Fine adjustment device, detection system and detection method used for ray non-nondestructive detection

A non-destructive testing and fine-tuning device technology, applied in measurement devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of deviation from the ideal rotation center, inconvenient operation, low efficiency, etc., and achieve the effect of improving detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

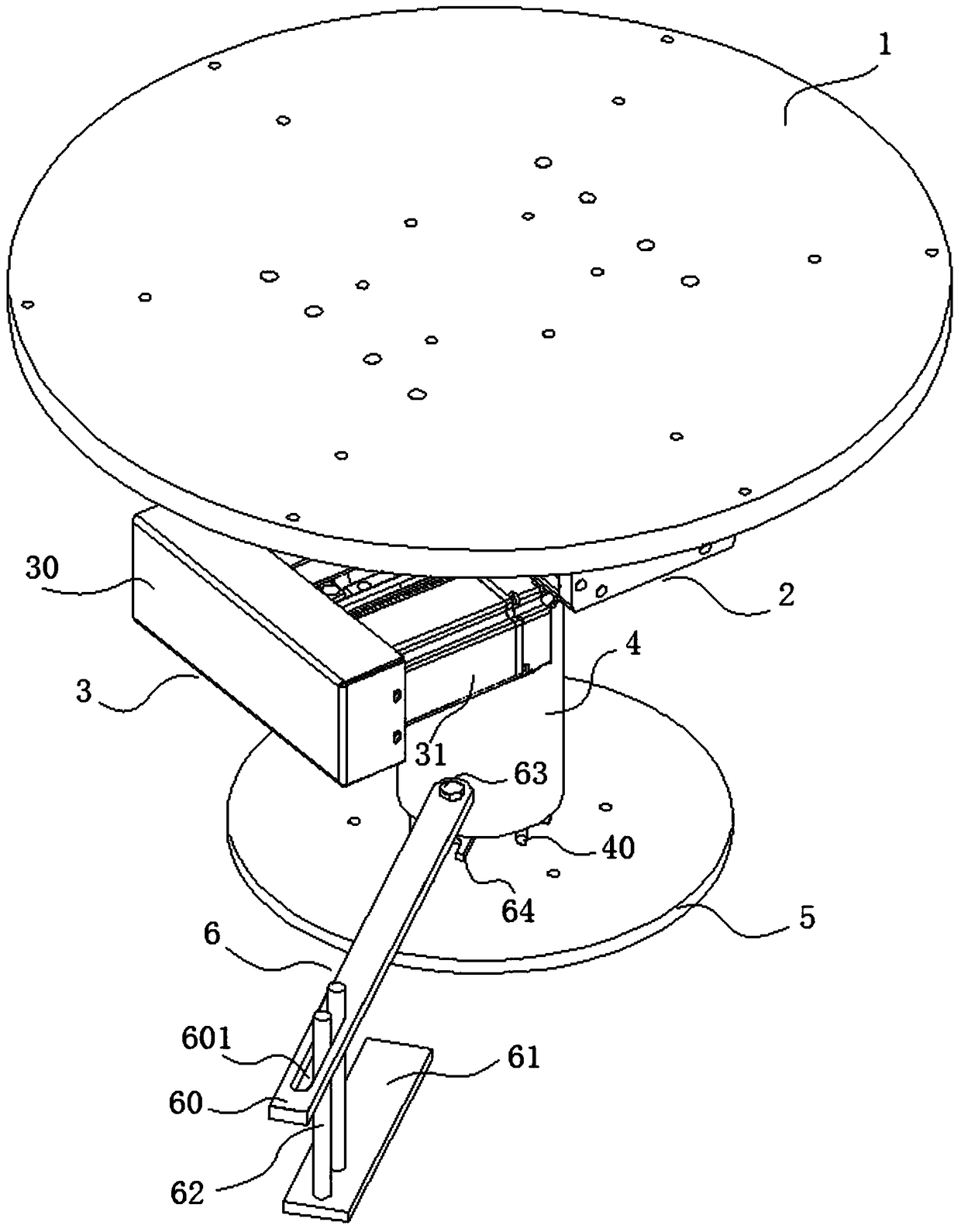

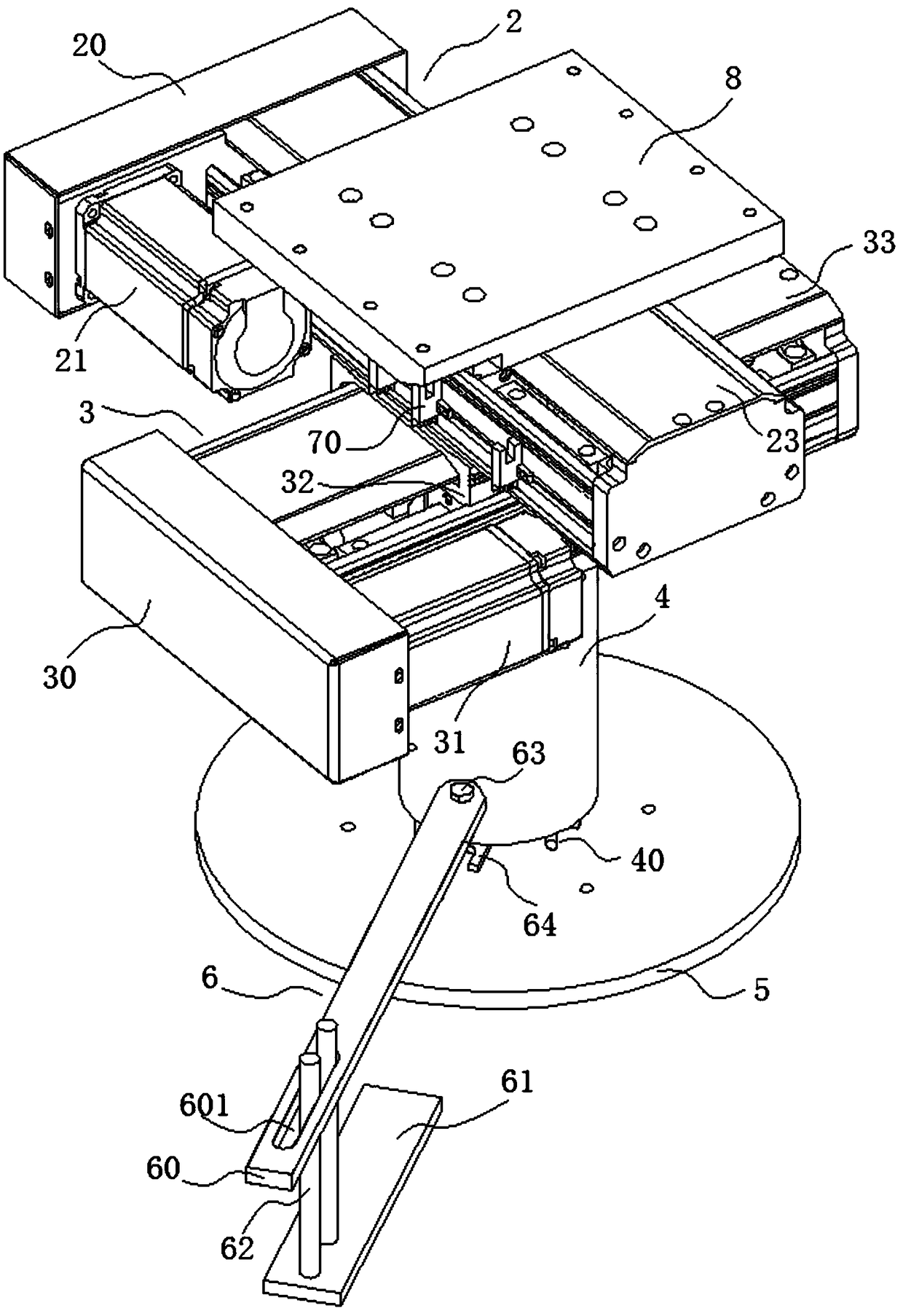

