A kind of molding method of the shell matched with the adapter

A molding method and adapter technology, which can be applied to household appliances, other household appliances, household components, etc., can solve the problems of poor matching of adapters, and achieve the effects of improving adaptability, improving maintenance guarantee, simplifying assembly and difficulty of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

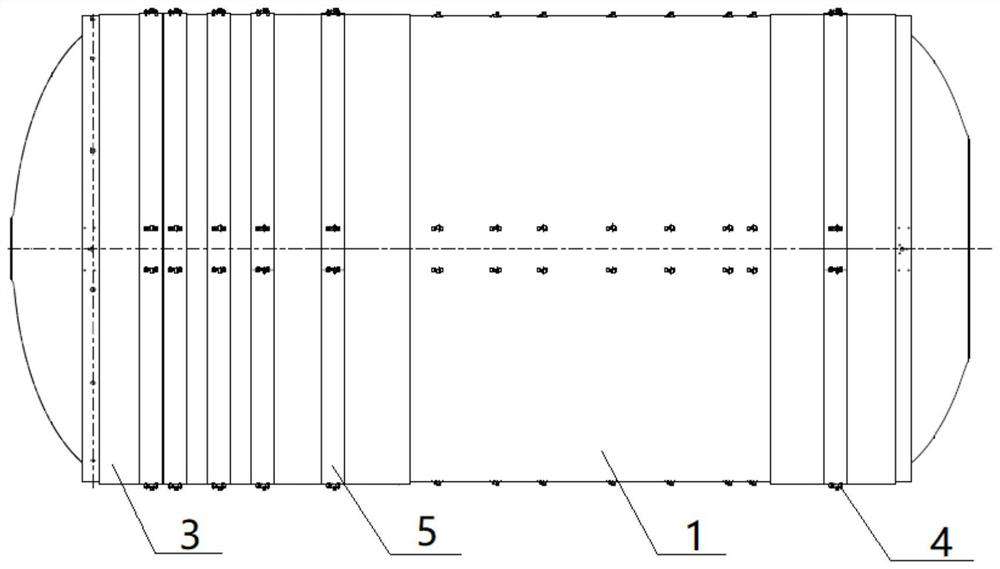

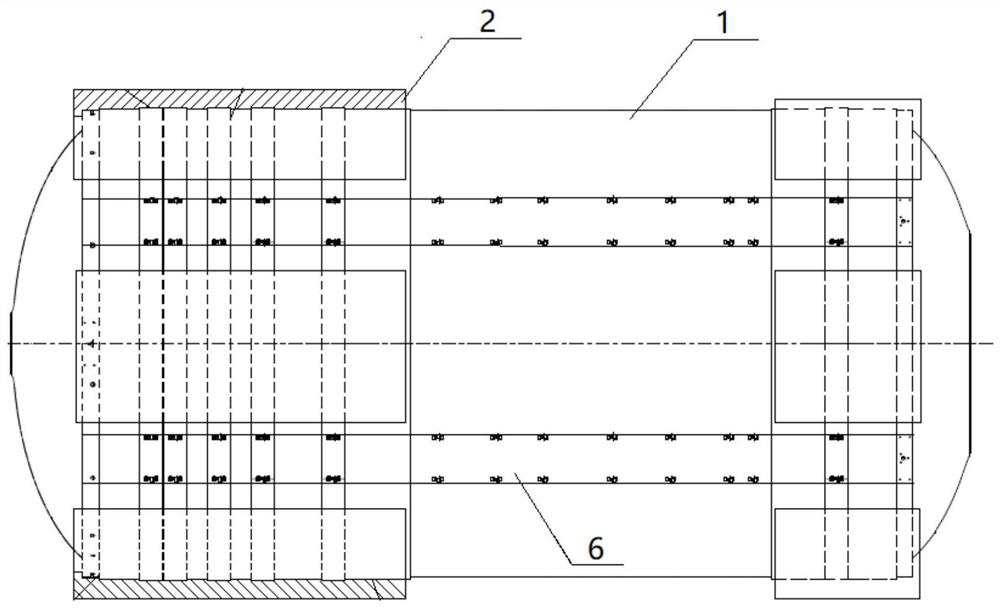

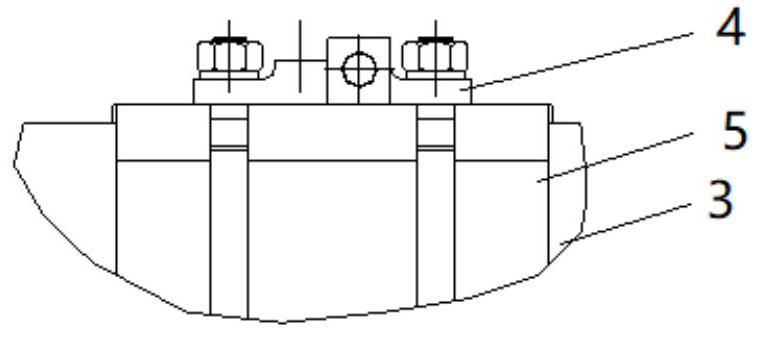

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0026] This embodiment provides a method for forming a housing matched with an adapter, and the specific steps are as follows:

[0027] The first step is to process the shell body 1 with an inner diameter of 2 m. The processing process is sequentially spinning, machining and heat treatment. The shell body 1 after heat treatment has a higher strength, so after heat treatment, no further damage to the shell body 1 is required. The cylindrical section is machined, and the shape and position deviation of the circular runout of the shell body 1 will inevitably occur during the heat treatment process, resulting in the circular runout value of the shell body 1 being ±6mm;

[0028] The second step is to carry out an internal pressure test on the shell body 1 of the first step to check whether the strength of the shell body 1 meets the requirements. If the internal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com