MT optical fiber micro connector and processing method of MT optical fiber micro connector

A processing method and connector technology, which is applied in the field of MT optical fiber micro connector processing and MT optical fiber micro connector, can solve problems such as large optical fiber stress, optical fiber breakage, and optical fiber breakage, and achieve the effect of protecting optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

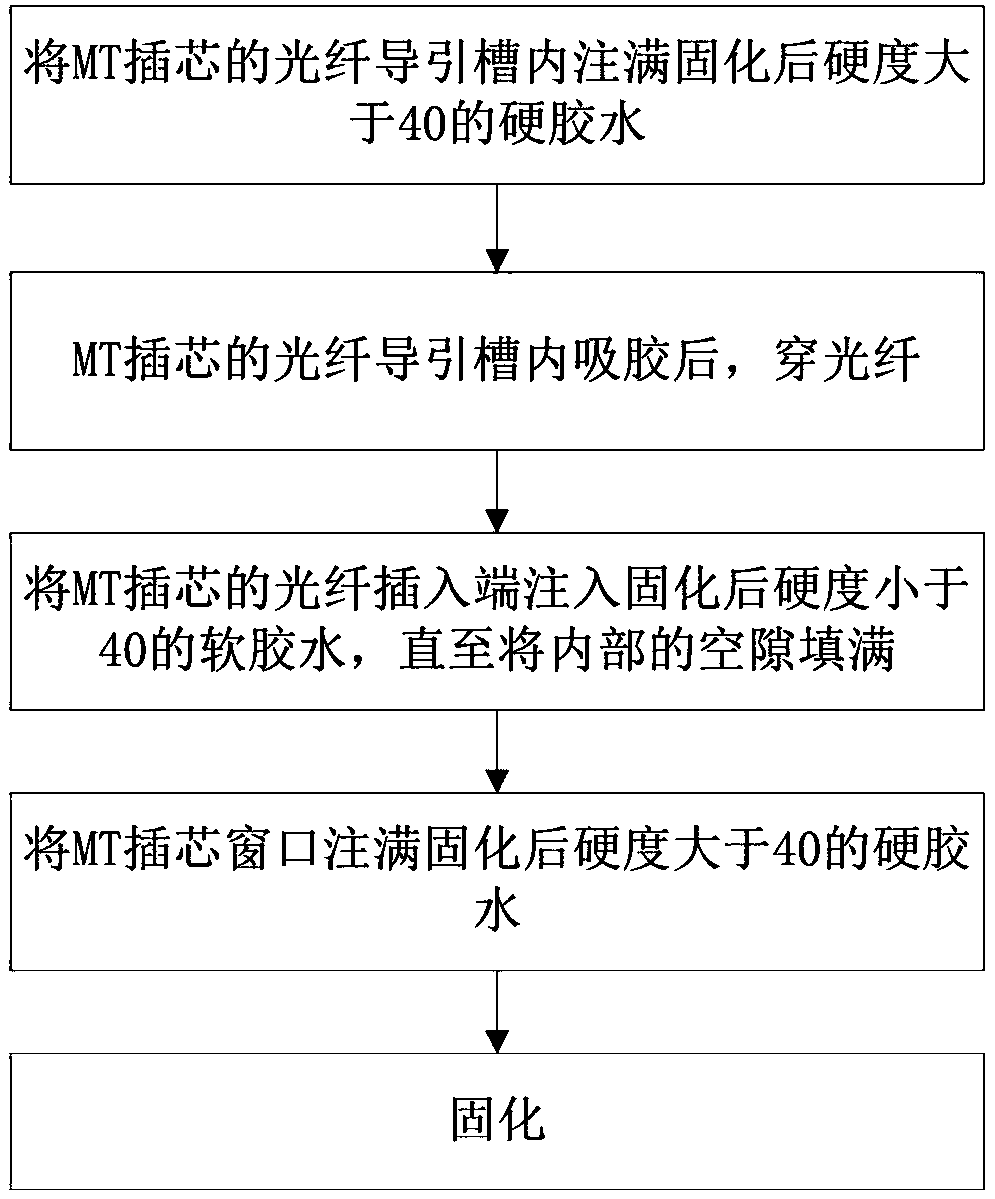

[0023] Such as Figure 1-Figure 3 As shown, the MT optical fiber micro connector processing method of the present invention comprises the steps:

