Calibration method for detecting surface pressure of bolted joint surface based on fbg sensor

A calibration method and sensor technology, applied in the direction of measuring fluid pressure, fluid pressure measurement using optical methods, and measurement of the change force of optical properties of materials when they are stressed, can solve the problems of cumbersome calibration process and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. The described specific examples are only for explaining the present invention, and are not intended to limit the present invention.

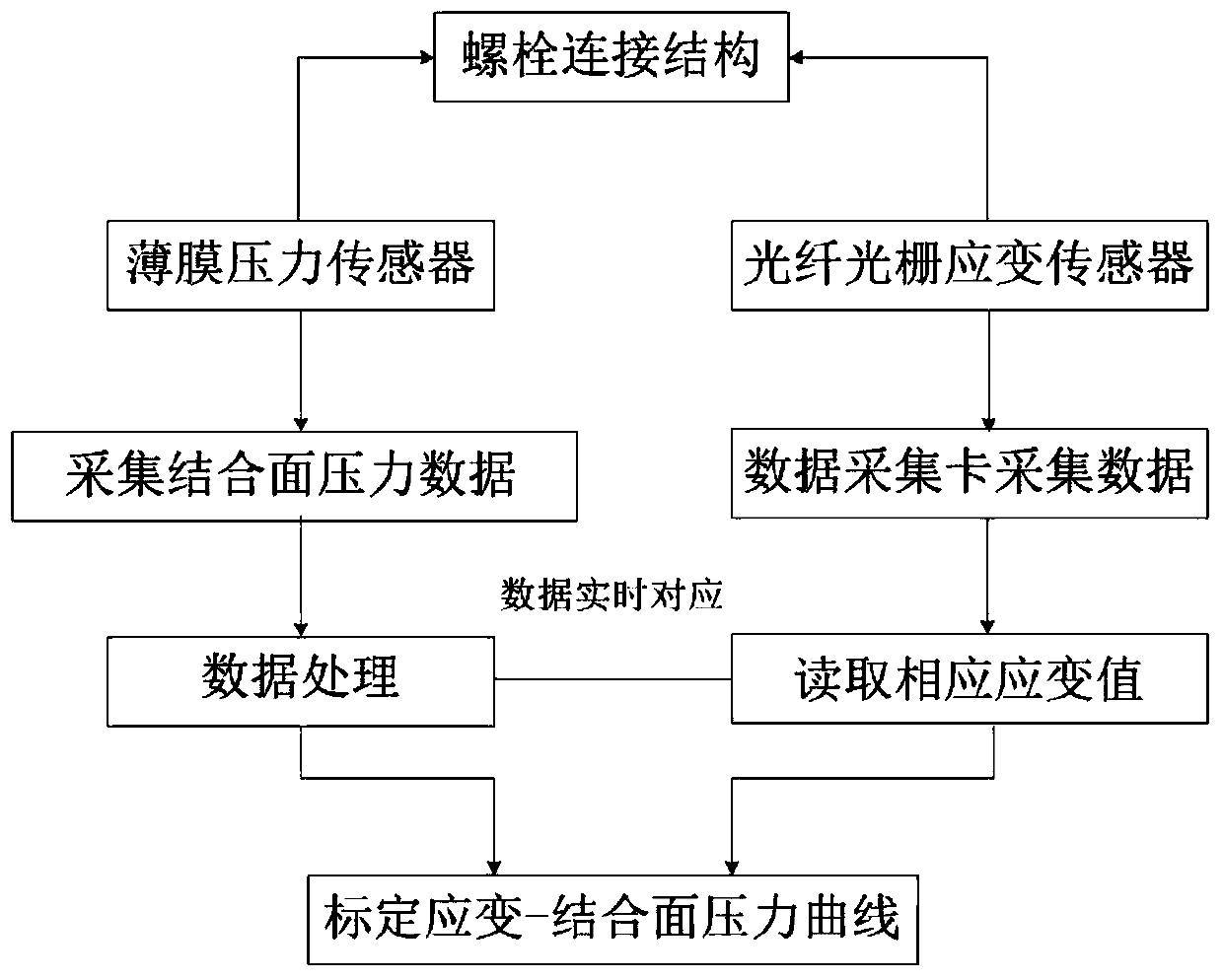

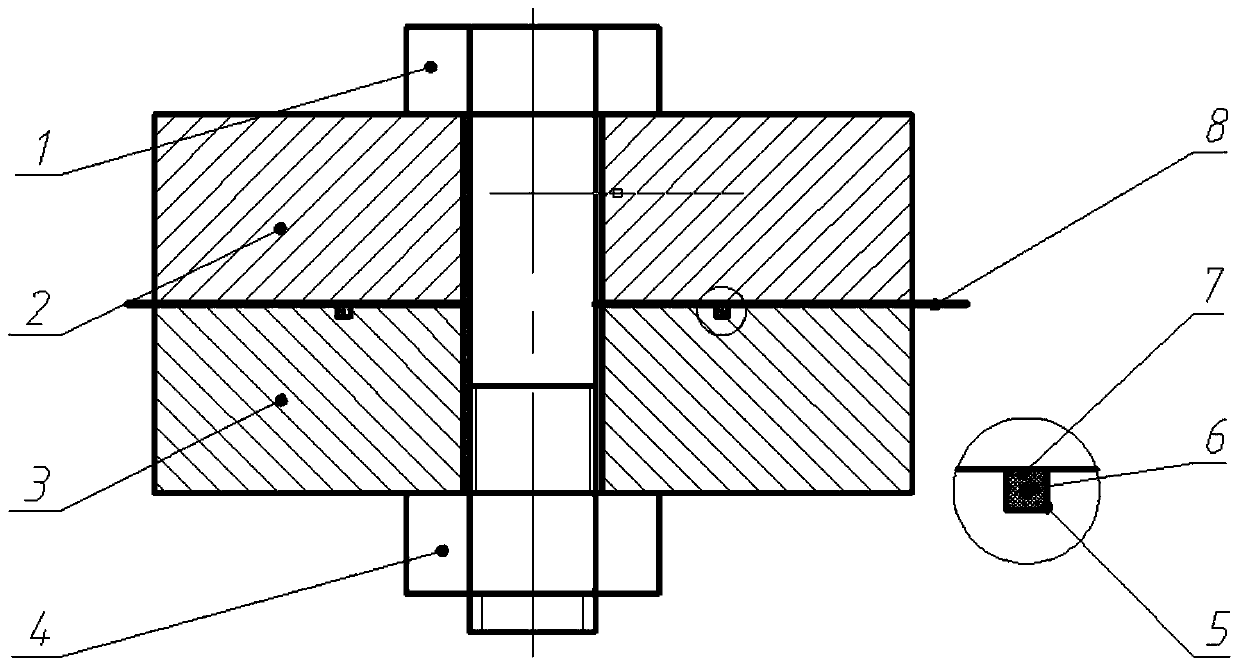

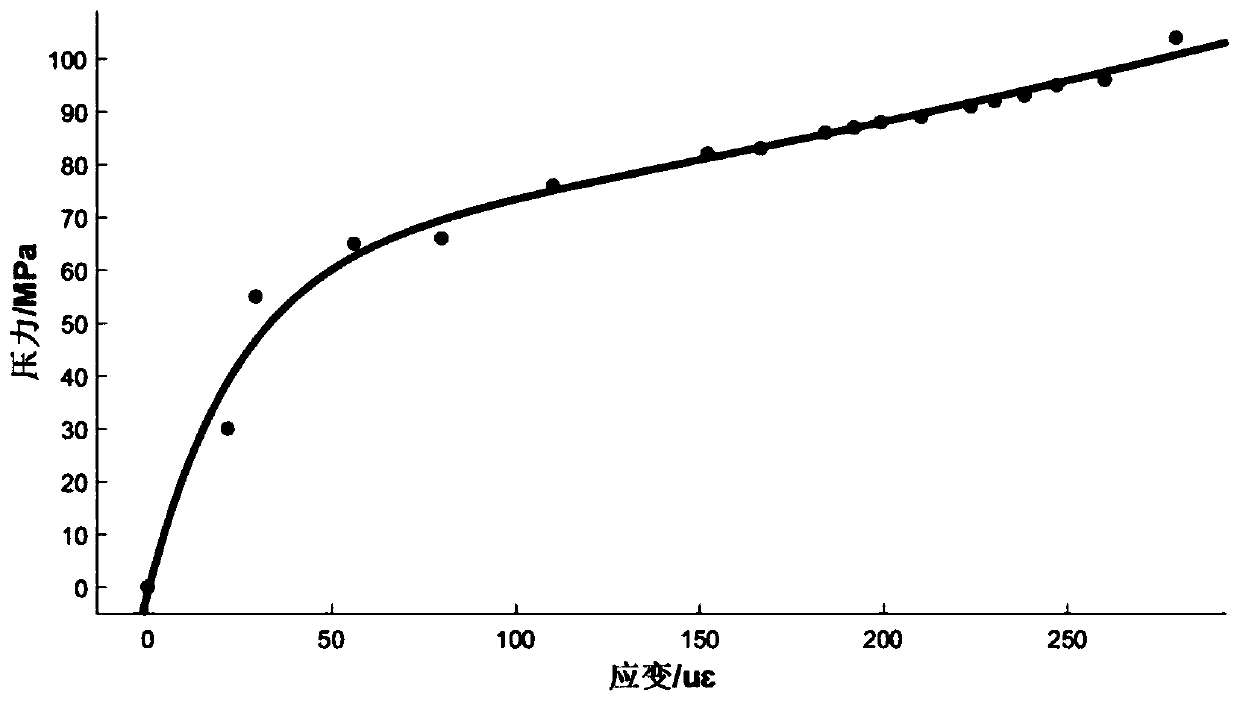

[0032] The calibration principle of the present invention is as attached figure 1 As shown, based on the characteristics of fiber gratings and the principle of FBG sensors, the FBG sensor is embedded in the connected part: a reasonable embedding groove is opened on the surface of the connected part, and it is embedded in the connected part according to the fiber grating packaging process. It is used to measure the strain value at the joint surface of the connection; at the same time, it is combined with a thin-film pressure sensor and placed between the connected parts to measure the pressure value at the joint surface of the bolt connection. The two sensors feed back in real time u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com