Opening-and-closing-type steel rail flash welding joint normalizing induction coil

A welding joint and induction coil technology is applied in the field of normalizing induction coils of open-close rail flash welding joints, which can solve the problems of difficulty in penetrating the induction coil, damage to the inner wall of the coil, and easy damage of the sensor, so as to reduce the use cost and The operator's labor intensity, prolonging the service life, and not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

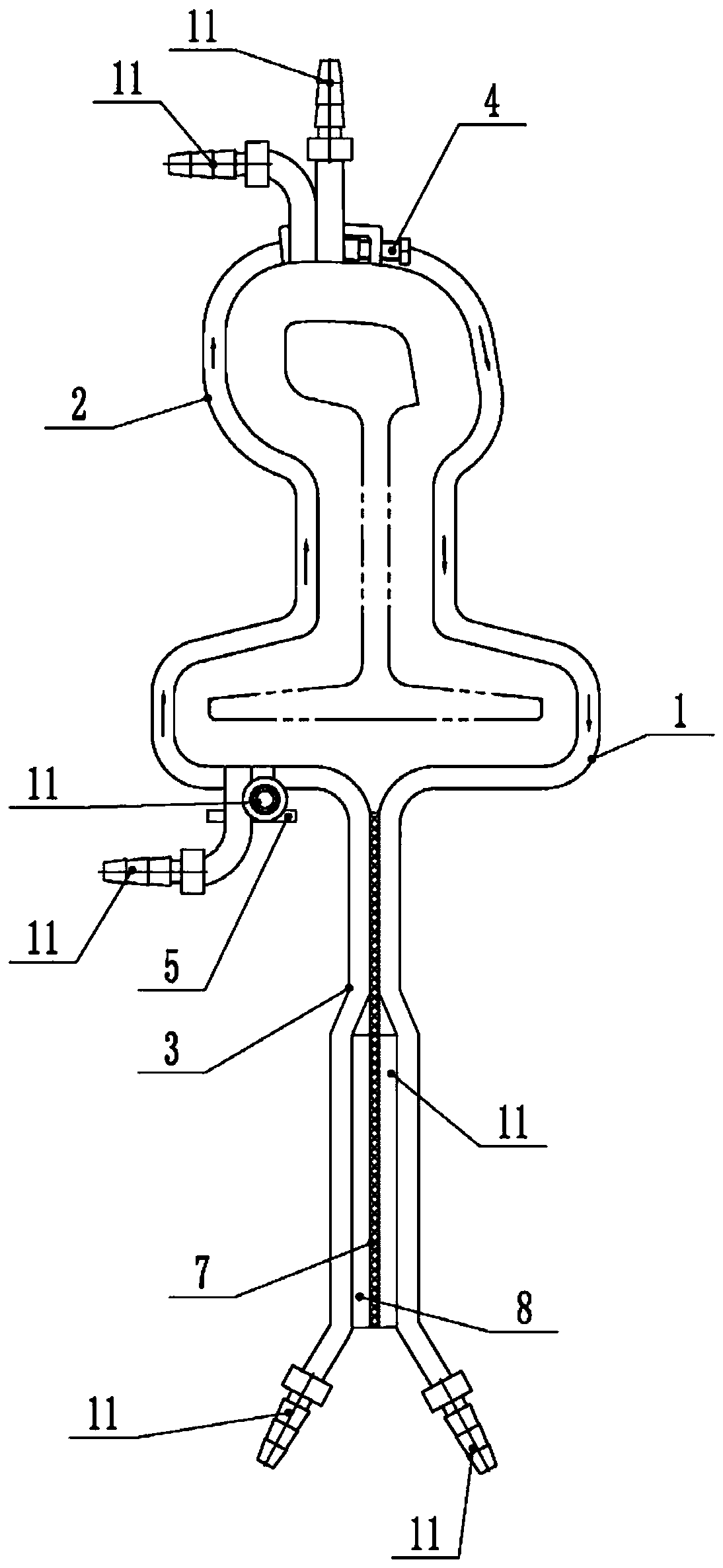

