Preparation method, product and application of a two-dimensional ultrathin stannous sulfide nanosheet

A stannous sulfide and nanosheet technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of low efficiency, long time, difficult to peel off two-dimensional materials, etc., and achieve good reproducibility and low cost. , Product quality controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Preparation of stannous sulfide bulk

[0056] (1) Mix sulfur powder and tin powder according to the stoichiometric ratio, and seal the mixture in a vacuum quartz glass tube after fully grinding;

[0057] (2) Use a tube furnace to heat the mixture from room temperature, the heating temperature is 500 ° C, the holding time is 24 hours, and the heating rate is 5 ° C min -1 After the heating is completed, the temperature is naturally lowered to obtain a stannous sulfide block.

[0058] 2. Electrolyte Preparation

[0059] Measure 50mL ultrapure water, weigh 7.1g Na 2 SO 4 , dissolve and stir with ultrapure water, and after cooling, dilute to volume in a 100mL volumetric flask to obtain 0.5M Na 2 SO 4 electrolyte.

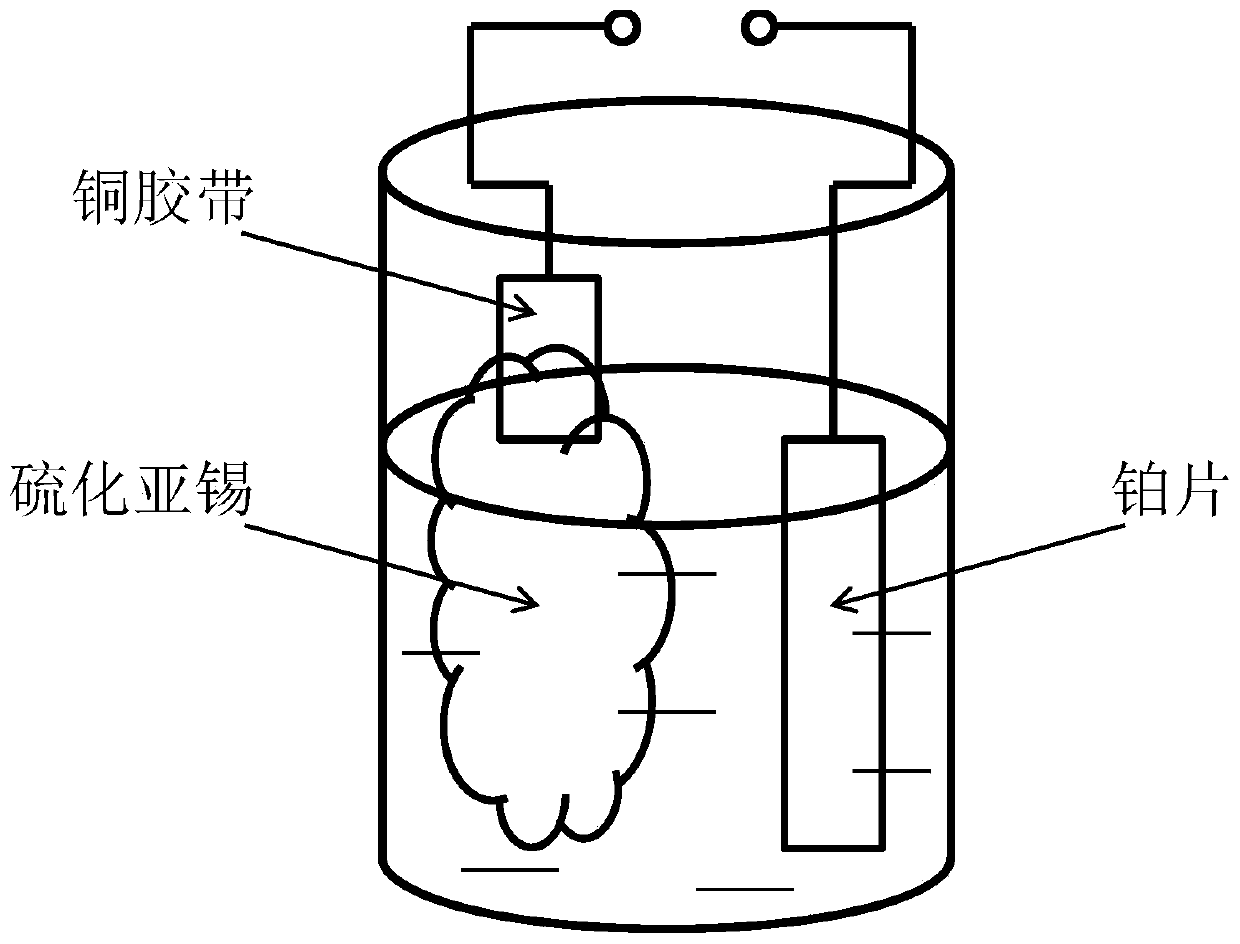

[0060] 3. If figure 1 As shown, the electrochemical exfoliation of stannous sulfide blocks by alternating cathode and anode

[0061] (1) Connect the stannous sulfide block to the electrode with conductive copper tape as the working electrode, and the pl...

Embodiment 2

[0084] Compared with Example 1, the only difference is that the dispersion solvent used in the ultrasonic process is isopropanol, and other conditions are the same. The obtained two-dimensional ultrathin Sn2S nanosheets have a current density of 11.7mA cm at -1.0V -1 , the faradaic efficiency of formic acid is 61.4%.

Embodiment 3

[0086] Compared with Example 1, the only difference is that the dispersion solvent used in the ultrasonic process is N-methylpyrrolidone, and other conditions are the same. The resulting two-dimensional ultrathin SnS nanosheets have a current density of 8.2 mA cm at -1.0V -1 , the faradaic efficiency of formic acid is 53.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

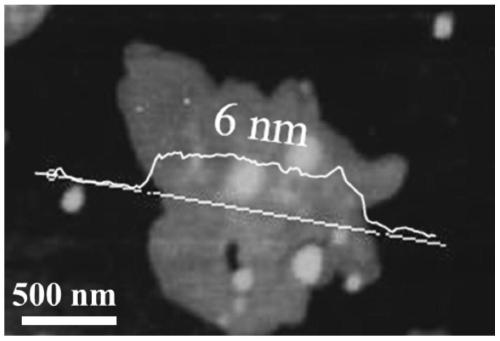

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com