Control device and control method for achieving C arm system follow-up motion

A control device and control method technology, applied in the field of medical equipment, can solve the problems of other joints that cannot be controlled, large-stroke operation is unfavorable for doctors to operate, and cumbersome operating procedures, so as to save time required for positioning, avoid inconvenient operation, and simple operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1. The embodiment of the present invention provides a control device for realizing the follow-up motion of the C-arm system, including an active drive element, an auxiliary control handle, an infrared switch and a force sensor. Each joint of the C-arm system is equipped with an active drive component, the auxiliary control handle is connected with the C-arm system through the force sensor, and the auxiliary control handle is provided with an infrared switch. In the open state, the force sensor obtains the operation intention and transmits the instruction to each joint The active drive element drives each joint of the C-arm system to move.

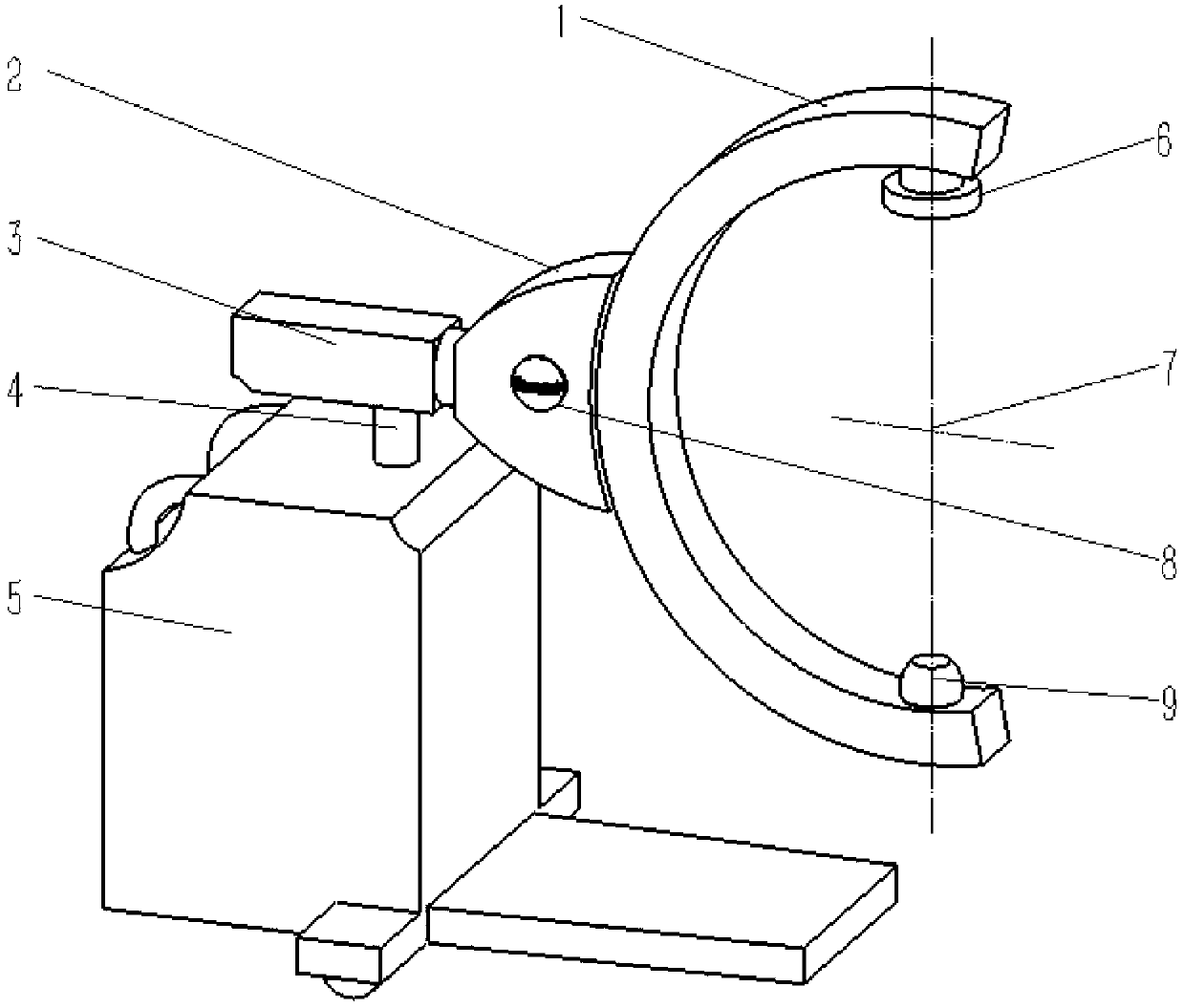

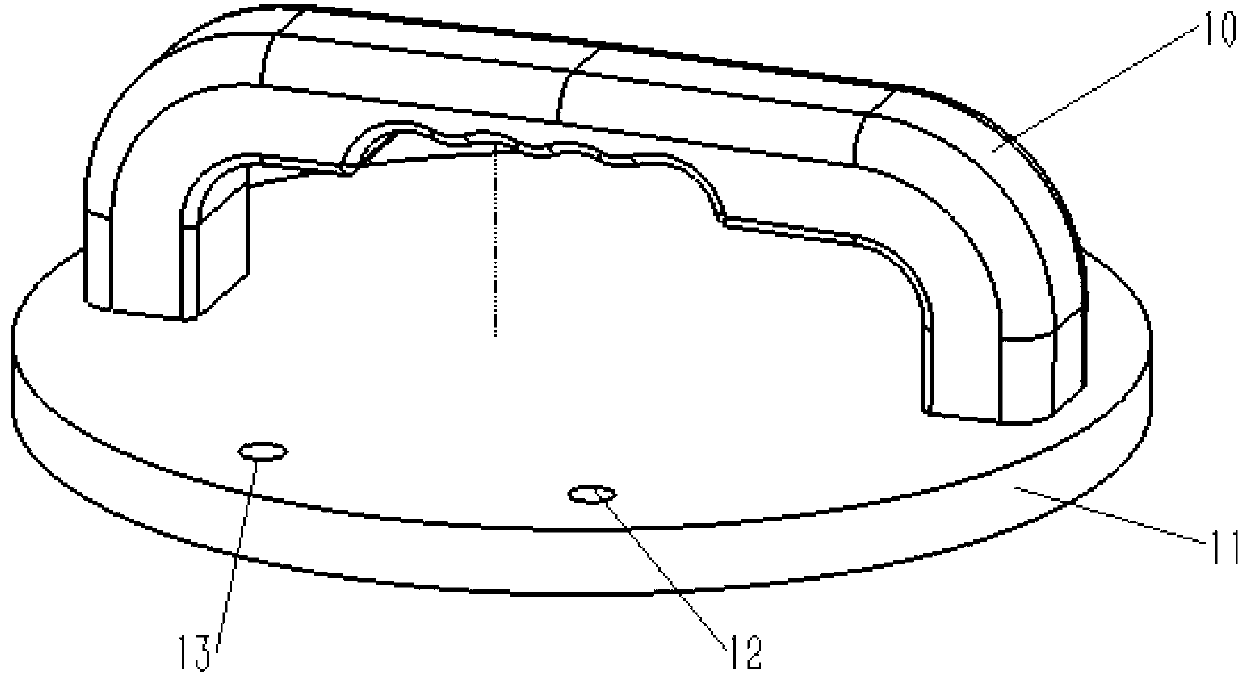

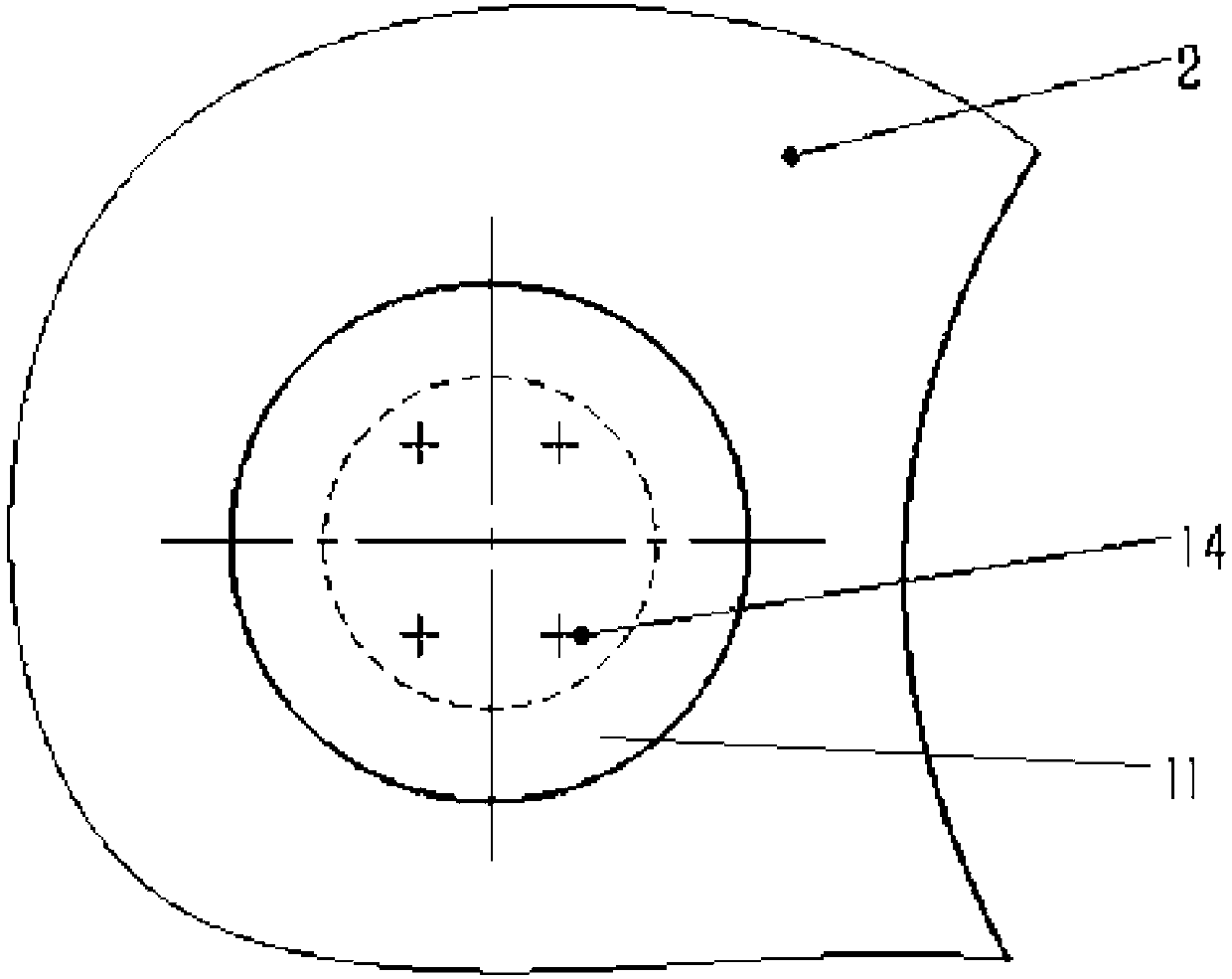

[0043] see figure 1 , in this embodiment, the structure of the C-arm system consists of four parts, including: X-ray system, C-arm (1), support arm (2), mobile frame (3) and lifting frame (5), the The X-ray system includes an X-ray light source (9) fixed at both ends of the C-arm (1) and an image detection device (6). The...

Embodiment 2

[0058] Example 2, please refer to Figure 5 , an embodiment of the present invention provides a control method for realizing the follow-up motion of a C-arm system, including the following steps:

[0059] (1) Control state detection: detect the infrared switch state of the auxiliary control handle. When the auxiliary control handle is not held, the infrared switch signal is 0, the follow-up motion function is turned off, and the system does not respond to the force sensor signal. C The arm system remains stationary, when the auxiliary control handle is held, the infrared switch signal becomes 1, the follow-up motion function is turned on, and the system responds to the force sensor signal;

[0060] Preferably, a period of start-up delay, such as 1 second, is set in the control state detection, that is, the system starts to respond to the force sensor signal after 1 second after the infrared switch is triggered.

[0061] (2) Force sensor signal processing: After filtering high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com