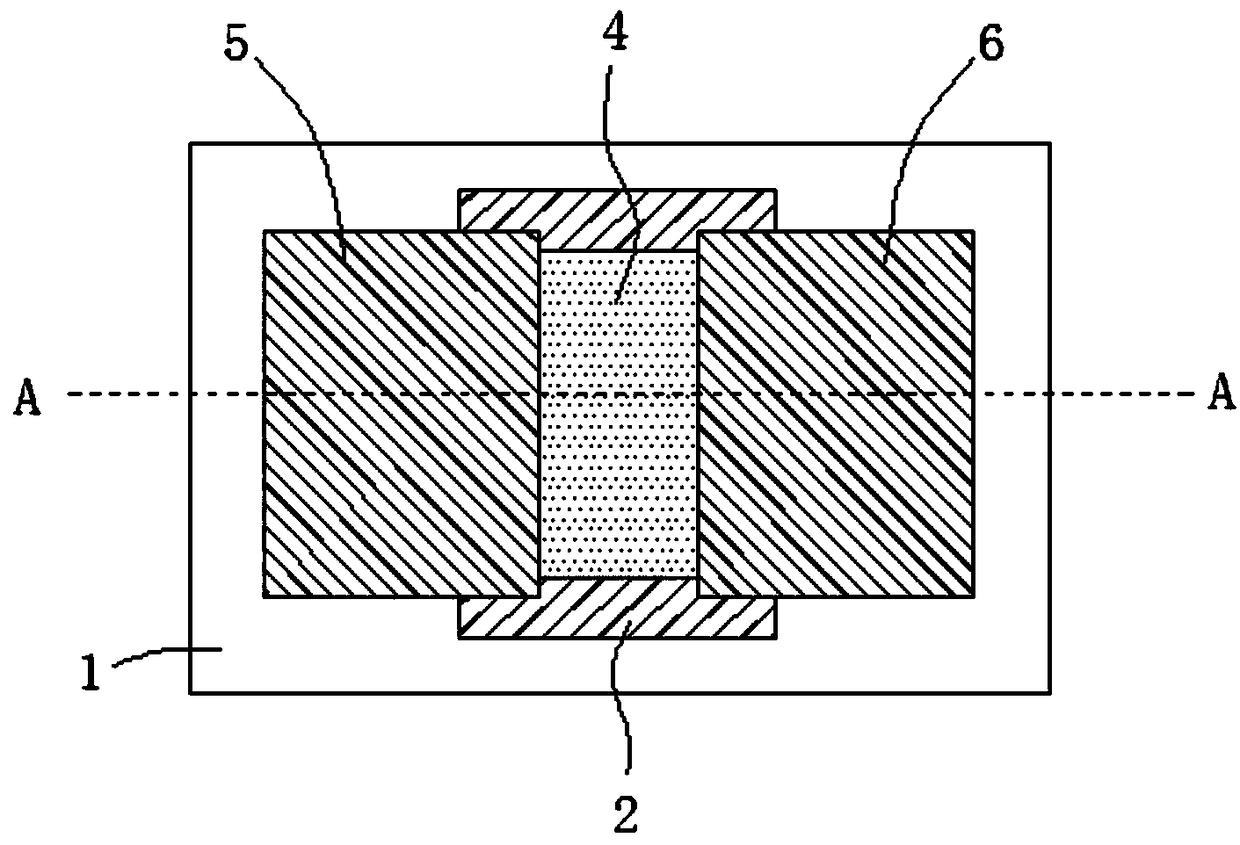

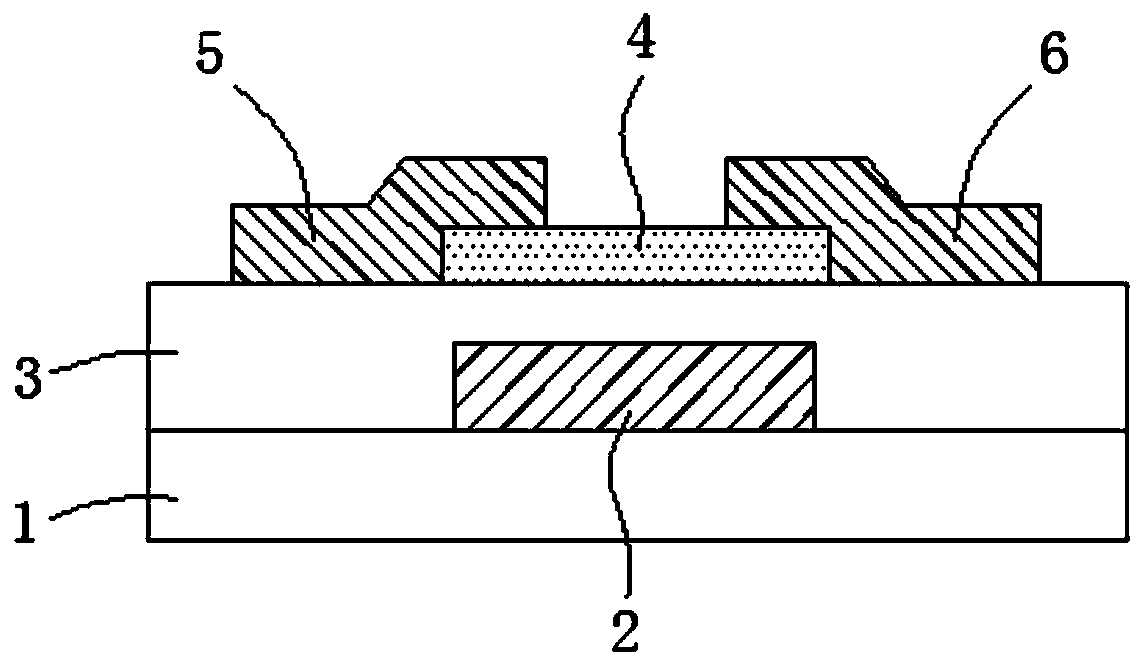

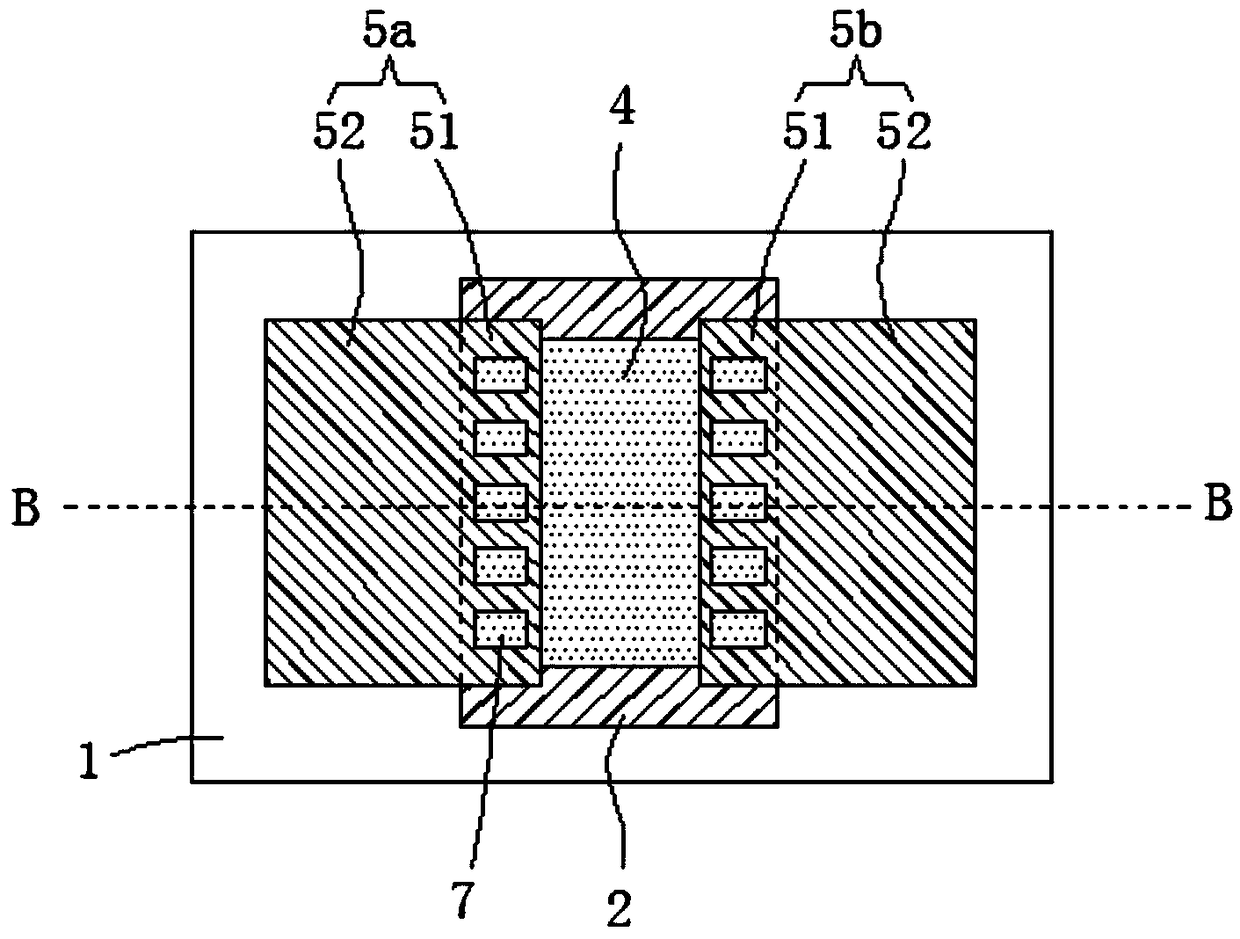

[0033] This embodiment provides a thin film transistor, refer to Figure 3 to Figure 5 , the thin film transistor includes a substrate 1, a gate electrode 2 disposed on the substrate 1, a gate insulating layer 3 covering the gate electrode 2, an active layer 4 disposed on the gate insulating layer 3, and a source electrode 5a and drain electrode 5b. The source electrode 5a and the drain electrode 5b are located in the same structural layer and are spaced apart from each other, the source electrode 5a is connected to the first end of the active layer 4, and the drain electrode 5b is connected to the active layer 4 the second end of .

[0034] Wherein, the source electrode 5 a and the drain electrode 5 b respectively include a first region 51 overlapping with the gate electrode 2 and a second region 52 outside the first region 51 . The