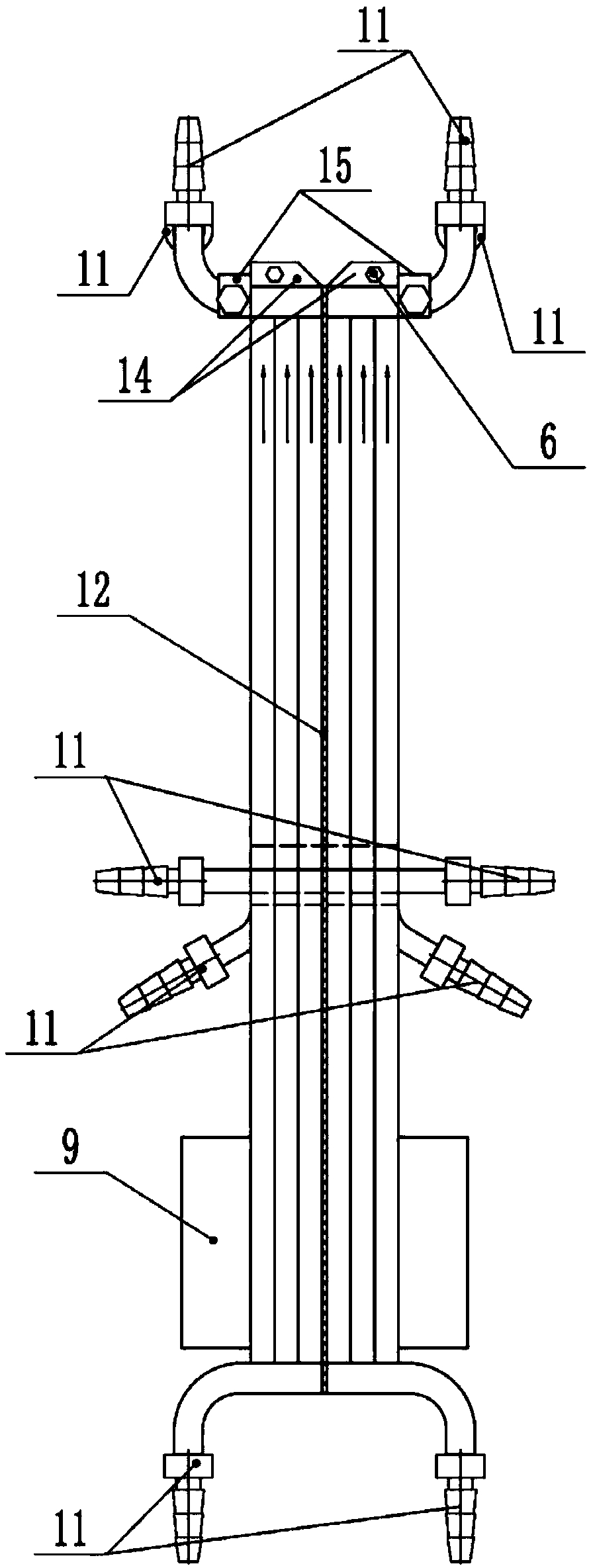

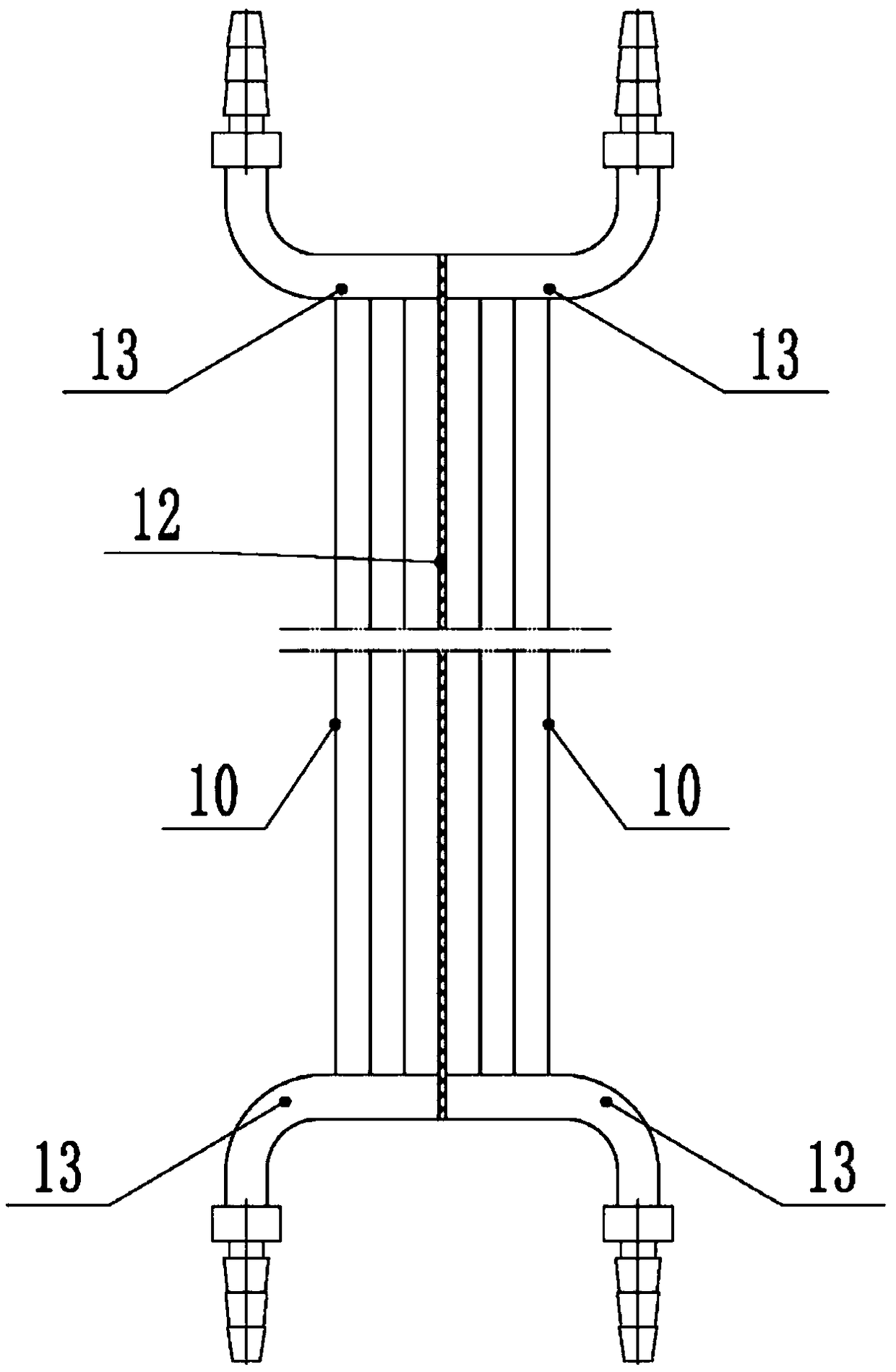

[0015] Attached below Figure 1-4 The present invention will be described in detail with specific embodiments.

[0016] A split-type rail flash welding joint normalizing induction coil, the induction coil is formed by connecting the right section 1, the left upper section 2, and the left lower section 3; the upper part of the right section 1 is bent to be right The upper left section 2 is bent into a shape that matches the left side of the rail joint; the upper end of the left upper section 2 and the upper end of the right section 1 are fixedly connected by a connecting device 4, and the left upper section The lower end of 2 and the upper end of the lower left section 3 are hingedly connected by a copper hinge 5, opening the connecting device 4 can make the left upper section 2 rotate to the left around the copper hinge 5; The lower side section 3 is horizontally bent toward the rail bottom of the rail joint, and after extending vertically downward from the middle of the rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com