Open and closed chest soil pressure balance dual-mode single-shield TBM heading machine

A technology of earth pressure balance and roadheader, which is applied in earth drilling, mining equipment, tunnels, etc., can solve problems such as high construction risks and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

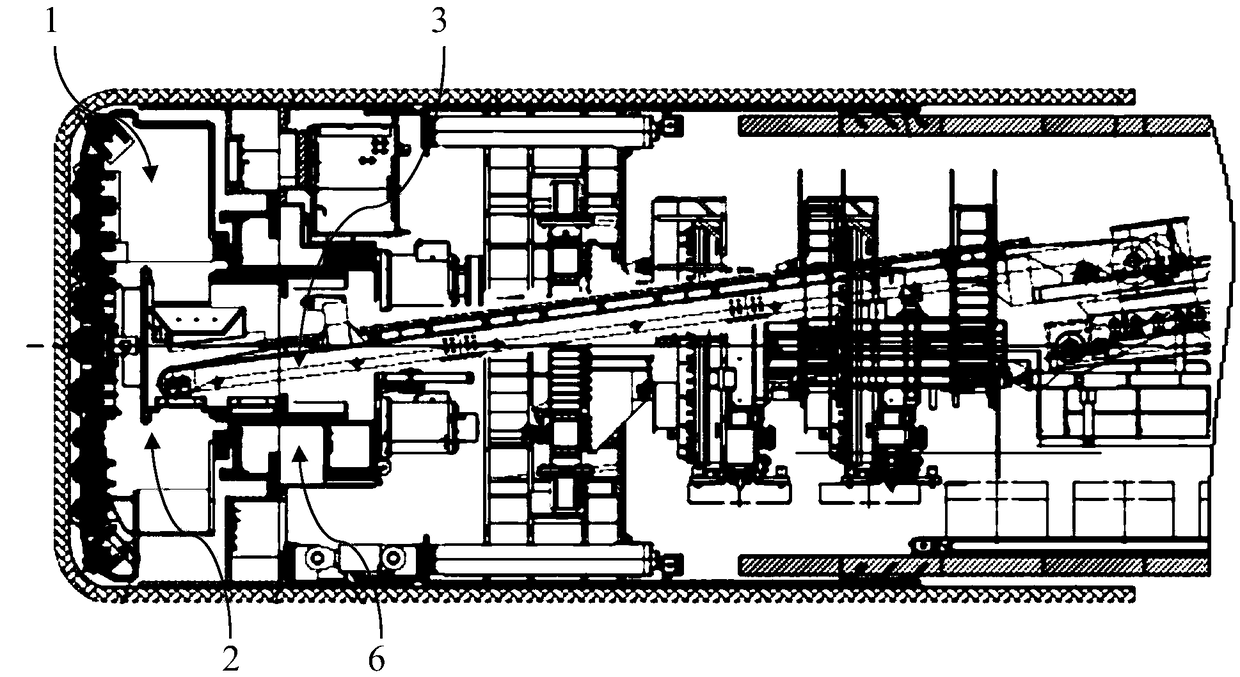

[0031] Such as figure 1 As shown, in the hard rock open mode, the conveying device 3 is a belt conveyor; wherein, during the shield excavation process, the soil collecting ring 2 is in the open state (such as Figure 5 As shown), the muck in the soil chamber 1 is discharged into the soil collection ring 2, and then transported to the auxiliary conveying device by the belt conveyor, and then the muck is discharged by the auxiliary conveying device. In the present invention, the soil tank 1 is in an open state (that is, a non-closed state) in the hard rock open mode.

