A high-elasticity hollow-shaped rubber health sole and a manufacturing process thereof

A production process, high elasticity technology, applied in the field of rubber products, can solve the problems of insufficient elasticity, high cost, energy consumption, etc., to achieve the effect of enhancing elasticity, eliminating transportation costs, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

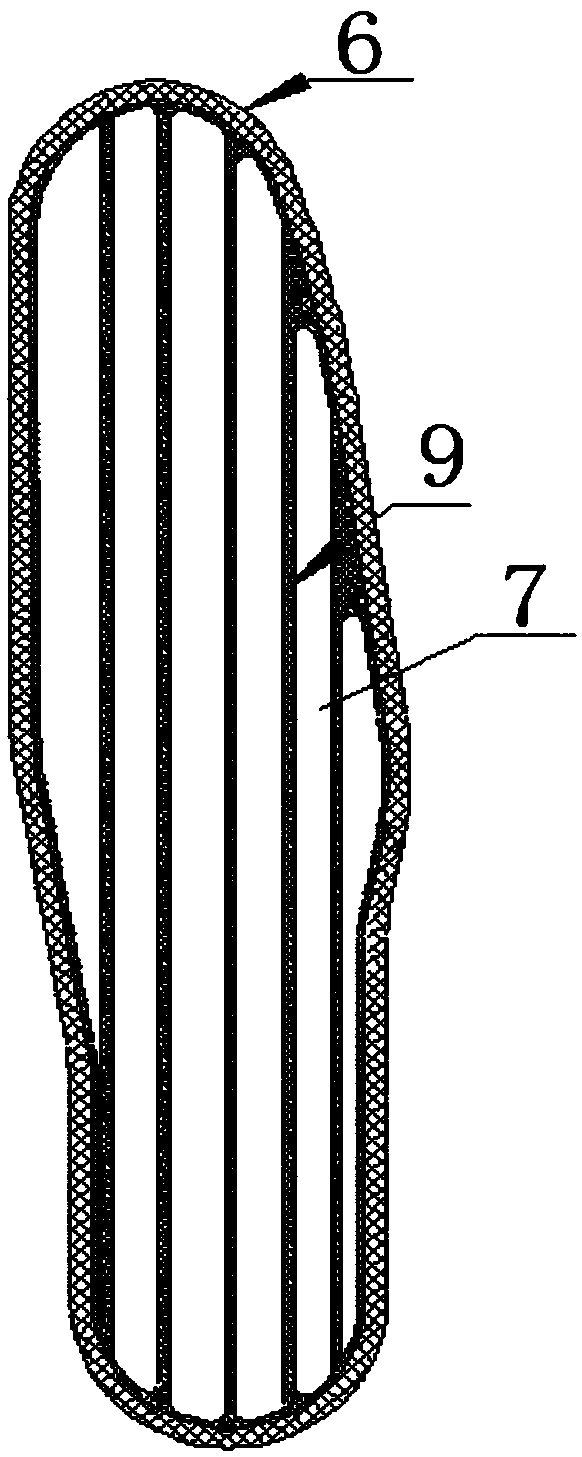

[0053] The high elasticity hollow molding rubber health-care sole of the present embodiment, as figure 1 , 2 As shown, the shoe sole body 6 is included, the inside of the shoe sole body 6 is a hollow sealed cavity, which enhances the elasticity, and the sealed cavity is evenly separated into the sole sub-cavity 7 by a partition 9, so as to ensure the improvement of elasticity. In addition, the support strength is improved, and the distribution of the partition 9 can also be coordinated with the meridians on the soles of the feet, which has the health care effect of promoting blood circulation and massage; the inner wall of the sole body 6 and the partition 9 are connected to form an integral structure. long life. Moreover, there is no need for additional inflation, and when a cavity leaks, it does not affect the use of the sole, and the partition 9 can be designed to be thin enough to not affect its elasticity.

