Automatic material feeding device

An automatic feeding and trough technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve problems affecting the efficiency of cylindrical cells entering the shell, disordered arrangement of aluminum shells, and inaccurate positioning of aluminum shells, etc., to achieve Reduce the degree of manual intervention, reduce damage, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing:

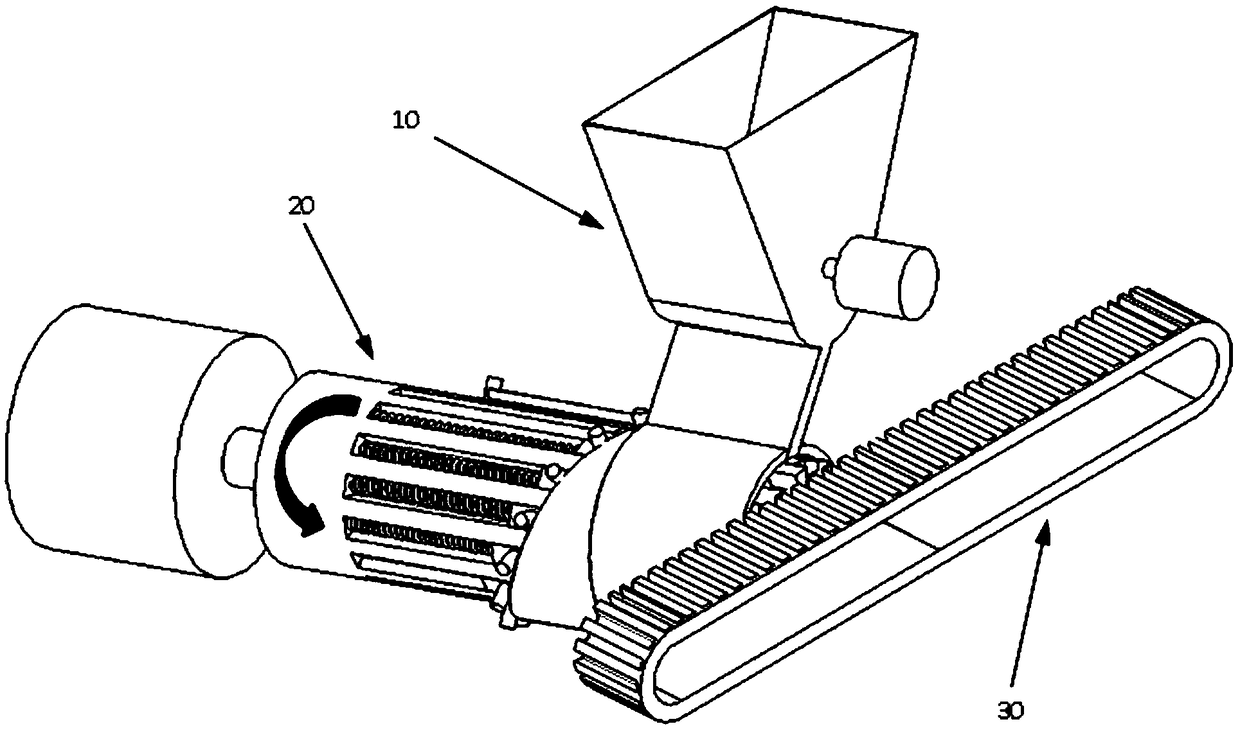

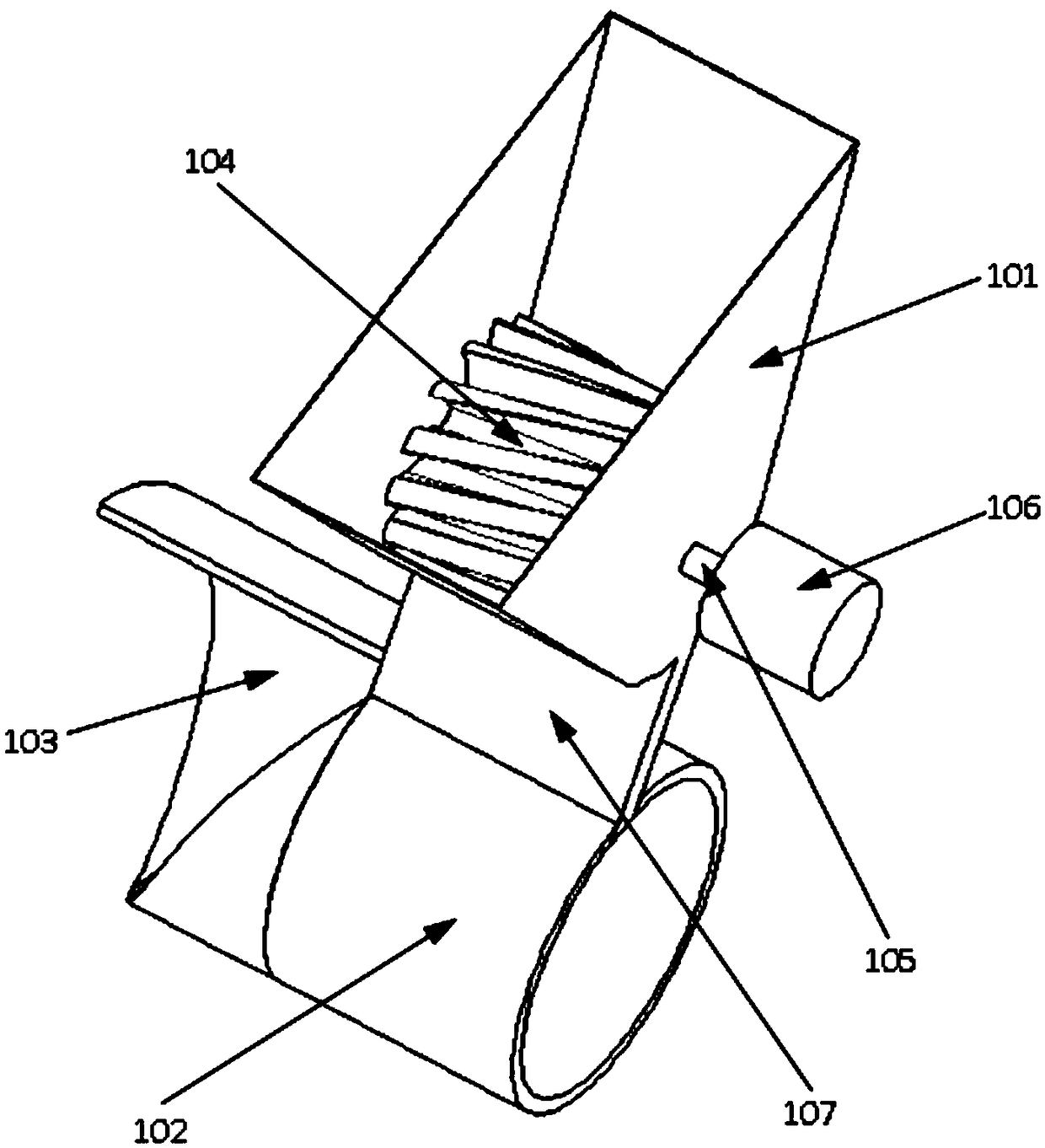

