Acoustic-electric dual-mode measurement method for gas-liquid two-phase bubbly flow velocity

A measurement method and bubbly flow technology, applied in fluid velocity measurement, velocity/acceleration/impact measurement, measurement device, etc., to achieve the effects of high speed, low cost and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The calculation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

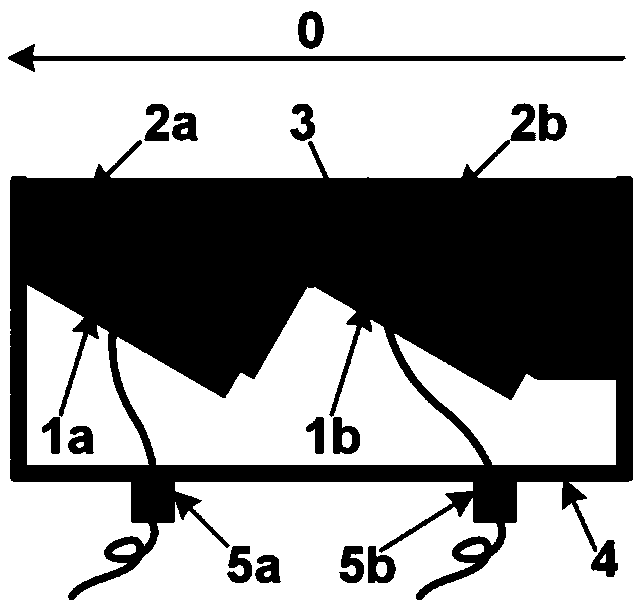

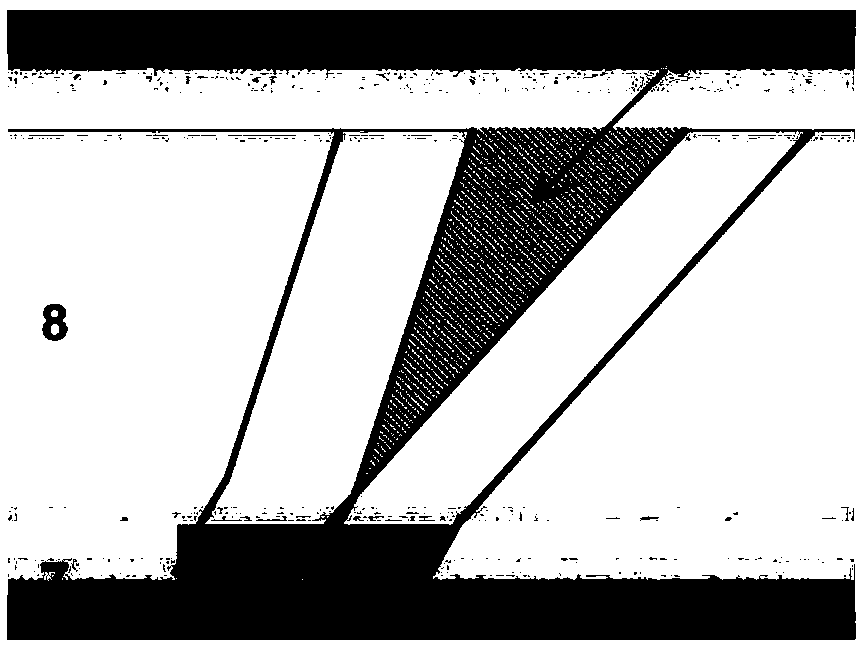

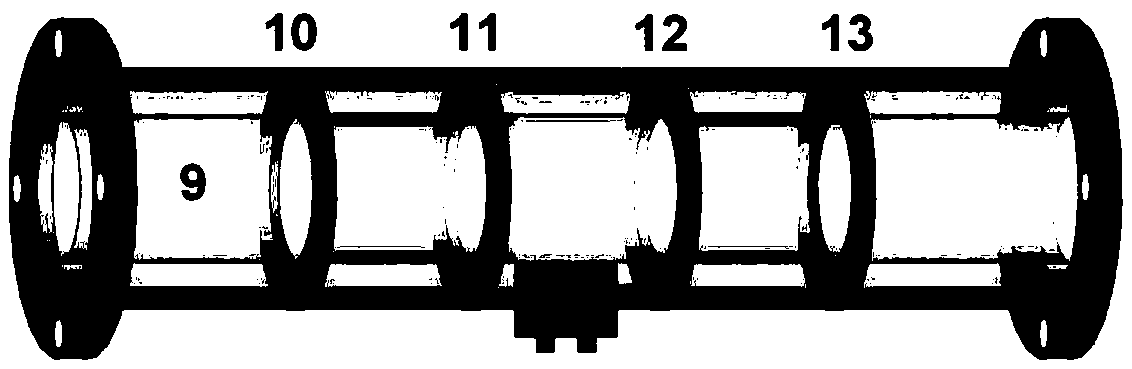

[0024] figure 1 It is a schematic diagram of the structure of the dual-crystal ultrasonic transducer in the measurement method of the present invention. The dual-crystal ultrasonic transducer used in the patent of the present invention includes a receiving piezoelectric ceramic chip 1a and a transmitting piezoelectric ceramic chip 1b, both of which are obliquely attached to acoustic coupling materials 2a and 2b cut into fixed geometric shapes. Between the two parts, a soundproof material 3 is placed to prevent mutual interference of sound waves. The inclination angle of chips 1a and 1b needs to ensure that the included angle between the normal direction of the plane where the chips are located and the incoming flow direction 0 is θ. A metal shell 4 is installed on the outermost side to protect the whole dual crystal transducer. The line i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com