A benchmark gear helical template

A technology of gear helix and helix, which is applied in the field of precision gear testing, can solve the problem that the first-grade precision gear helix sample manufacturing technology is still blank in China, and achieve the effects of structural symmetry, high processing accuracy, and quality balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

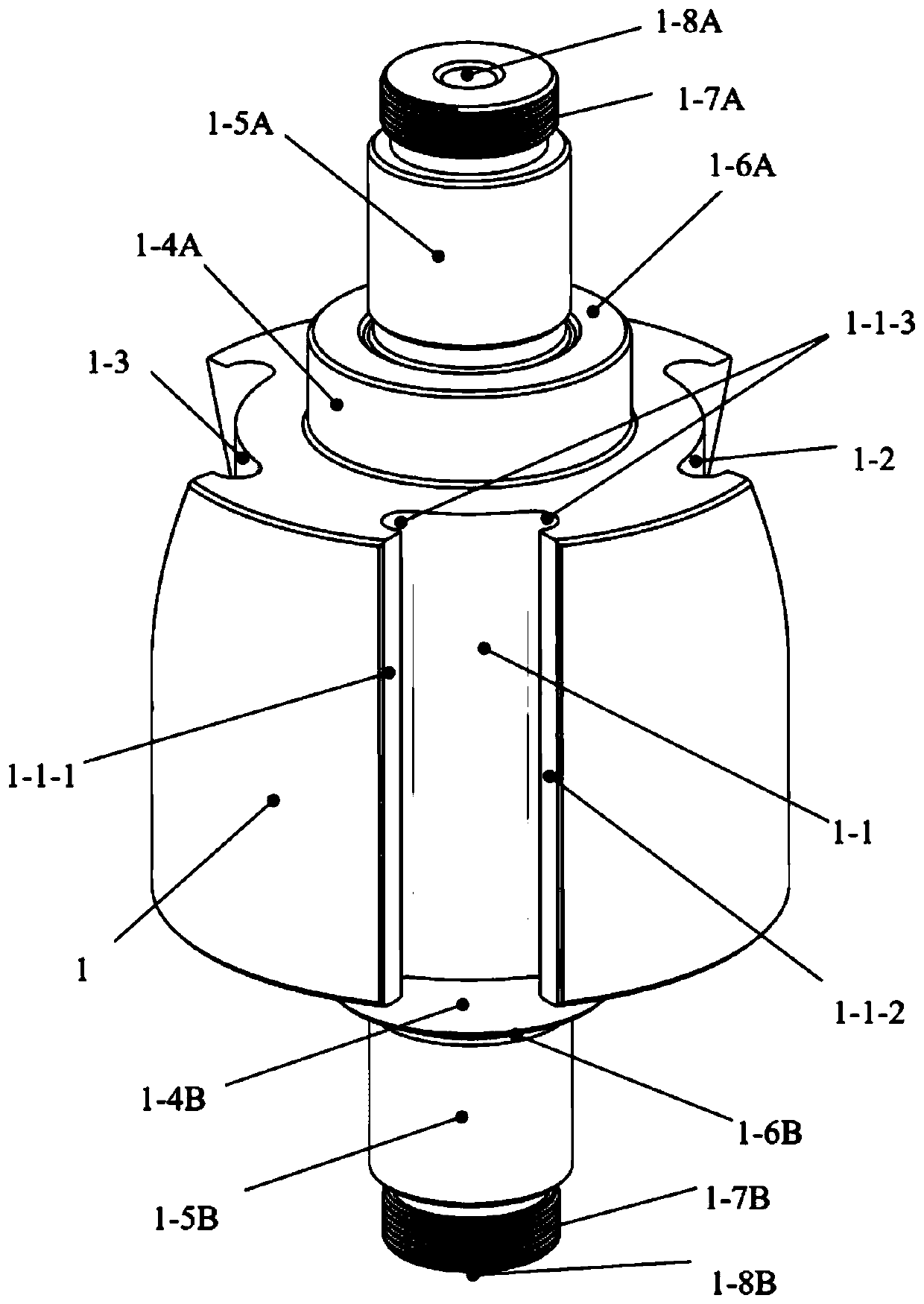

[0017] Taking the reference gear helical model 1 (hereinafter referred to as the model) with a pitch circle diameter of 120 mm and a tooth width of 100 mm as an example, the design ideas and structural features of the model are described.