Embodiment 2

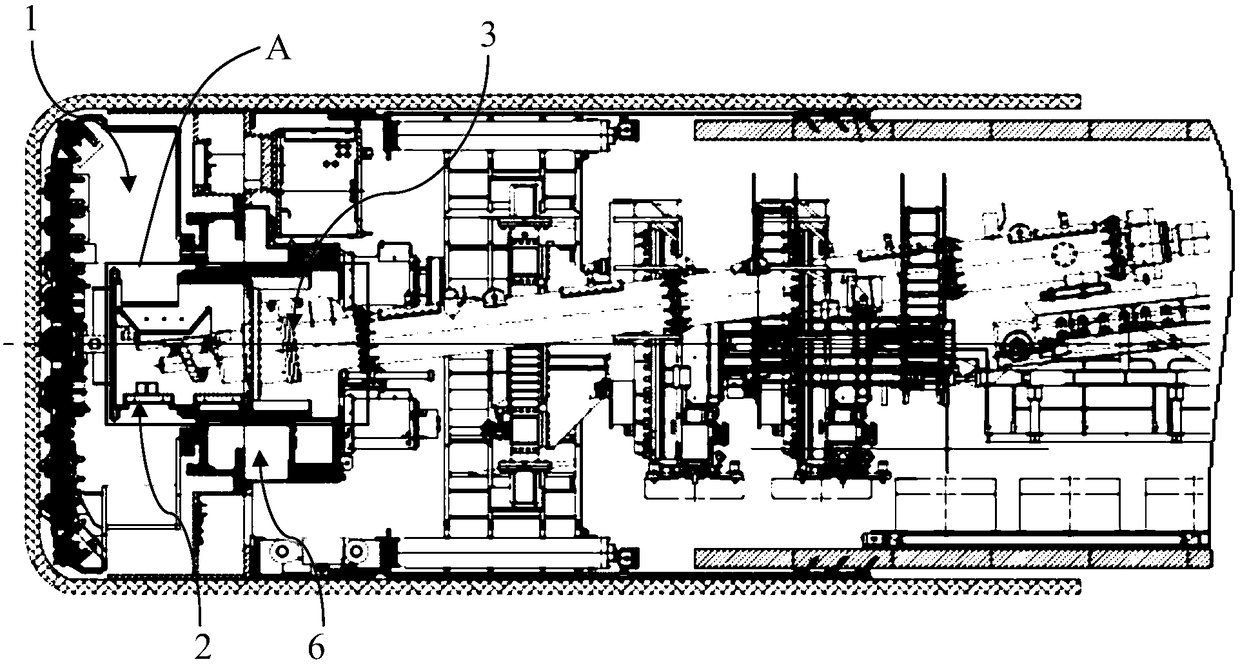

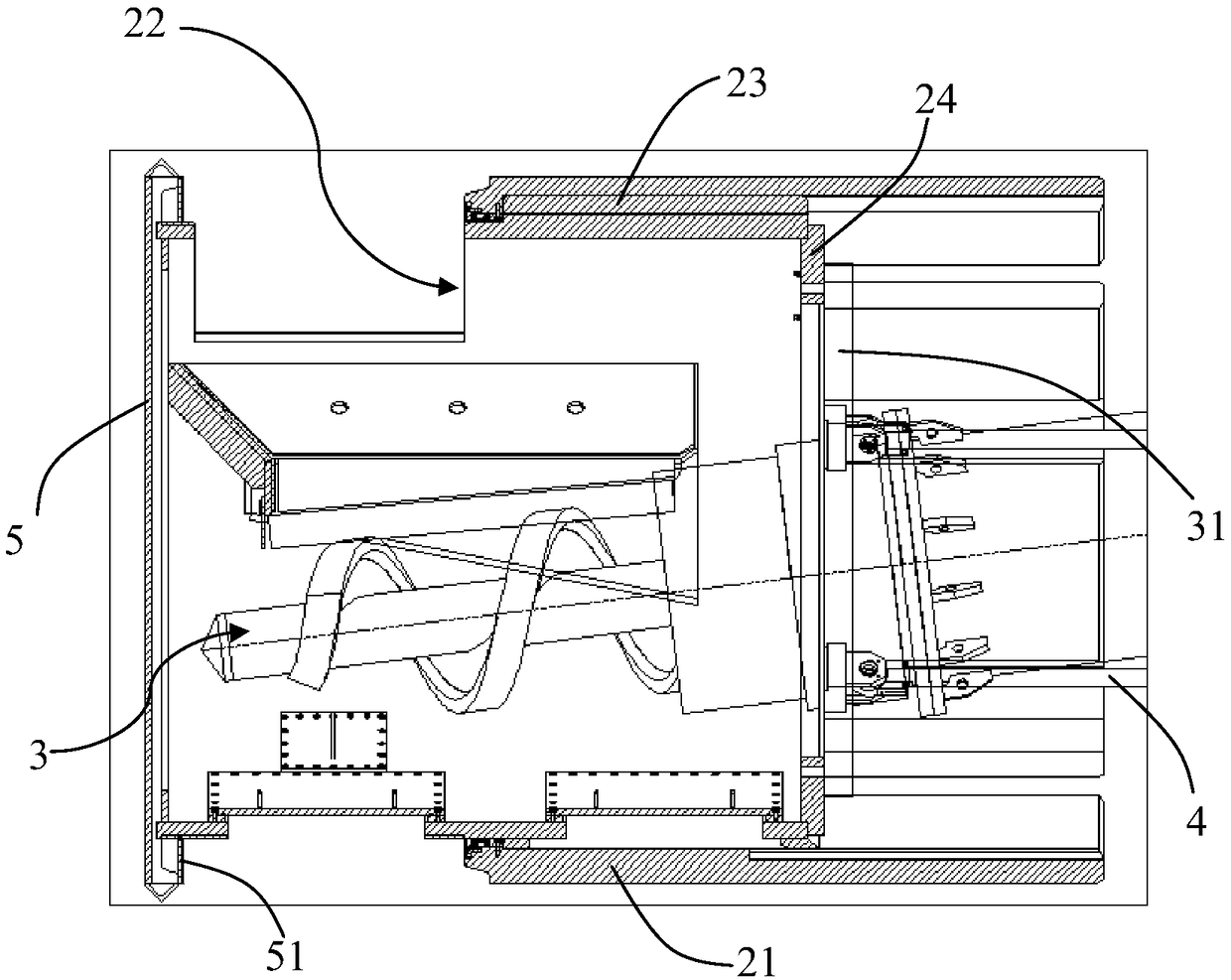

[0033] Such as figure 2 and image 3 As shown, in the closed-chest earth pressure balance mode, the conveying device 3 uses a screw machine; further, the screw machine is fixed to the cover plate 24 through the flange 31, and a through hole is formed in the middle of the flange 31, and the screw machine is inserted into the And be fixed in the through hole, the plate surface of the cover plate 24 is fixedly connected to the disk surface of the flange 31 . In this embodiment, the connection between the flange plate 31 and the cover plate 24 is used to ensure the tightness of the connection between the screw machine and the cover plate 24, thereby ensuring that the soil tank 1 is in a closed state. In the present invention, the cover plate 24 and the moving ring 22 are integrally formed (that is, the sealing connection between the cover plate 24 and the moving ring 22); a gasket is also provided between the cover plate 24 and the flange 31 to ensure that the cover plate 24 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com