Centrifugal stone removing grain dryer

A technology for grain dryers and drying towers, which is applied in the direction of centrifuges, non-progressive dryers, dryers, etc., which can solve the problems of single and simplified functions and poor drying effects, and achieve improved drying effects and simple structure , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

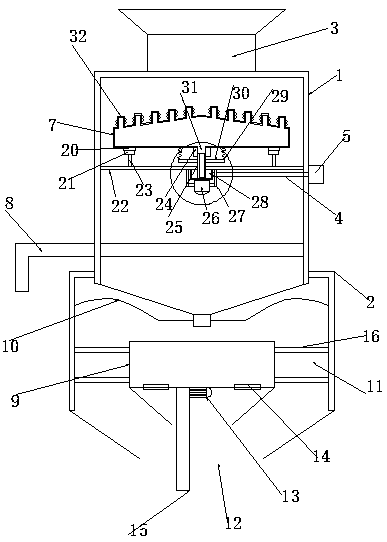

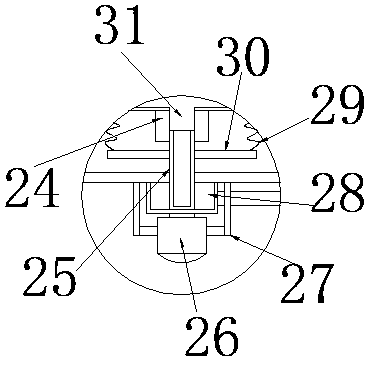

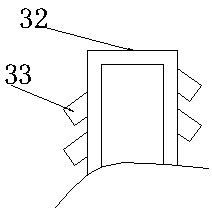

[0021] see Figure 1~4 , in the embodiment of the present invention, a centrifugal stone removal grain dryer, comprising a drying tower 1 and a stone removal equipment 2, said drying tower 1 and stone removal equipment 2, the top of the drying tower 1 is provided with a feed port 3 , one side of the drying tower 1 is connected to the hot air passage 4, and the right end of the hot air passage 4 is connected to the hot air blower 5, and the inside of the drying tower 11 is provided with a dispersed drying mechanism, which includes a drying plate 7 for drying The upper end surface of the disc 7 is a conical surface, and several dispersing columns 32 are evenly distributed on the conical surface. The inside of the drying disc 7 is provided with a buffer cavity, and the inner cavity of the dispersing column 32 is connected with the buffer cavity. Several jet pipes 33 are arranged, and the air outlet ends of the jet pipes 33 face the conical surface, and the air inlet 31 at the low...

Embodiment 2

[0031] The difference from Embodiment 1 is that the drying tray is made of metal material, which greatly improves its thermal conductivity and helps to dry materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com