Novel longitudinal-flexural compound space elliptical vibration ultrasonic turning method and device

A compound space and elliptical vibration technology, which is applied in the direction of vibrating fluid, turning equipment, auxiliary devices, etc., can solve problems such as tool damage, reduce cutting heat, facilitate connection, and improve processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

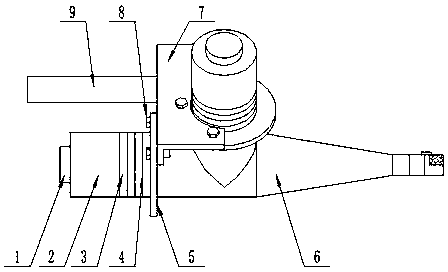

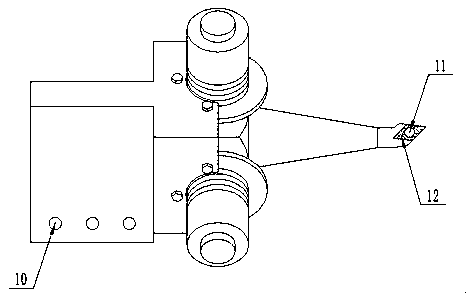

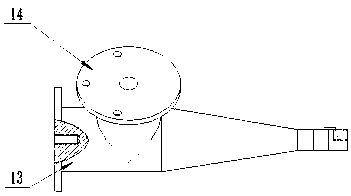

[0028] Example: see Figure 1-Figure 7 , In the figure, 1-connecting bolt, 2-reflective end, 3-piezoceramic plate, 4-electrode plate, 5-flange, 6-horn, 7-fixing frame, 8-fixing bolt, 9- Fixing plate, 10- mounting hole, 11- turning tool fixing screw, 12- turning tool, 13- internal threaded hole, 14- first big end, 15- second big end, 16- internal threaded hole, 17- internal thread Hole, 18-the third big end, 19-boring tool fixing bolt, 20-boring tool, 21-rectangular section horn.

[0029] The new longitudinal-bending composite spatial elliptical vibration ultrasonic turning device is mainly composed of the reflecting end 2, the piezoelectric ceramic sheet 3, the electrode sheet 4, the horn 6 and the turning tool 12. Among them, the horn 6 has three big ends, the first big end 14 is coaxial with the main body of the horn 6, the second big end 15 and the third big end 18 are distributed along the radial direction of the horn 6 and perpendicular to each other. The reflecting end 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com