Integrated circuit chip testing sorting device and working method thereof

A technology for integrated circuits and sorting devices, which is applied in the field of integrated circuit chip testing and sorting devices, can solve problems such as low testing efficiency and complex structure, and achieve the effects of high work efficiency, high testing precision, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

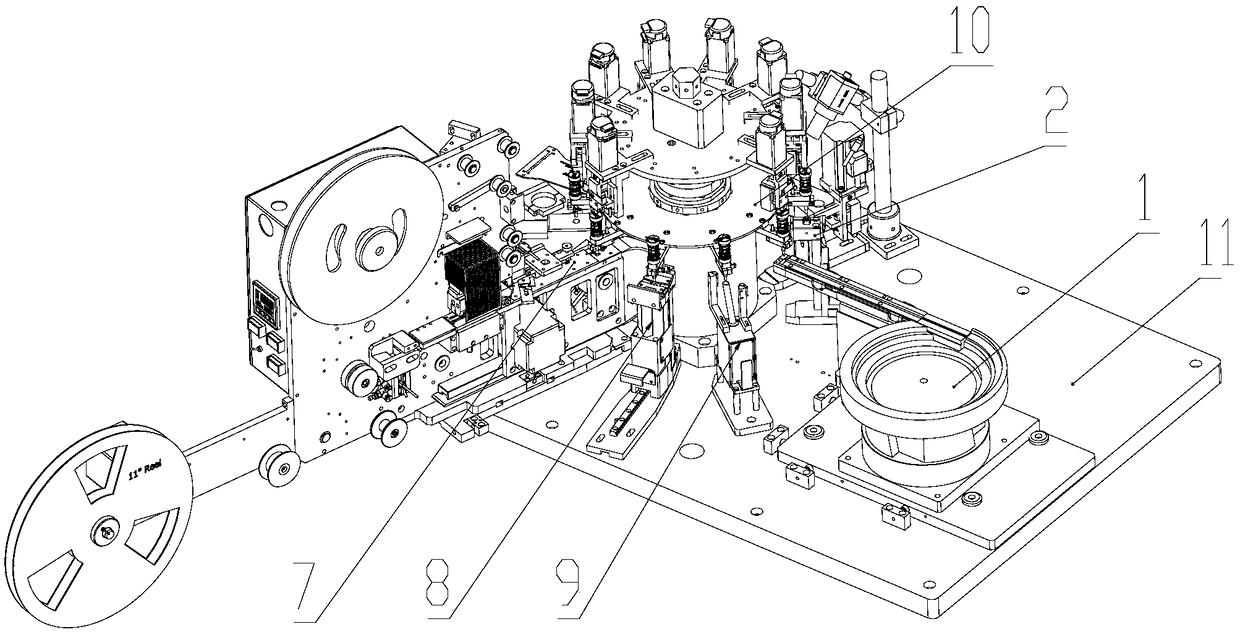

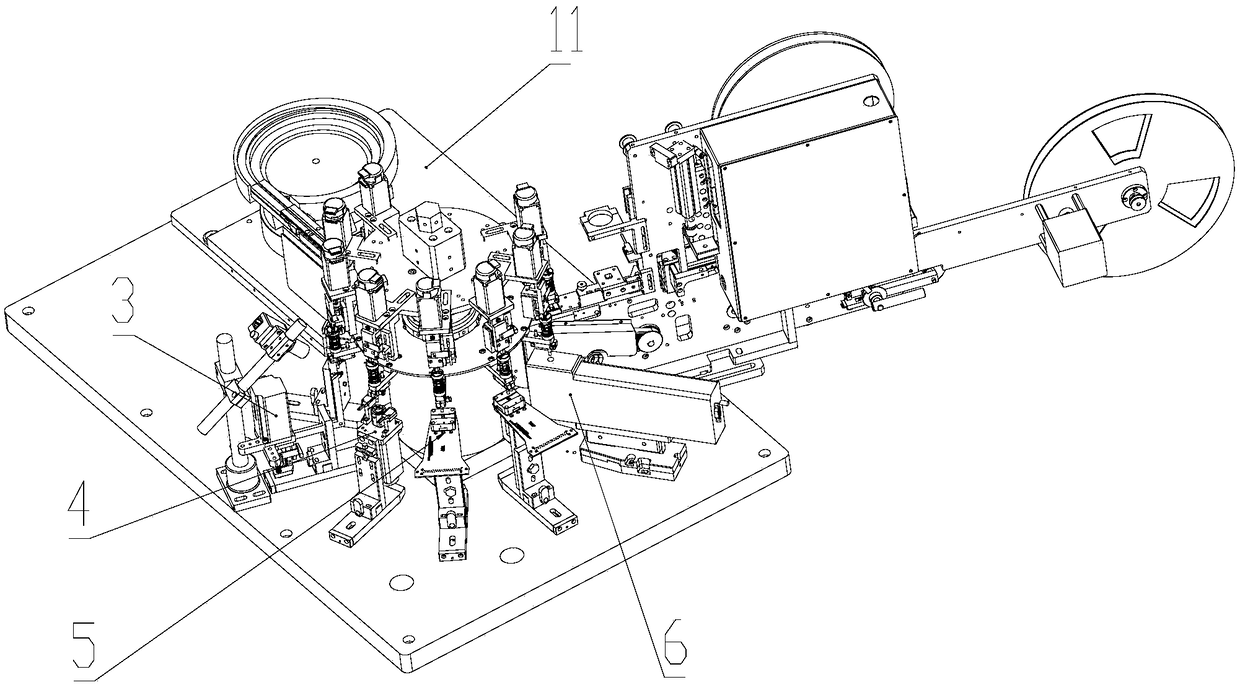

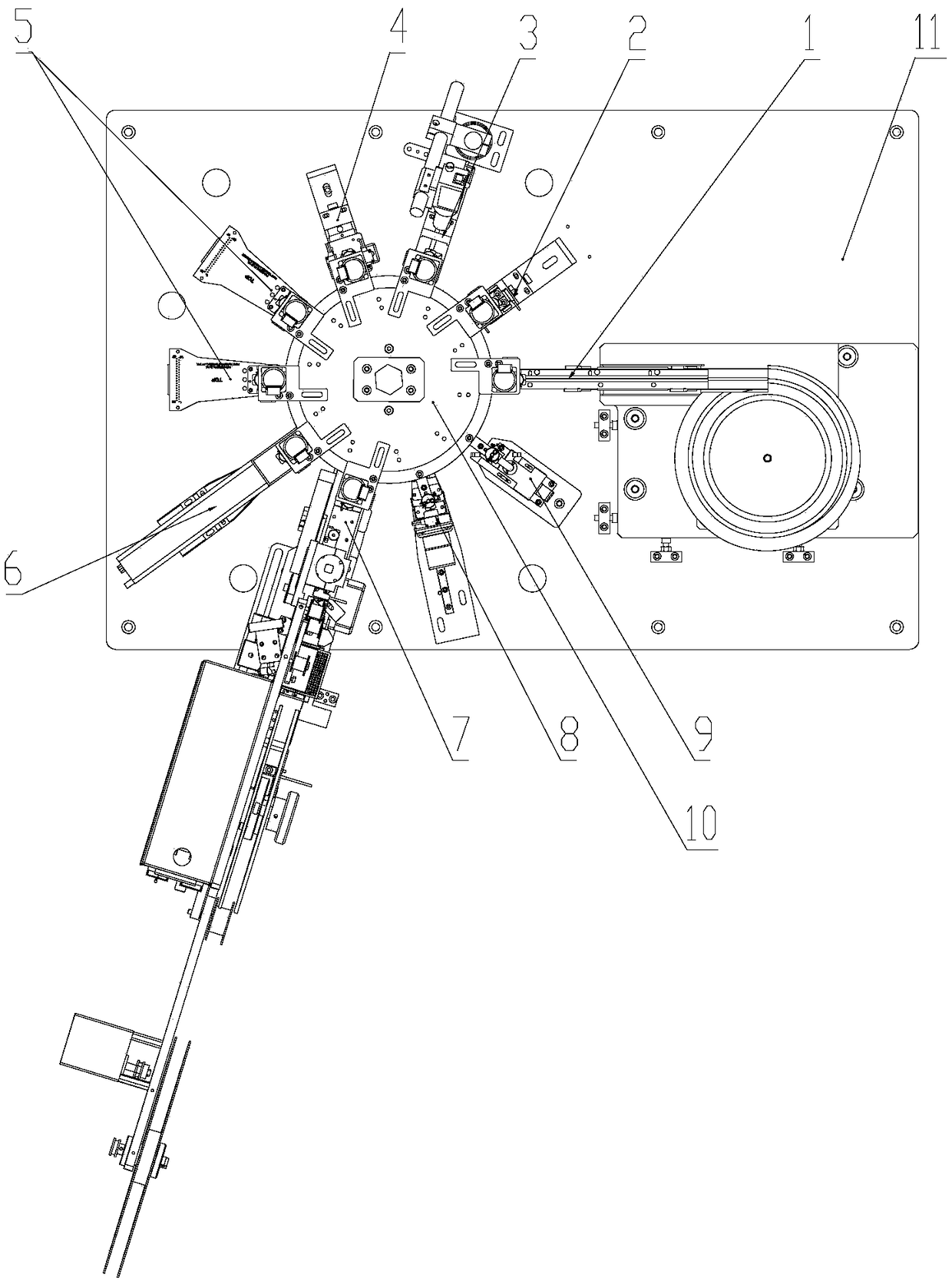

[0031] Referring to Fig. 1, the integrated circuit chip test and sorting device includes a test and sorting platform 11, and an automatic feeding system 1, a positioning system 2, a Mark detection system 3, a direction correction system 4, and a testing system arranged on the test and sorting platform 11 5. 3D detection system 6, braiding system 7, discharge system 8, overflow system 9 and turret system 10. The turret system 10 is located at the center of the test sorting platform 11 . The first, second, third, fourth, fifth, sixth, seventh, eighth, ninth and tenth functions are evenly arranged radially on the outer edge of the test sorting platform 11 around the turret system 10 Station. Feeding system 1, positioning system 2, Mark detection system 3, direction correction system 4, first test system 5, second test system 5, 3D detection system 6, tape system 7, discharge system 8 and overflow system 9 , correspondingly installed on the first, second, third, fourth, fifth, s...

Embodiment approach 2

[0045] Embodiment 2 is basically the same as Embodiment 1, except that there is one testing system 5, nine functional stations, a feeding system 1, a positioning system 2, a Mark detection system 3, a direction correction system 4, The first test system 5, the second test system 5, the 3D detection system 6, the braiding system 7, the discharge system 8 and the overflow system 9 are installed in the first, second, third, fourth and third Fifth, sixth, seventh, eighth, and ninth functional stations.

[0046] The working method of Embodiment 2 is as follows: the integrated circuit chip enters the turret system 10 through the automatic feeding system 1, the vacuum suction pen on the first functional station takes out the chip, and the direct drive servo main motor 10.1 rotates one grid, that is, rotates 40 °, the vacuum suction pen absorbs the chip and moves to the positioning system 2 on the second functional station. The positioning system positions the chip at the center of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap