Patents

Literature

93 results about "Process control block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

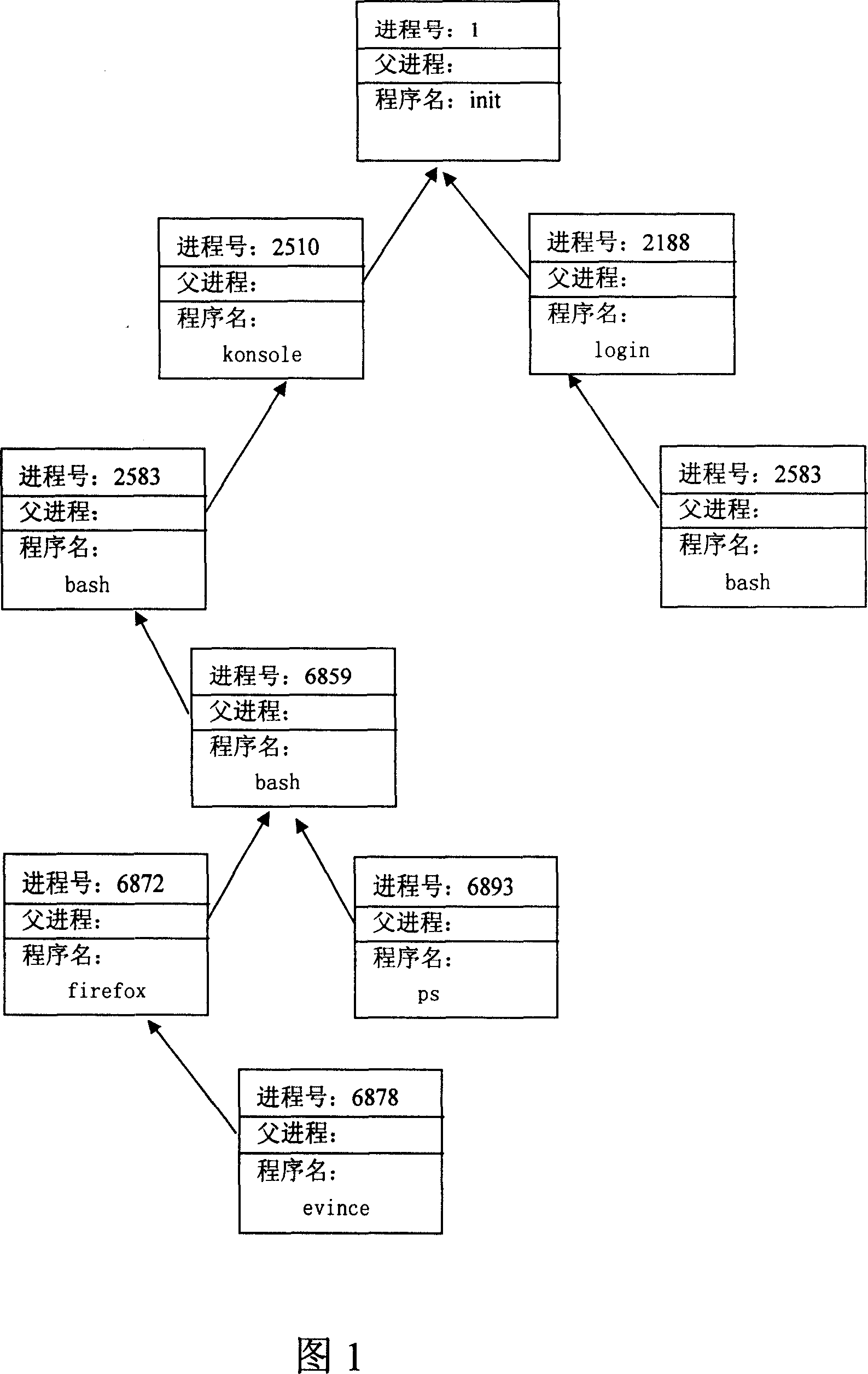

Process Control Block (PCB, also called Task Controlling Block, Entry of the Process Table, Task Struct, or Switchframe) is a data structure in the operating system kernel containing the information needed to manage the scheduling of a particular process. The PCB is "the manifestation of a process in an operating system."

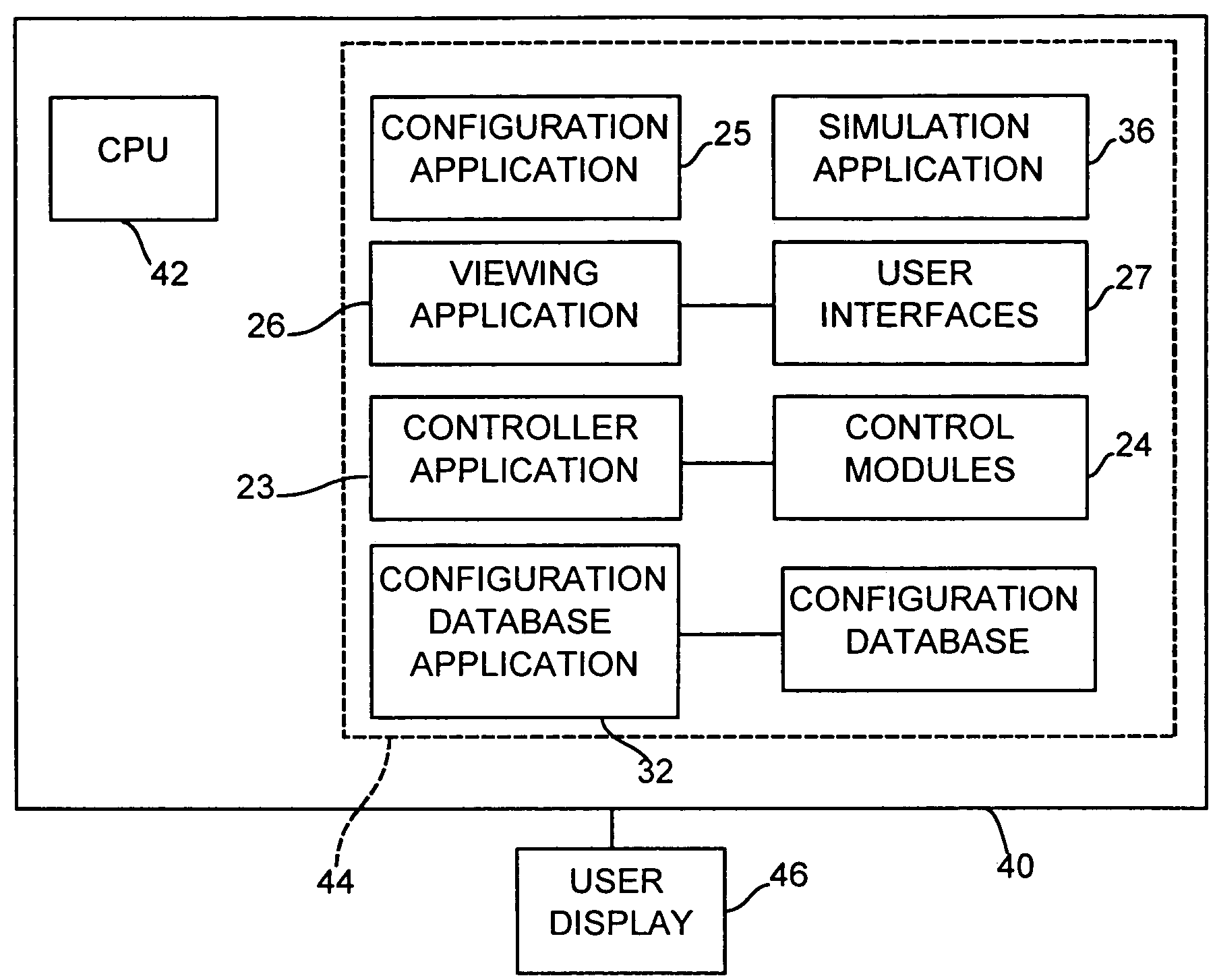

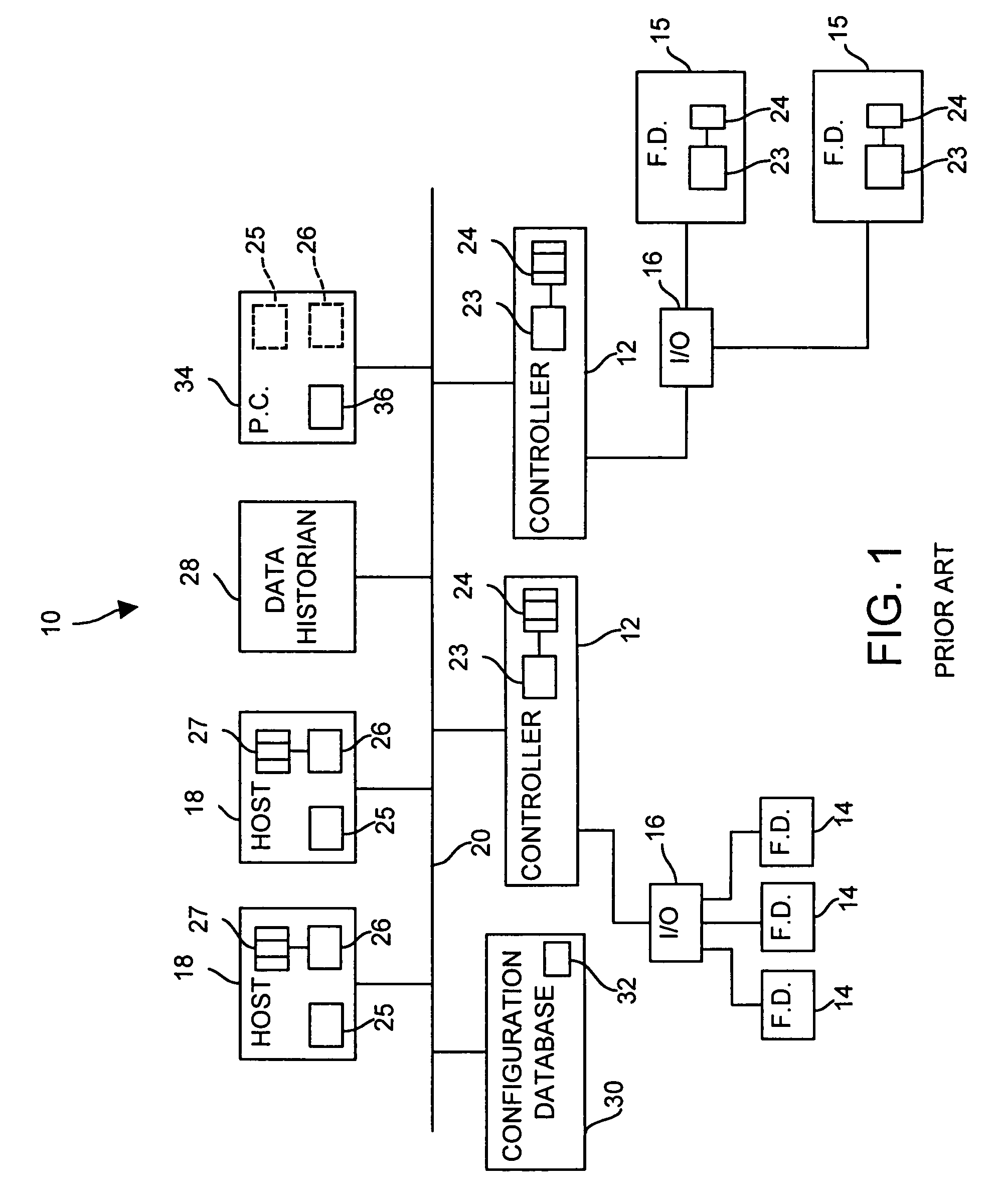

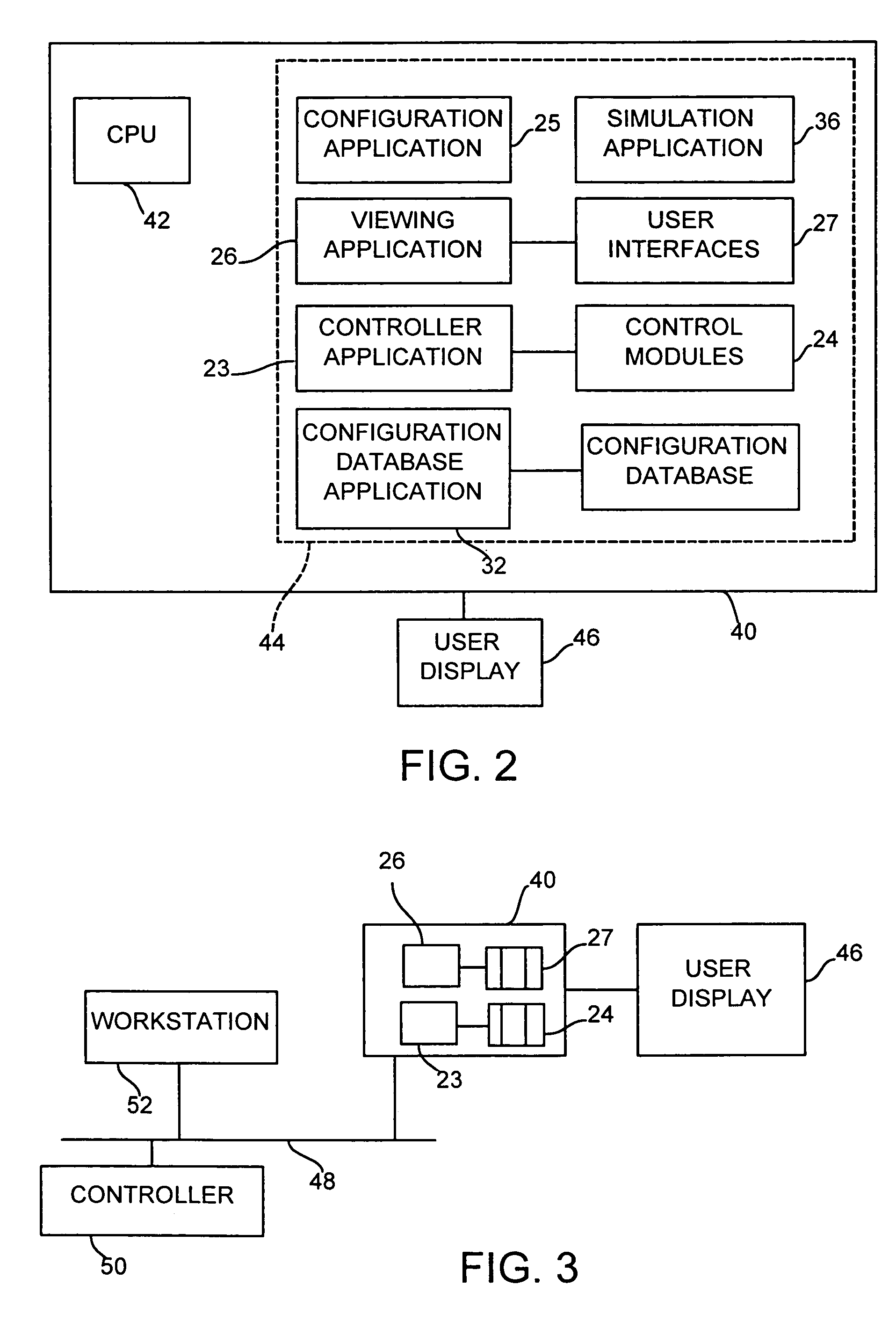

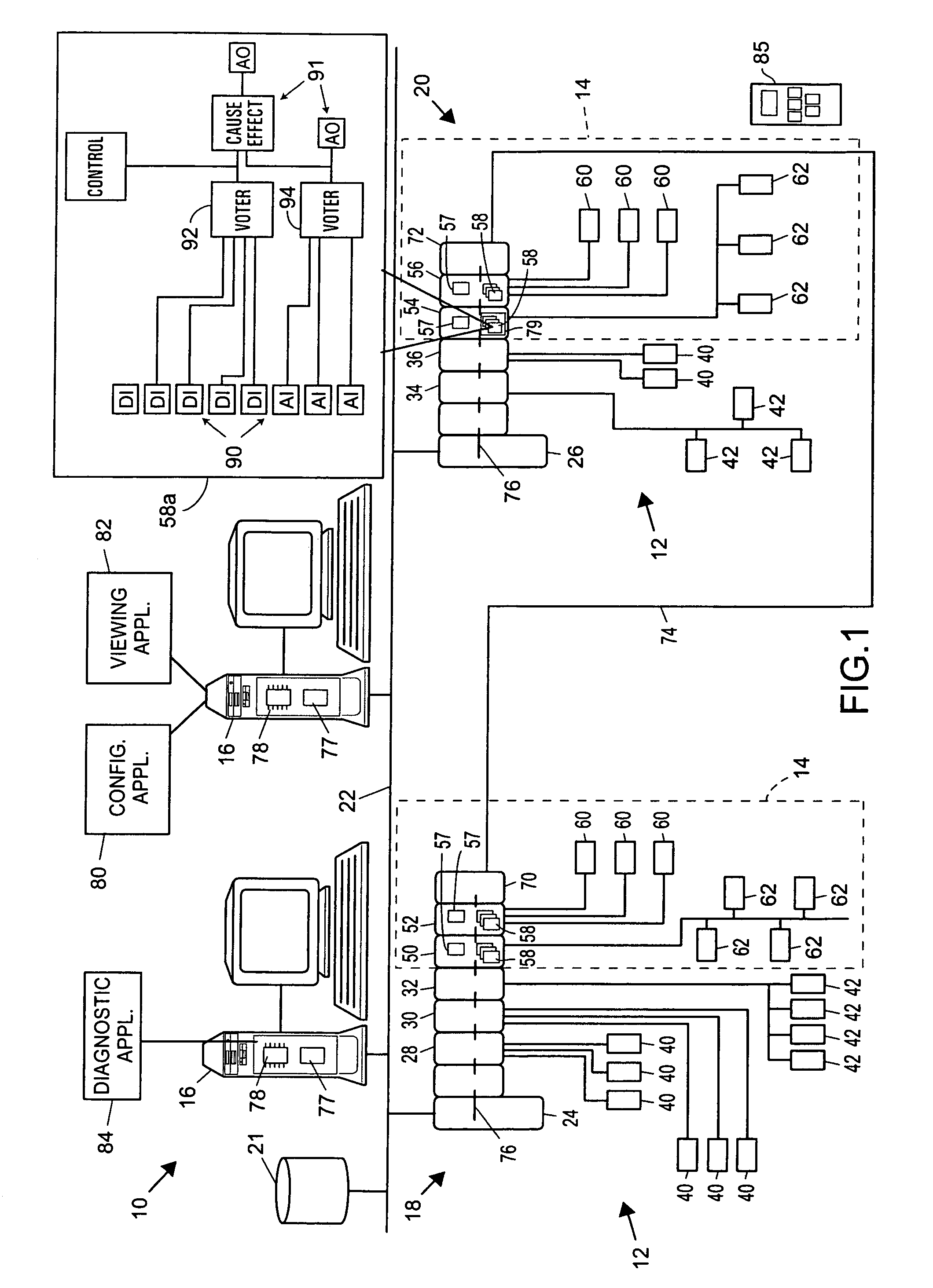

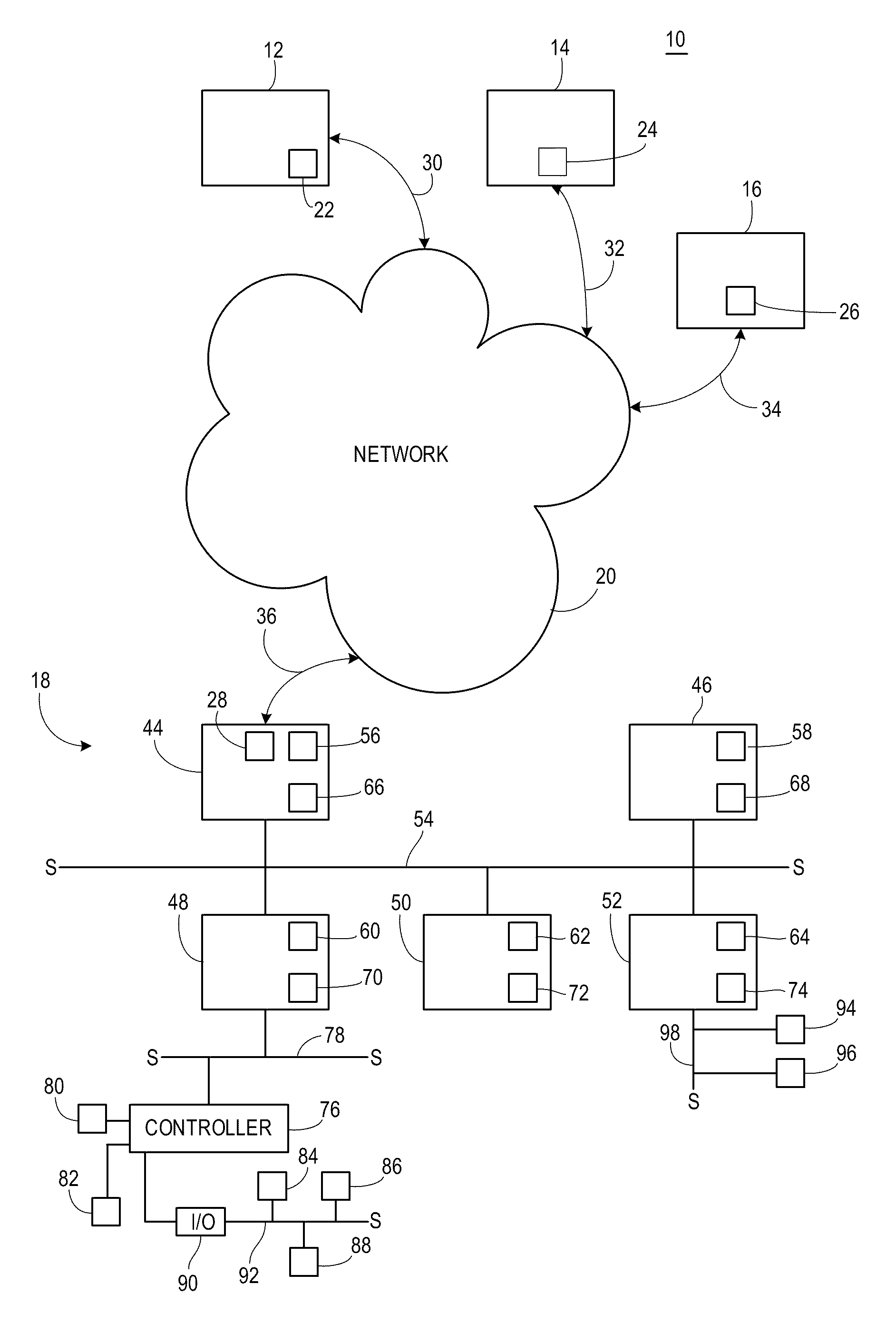

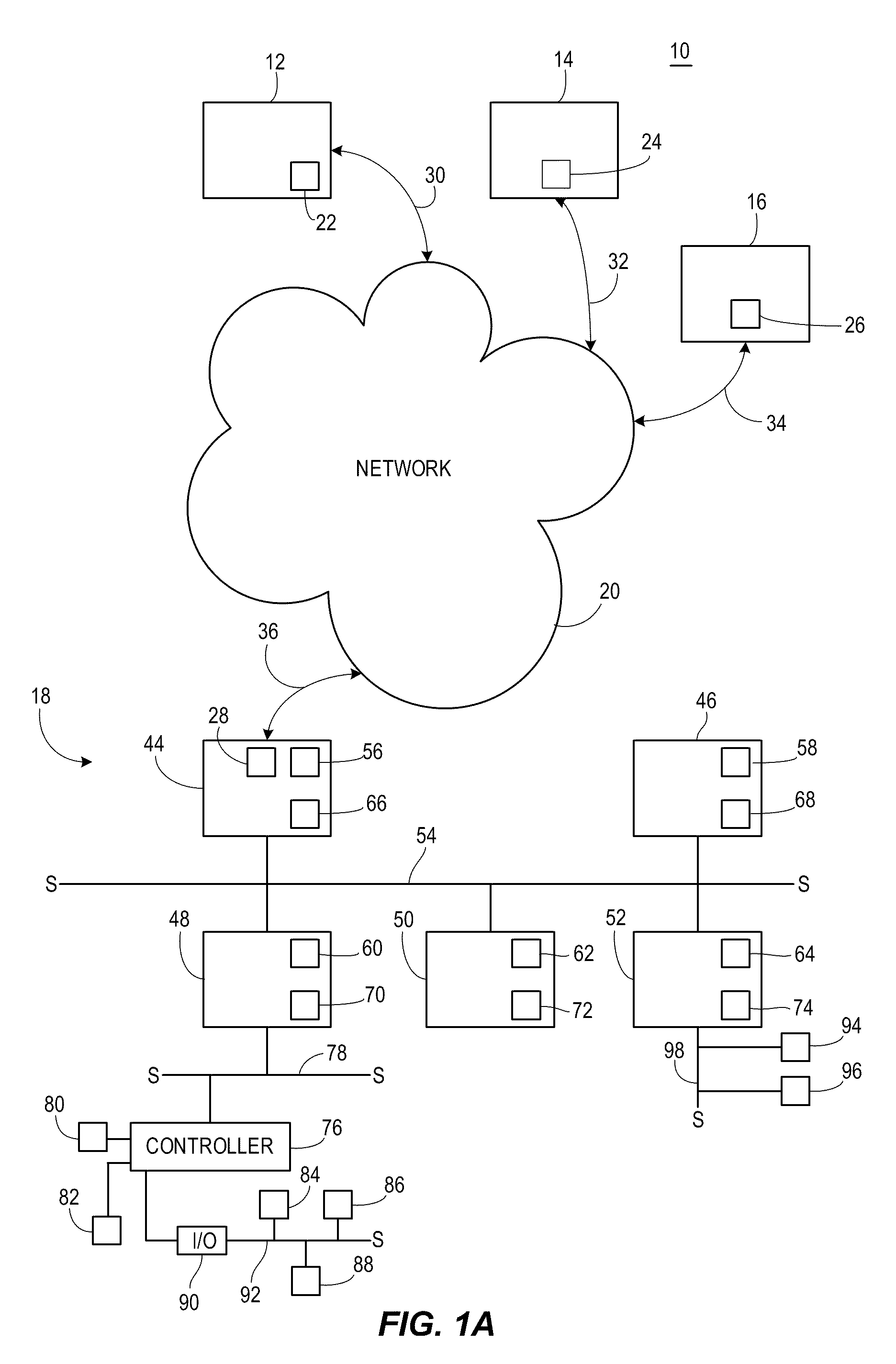

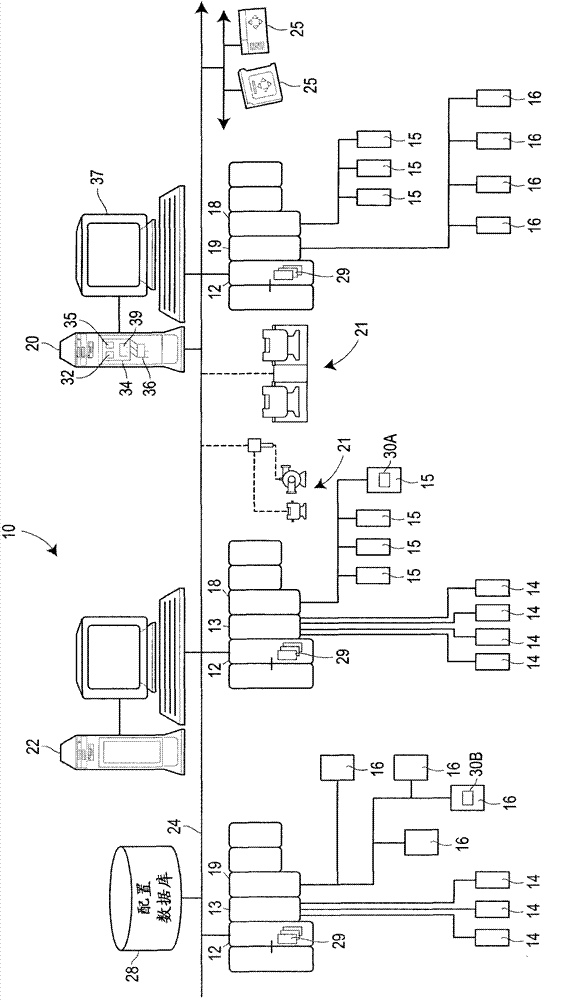

Integrated distributed process control system functionality on a single computer

InactiveUS7257523B1Reduce developmentEase in testingSafety arrangmentsComputer controlControl systemWorkstation

An apparatus is adapted to be used to create software and programming instructions for a distributed process control system having a user workstation remotely located from a distributed controller that controls one or more field devices using control modules. The apparatus includes a computer having a memory and a processing unit as well as a configuration application and a controller application stored on the computer memory to be executed on the processor. The configuration application is further capable of being executed on the user workstation of the distributed process control system to create the control modules for execution by the distributed controller while the controller application is adapted to be executed on the distributed controller to implement one of the control modules during operation of the distributed process control system. In this system, the configuration application, when run on the computer, creates a first control module capable of being used by the distributed controller within the distributed process control system and the controller application causes execution of the first control module within the computer to thereby simulate operation of the distributed process control system. The use of this system enables the simulation and testing of distributed process control system software and control modules without the use of the hardware, e.g., the distributed process controller and field devices, which will ultimately run that software.

Owner:FISHER-ROSEMOUNT SYST INC

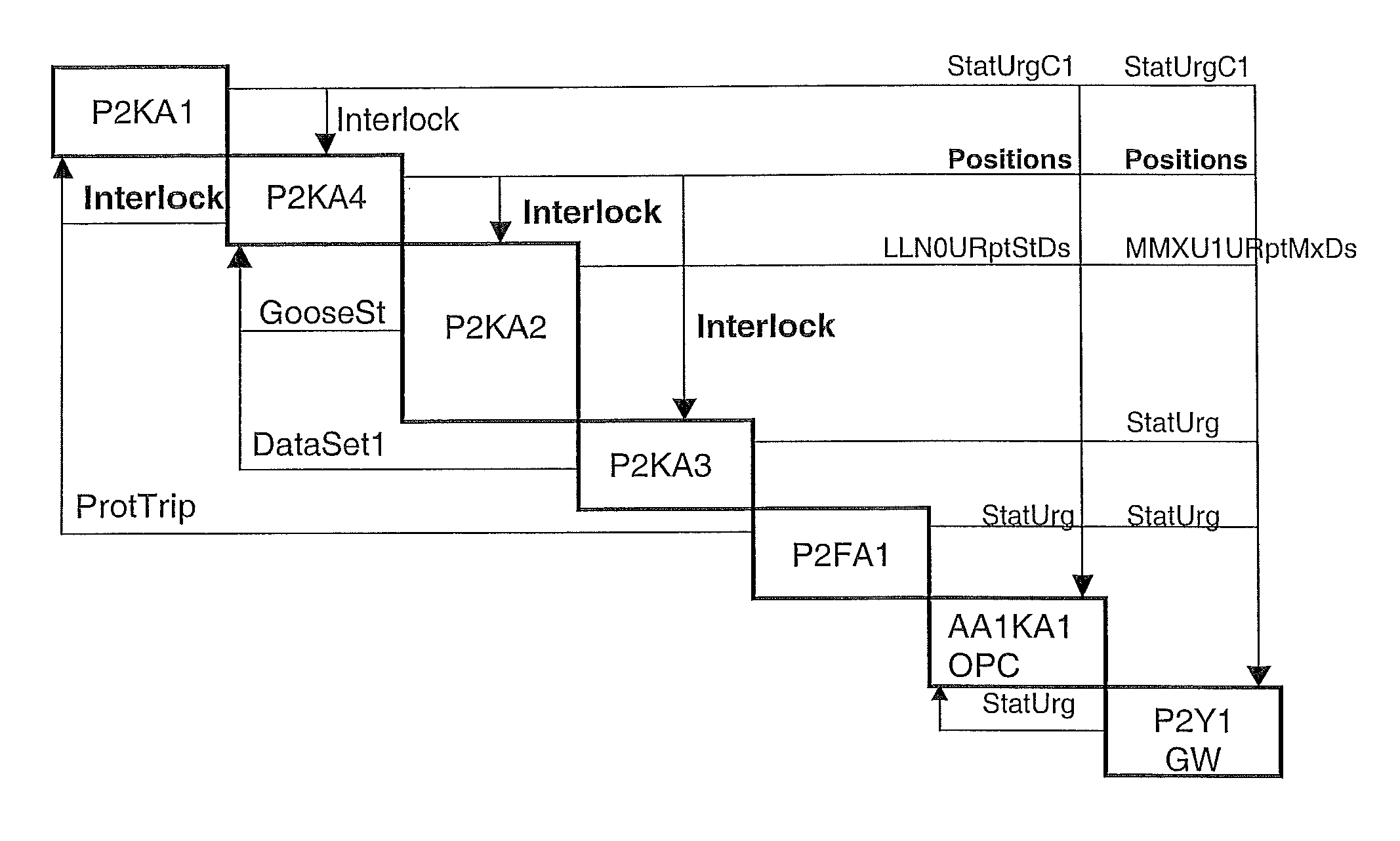

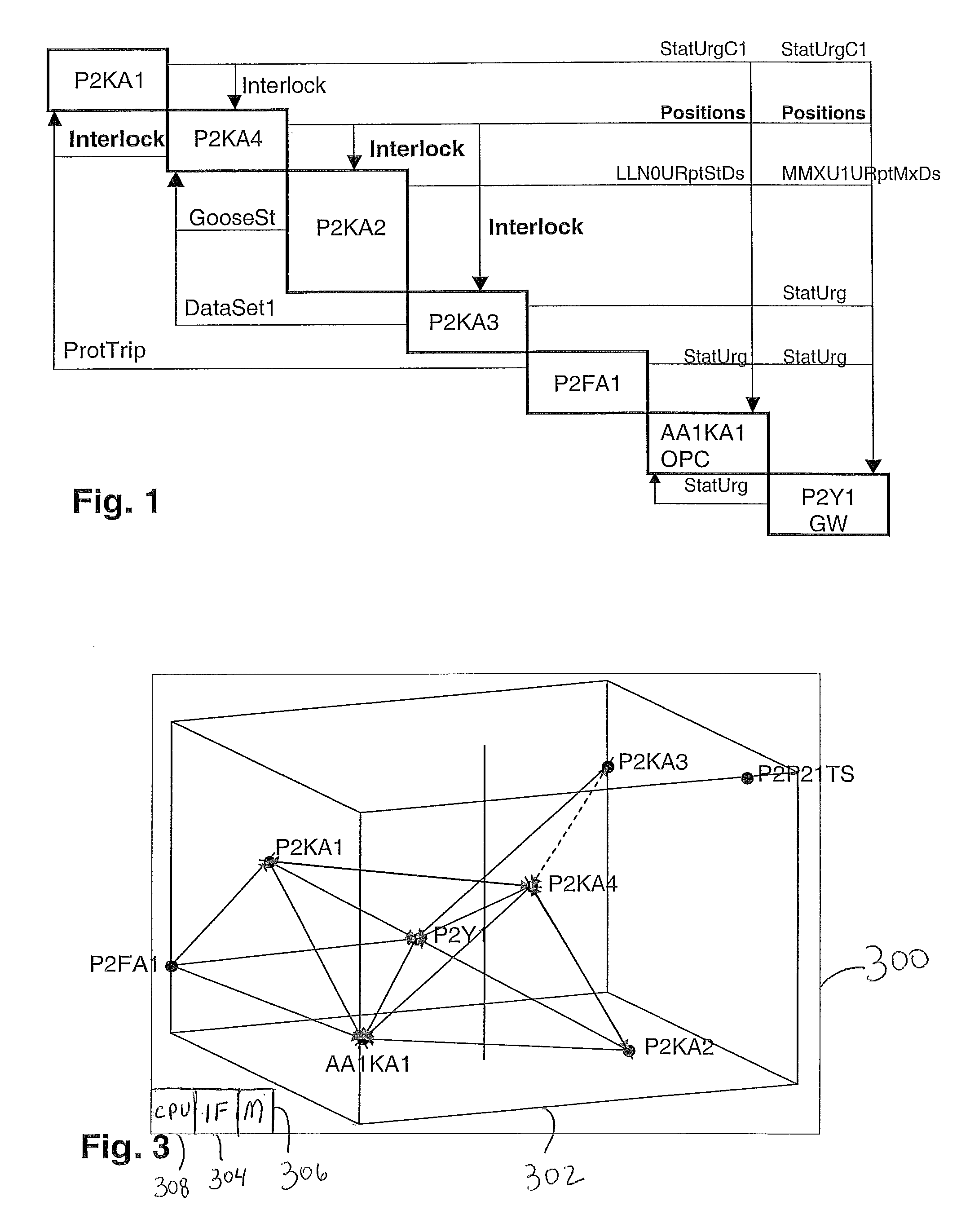

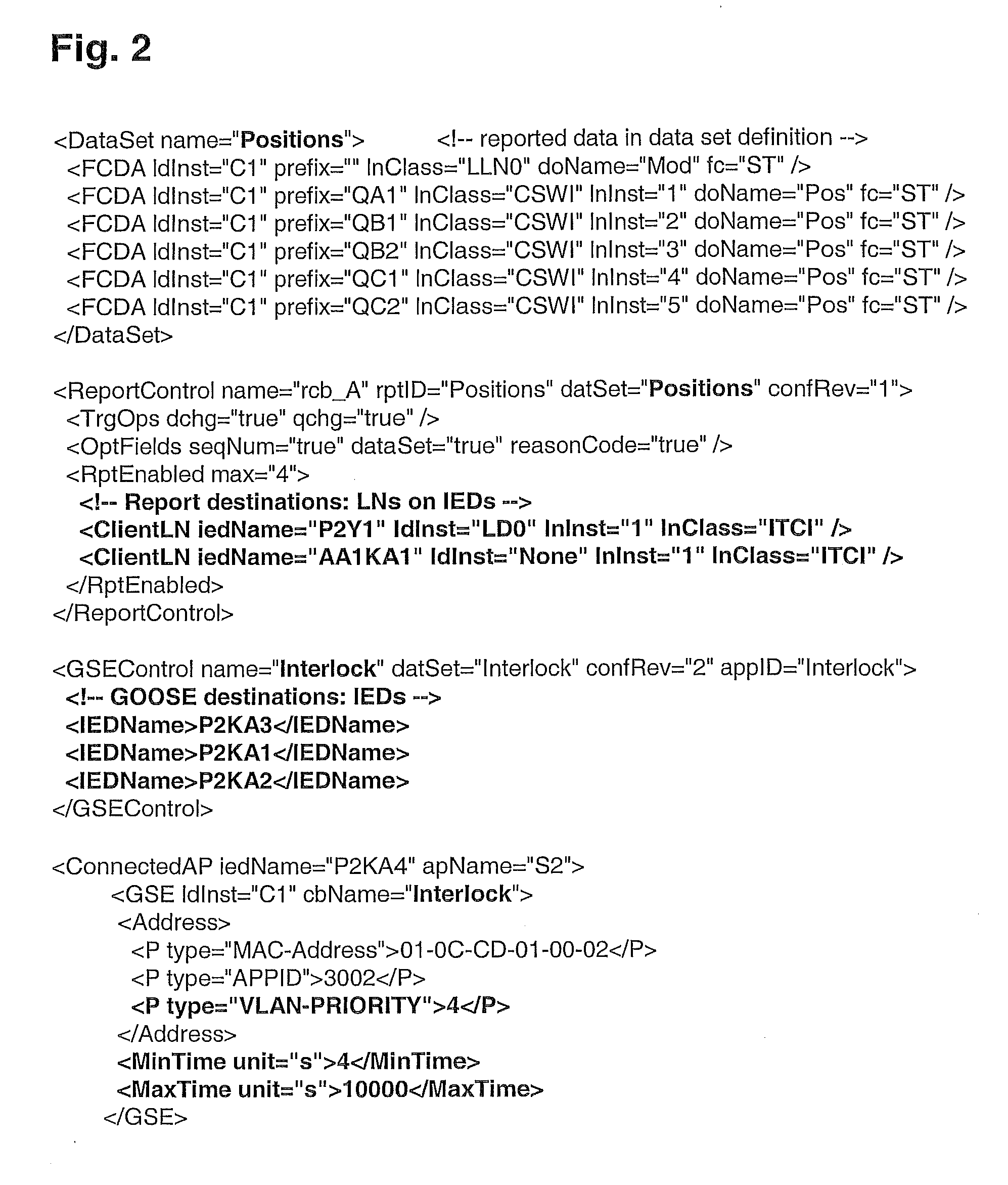

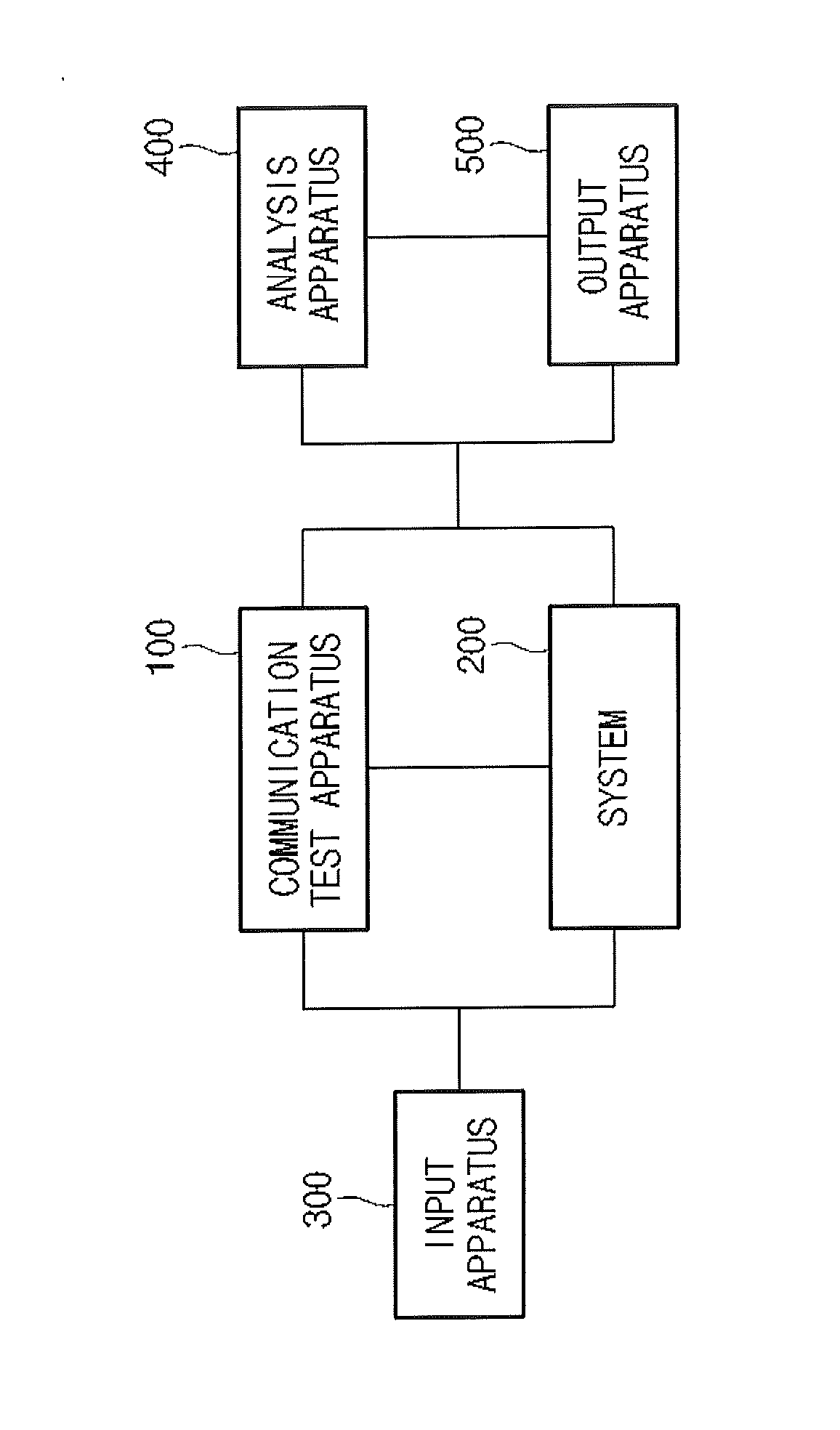

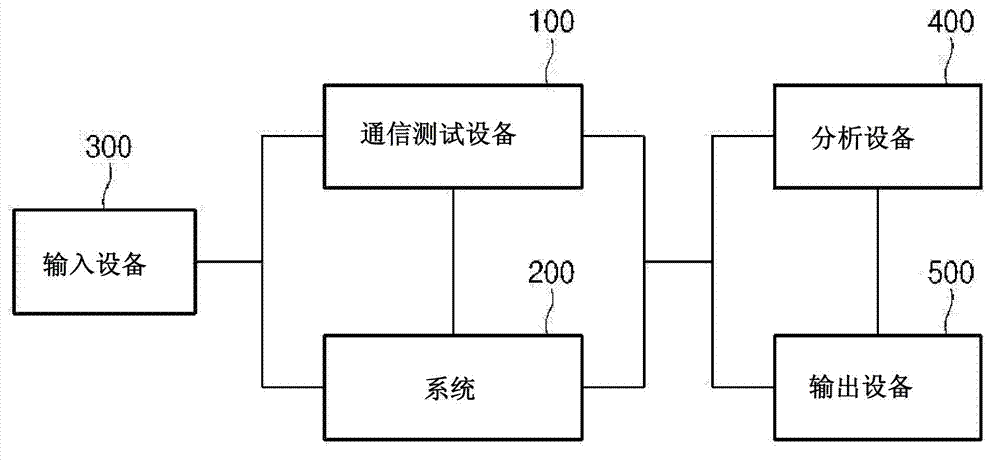

Analyzing communication configuration in a process control system

An analysis of a communication configuration in a process control (PC) or substation automation (SA) system is disclosed, wherein network messages, and / or respective message sources, configured for transmission across a communication network of the system can be evaluated. From a logical data flow description that is part of a standardized configuration representation of the PC or SA system and which includes, in the form of control blocks, formal information for every message, receiver intelligent electronic devices (IEDs) can be retrieved or determined. For each retrieved receiver IED, the totality of all network messages destined for or directed to this particular receiver IED can be evaluated or processed (e.g. in view of a subsequent network load analysis, virtual local area network assignment, or graphical display of the data flow). Exemplary network messages of interest include cyclic point-to-point reports, periodic or repeated real-time multicast messages (Sampled Values SV) and event-based multicast messages (generic object oriented substation events GOOSE).

Owner:HITACHI ENERGY SWITZERLAND AG

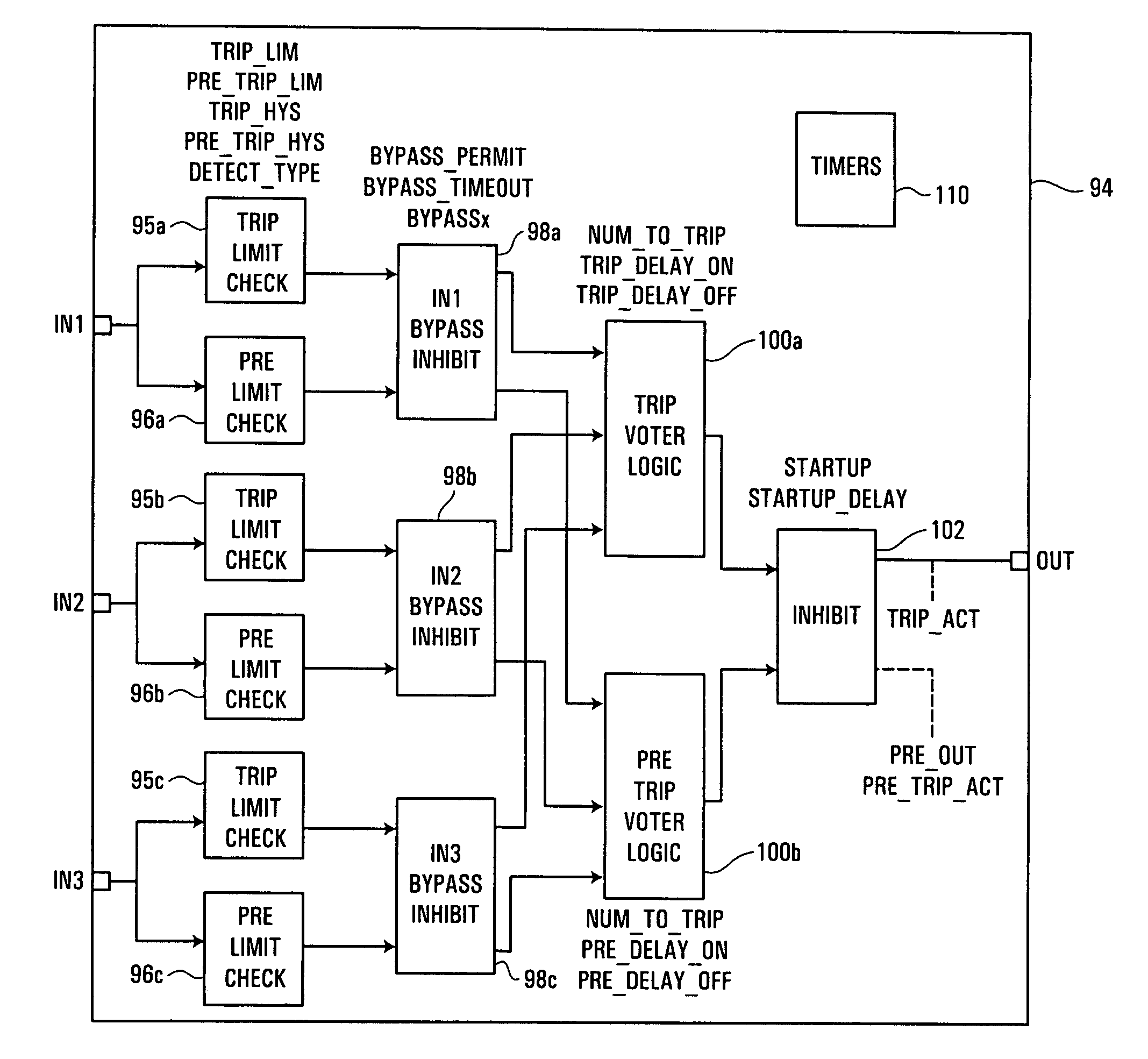

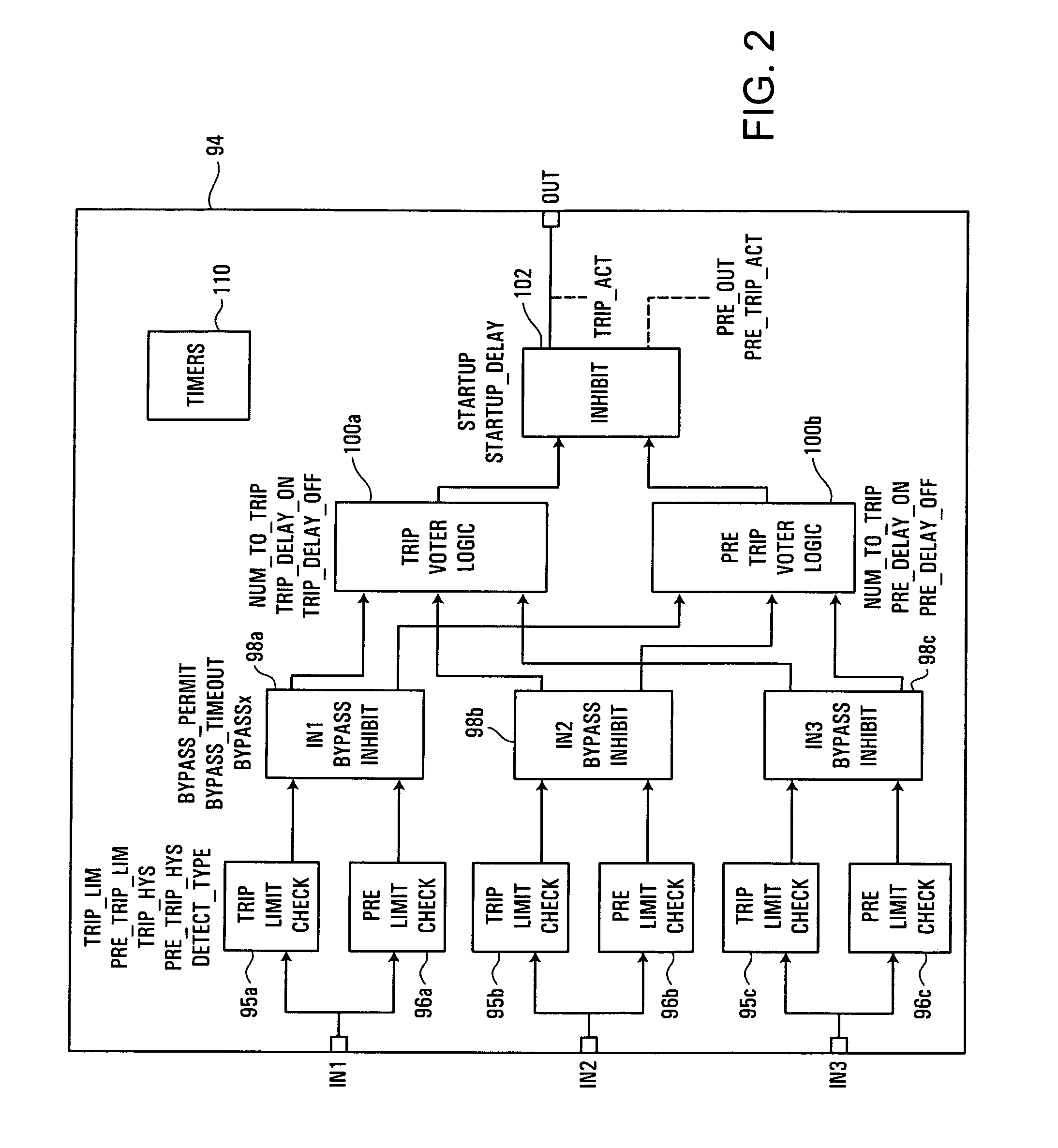

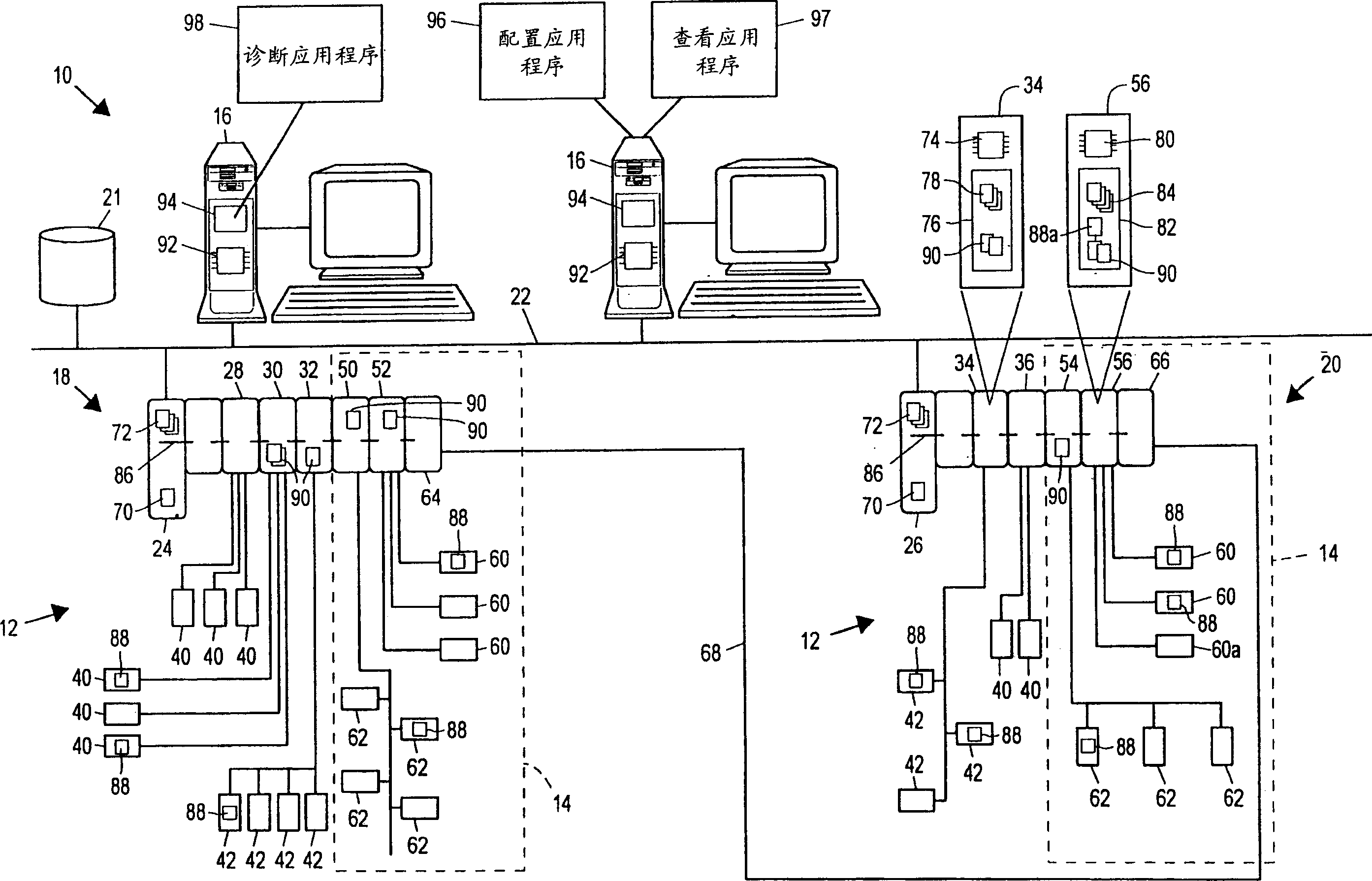

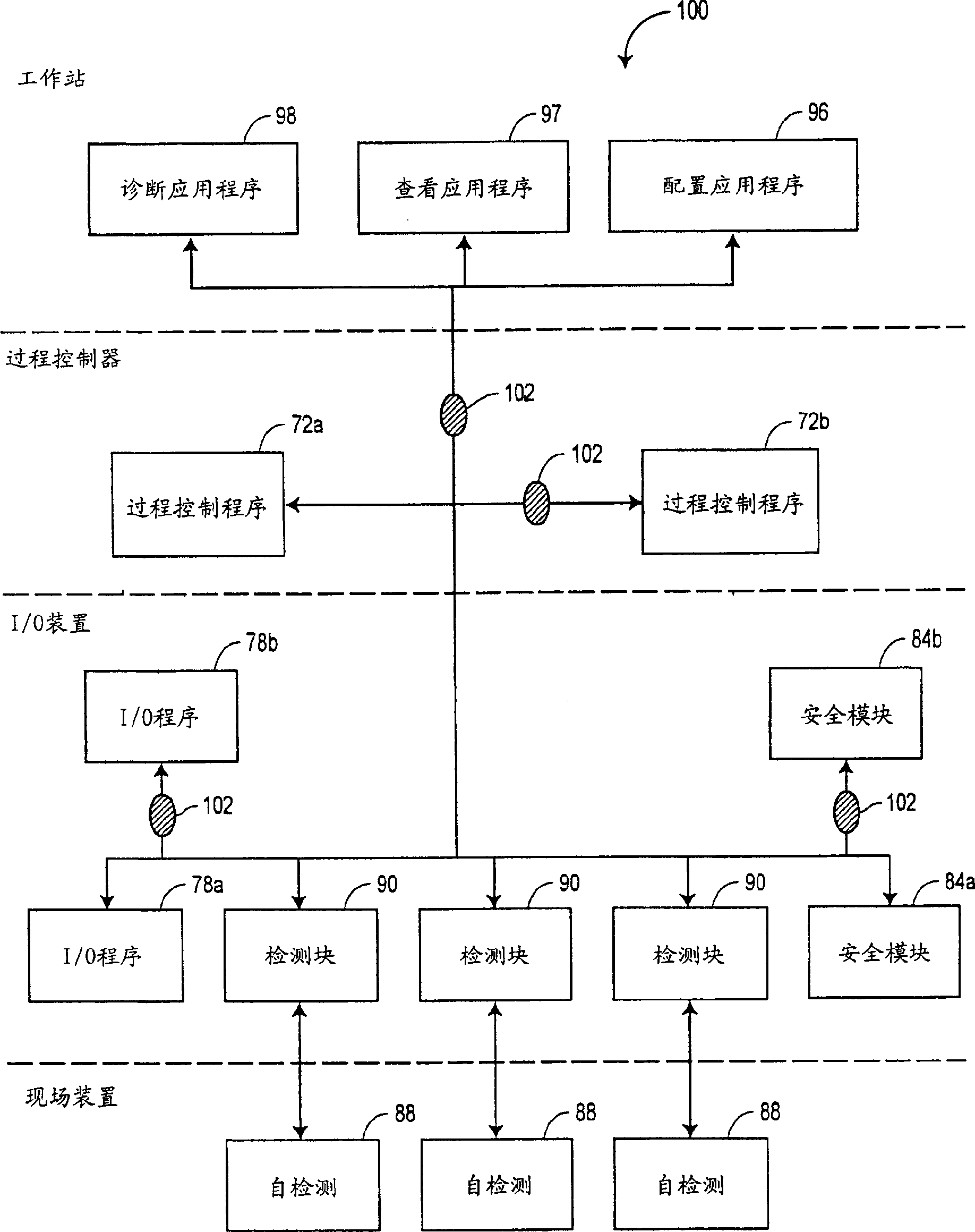

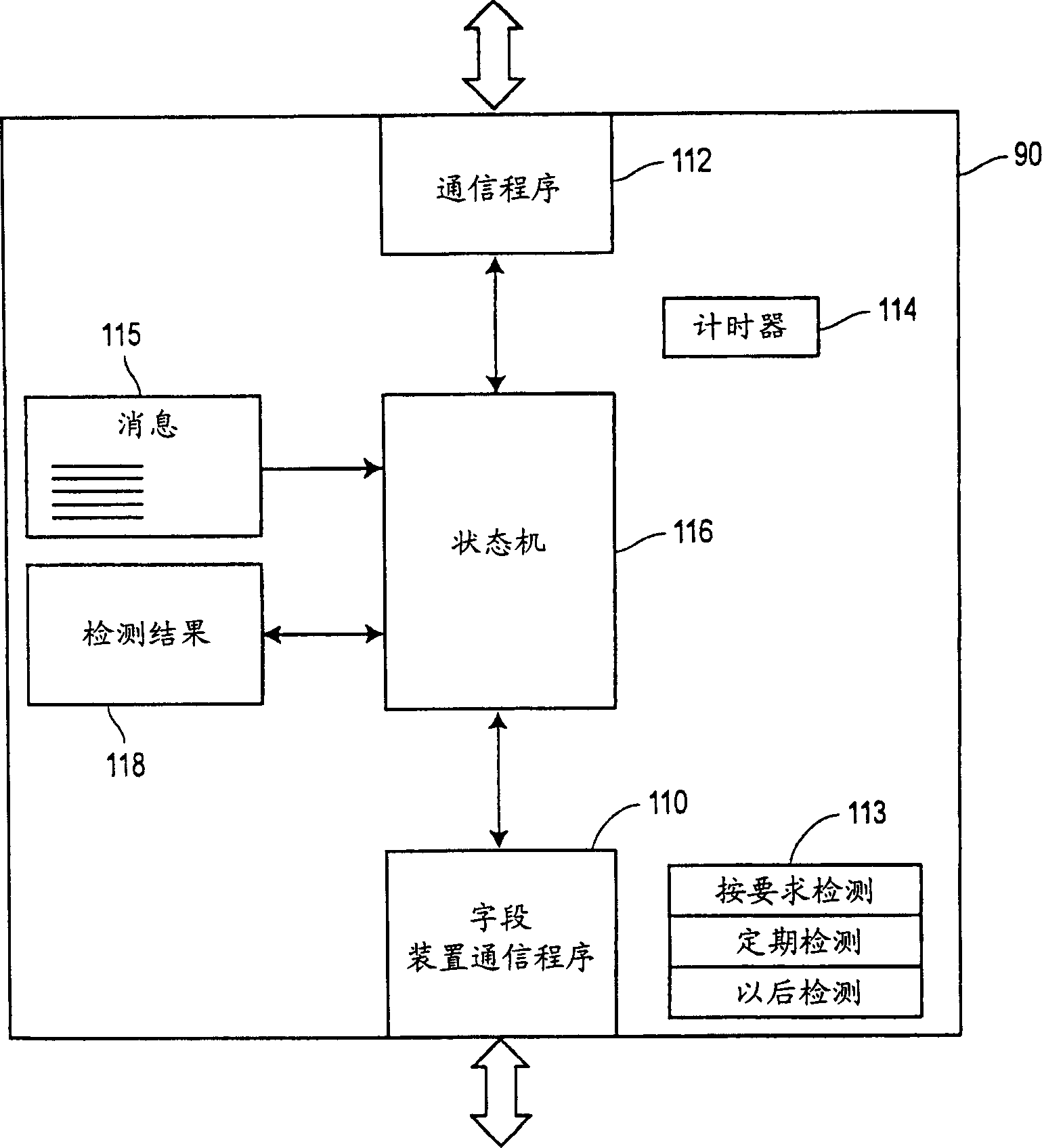

Coordination of field device operations with overrides and bypasses within a process control and safety system

InactiveUS7010450B2Avoid procedureOperation failureElectric testing/monitoringStructural/machines measurementSafety instrumented systemHand held

A process control or safety instrumented system uses function block logic to coordinate the logic within the process control or safety instrumented system with operational states of field devices, even when these operational states are initiated externally to the process control or safety system. Logic within input or voter function blocks associated with field devices may monitor and determine when the associated field devices are being put into testing or calibration modes and may automatically initiate appropriate bypass or override functionality in response to such detected field device configuration states. Likewise, the function block logic may automatically remove the bypass or override functionality when the field devices are placed back into their normal operational configuration states. This automatic initiation of bypasses and overrides helps to prevent a safety system within a process plant from initiating a shut-down procedure as a result of a device test initiated manually by, for example, a hand-held device attached to a field device. Likewise, the automatic removal of bypasses and overrides helps to prevent a safety system within a process plant from failing to operate properly because a user forgot to manually remove a bypass or override that was set up to allow a device test.

Owner:FISHER-ROSEMOUNT SYST INC

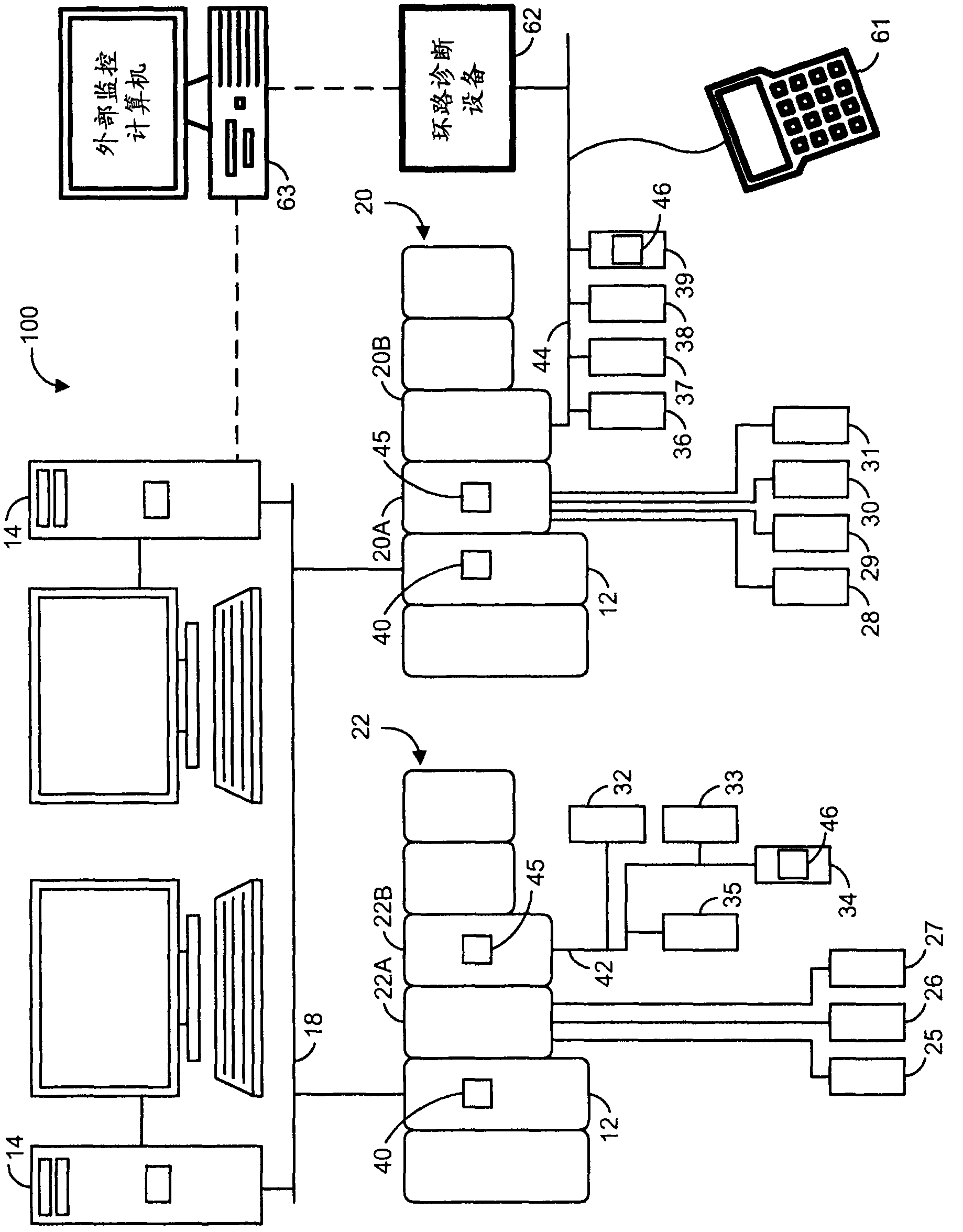

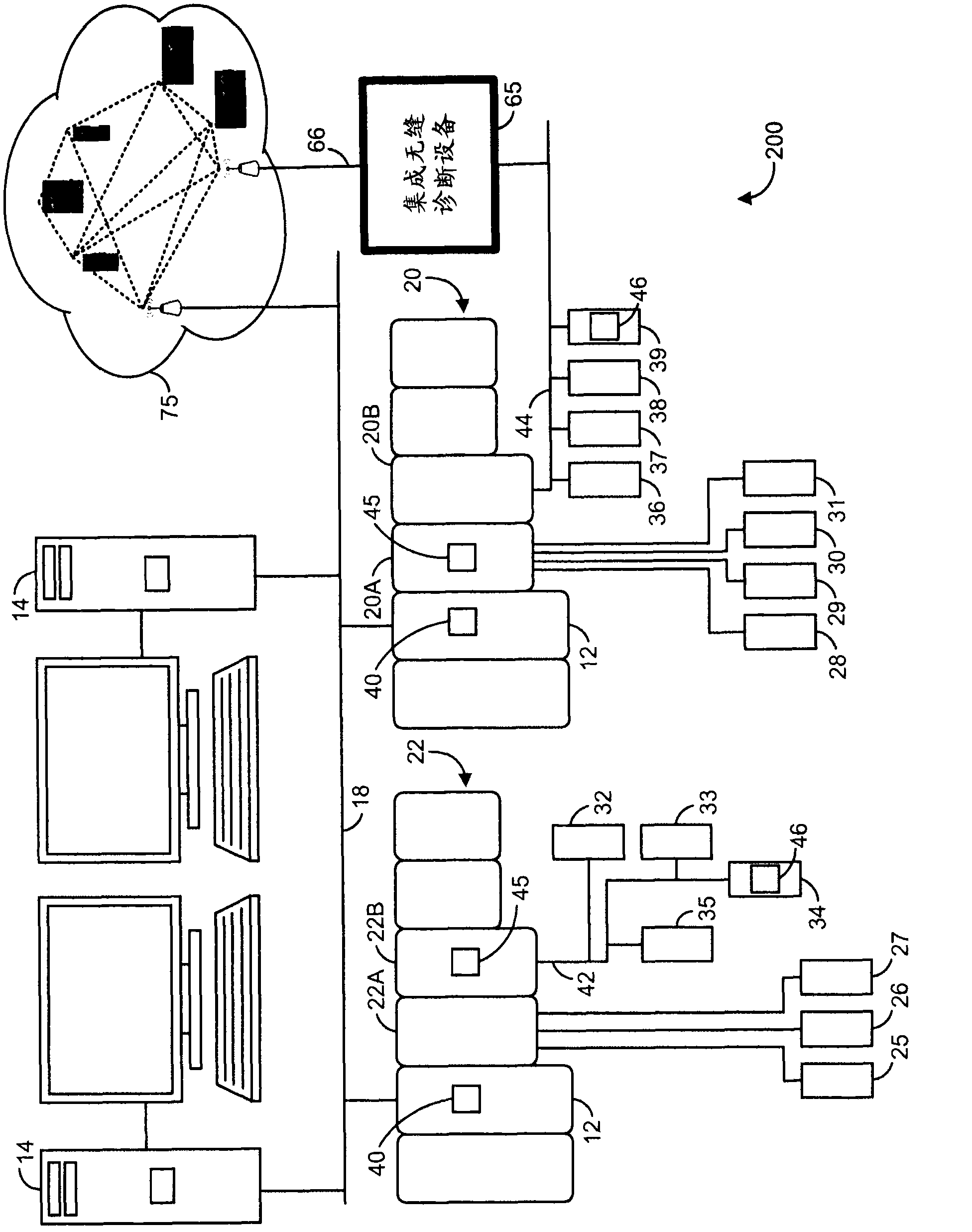

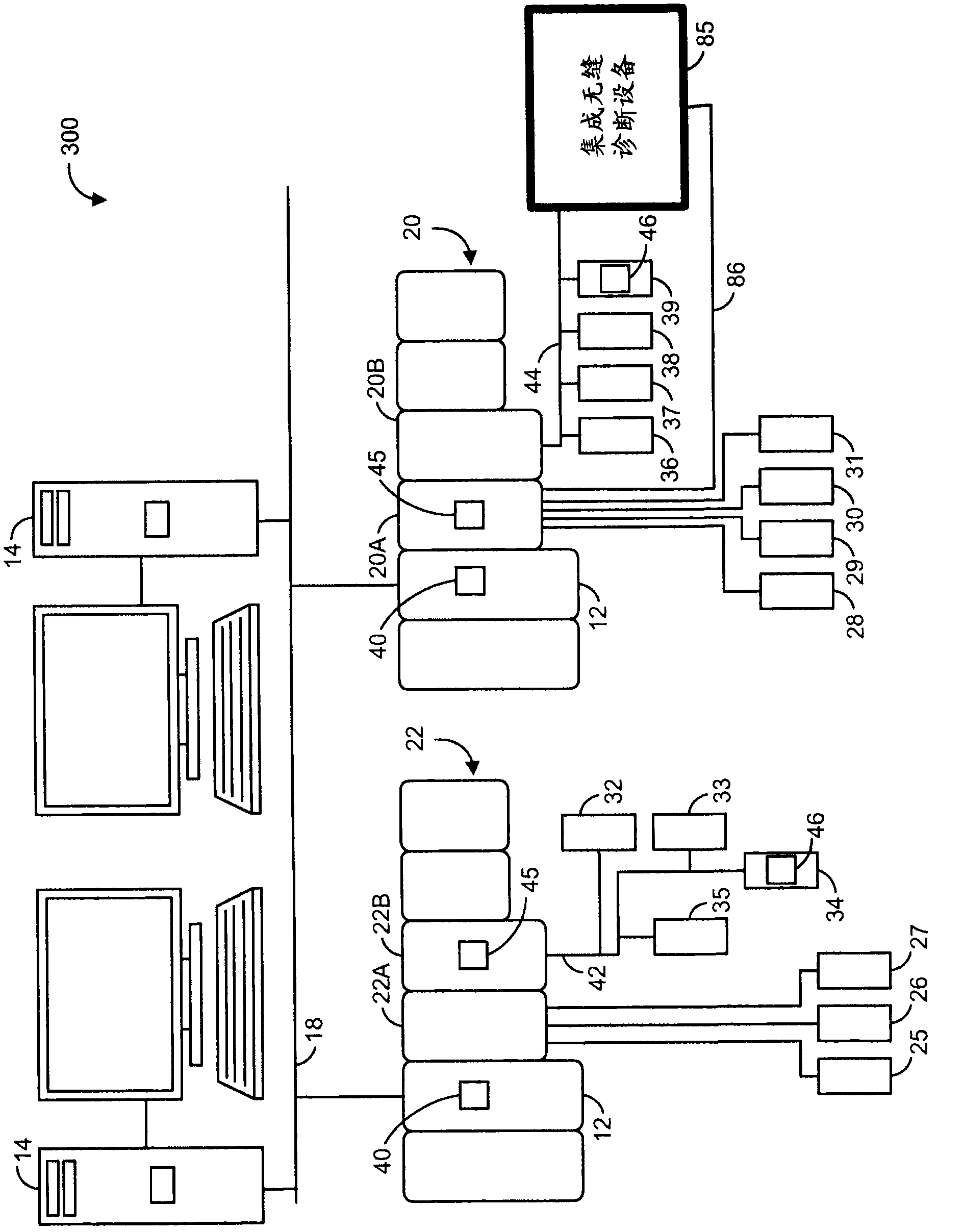

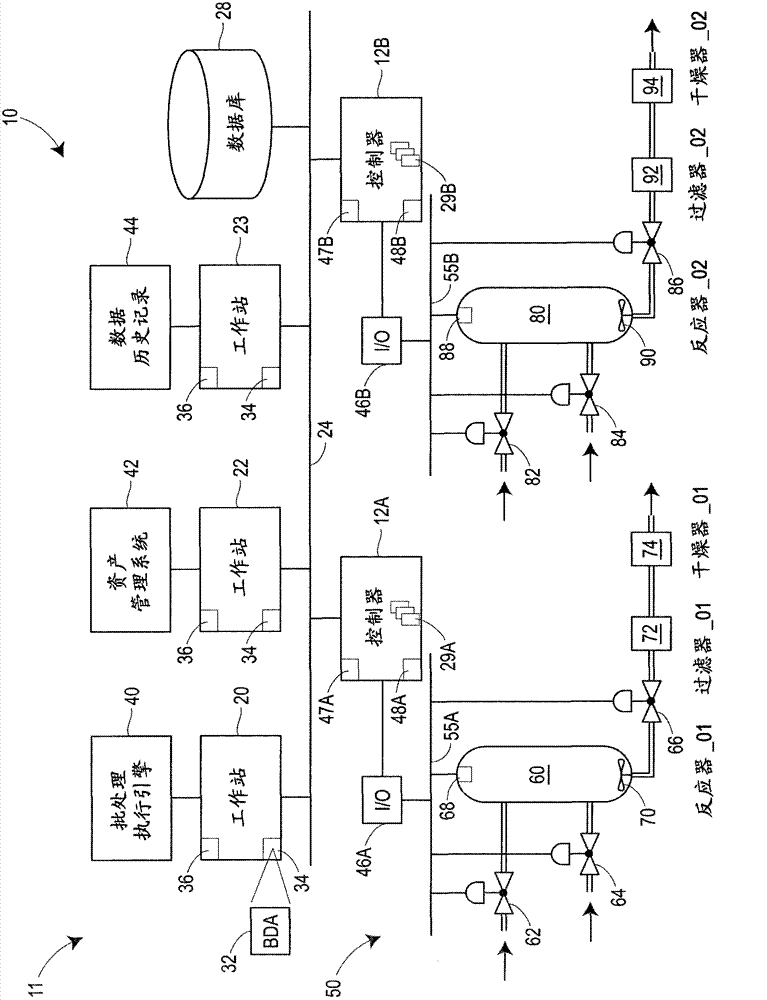

Seamless integration of process control devices in a process control environment

InactiveCN102375453AMinimize changesIncrease variabilityProgramme controlElectric testing/monitoringDiagnostic dataTelecommunications link

The invention relates to a process control system and a diagnostic device and an interface device for the process control system. In order to facilitate seamless integration of process control devices in a process control system, an integrated seamless diagnostic device collects diagnostic data related to the operation of, or problems associated with, one communication link that supports one process control protocol but communicates the collected diagnostic data to other entities in the process control system via another communication link that supports a different process control protocol. As a result, problems with the communication link monitored by the integrated seamless diagnostic device can be reported to the appropriate entities in the process control system as they occur and without unwanted delay. Moreover, problems with the monitored communication link can be communicated to the appropriate entities via process control protocols that are understood by those entities (and other entities in the process control system) and without consuming the potentially valuable resources of the monitored communication link.

Owner:FISHER-ROSEMOUNT SYST INC

Debugging method for applied programm in simulator of embedded system

InactiveCN1645339AAvoid the problem of lack of debuggerImprove performanceSoftware testing/debuggingOperational systemApplication software

A method for debugging application program on simulator in embedded system includes fetching out core symbol file generated during compile of operation system to obtain process control block information of application program in simulator memory as result to obtain control ability of corresponding application program for realizing the debugging of application program operated in simulator and above operation system.