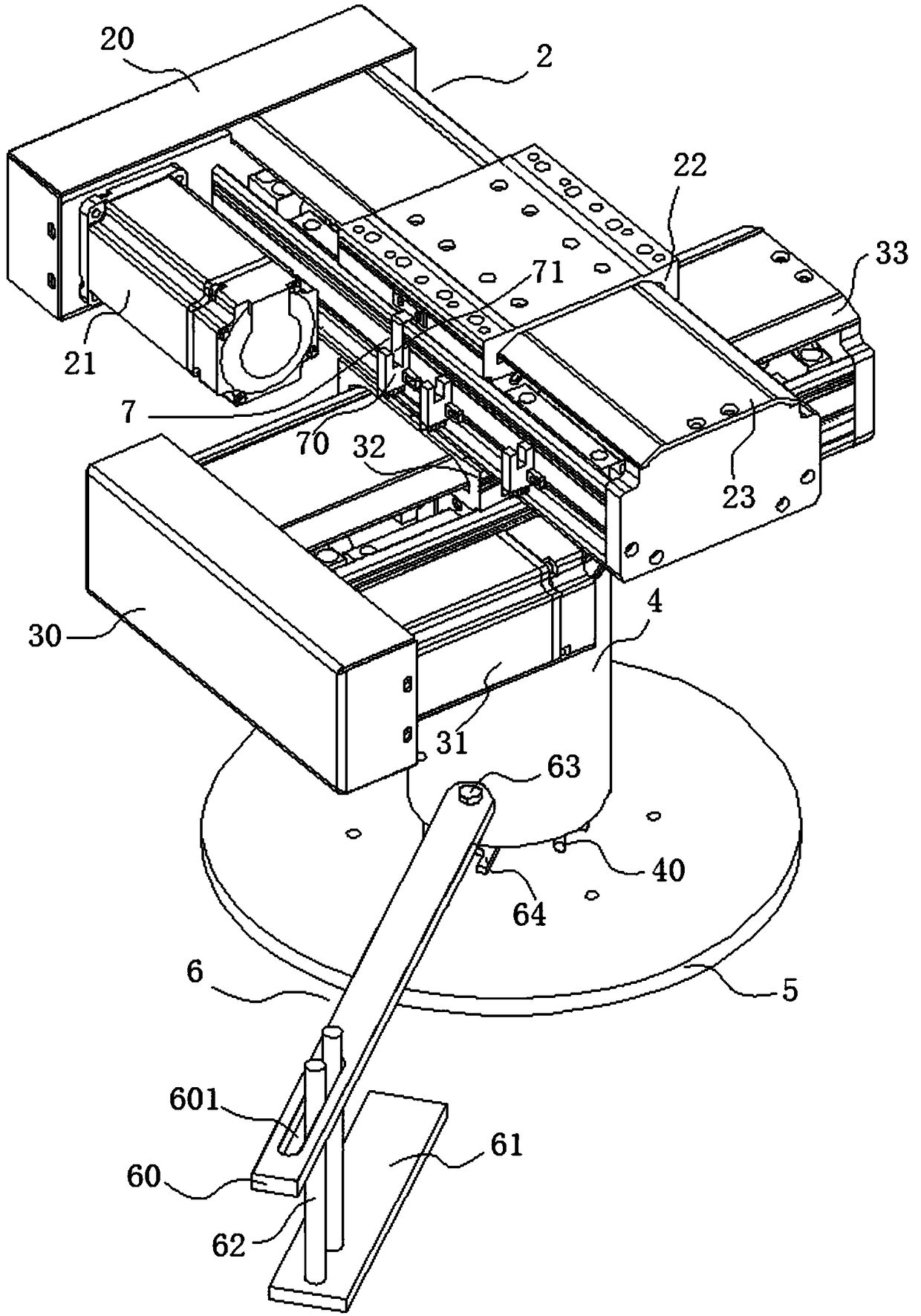

[0031] like Figure 1 to Figure 5 As shown, this embodiment provides a fine-tuning device for ray nondestructive testing, and a fine-tuning device for ray non-destructive testing, including: a stage 1 for placing an object to be inspected; an X-axis fine-tuning mechanism 2, Connected to the lower end of the stage 1, used to move the stage 1 along the X-axis direction; The position of stage 1.

[0032] Specifically, in this embodiment, a fine-tuning device for ray non-destructive testing is added to the existing industrial CT equipment, and an intelligent PLC control program is added on the basis of the existing industrial CT control system. There is a one-key reset button, an anti-misoperation button, etc., the position of the object to be inspected is adjusted by a fine-tuning device; it ensures that the operator is convenient, fast and error-free during operation. The control panel is located in the inspection room, away from the radiation area of industrial CT. The runn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap