Efficient energy-saving biomass plastic molding machine

A high-efficiency, energy-saving, and biomass-based technology, applied in the field of gluing machines, can solve problems such as low work efficiency and inability to automatically separate from the white mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

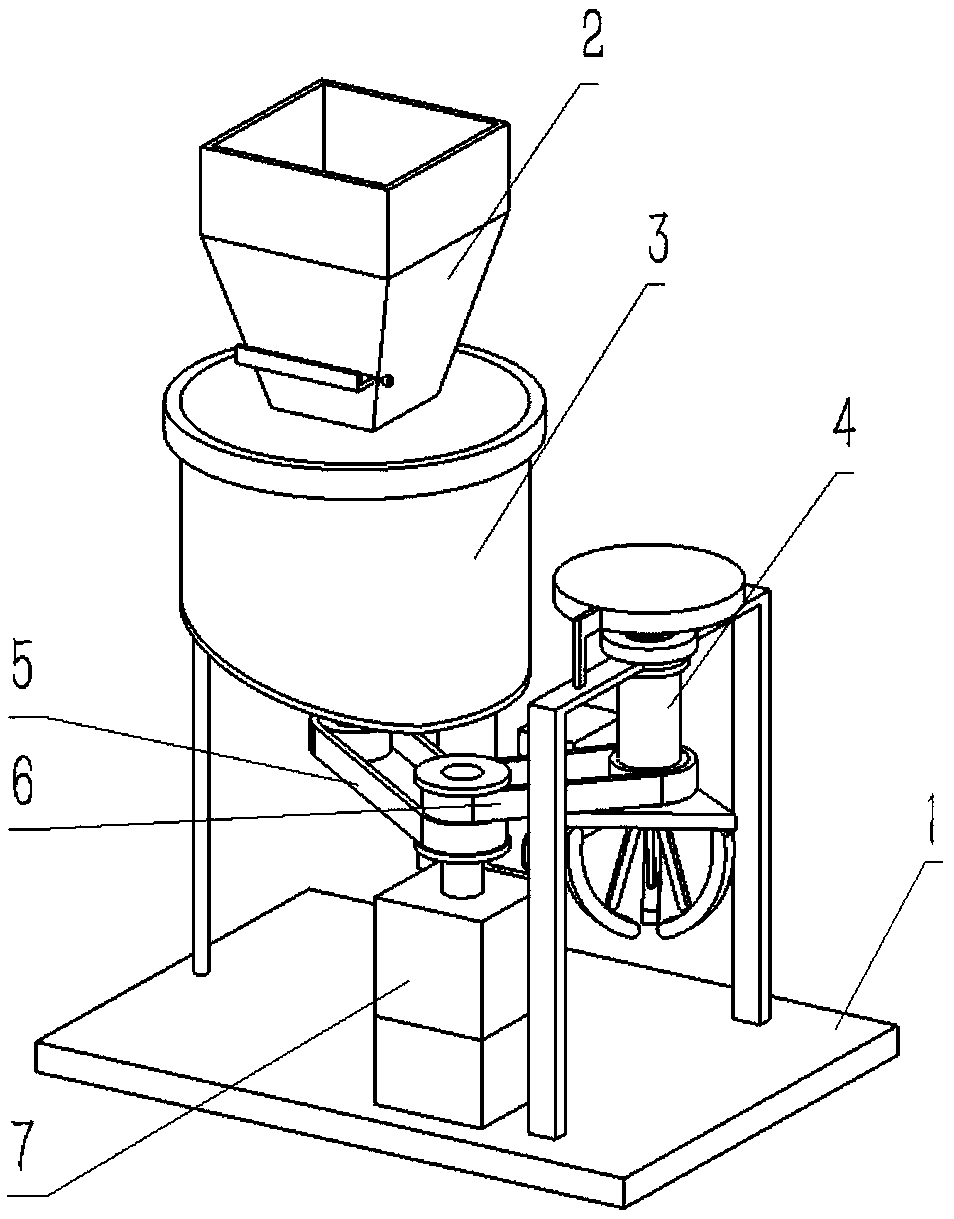

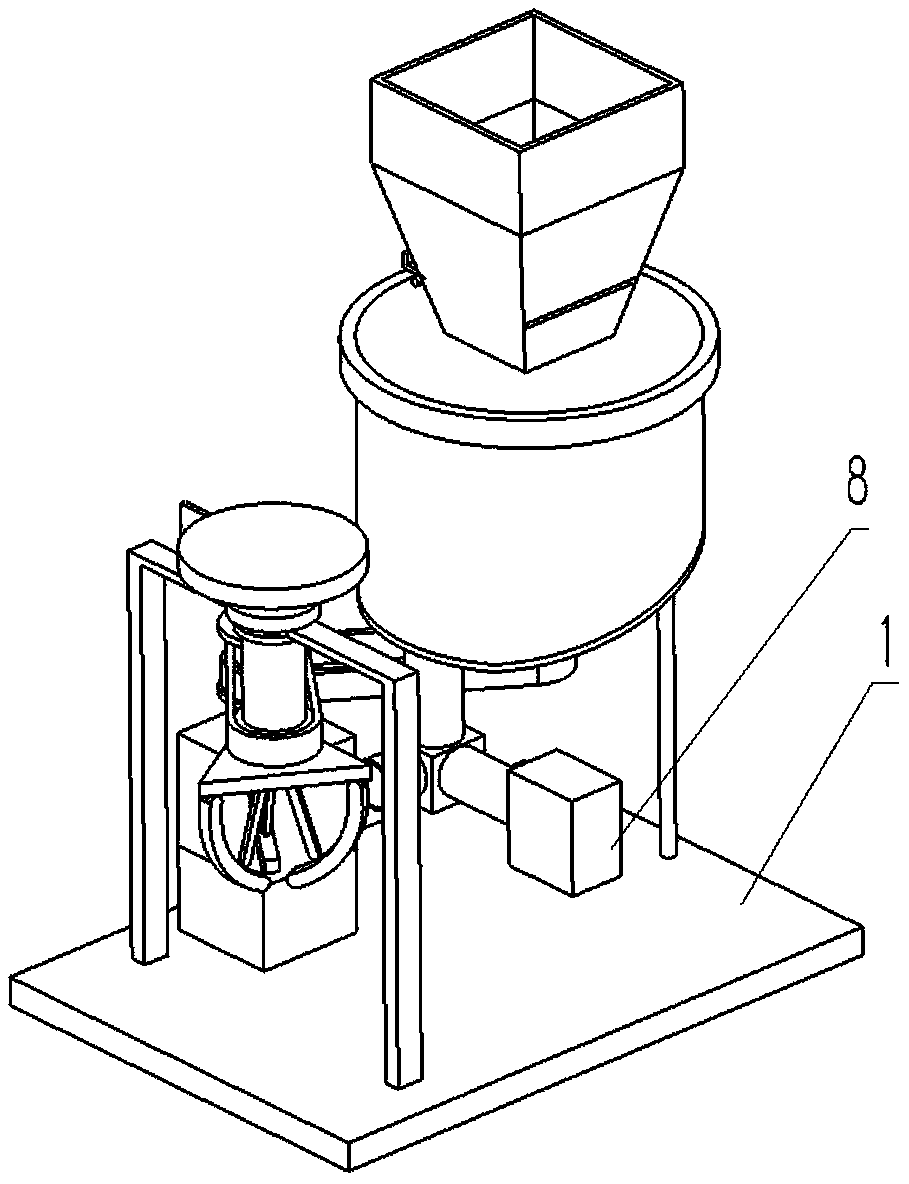

[0036] Combine below Figure 1-17 Describe this embodiment, a high-efficiency and energy-saving biomass gluing machine, including a chassis assembly 1, a feeding assembly 2, a melting furnace 3, a clamping assembly 4, a timing belt I5, a timing belt II6, and a power source 7 And the injection assembly 8, the feed assembly 2 is fixedly connected to the upper end of the melting material furnace 3 and the feeding assembly 2 communicates with the inner end of the melting material furnace 3, and the melting material furnace 3 is fixedly connected to the bottom frame assembly 1 The left end of the bottom frame assembly 4 is rotatably connected to the upper side of the right end of the bottom frame assembly 1, the power source 7 is fixedly connected to the front side of the bottom frame assembly 1, and the timing belt I5 is connected between the power source 7 and the melting furnace 3 , the synchronous belt II6 is connected between the power source 7 and the clamping assembly 4, the...

