Sushi rice sausage and manufacture method thereof

A technology for sushi and rice, which is applied in the field of food processing, can solve the problem of single taste of enema, and achieve the effect of high nutritional value, large market prospect, and unique and novel taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

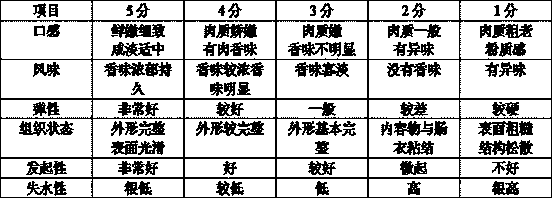

Image

Examples

Embodiment 1

[0022] A kind of sushi rice sausage, made of the following raw materials in parts by weight: 50 parts of seawater surimi, 300 parts of salmon, 12 parts of protein isolate, 30 parts of starch, 12 parts of salt, 8.2 parts of sugar, 6 parts of monosodium glutamate, 1.5 parts of sesame oil, 20 servings of meat floss, 220 servings of rice, 8 servings of seaweed, 110 servings of cucumber, and 5 servings of small ingredients.

[0023] The above-mentioned production method comprises the following steps:

[0024] Step 1: Thaw seawater AA surimi and salmon surimi naturally.

[0025] Step 2: Steam and cool the rice in advance, wherein the weight ratio of rice to water is 1:1.3.

[0026] Step 3: Dice the cucumber, soak the seaweed in water and chop it, and crush the meat floss for later use.

[0027] Step 4: First chop and mix seawater surimi and salmon surimi evenly, then reduce to first level and add salt, sugar, monosodium glutamate, small ingredients and continue stirring for five m...

Embodiment 2

[0033] A kind of sushi rice sausage, made of the following raw materials in parts by weight: 210 parts of seawater surimi, 140 parts of salmon, 14 parts of protein isolate, 35 parts of starch, 14 parts of salt, 8.4 parts of sugar, 7 parts of monosodium glutamate, 2 parts of sesame oil, 25 servings of meat floss, 225 servings of rice, 10 servings of seaweed, 115 servings of cucumber, and 6 servings of small ingredients.

[0034] The above-mentioned production method comprises the following steps:

[0035] Step 1: Thaw seawater AA surimi and salmon surimi naturally.

[0036] Step 2: Steam and cool the rice in advance, wherein the weight ratio of rice to water is 1:1.3.

[0037] Step 3: Dice the cucumber, soak the seaweed in water and chop it, and crush the meat floss for later use.

[0038] Step 4: First chop and mix seawater surimi and salmon surimi evenly, then reduce to first level and add salt, sugar, monosodium glutamate, small ingredients and continue stirring for five m...

Embodiment 3

[0044] A kind of sushi rice sausage, made of the following raw materials in parts by weight: 320 parts of seawater surimi, 30 parts of salmon, 16 parts of protein isolate, 40 parts of starch, 16 parts of salt, 8.6 parts of sugar, 8 parts of monosodium glutamate, 3 parts of sesame oil, 30 servings of meat floss, 230 servings of rice, 12 servings of seaweed, 120 servings of cucumber, and 7 servings of small ingredients.

[0045] The above-mentioned production method comprises the following steps:

[0046] Step 1: Thaw seawater AA surimi and salmon surimi naturally.

[0047] Step 2: Steam and cool the rice in advance, wherein the weight ratio of rice to water is 1:1.3.

[0048] Step 3: Dice the cucumber, soak the seaweed in water and chop it, and crush the meat floss for later use.

[0049] Step 4: First chop and mix seawater surimi and salmon surimi evenly, then reduce to first level and add salt, sugar, monosodium glutamate, small ingredients and continue stirring for five mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com