Side pushing self-lock device

A technology of self-locking device and self-locking clamp, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of complex positioning, easy to be damaged by the clamp, and slippage of the workpiece, and achieve the effect of simple positioning and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of the following embodiments is used to help understand the invention, but does not constitute a limitation to the invention.

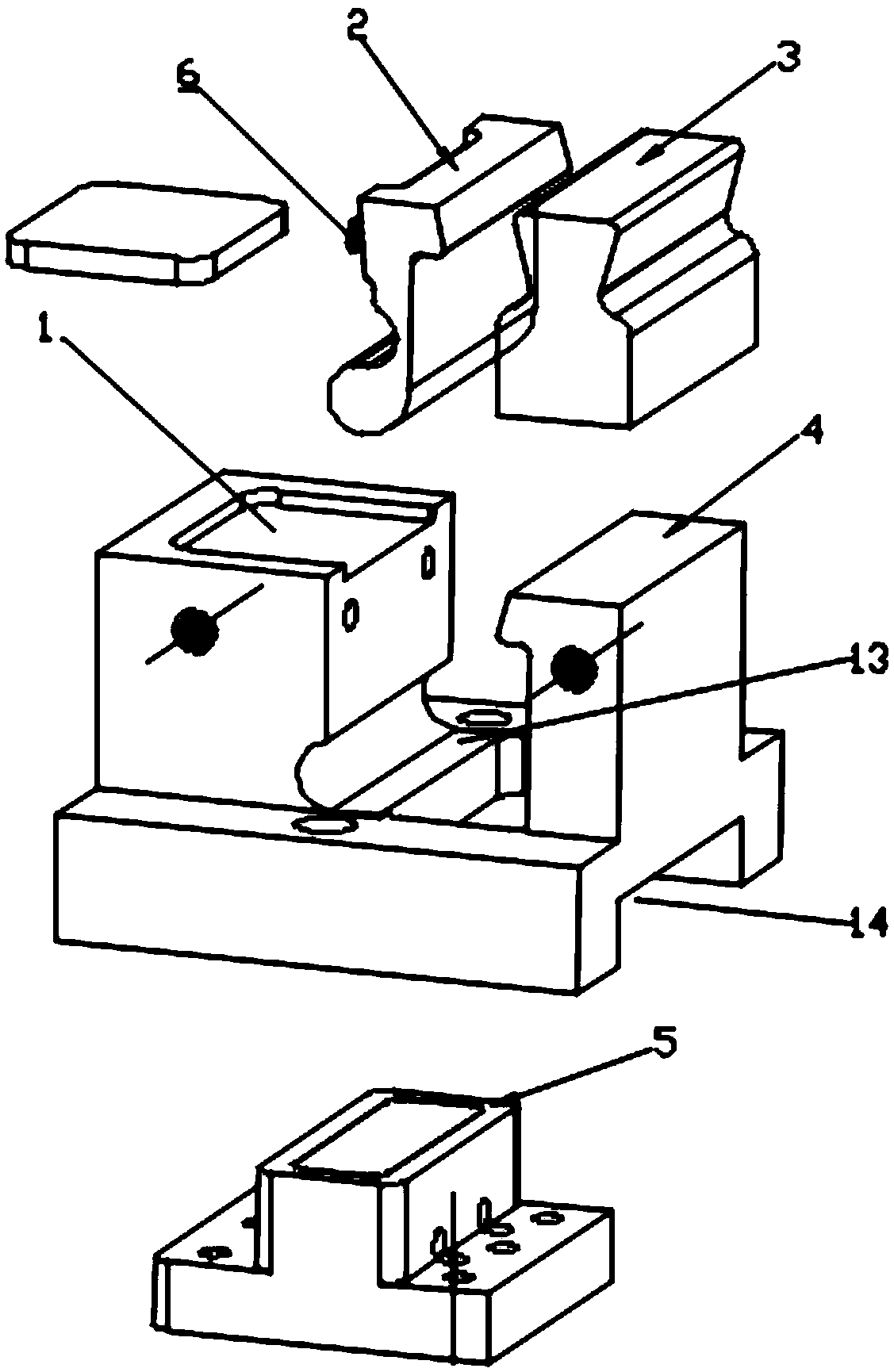

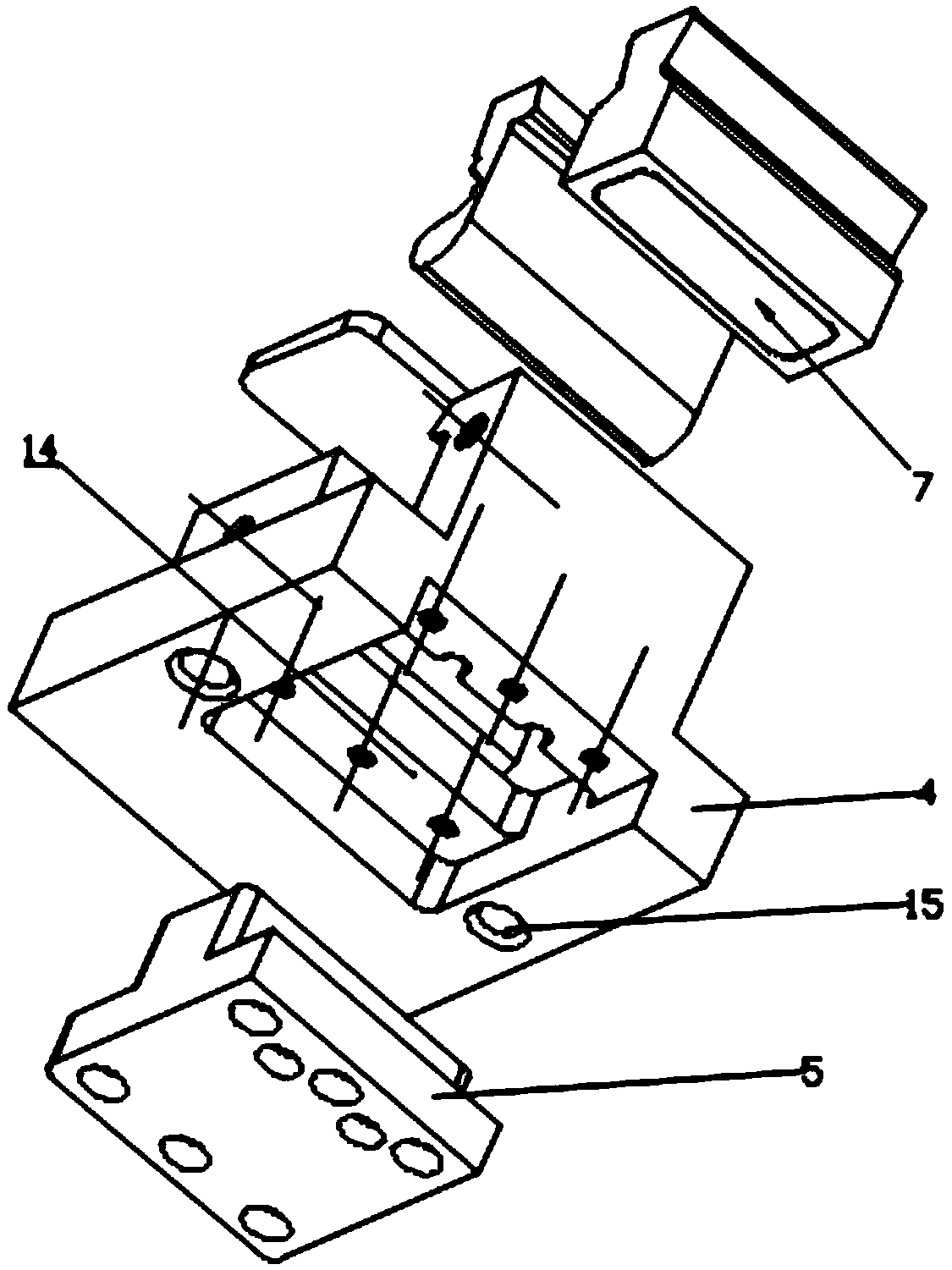

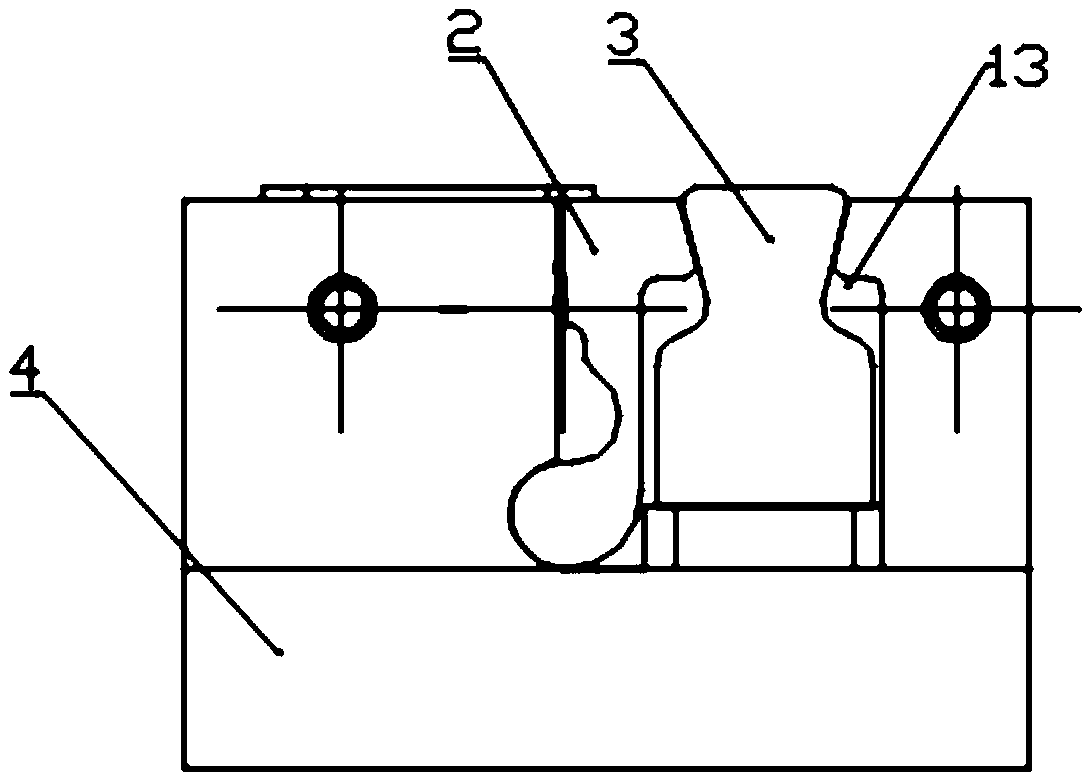

[0020] figure 1 , figure 2 A side push self-locking device of the present invention is shown, which includes a side push self-locking fixture; the side push self-locking fixture includes an upper mold base 4, and the upper mold base 4 is provided with 3 grooves, which are respectively: opened in The inner side of the upper die base 4 and the magnetic groove 13 at the bottom of the upper die base 4; the bottom groove 14 at the bottom of the upper die base 4; the processing groove 1 above the upper die base 4 and bordering on the magnetic groove 13; the magnetic groove 13 A side push block 2 and a convex slide block 3 are arranged inside, the side push block 2 and the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com