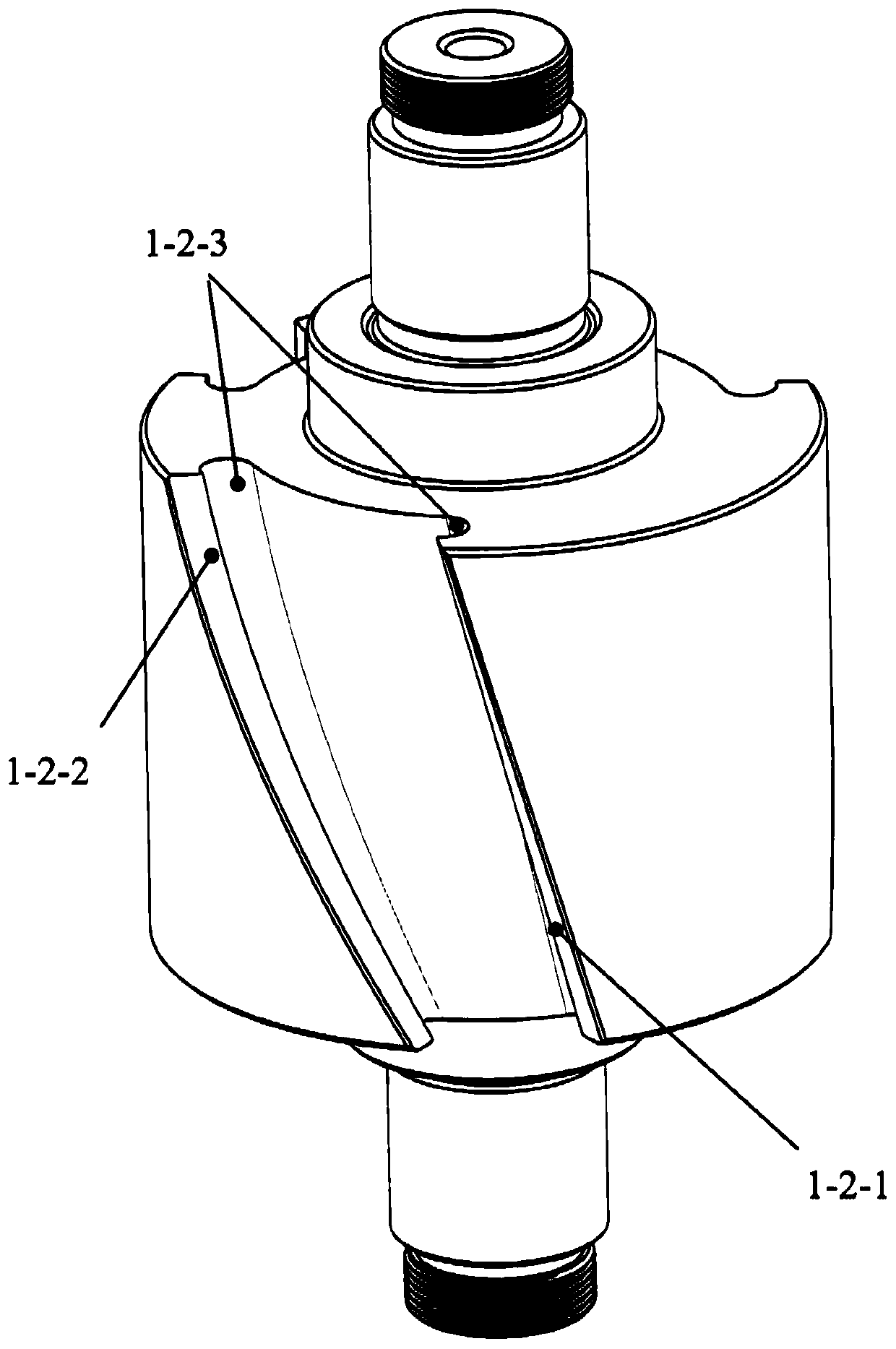

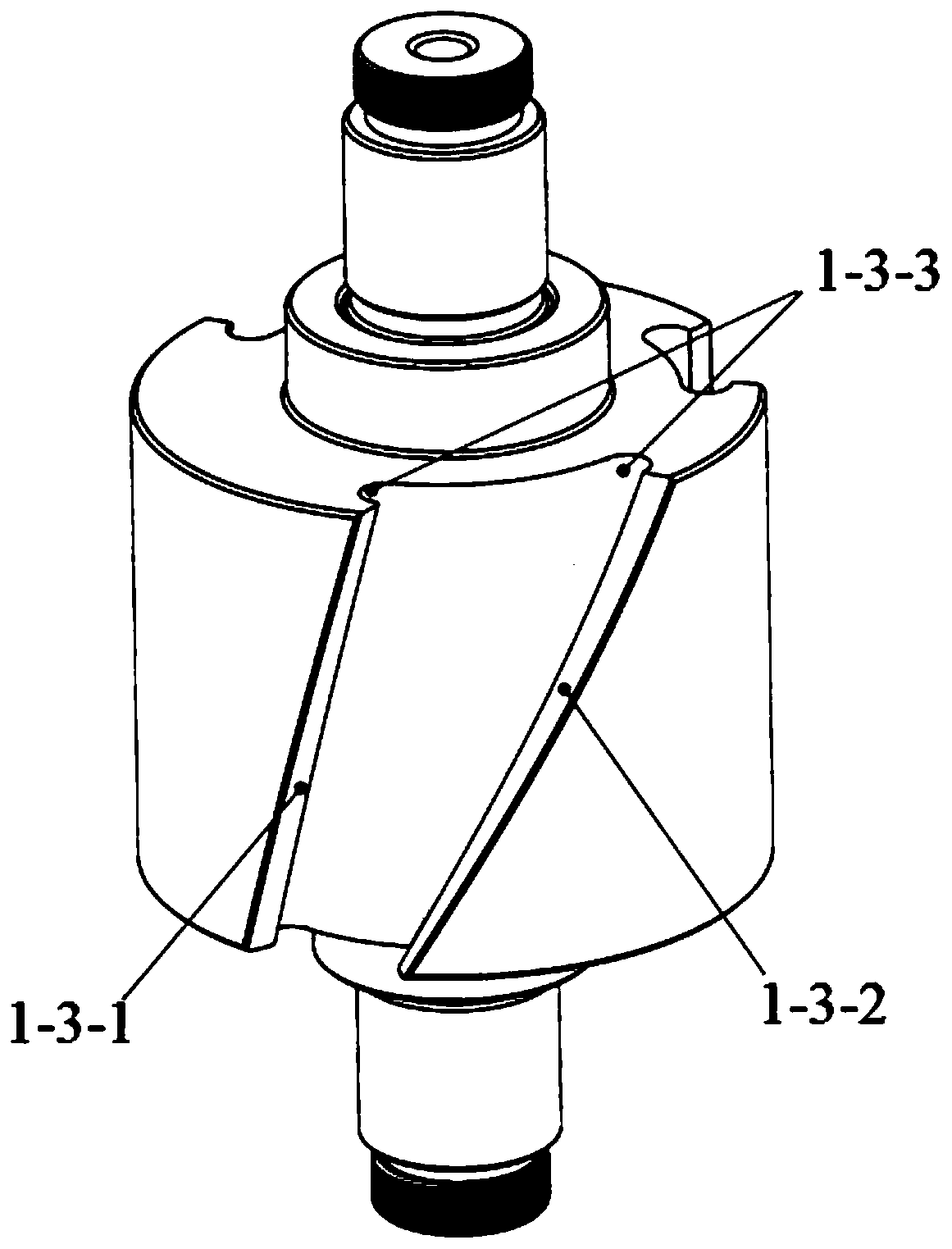

[0018] The maximum diameter of the outer circle of the model is set to 126mm, the involute cylindrical surface and the involute helical surface start from the base cylindrical surface, and the chamfer of the tooth top and tooth root is not greater than 0.5mm to ensure the development length of the involute. There are three tooth grooves processed on the outer cylindrical surface of the template, which are straight tooth groove 1-1, left-handed tooth groove 1-2 and right-handed tooth groove 1-3. Straight tooth grooves include one involute cylindrical surface with 0° helix angle, left-handed tooth grooves include one left-handed 15° and left-handed 30° involute helical surfaces, right-handed tooth grooves include right-handed 15° and right-han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com