Collector for flotation of oxidized coal slime, preparation method, and flotation method

A coal slime flotation and collector technology, applied in flotation, solid separation and other directions, can solve the problems of low separation efficiency, high chemical consumption and flotation cost, and achieve improved flotation efficiency, mature trading market, and high price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Specifically, the above preparation method includes the following steps:

[0041] Add diethylene oxide and C 7 ~C 9 The aromatic ether is added to the hydrocarbon oil, stirred for more than 15 minutes (for example, 15-25 minutes), and mixed uniformly to obtain the above-mentioned oxidized coal slime flotation collector.

[0042] The invention also provides a flotation method for oxidized coal slime. The oxidized coal slime is formulated into a flotation slurry, the collector and foaming agent are added to the flotation slurry for stirring, and then flotation is separated to obtain Flotation clean coal and flotation tailings.

[0043] Compared with the prior art, the beneficial effects of the oxidized coal slime flotation method provided by the present invention are basically the same as the beneficial effects of the above-mentioned oxidized coal slime flotation collector, which will not be repeated here.

[0044] As the collector of oxidized coal slime flotation can be C 10 ~C ...

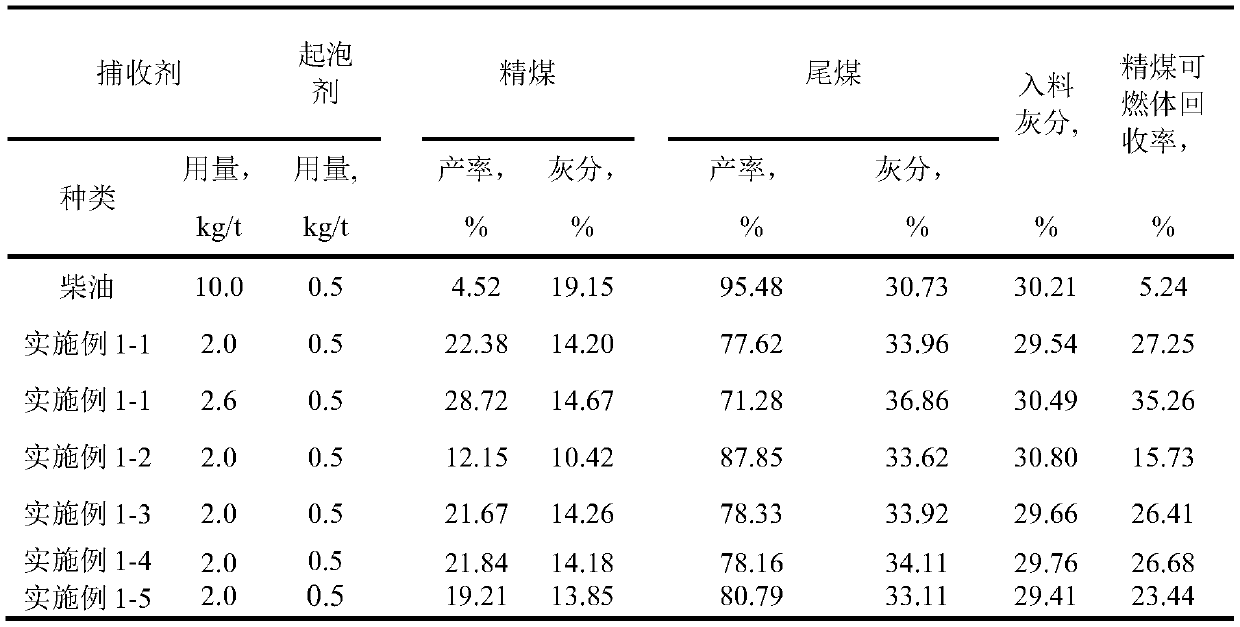

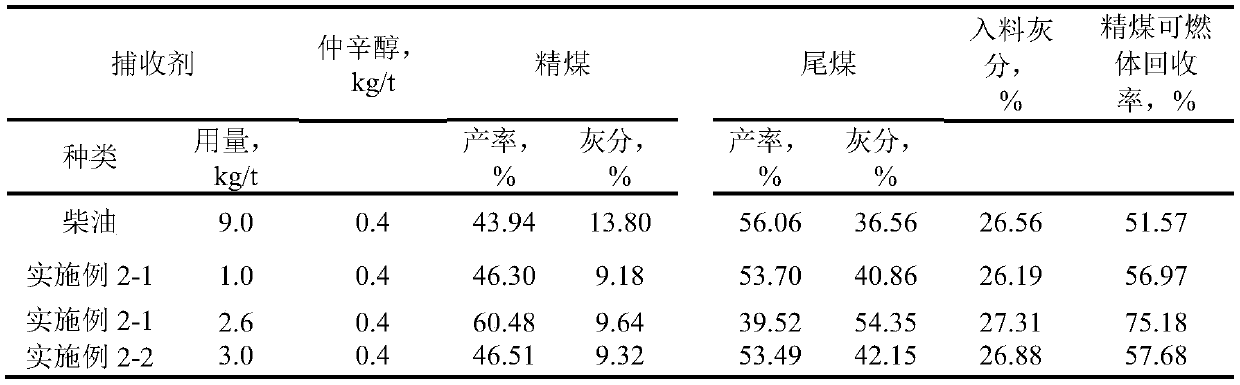

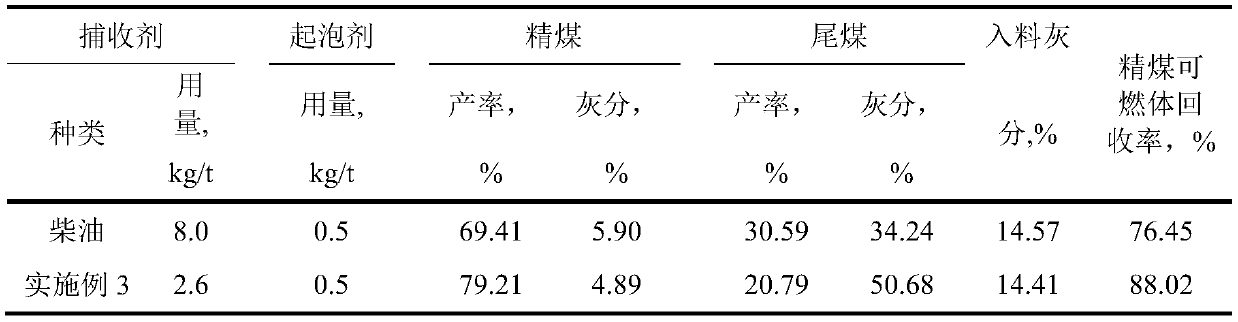