Owner:ZHEJIANG UNIV

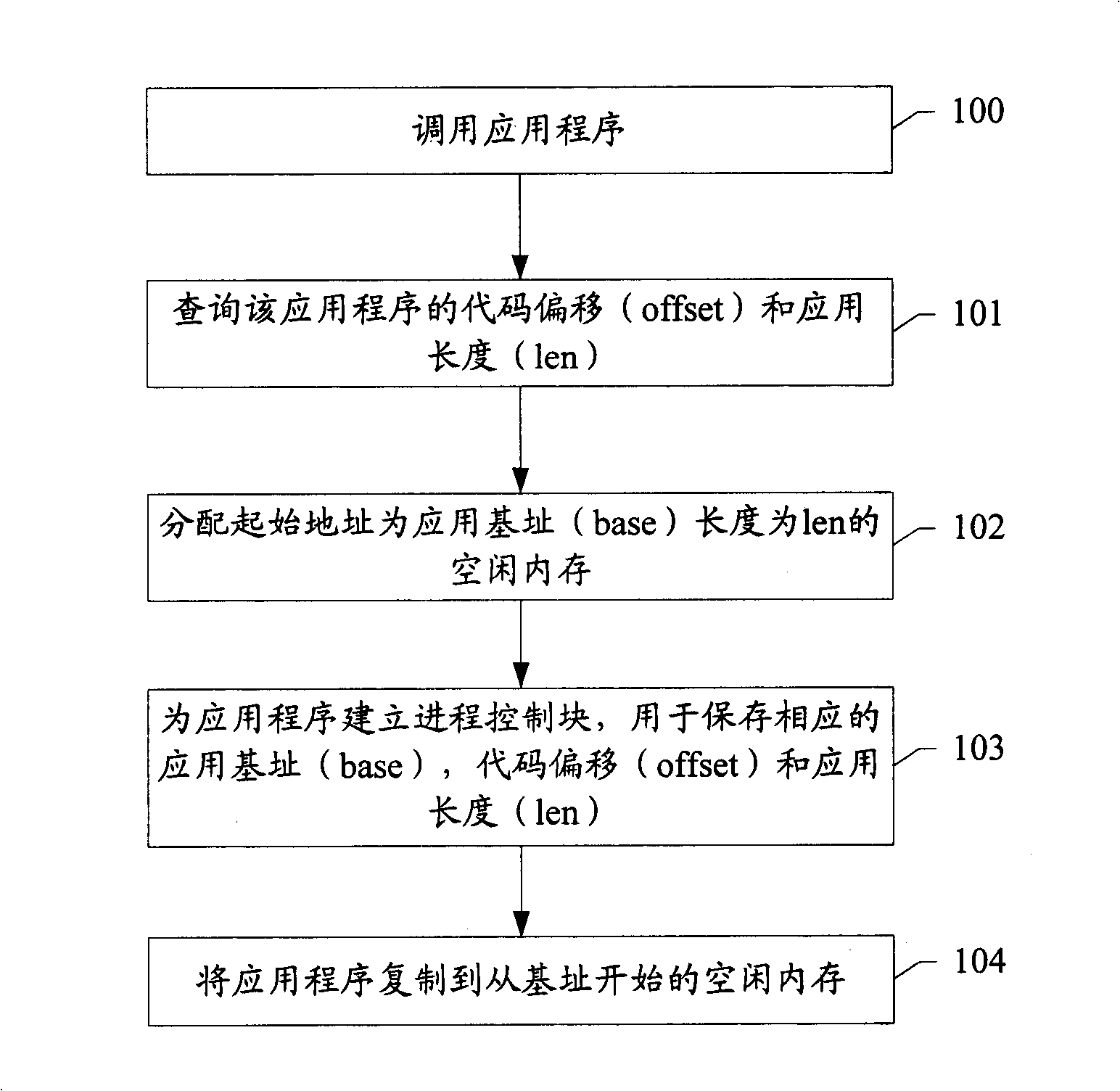

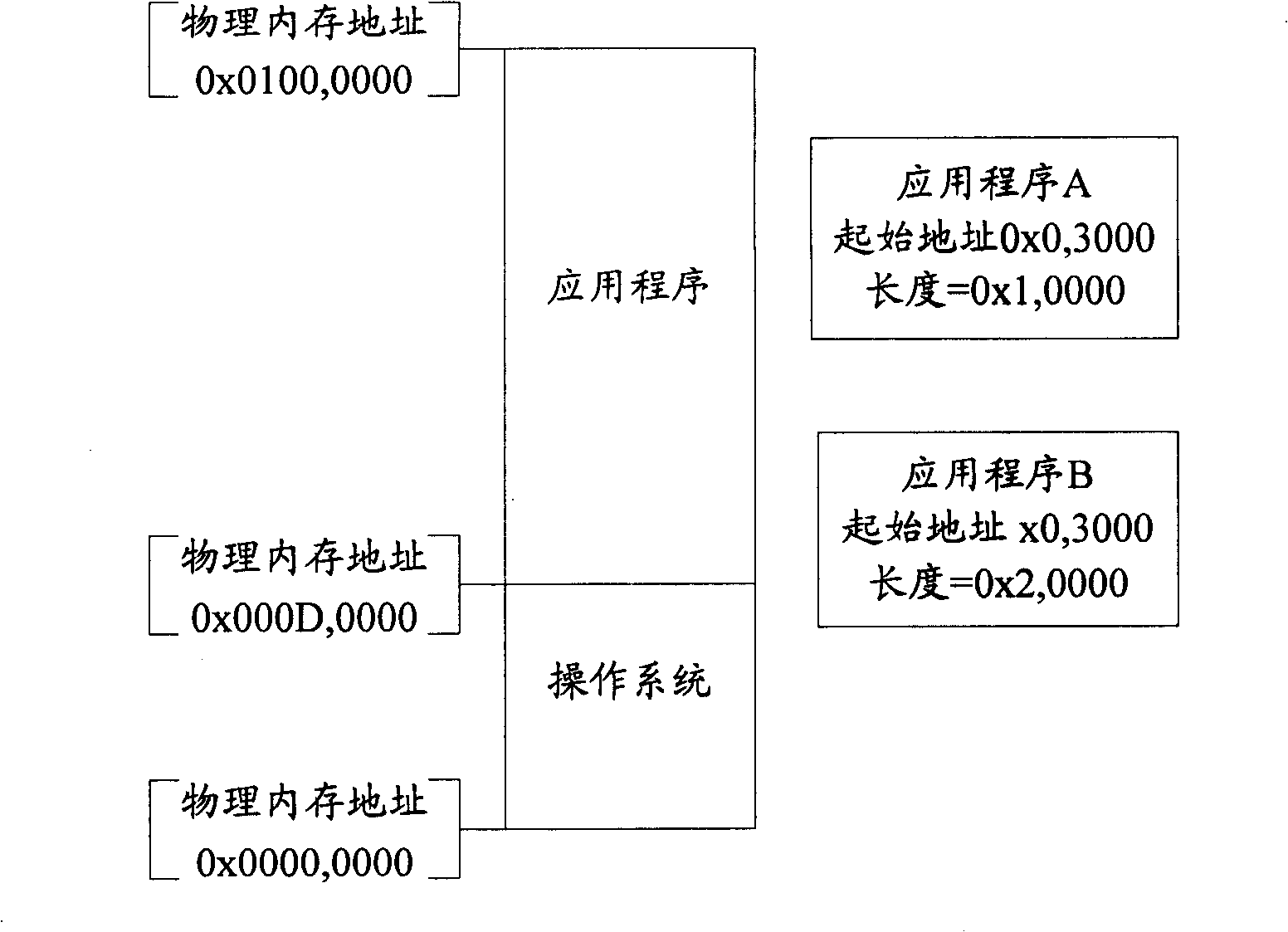

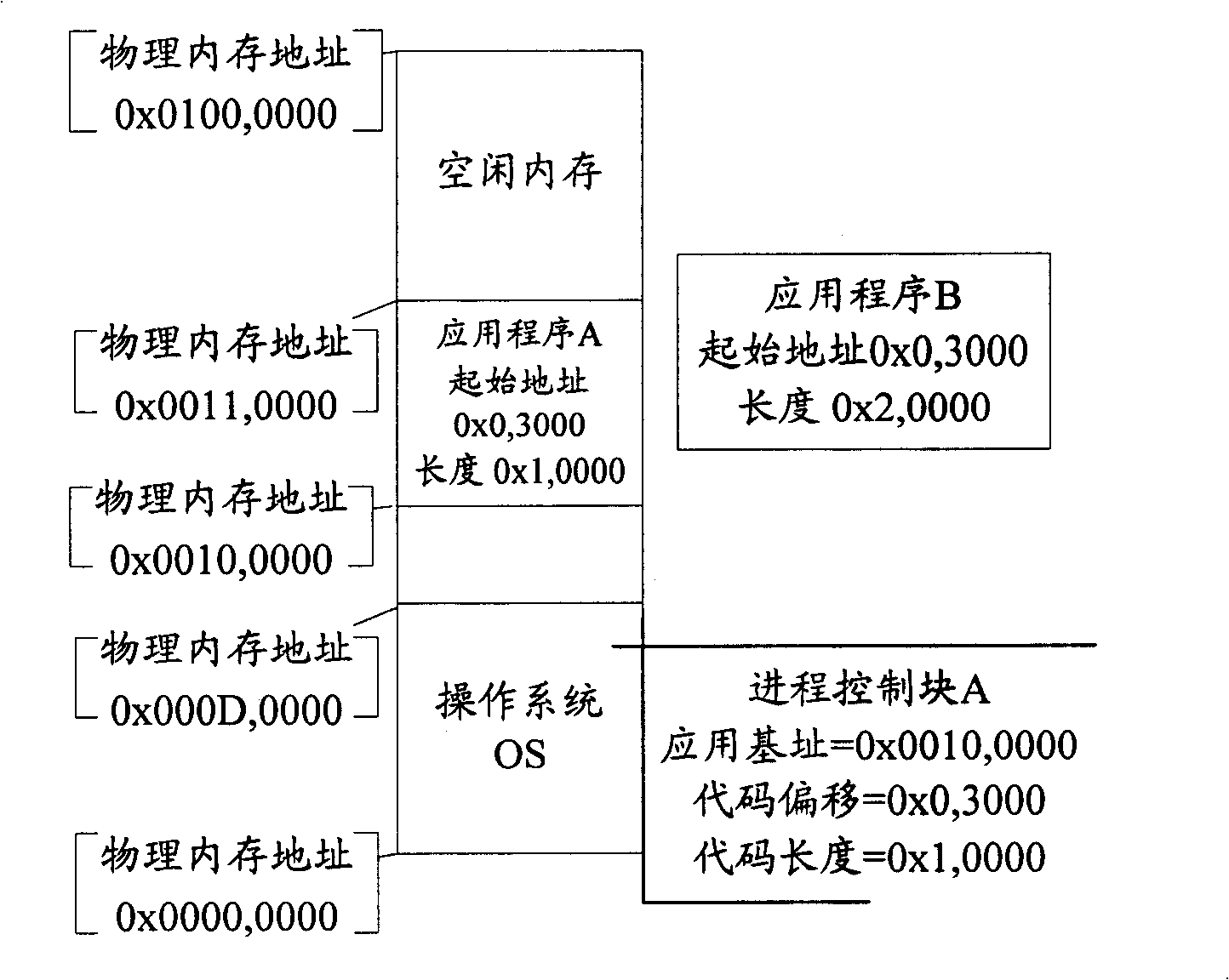

Method for relocated loading application program and address relocation device

InactiveCN101246427AEasy loadingImplement dynamic loadingMemory adressing/allocation/relocationProgram loading/initiatingOperational systemApplication software

The invention discloses a method for repositioning and loading an application program comprising invoking the application program, enquiring code skewing and application length of the application program, allotting idle EMS memory whose length is more than or equal to the length of application to the application program according to the allotment situation, creating progress control block, saving beginning address, code skewing and application length of the idle EMS memory, copying the code of the application program to the idle EMS memory. The invention also discloses an address reposition device supporting the application program repositioning and loading. In the method, the operation system can load the application program according to present EMS memory, avoid to manage the application program page and to analysis symbolic information and address reposition information so that dynamic loading of the application program is simplified and the application program encoded in a same address can be operated on the operation system simultaneously.

Owner:SUNPLUS TECH CO LTD +1

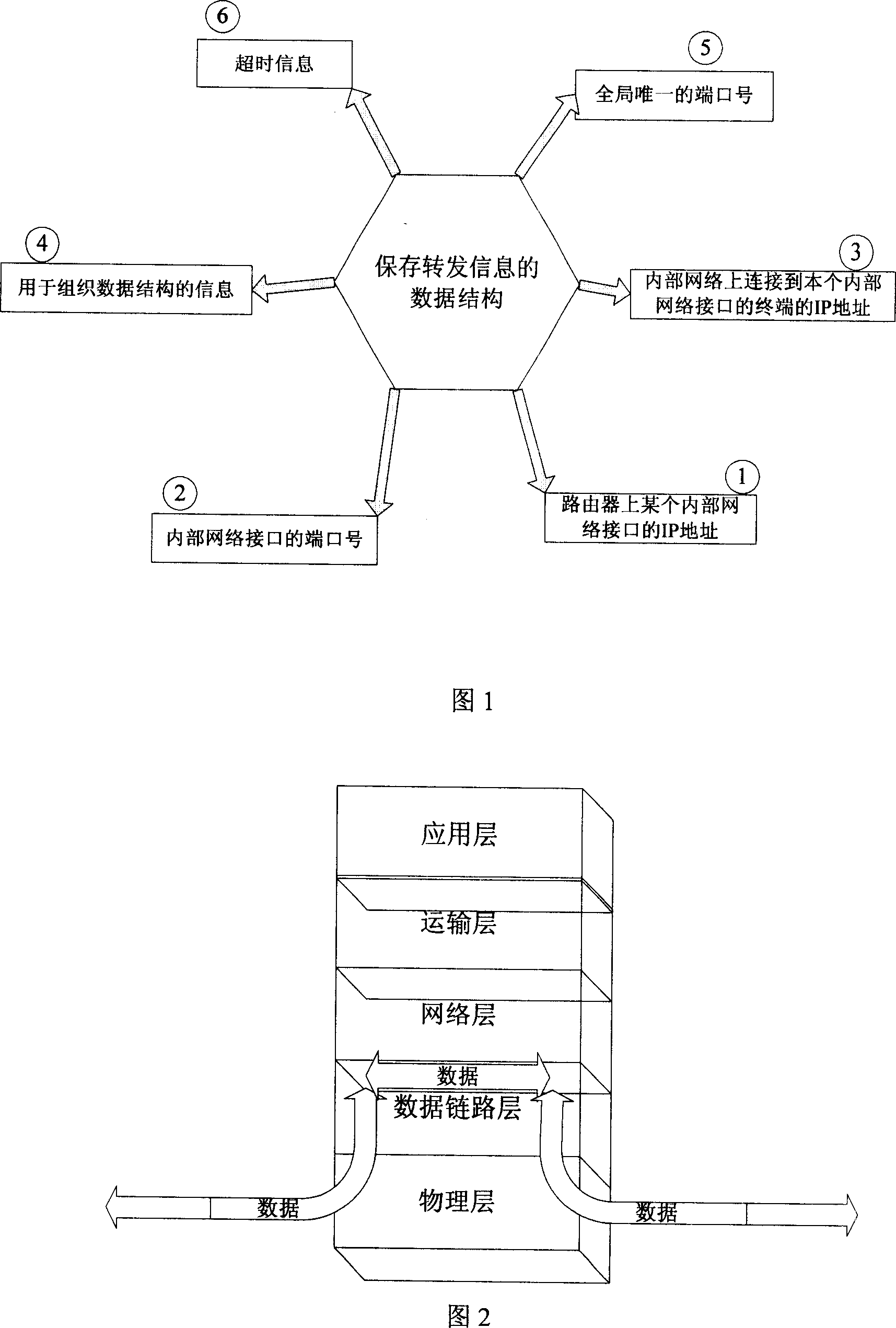

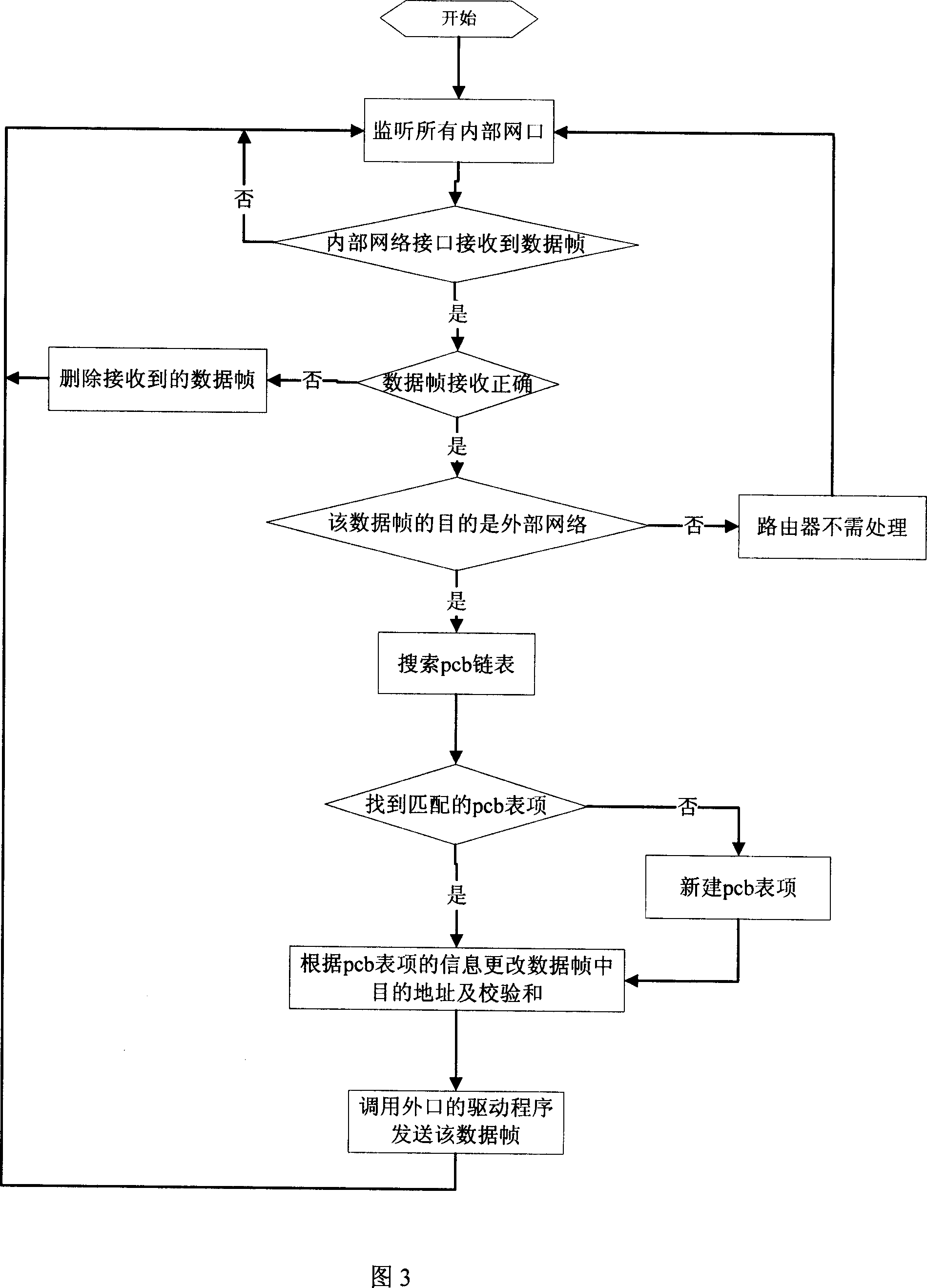

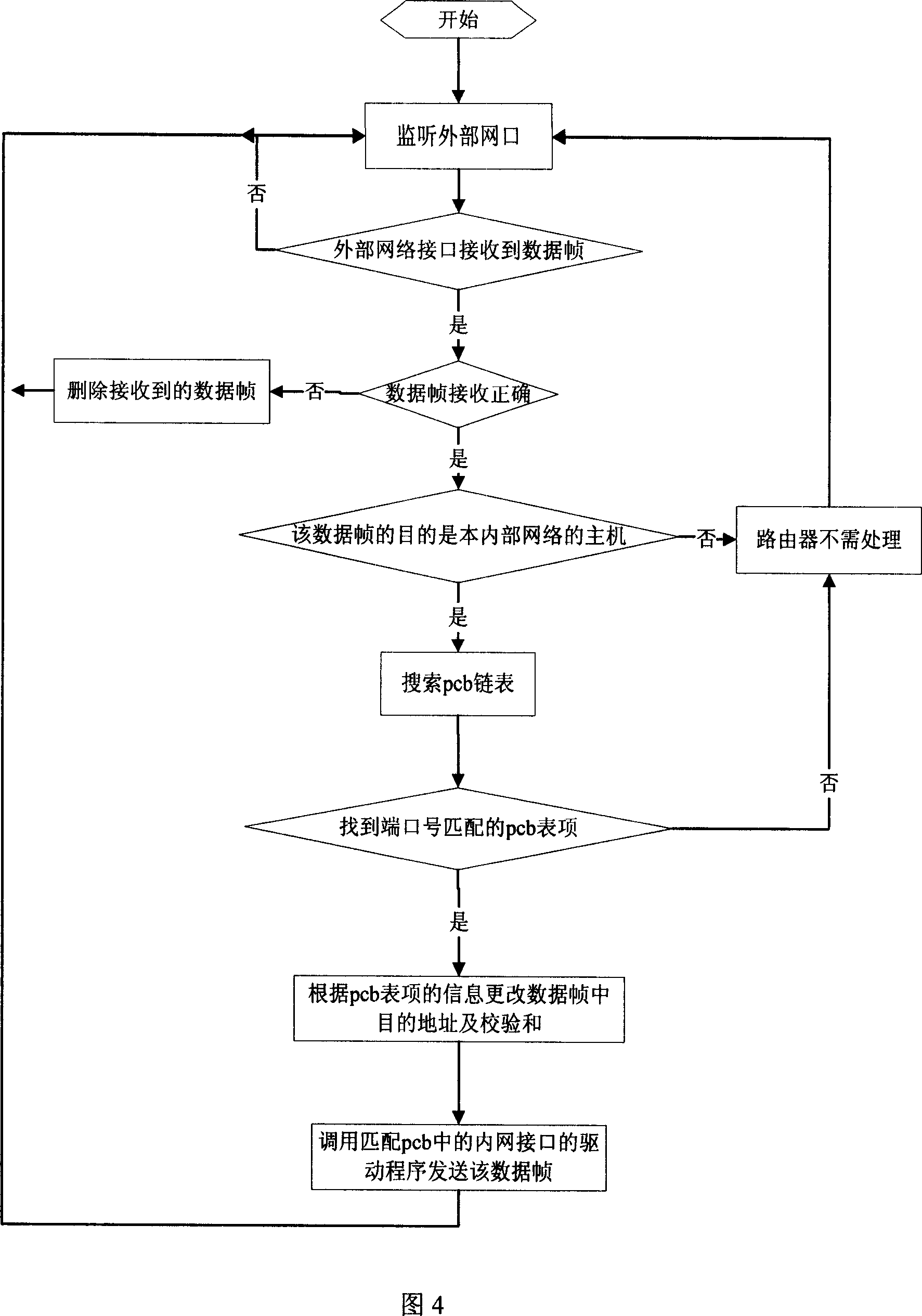

A method for network address translation

ActiveCN1996945AImprove conversion efficiencyThe principle is simpleNetwork connectionsIp addressNetwork addressing

This invention discloses one network address conversion method to realize conversion between public and private network addresses by use of process control block, wherein, the method comprises the following steps: converting the private address into public address; converting the private address into public address and establishing control block in the house network gate and modifying the data frame terminal number and source IP address and sending the data frame to the public network; modifying the data frame aim IP address and aim terminal number according to the process control block information.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