Embodiment 2

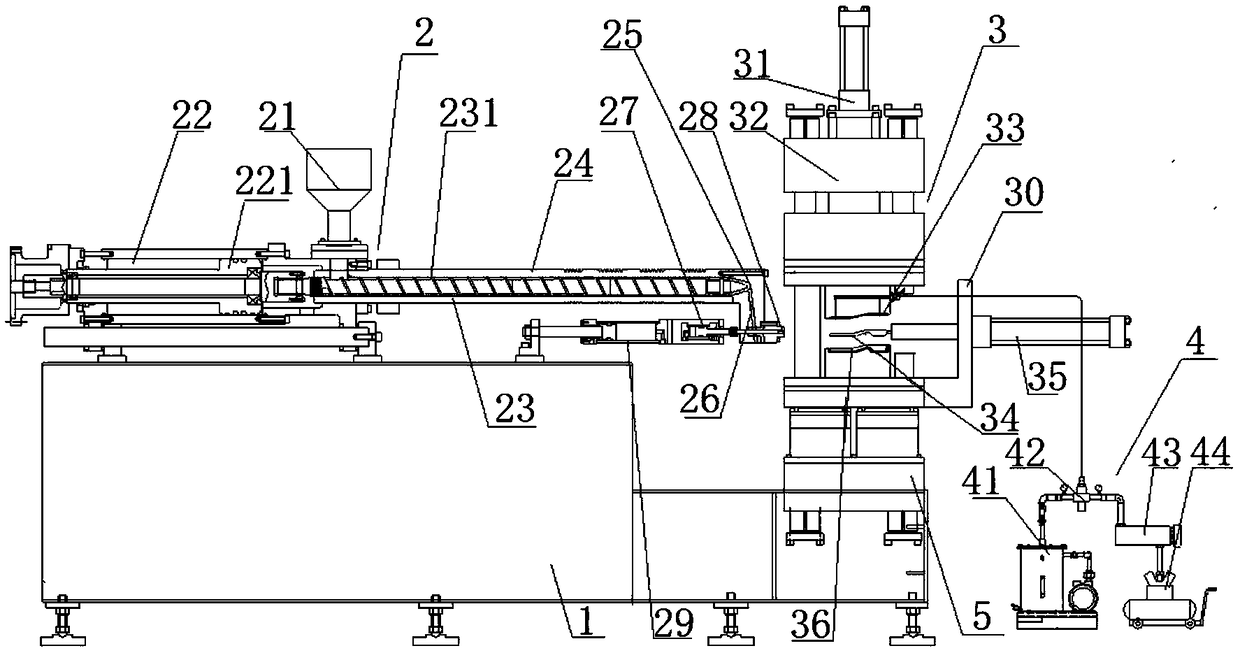

[0055] The high elasticity hollow molding rubber health-care sole of the present embodiment, as figure 1 , 2 As shown, the basic structure is the same as in Embodiment 1, and the improvement is that: the partition plate 9 and the sole body 6 are an integrated structure that is released from the same mold; the injection, hollowing and vulcanization processes are completed in the same mold cavity, and the mold cavity includes The upper half mold 33, the inner mold core 36 and the lower half mold 34 are manufactured by one-step injection, hollowing, and vulcanization processes of a one-time molding production system, which avoids circulation of products in various processes, thereby reducing production costs. The one-time molding production system includes an injection machine base 1, a die vulcanization stand 5, an injection device 2 and a die vulcanization device 3 respectively fixed on both, and an inflation and exhaust device 4 beside the die vulcanization stand 5; The injec...

Embodiment 3

[0068] The high-elastic hollow molding rubber health-care sole of the present embodiment is used to produce the basic structure of the one-time molding production system of rubber health-care sole with the same embodiment 2, and the improvement is that the air needles 47 are also evenly distributed on the lower half mold 36, once The charging and exhausting device 4 in the permanent molding production system also includes an electronically controlled three-way valve 42, an air heater 43 and a pipe joint 46; The three-way valve 42 is connected, the vacuum exhaust station 41 is connected with the electric control three-way valve 42 through the air pipe, and the high-pressure air pipe 45 is connected with the electric control three-way valve 42. The other end of the high-pressure air pipe 45 communicates with the gas needle 47 through the pipe joint 46, and the pipe joint 46 is fixed on the die vulcanization platform 5, and through the electronically controlled three-way valve 42,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com