first region 51 of the source electrode 5 a and the drain electrode 5 b is formed with a hollow pattern 7 , where the active layer 4 is exposed...

Embodiment 2

[0045] The difference between the thin film transistor provided in this embodiment and Embodiment 1 is that, as Image 6 As shown, in the source electrode 5 a and the drain electrode 5 b, the hollow pattern 7 is formed in the first region 51 and the second region 52 . In the thin film transistor in this embodiment, on the basis of reducing the parasitic capacitance between the gate electrode and the source / drain electrodes, the hollow pattern 7 is also formed in the second region 52, thereby increasing the flexibility of the thin film transistor. The thin film transistor structure provided in this embodiment, when applied to a flexible display device, can improve the bending performance of the flexible display device.

Embodiment 3

[0047] The difference between the thin film transistor provided in this embodiment and Embodiment 1 is that, as Figure 7 and Figure 8 As shown, the first region 51 of the source electrode 5a and the drain electrode 5b is a comb-like structure, the comb-tooth portion 8 of the comb-like structure is connected to the active layer 4, and between two adjacent comb-tooth portions 8 The gap between them is formed as the hollow pattern 7 .

[0048] Specifically, such as Figure 8 As shown, the line width L2 of the comb-tooth portion 8 is preferably set to 1-5 μm, and the distance D2 between two adjacent comb-tooth portions 8 (ie the width of the hollow pattern 7 ) is preferably set to 1-10 μm.

[0049] It should be noted that, as a structural change of this embodiment, the manner of Embodiment 2 can be referred to, and the second region 52 of the source electrode 5a and the drain electrode 5b in this embodiment is also provided with a hollow pattern 7 to improve Flexible properti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com