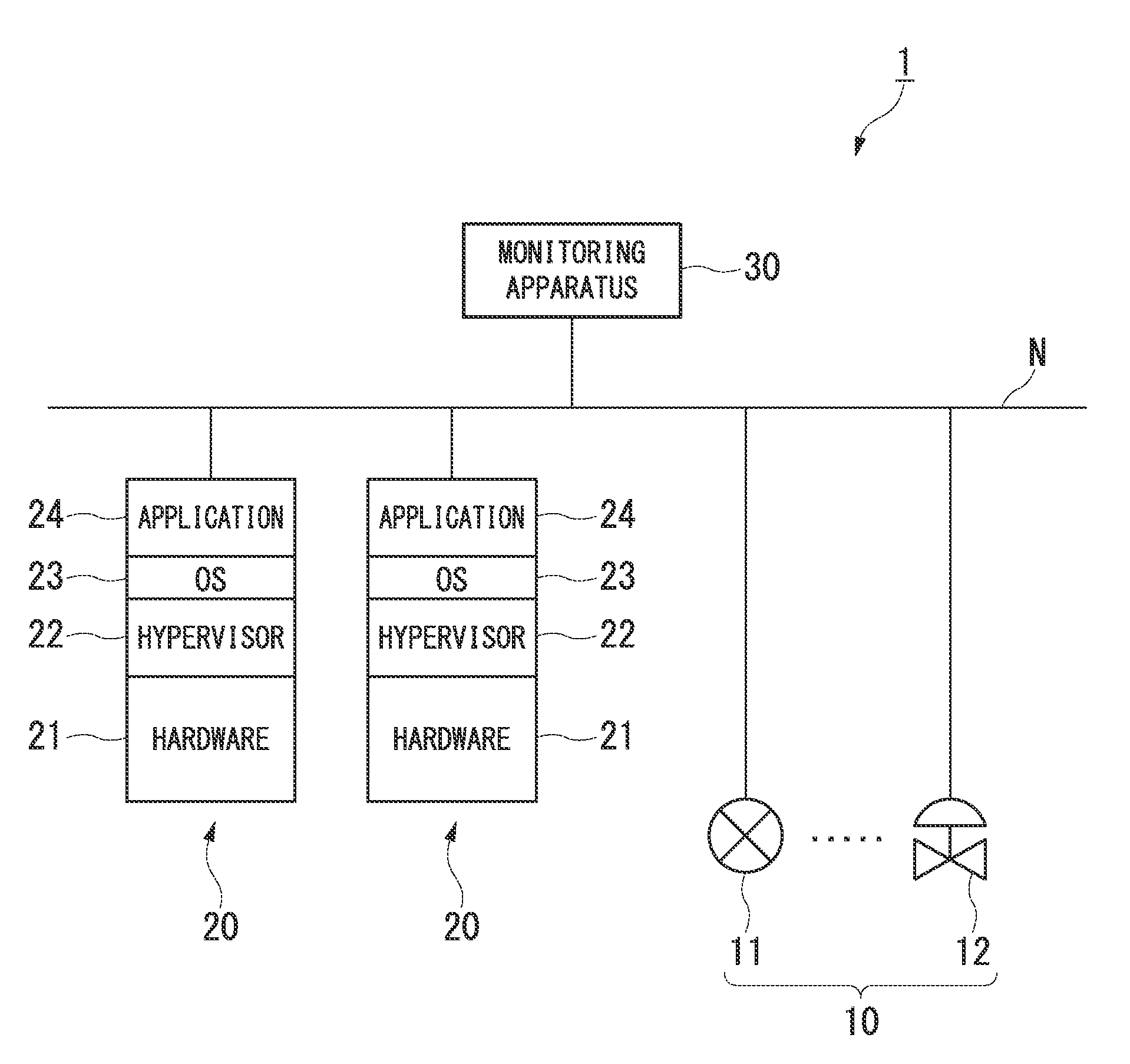

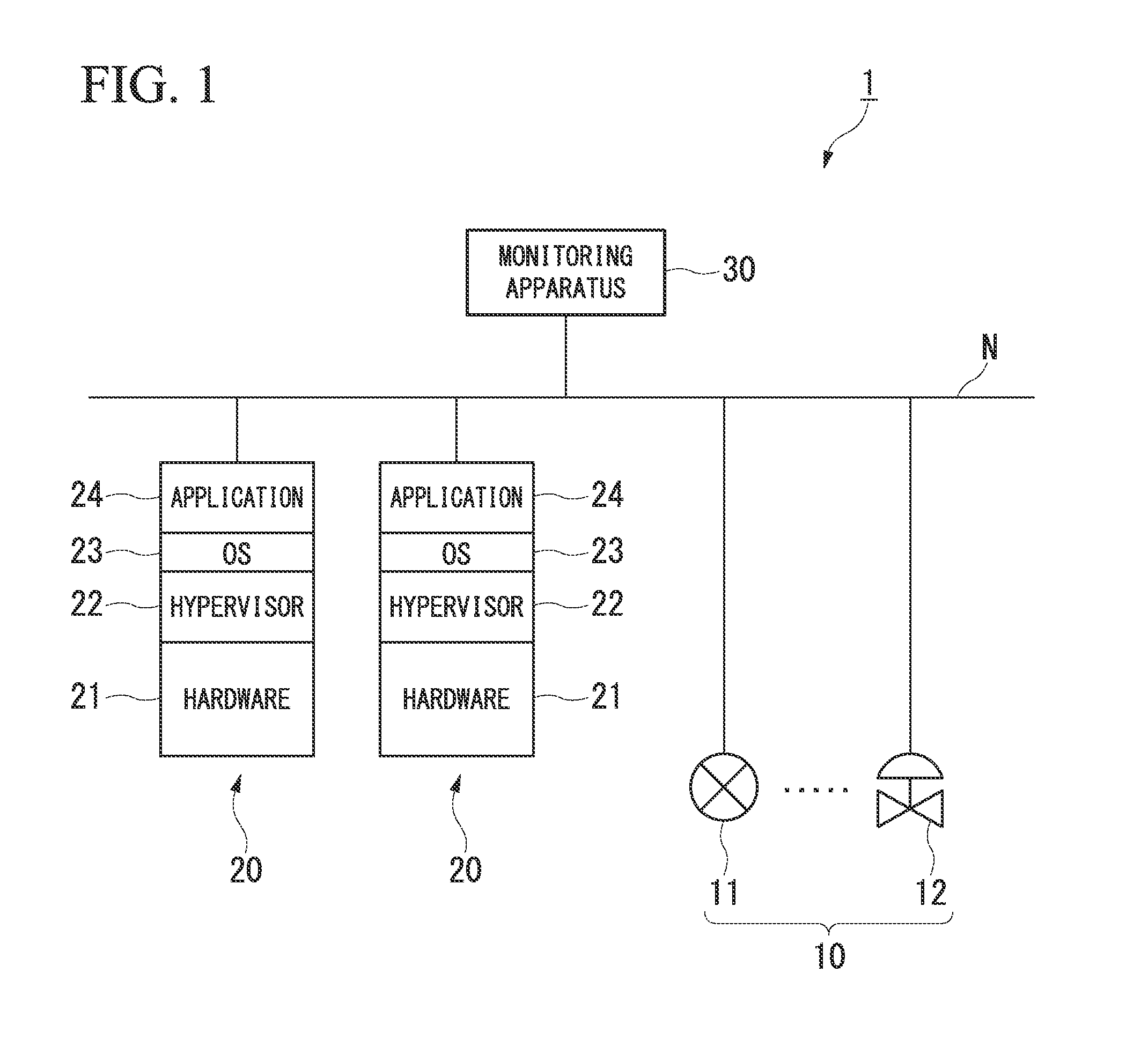

Process control system

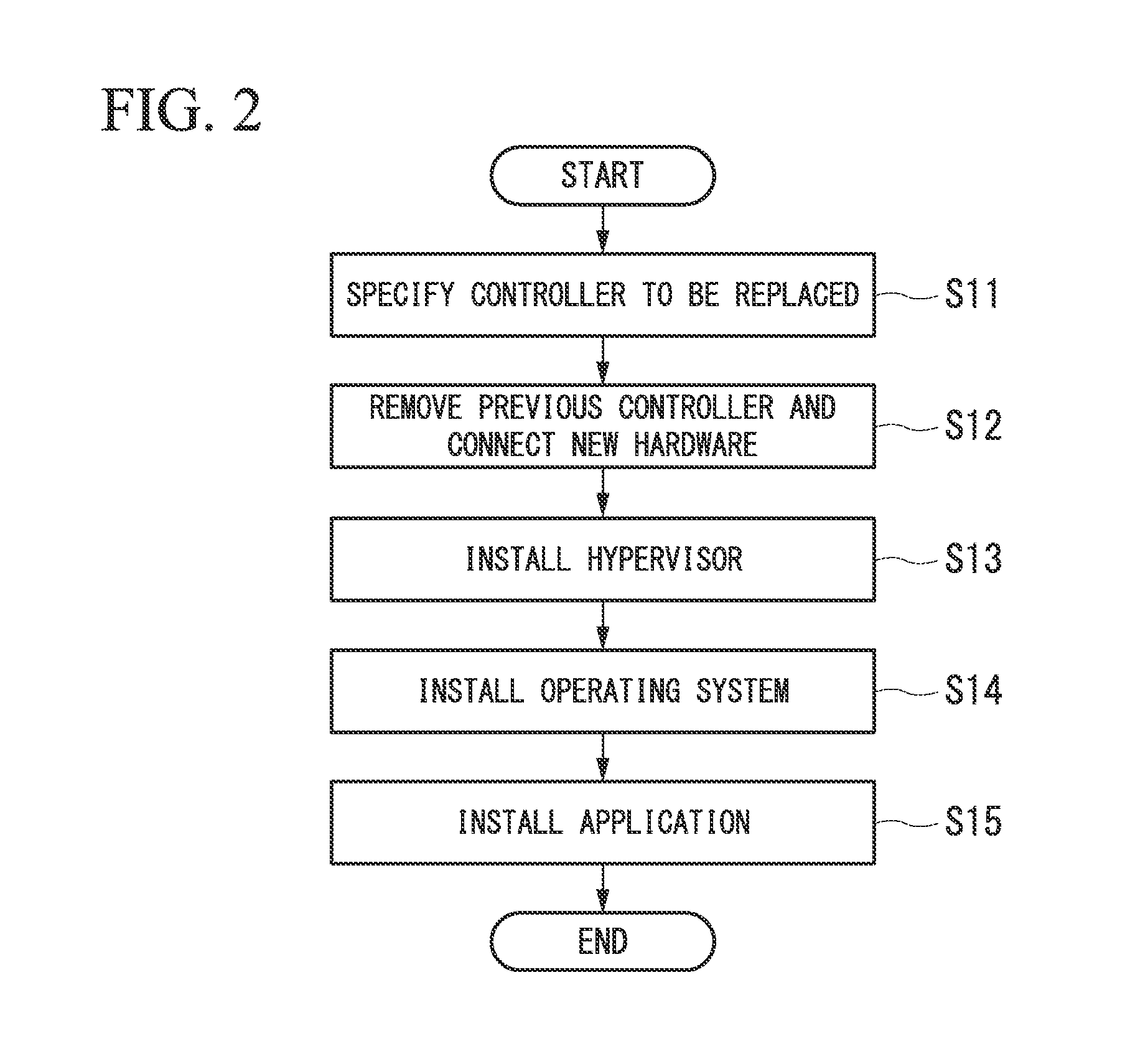

ActiveUS20130253671A1Control performanceProgramme controlSafety arrangmentsControl systemEngineering

A process control system performing control of an industrial process implemented in a plant, may include: a network provided in the plant; a plurality of field devices connected to the network, each of the plurality of field devices is configured to perform at least one of measurement and actuation required for control of the industrial process; and a controller, connected to the network, having a virtual part configured to operate in hardware in place of hardware, and a control unit configured to operate in the virtual part and to control operations of the field devices via the network, the controller being configured to enable replacement of hardware without changing the control unit.

Owner:YOKOGAWA ELECTRIC CORP

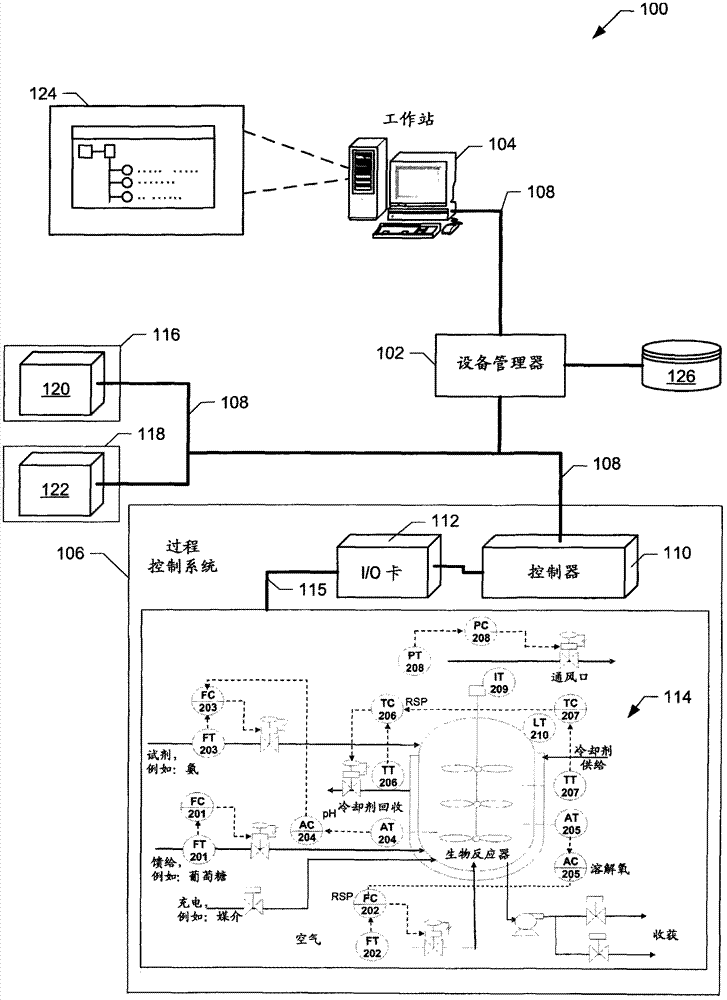

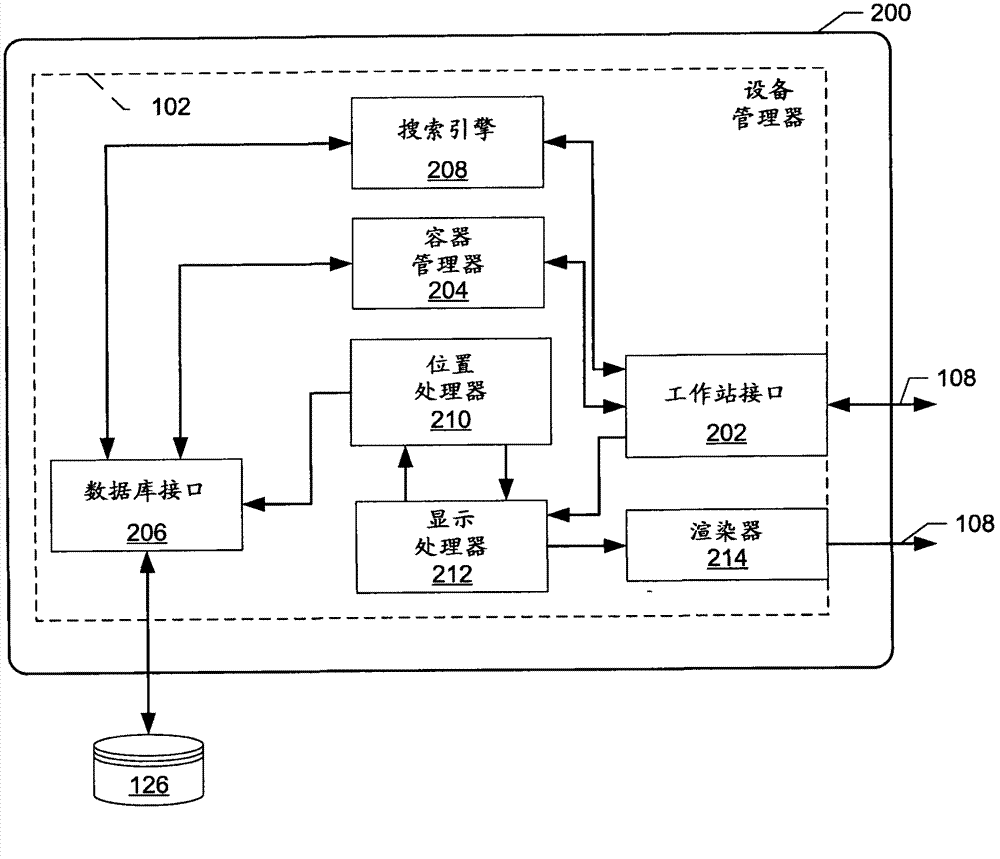

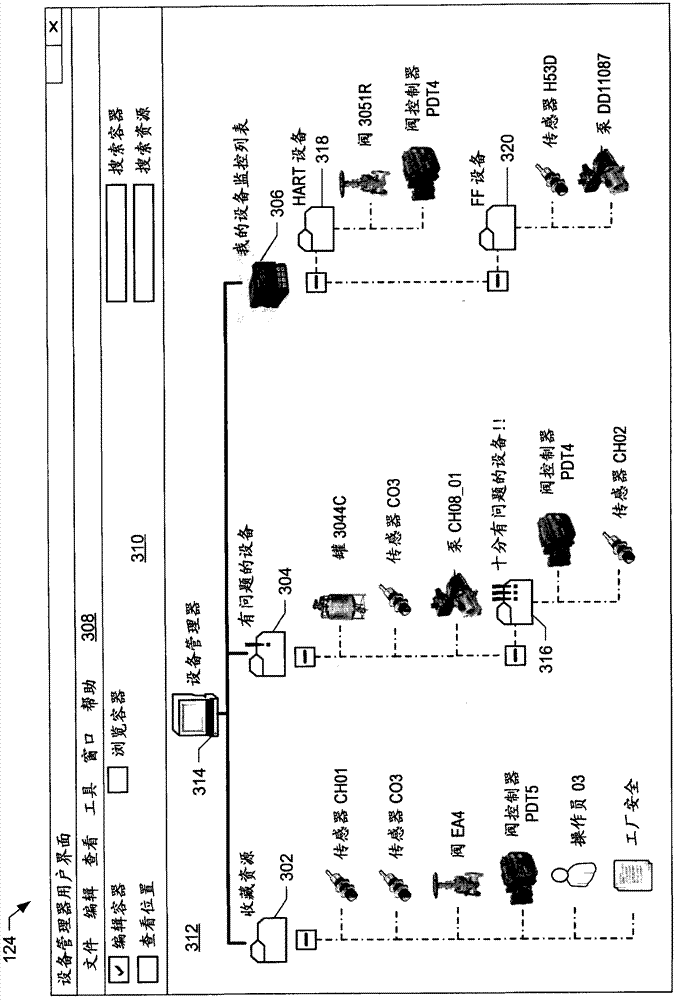

Methods and apparatus to manage process control resources

ActiveCN102736582AElectric testing/monitoringProgramme total factory controlControl systemComputer science

Example methods and apparatus to manage process control resources are disclosed. A disclosed example method includes receiving a selection of a first process control resource within a process control system to be associated with a logical container, the logical container including other process control resources that have a same user defined characteristic in common with the first process control resource, creating an entry within the logical container for the first process control resource by storing an identifier of the first process control resource in the logical container, and assigning the first process control resource to the logical container so that the identifier of the first process control resource links to process control information associated with the first process control resource.

