Acoustic-electric dual-mode measurement method for oil-gas-water three-phase flow separation phase velocity

A measurement method, oil-gas-water technology, applied in fluid velocity measurement, velocity/acceleration/impact measurement, measurement device, etc., can solve the problem of different Doppler frequency shift, etc., and achieve the effect of high speed, low cost and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the drawings.

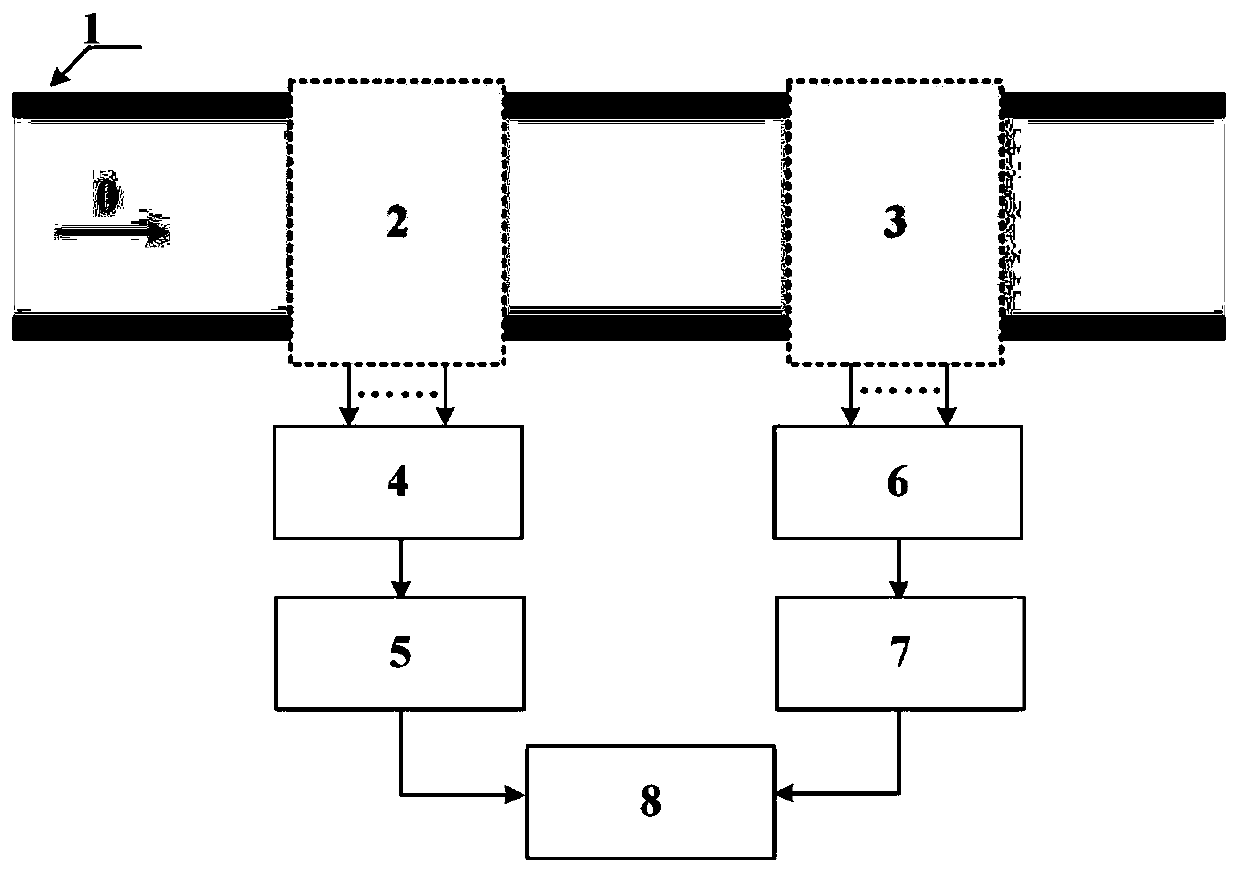

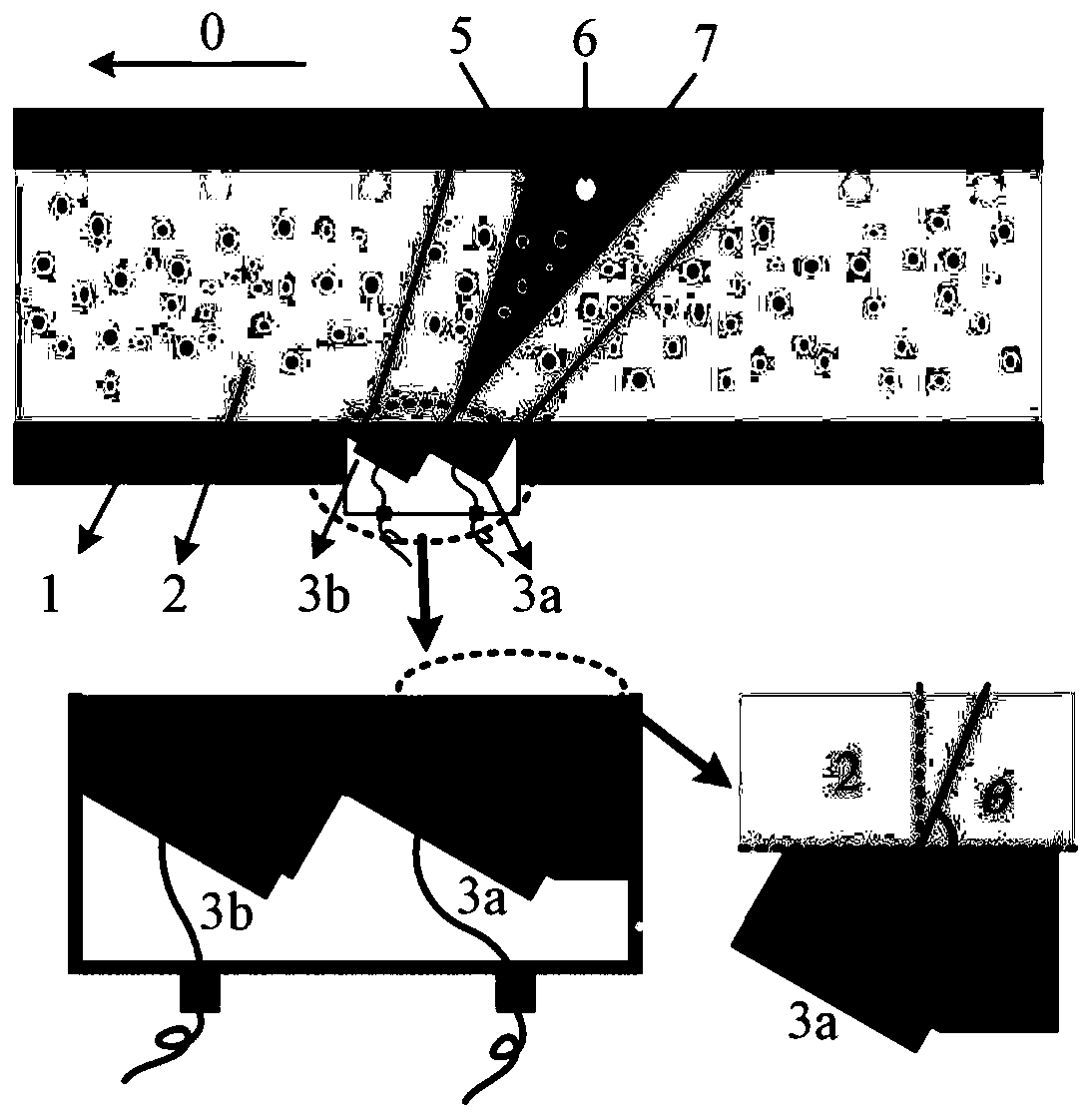

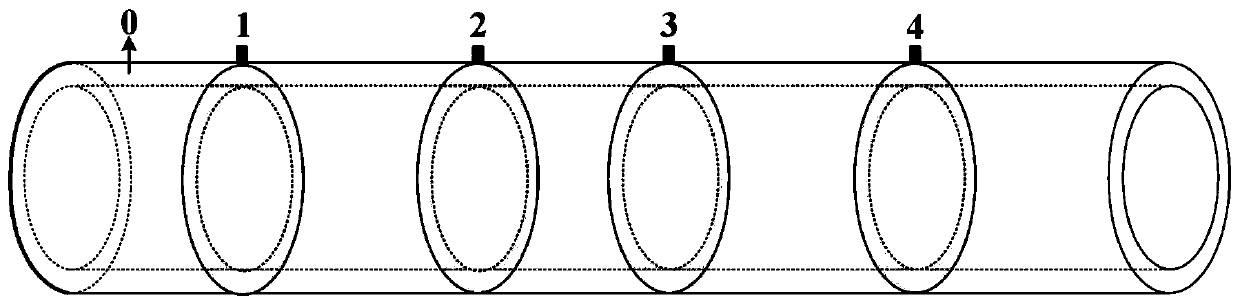

[0030] figure 1 It is a structural schematic diagram of the ultrasonic and electrical dual-mode measurement system in the measurement method of the present invention. The electrical sensor is described by taking a conductance ring sensor as an example. The measurement system consists of a group of electrical sensor arrays 2 installed on the experimental pipe section 1 and an electrical signal generation and acquisition unit 4 connected thereto, a group of ultrasonic sensor arrays 3 and an ultrasonic signal generation and acquisition unit 6 connected thereto. The electrical sensor array 2 is composed of four ring-shaped metal electrodes embedded in the inner wall of the pipeline at certain intervals; the ultrasonic sensor array 3 is composed of a group of dual-crystal ultrasonic transducers with integrated transceiver installed on the same side of the pipeline. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com