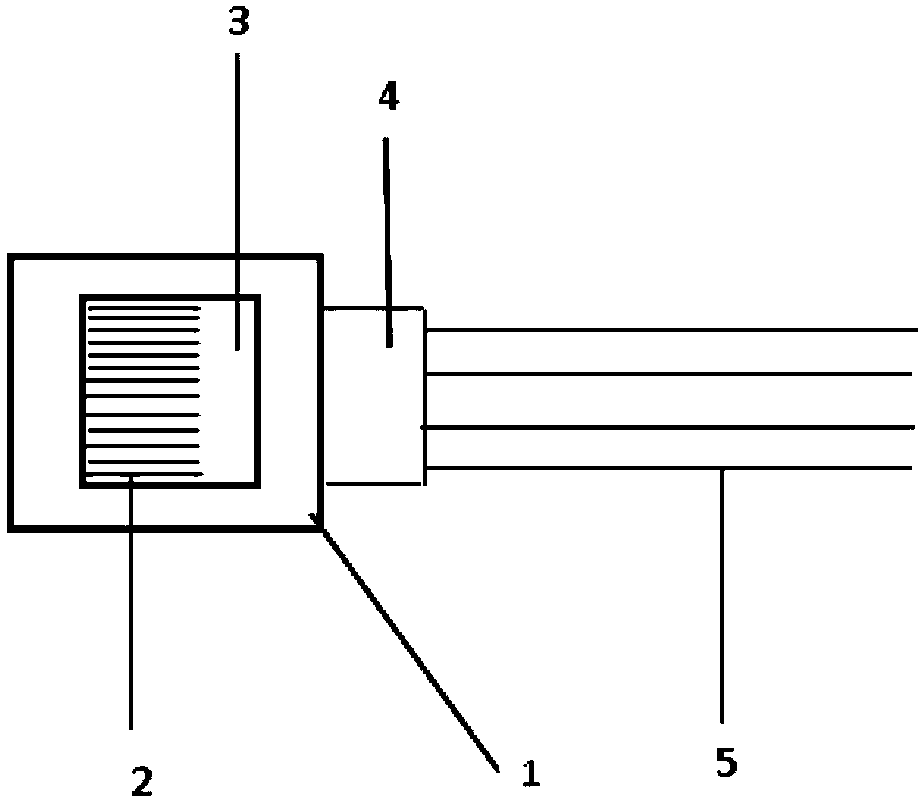

[0024] S1: Fill the optical fiber guide groove 2 on the step of window 3 of MT ferrule 1, that is, the first glue injection position 6, with 353ND glue. The 353ND glue is hard glue with a hardness greater than 40 after curing, and it can also be used for other Special hard glue, such as epoxy resin glue, structural glue, etc.

[0025] S2: After absorbing glue in the fiber guide groove 2 of the MT ferrule, pass the fiber 5;

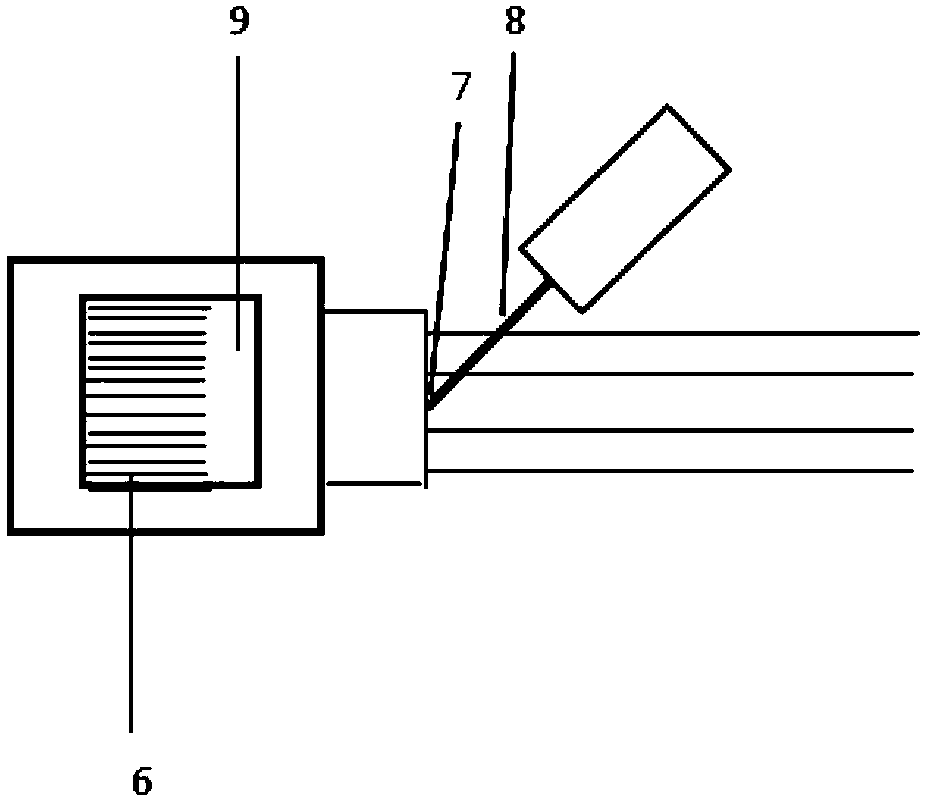

[0026] S3: After threading the optical fiber 5, inject soft glue with a hardness less than 40 after curing into the boot tail of the MT ferrule, that is, the fiber insertion end 4, put the needle 8 into the soft glue injection position 7 at the boot tail and inject until the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com