specific Embodiment approach 2

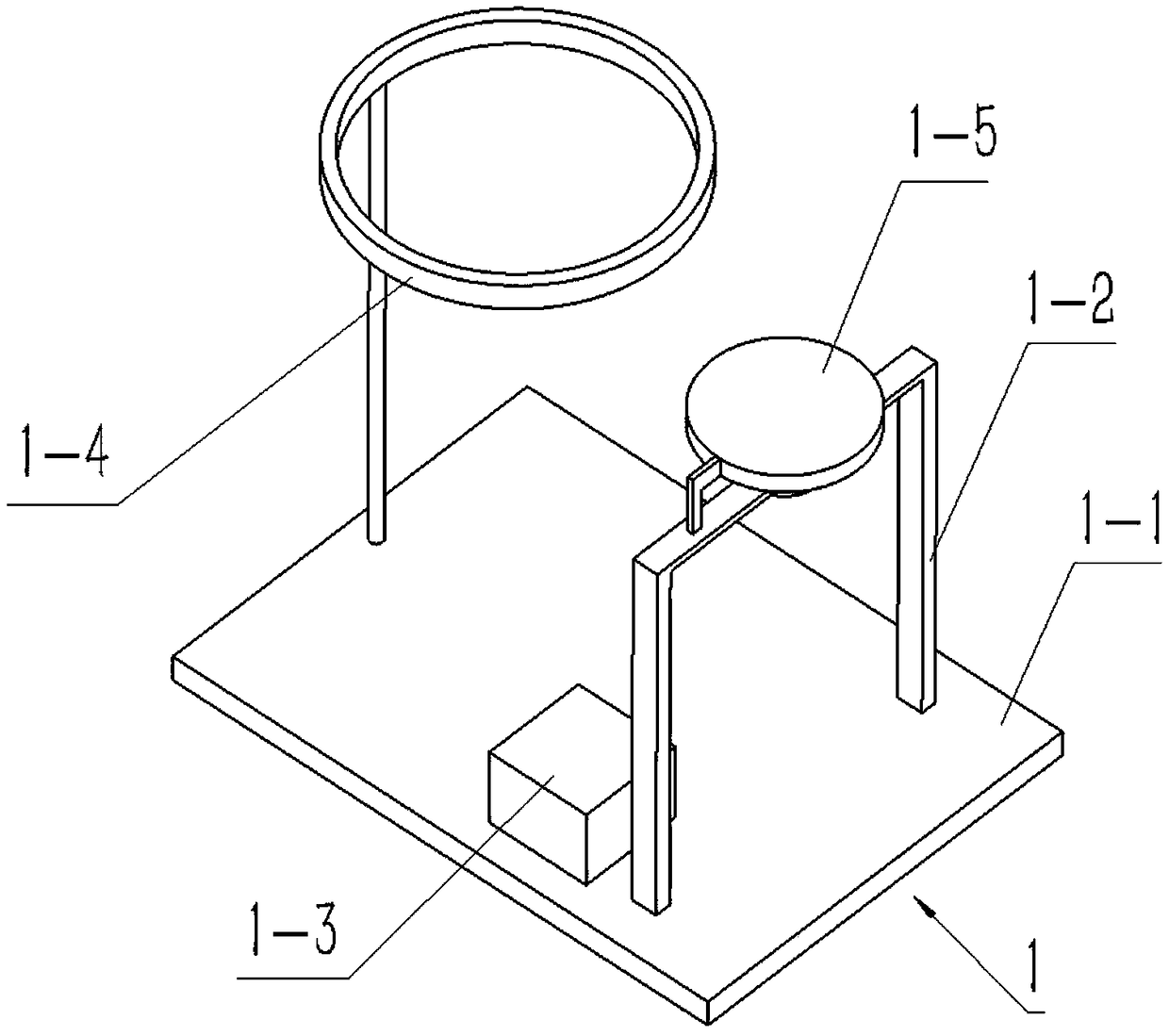

[0037] Combine below Figure 1-17 This embodiment will be described. This embodiment will further describe the first embodiment. The chassis assembly 1 includes a bottom plate 1-1, a right bracket 1-2, a fixing boss 1-3, a left fixing frame 1-4, Slot plate 1-5, slot plate fixing connecting rod 1-6, slot plate body 1-7, spiral groove 1-8 and flat groove 1-9, motor 1-10 and stepped pulley 1-11, right side bracket 1- 2 is fixedly connected to the right side of the upper end surface of the bottom plate 1-1-, the left fixed frame 1-4 is fixedly connected to the left side of the upper end surface of the bottom plate 1-1, and the fixed boss 1-3 is fixedly connected to the bottom plate 1- 1, the fixed boss 1-3 is located between the right side bracket 1-2 and the left side fixed frame 1-4, the slot plate 1-5 includes the slot plate fixing link 1-6, the slot plate body 1-7, The spiral groove 1-8 and the flat groove 1-9, the groove plate fixing connecting rod 1-6 are fixedly connected ...

specific Embodiment approach 3

[0039] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the feeding assembly 2 includes a feeding shell 2-1, a limit screw 2-2, a side slide plate 2-3, a chute 2-4, a screw thread Hole 2-5, two rectangular chute 2-6 and two rectangular slide blocks 2-7, the inner end of feeding shell 2-1 is hollowed out, and chute 2-4 is arranged on the feeding shell 2-1, slides The groove 2-4 runs through the feeding shell 2-1 left and right, the threaded hole 2-5 is set on the left side of the front face of the feeding shell 2-1, and the two rectangular chute 2-6 are respectively set at the front and back of the chute 2-4 On both sides, the threaded hole 2-5 communicates with the rectangular chute 2-6 on the front side of the chute 2-4, the limit screw 2-2 is threaded in the threaded hole 2-5, and the two rectangular sliders 2-7 are respectively Fixedly connected to the front and rear sides of the right end of the side slide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com