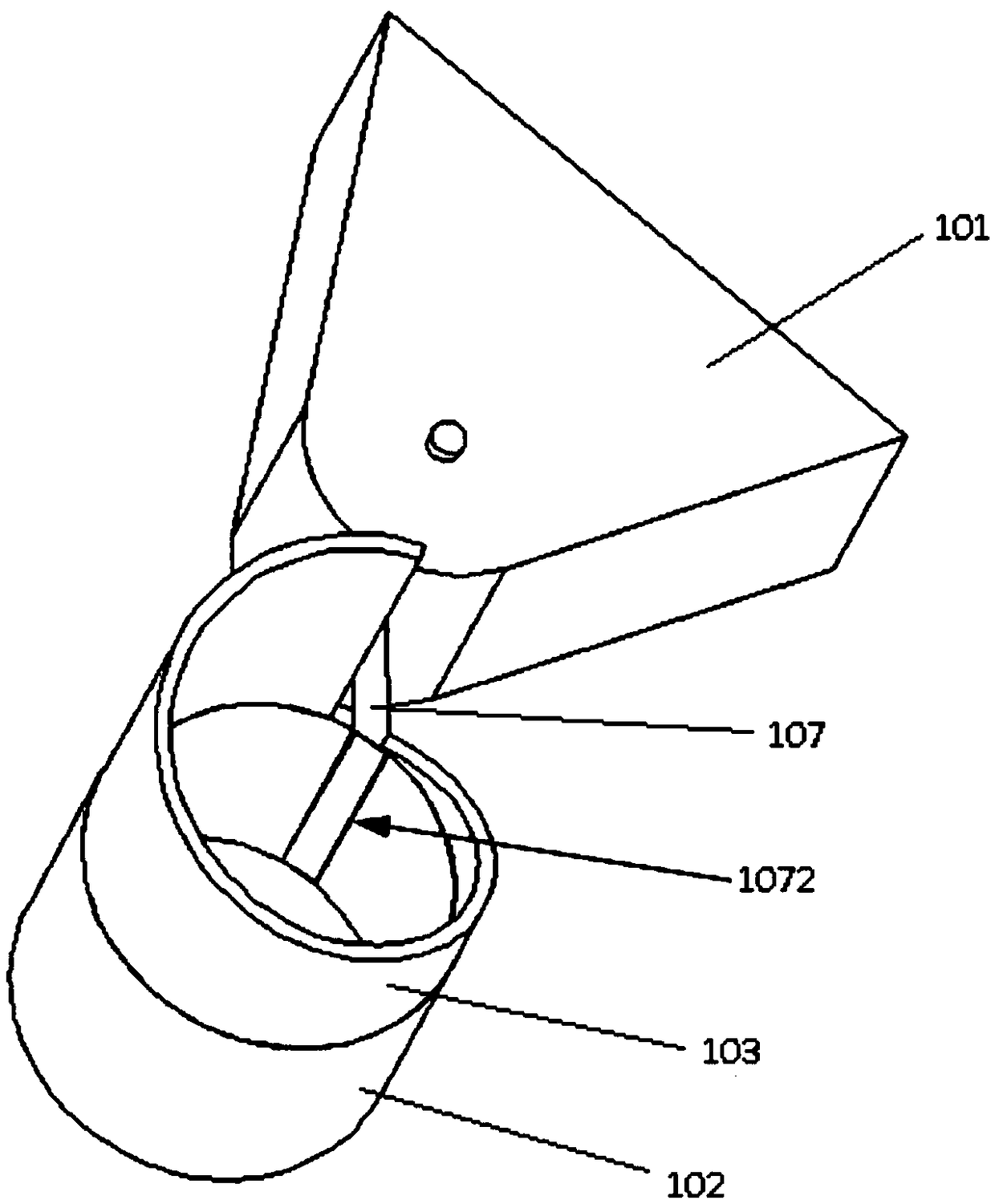

[0048] Such as figure 1 As shown, an automatic feeding device includes a feeding mechanism 10 and a propulsion mechanism 20;

[0049] Such as Figure 6As shown, the propulsion mechanism 20 includes a rotating wheel 201, and the outer wall of the rotating wheel 201 is provided with feeding grooves 2011 at equal intervals in the axial direction, and a push block 2013 is movable in the feeding groove 2011. The inner end of the block 2013 is connected to the inner wall of the feeding chute 2011 through an elastic member, and a stop post 2014 is installed on the push block 2013 at one end of the elastic member;

[0050] In a further solution, the blocking column 2014 is movably installed on the push block 2013 and rotates around its own central axis. When the helix of the spiral cover rotates tangentially to the retaining post, the retaining post can rotate freely, avoiding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com