Owner:FISHER-ROSEMOUNT SYST INC

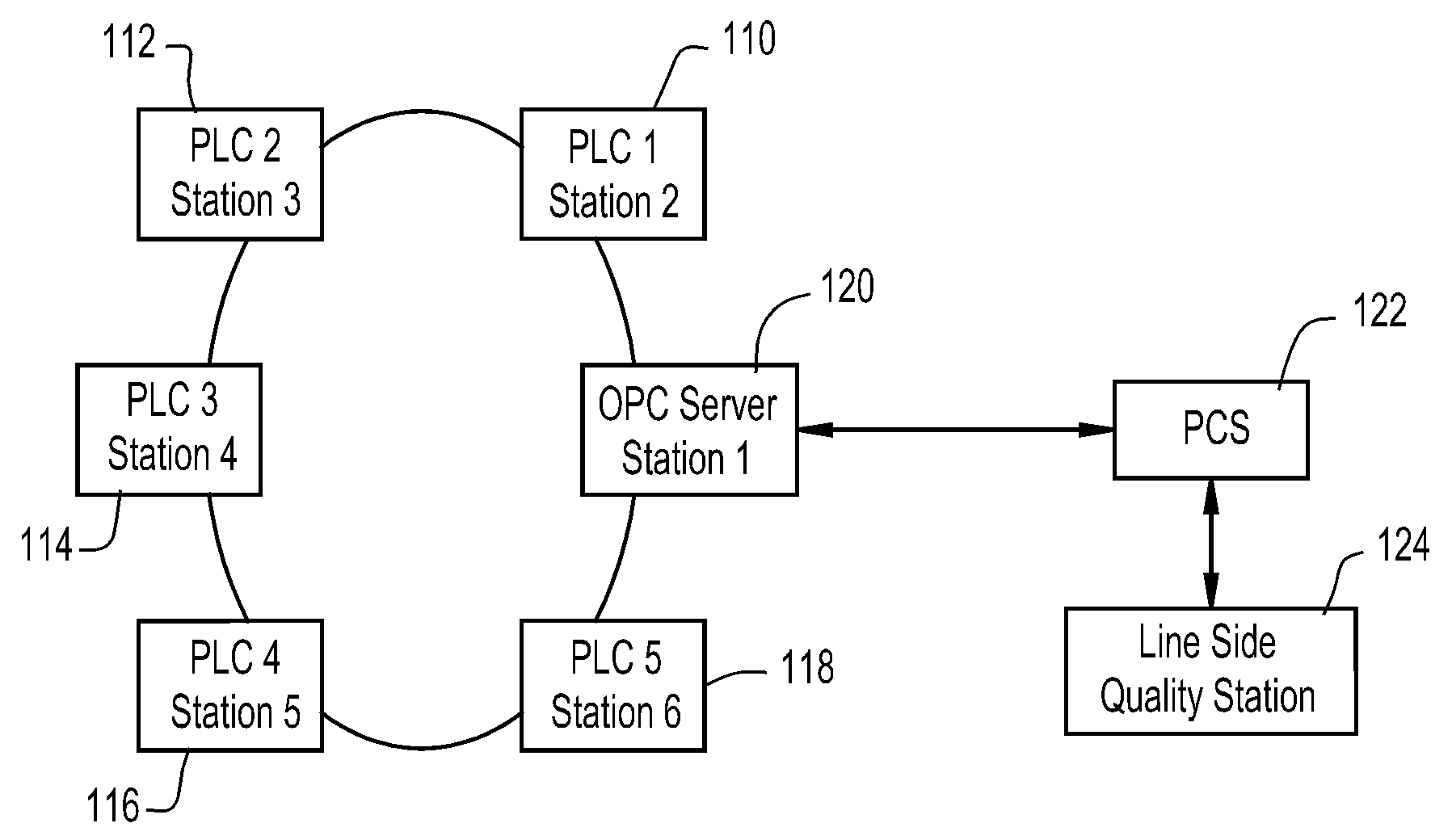

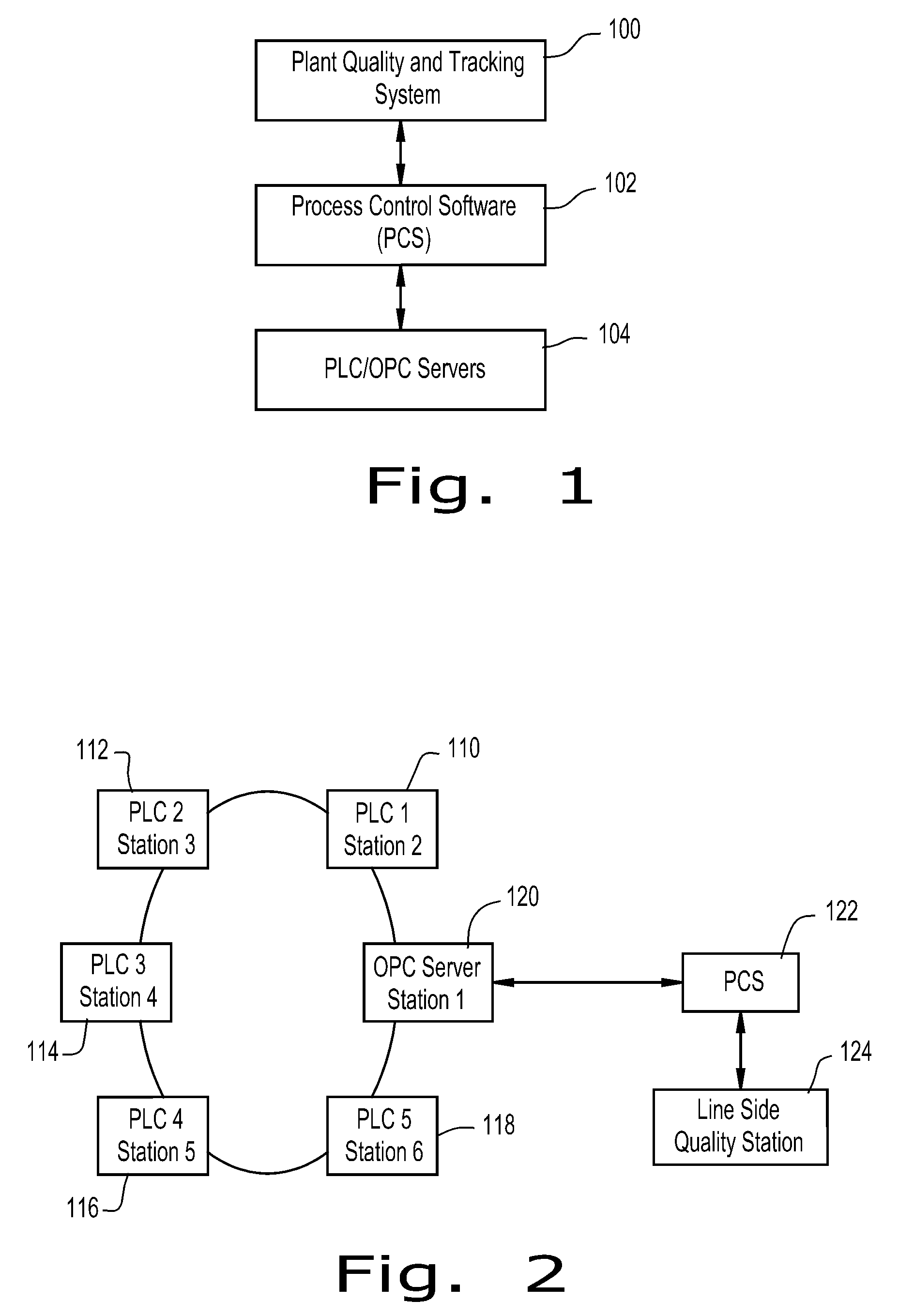

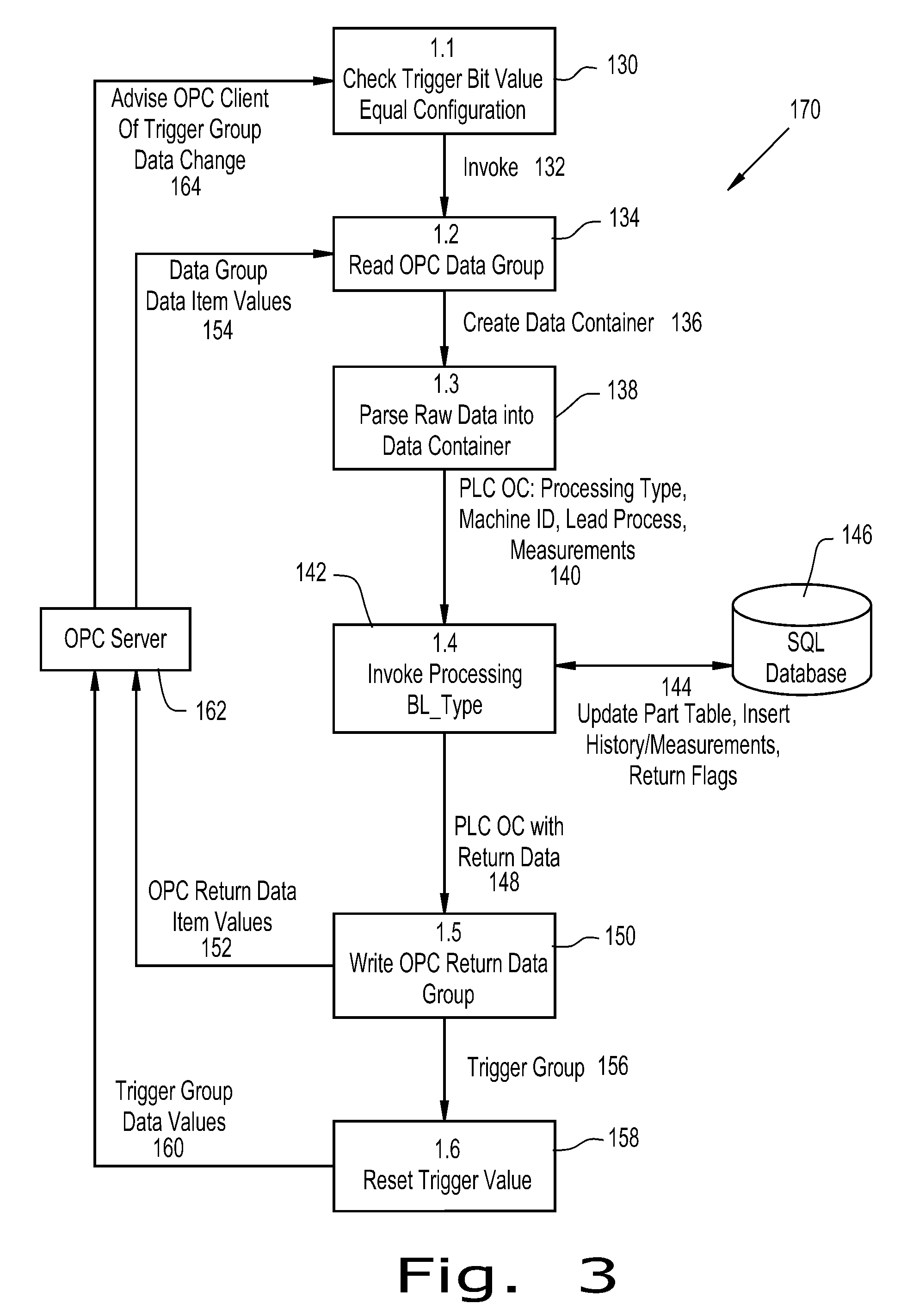

Process control system with ability to exchange data with production line machine controllers

InactiveUS20090248173A1Raise the possibilityReduces part defectComputer controlSimulator controlProduction lineControl system

A system and method for integrating a production line process control system (PCS) with production line machine controllers to record data about processes completed on a production line. The PCS receives data from line controllers regarding processes that are completed on each part. Process data including process order data is stored by the PCS and used to instruct line controllers on whether a particular part should be accepted for machining or handled in another way. Rejected parts are flagged electronically so when they arrive at a subsequent line controller, they are directed to a chute containing parts removed from the production process. The PCS and line controllers exchange data about each part and applicable processes as it proceeds through production. The PCS records the data to develop a complete part history. The PCS integrates with a plant quality and tracking system that records the historical data.

Owner:HONDA MOTOR CO LTD

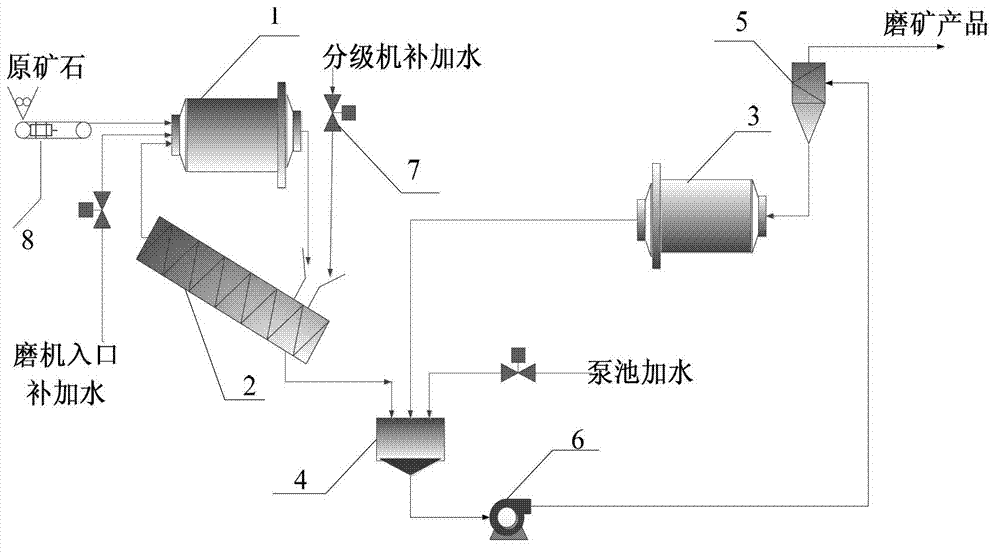

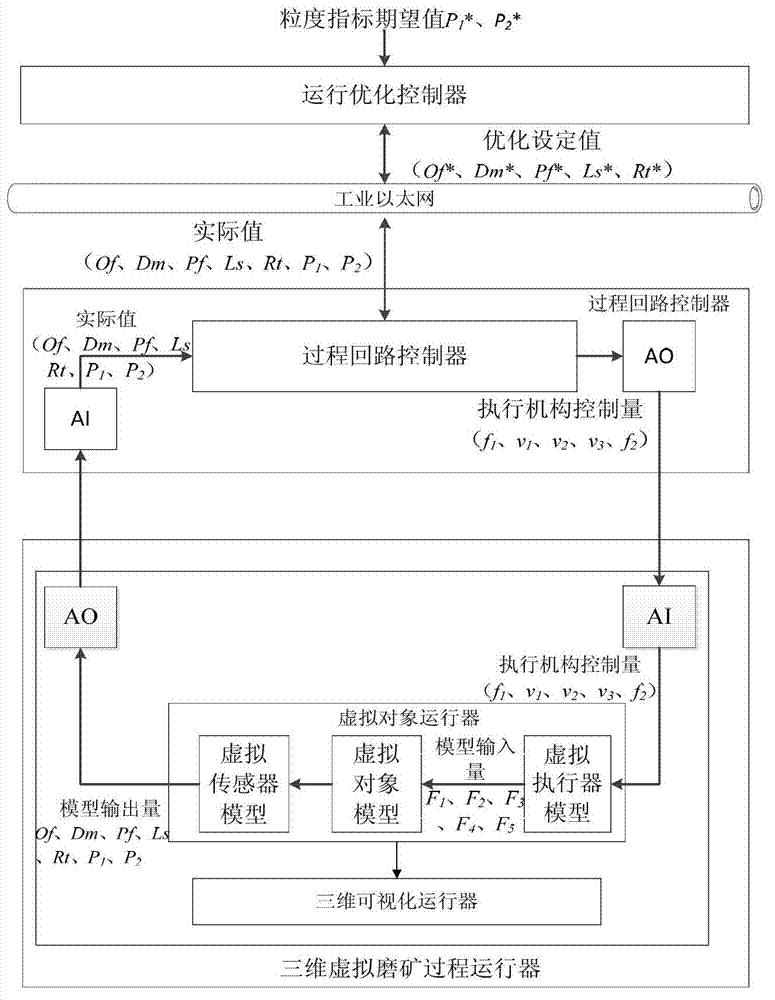

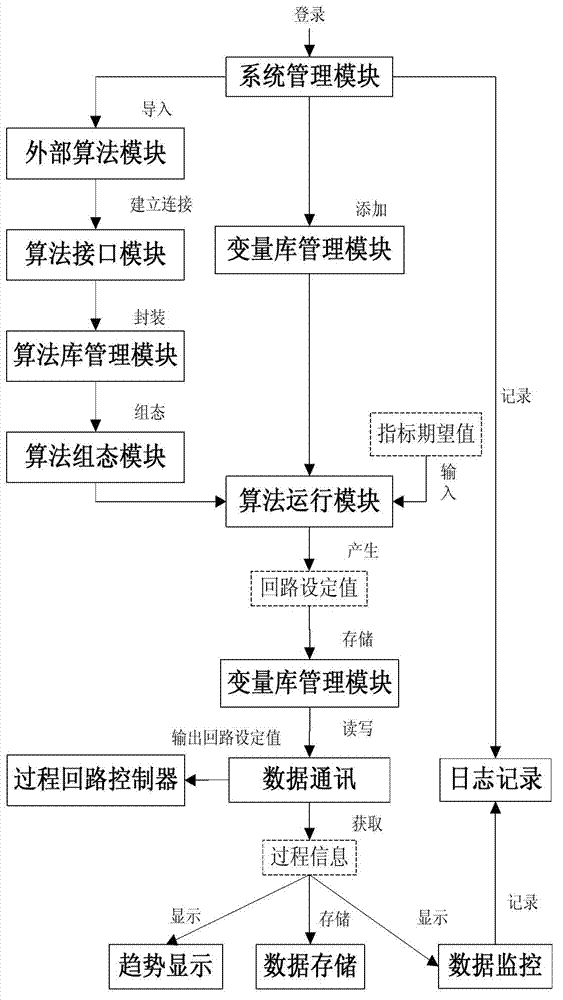

Experimental system and method of ore grinding process control

ActiveCN103092072ASolve the problems of relying on artificial experience, strong randomness, and unreasonable decision-makingWith three-dimensional visual effectAdaptive controlLoop controlAutomatic control

The invention relates to an experimental system and a method of ore grinding process control, and belongs to the technical field of automatic control. The system comprises an operation optimization control device, a process loop control device, and a three-dimensional virtual ore grinding process operation device, wherein the three-dimensional virtual ore grinding process operation device comprises a virtual object operation device and a three-dimensional visualization operation device, new software and hardware technologies and simulation technologies are used on the process loop control device to enable the process loop control device in development and the three-dimensional virtual ore grinding process operation device to be as close as possible to a real industrial environment, and the process loop control device has good visuality and compatibility. The system further integrates the operation optimization control device, so that the problems that in the real industrial process, the loop set value is depended on human experience, arbitrariness is high, and decisions are unreasonable are solved. Therefore, the experimental system and the method of the ore grinding process control are good in versatility, strong in compatibility, and have three-dimensional visual effects. The experimental system and the method of the ore grinding process control are free from the restriction of a hardware device. The dynamic substitution between the optical control algorithm and the device model algorithm can be achieved, and the openness is good.

Owner:NORTHEASTERN UNIV

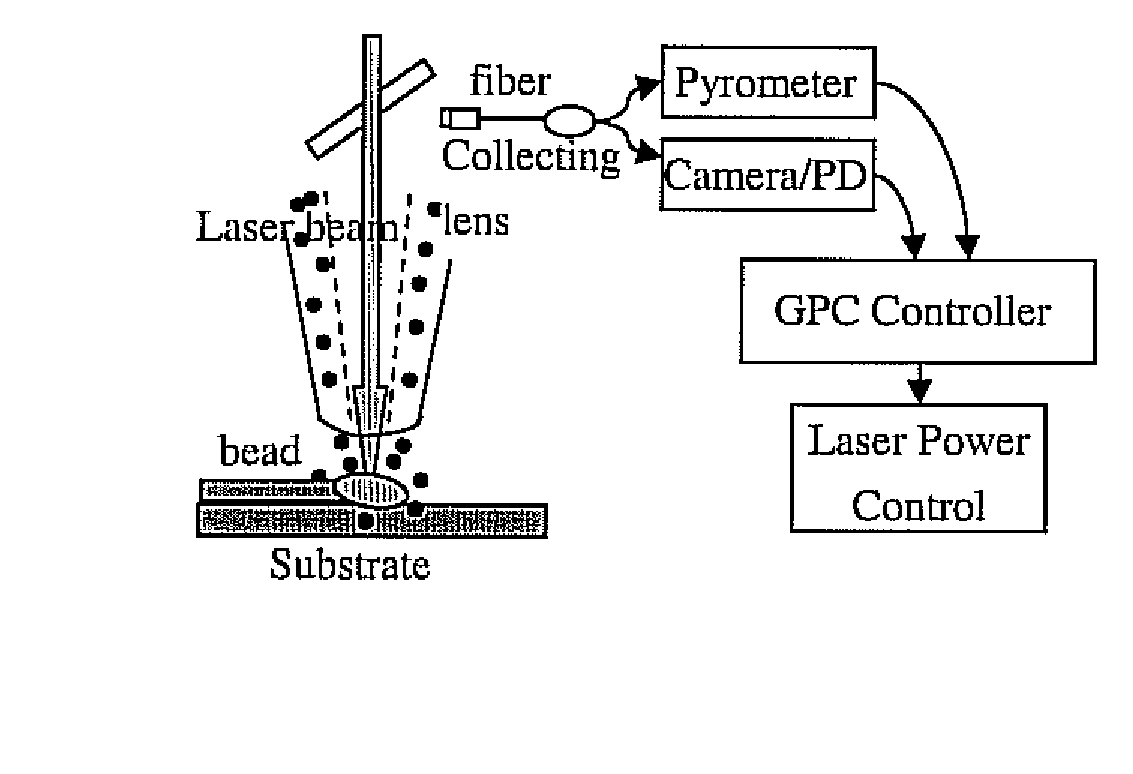

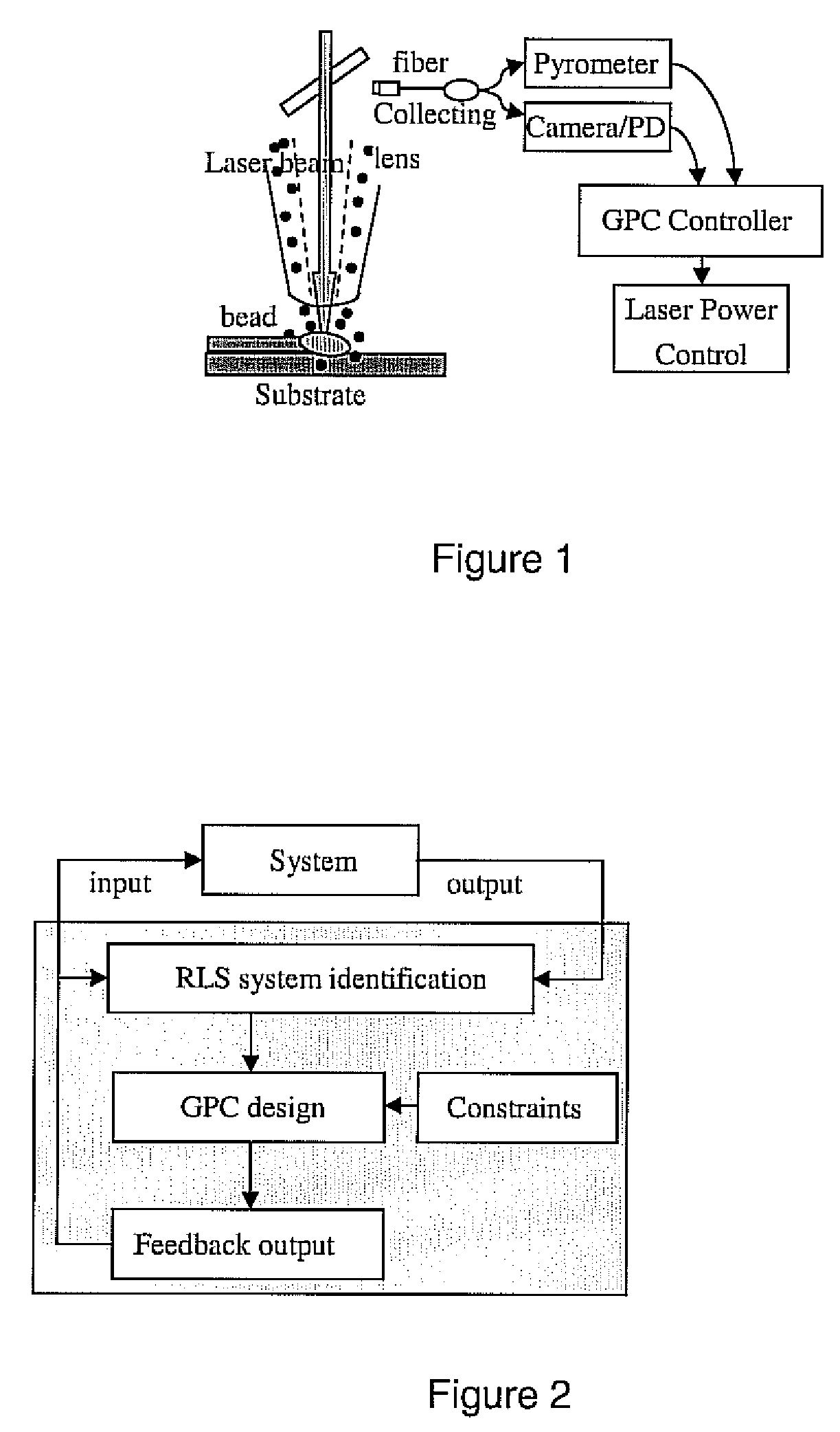

Real-time implementation of generalized predictive algorithm for direct metal deposition (DMD) process control

A direct metal deposition (DMD) process is stabilized by monitoring the temperature and the shape of the melt pool during deposition, applying a recursive least square (RLS) model estimation algorithm to adaptively identify process characteristics in accordance with the temperature and the shape of the melt pool, and delivering the process characteristics to a generalized predictive controller with input constraints to control the process. The process may be controlled by adjusting laser power or by adjusting the speed of the movement of the laser. In the preferred embodiment the temperature is monitored using a two-color pyrometer, and the shape of the melt pool is monitored by detecting the edge of the melt pool with a camera and / or photodetector.