Embodiment 1

[0067] Coal slime properties: The deep oxidized coal sample comes from an open coal storage yard in a mining area in Inner Mongolia, and the ash content of the coal slurry is 30%. The particle size of the coal sample is relatively fine, and -0.074mm size slime accounts for 60% of the coal sample.

[0068] Operating conditions: 1.5L XFD type hanging trough flotation machine is used, and the spindle speed is 2000rpm. Weigh 120g of dry coal slime and pour it into a flotation tank filled with tap water to prepare a flotation slurry (pulp concentration 80g / L), add a collector and stir for 3 minutes, add a foaming agent, sec-octanol, and stir for 30 seconds, then add gas (Flotation machine inflation volume J g 0.8cm / s) After foaming for 3 minutes, the scraped foam and the residue at the bottom of the tank are the flotation clean coal and the flotation tailing coal. They are filtered, dried and weighed respectively, and the product combustible recovery rate is calculated. Table 2 show...

Embodiment 1-1

[0070] In Example 1-1, in terms of mass fraction, the ratio of the flotation collector was 75% diesel, 5% diethylene oxide, and 20% mixture of anisole, phenylethyl ether and phenylpropyl ether. The preparation process is as follows: the mixture of diesel oil, diethylene oxide, anisole, phenylethyl ether and phenylpropyl ether is mixed in proportion, and then stirred at a speed of 1000 rpm for 15 minutes to obtain the flotation collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com