Overall structure of thermal automation system of thermal power plant

An automation system, a technology for thermal power plants, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the problem of few functional applications, the failure of effective mining and utilization of massive operating data of units, and the lack of thermal power plants. Thermal automation system overall architecture design and research issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0035] Example.

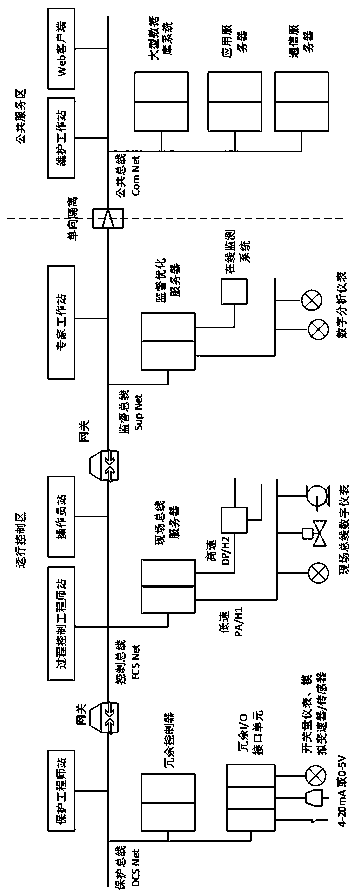

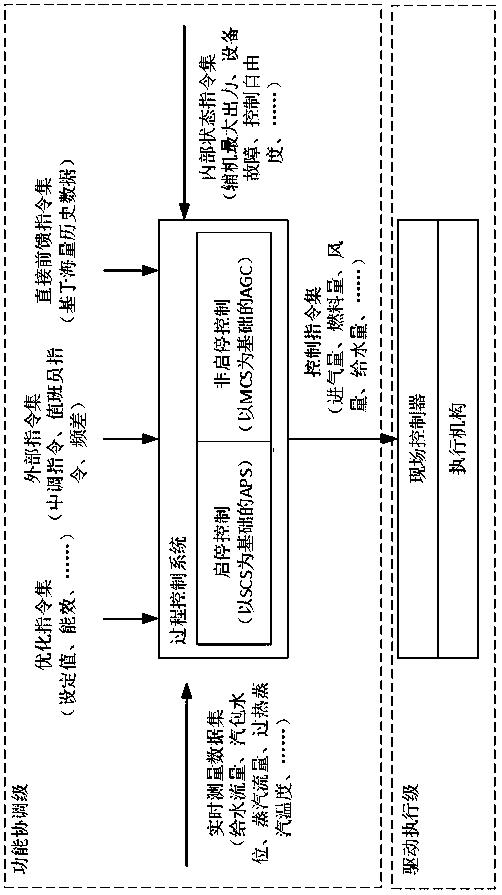

[0036] The overall architecture of the thermal automation system of a thermal power plant consists of four parts, which are measurement communication, equipment protection, process control, and supervision optimization. The overall architecture is as follows: figure 1 As shown, it is mainly aimed at the thermal automation system in the operation control area, and the public service area refers to the enterprise information system architecture.

[0037] 1. Measuring communication

[0038]Measuring communication consists of field sensors, transmitters, actuators and communication networks. The communication network is described as follows:

[0039] 1) Protection bus: Based on DCS industrial Ethern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com