Heat Treatment Method for Pinion Gears of Automobile Electric Steering System

A technology of electric steering system and heat treatment method, used in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of large differences in hardness, uneven matching of gear strength and toughness, etc., to achieve high uniformity and ensure tooth shape accuracy. and gear mechanical properties, the effect of solving the difference in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Please refer to figure 2 , image 3 and Figure 4 , a heat treatment method for a pinion gear of an automotive electric steering system, including the steps of charging, heating, quenching, and tempering in sequence.

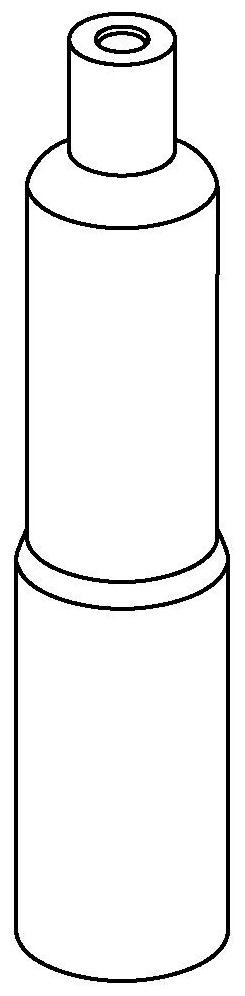

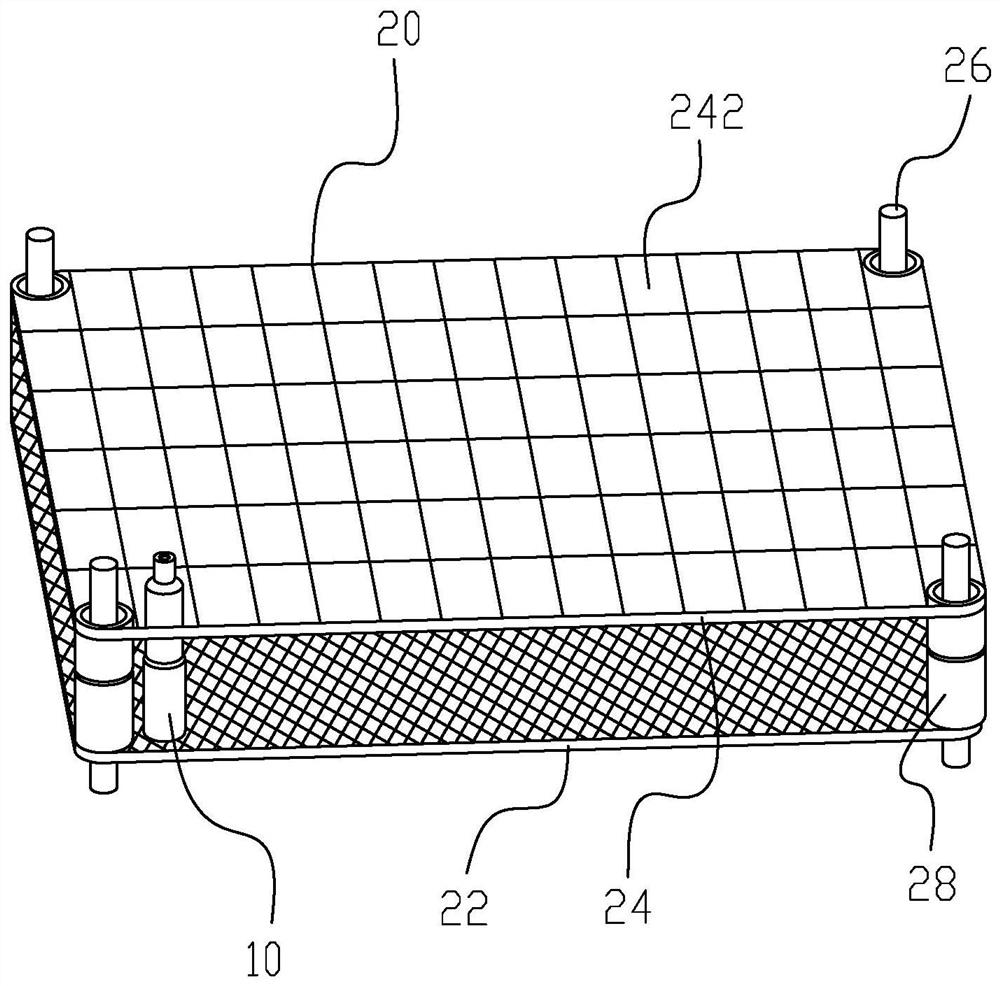

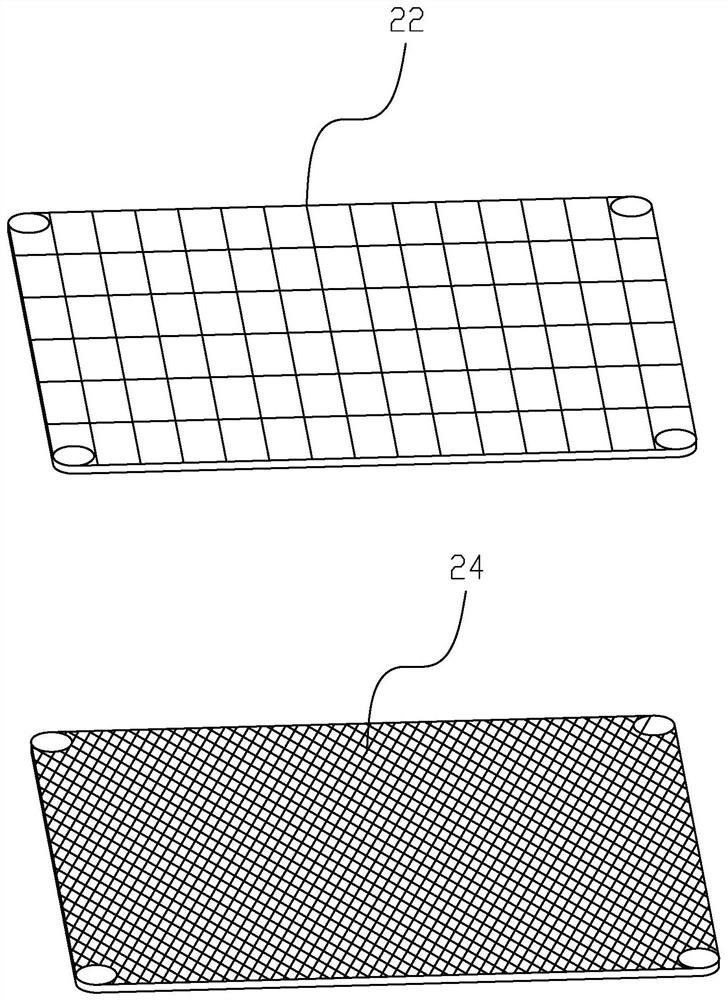

[0028] Loading step: the gear 10 is installed in the material basket 20, and the distance between the gears 10 and 10 is kept 1-5 cm. Preferably, the distance between the gears 10 is 2-3 cm. Preferably, the gear 10 is placed vertically with the big end facing down. Preferably, the material basket 20 includes a horizontally arranged loading mesh 22 and a horizontally arranged separating mesh 24, the gear 10 stands on the loading mesh 22, the separating mesh 24 is located above the loading mesh, and the separating mesh 24 Corresponding to each gear, there is a grid 242 to frame the gear 10, and the corresponding four corners of the loading mesh 22 and the separating mesh 24 are respectively connected in series with connecting rods 26, and the loading m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com