Owner:P O M GRP THE

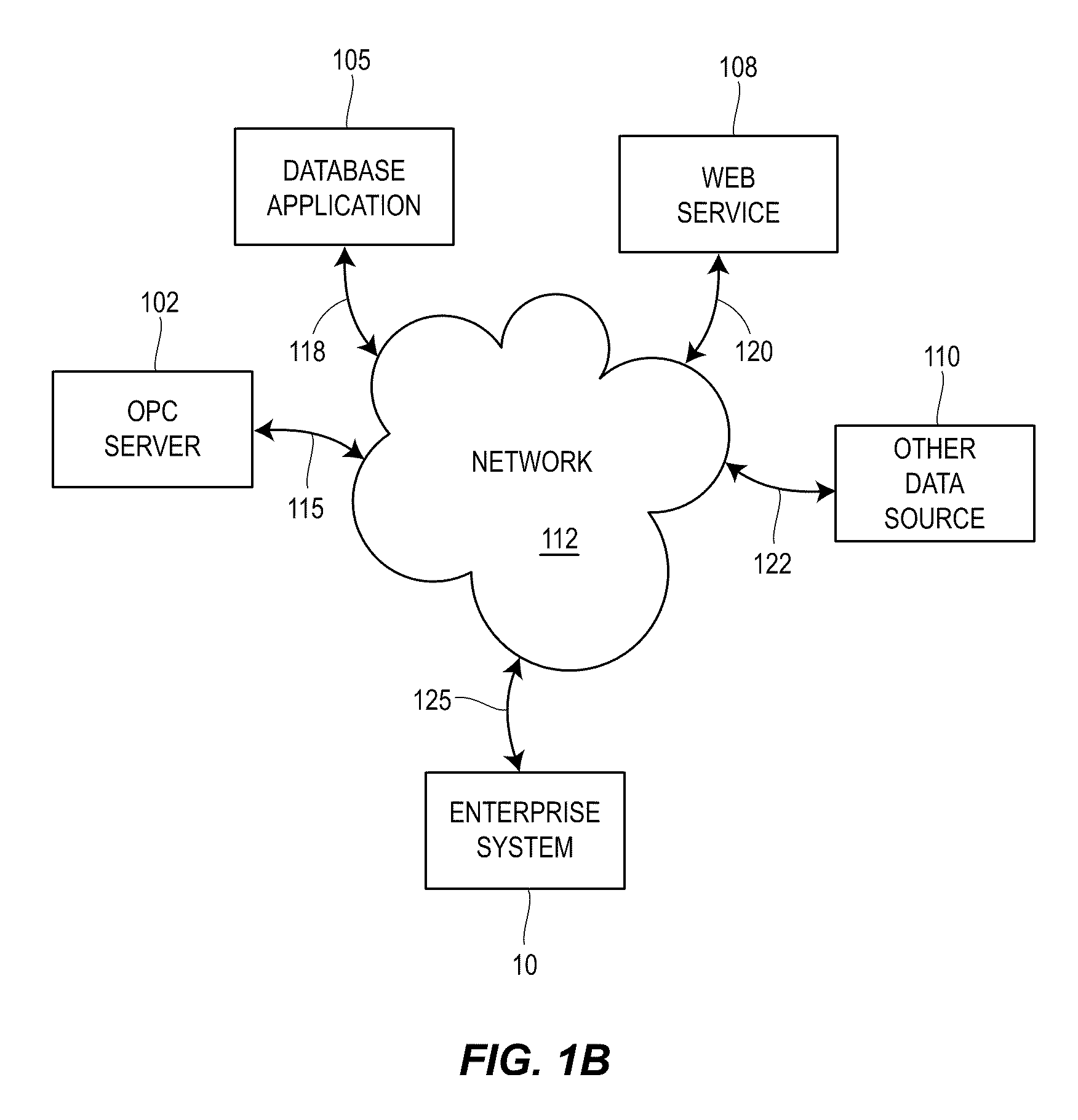

Process control system with integrated external data sources

Methods and systems for integrating external and / or enterprise data into a process control system are disclosed. A user interface may be provided to enable browsing and selection of a data item from an external and / or enterprise data source. The selected data item may be associated with a process control entity. At run time, independent of a configuration of the process control entity, an external data integration server or instance of an external data integration service at a process control computing device may periodically communicate with the data source to obtain an updated current value and updated current status for the selected data item for use by the process control entity. The external data integration server and / or external data integration service may consolidate access of external / enterprise data across process control entities, optimize communications with various data sources, and maintain a status of communication with each various data source.

Owner:FISHER-ROSEMOUNT SYST INC

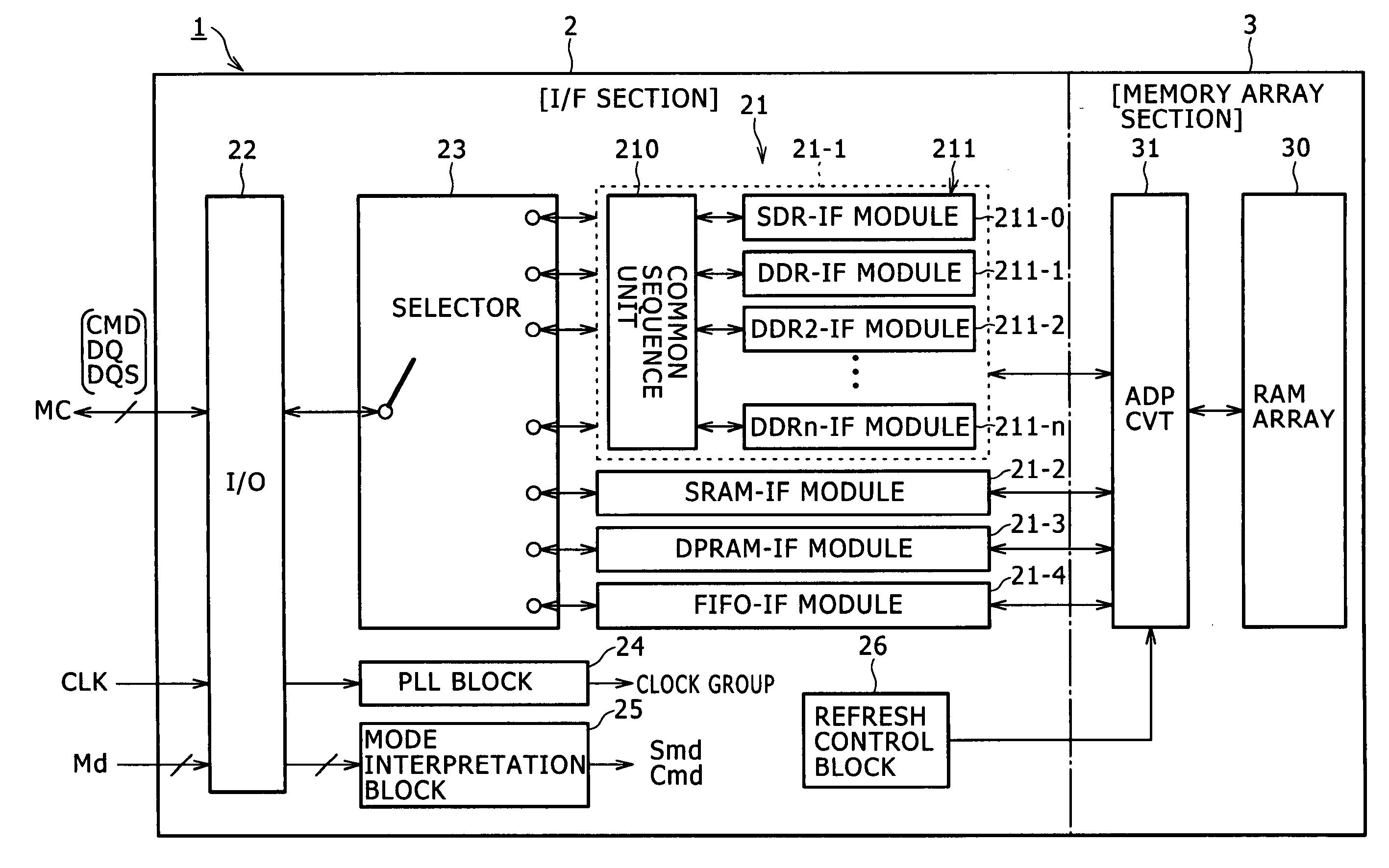

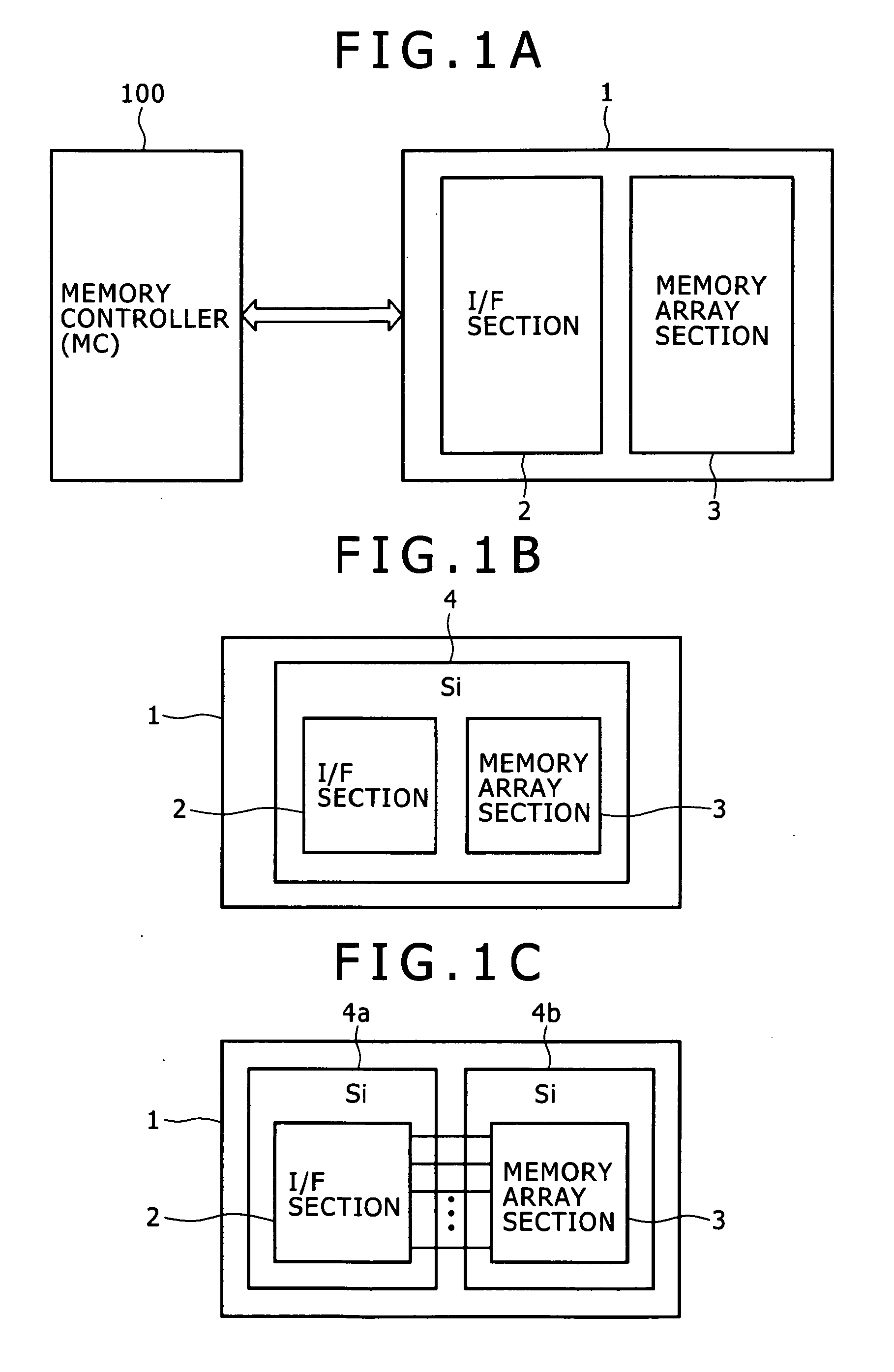

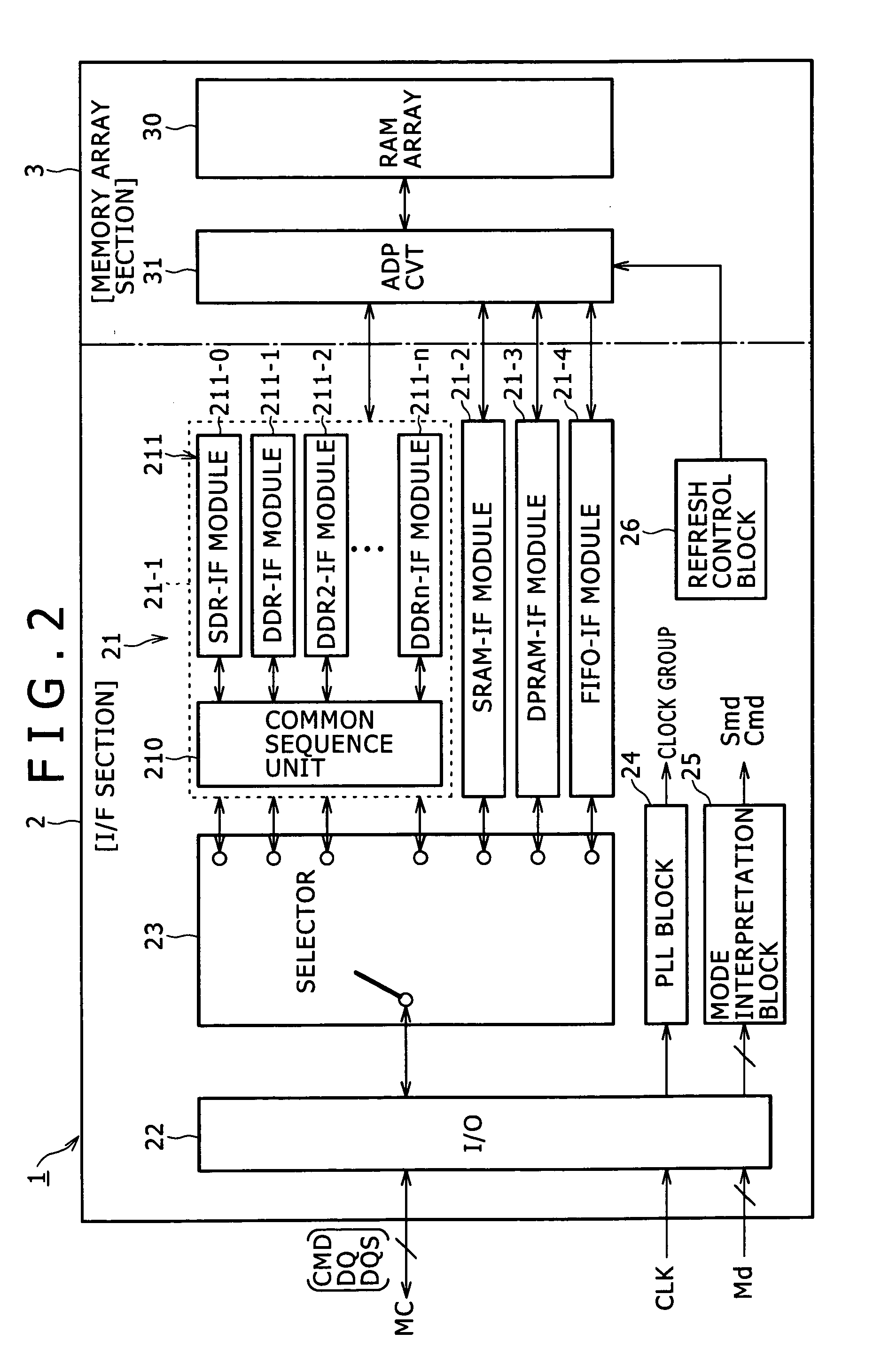

Semiconductor memory device and operation method therefor

Disclosed herein is a semiconductor memory device, including: a memory array section wherein a memory array which requires a refresh operation is formed; an interface section configured to carry out an interfacing process between an external apparatus and the memory array section; and a refresh control block for controlling the refresh operation; the interface section configured to include a plurality of interface modules individually corresponding to a plurality of memory types and selectively applied to the interfacing process between the external apparatus and the memory array section; the refresh control block having a function of issuing a refresh command within a refresh cycle and another function of preventing, if, upon issuance of the refresh command, an access command and the refresh command to the memory array are estimated to collide with each other, the collision.

Owner:SONY CORP

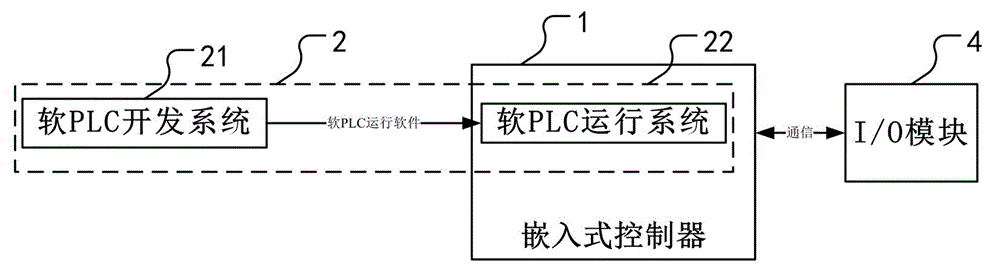

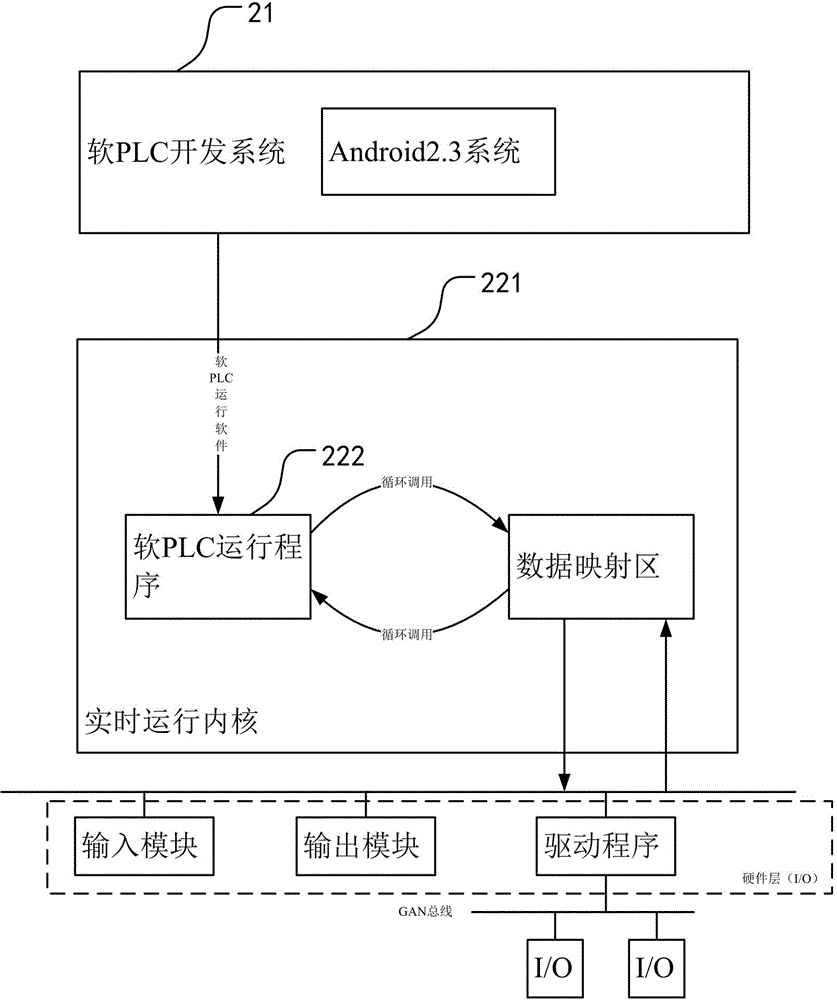

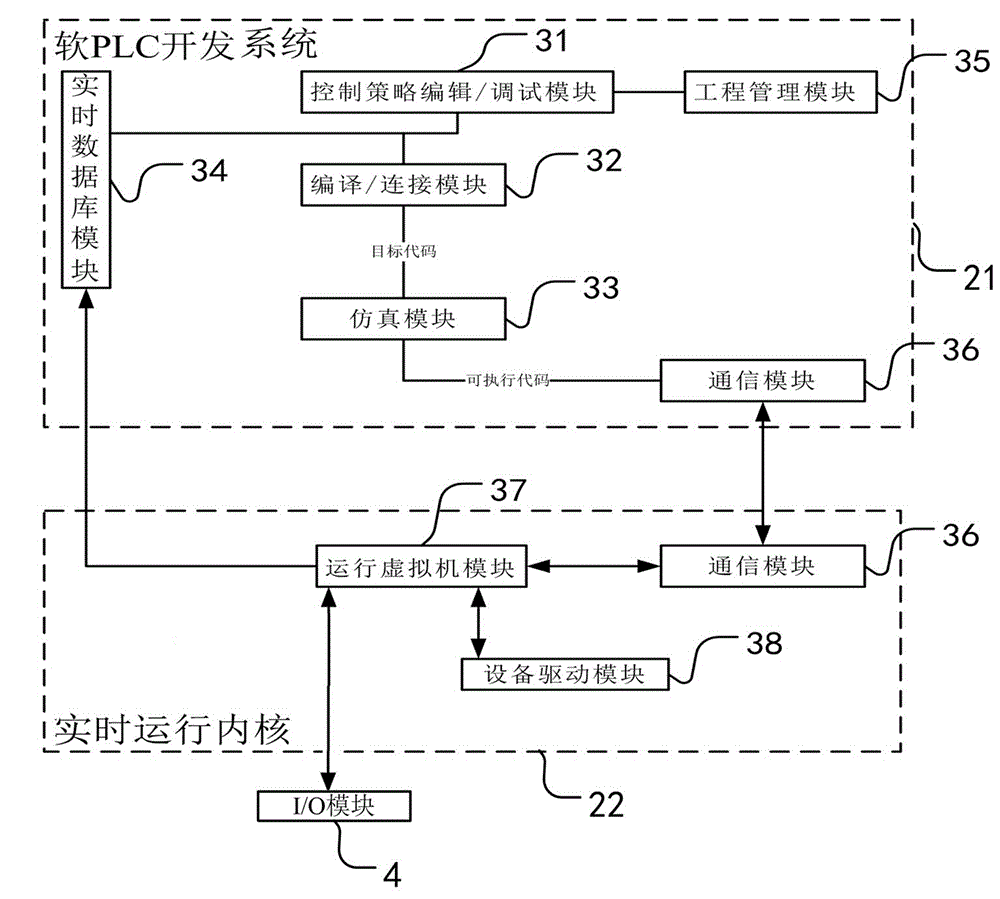

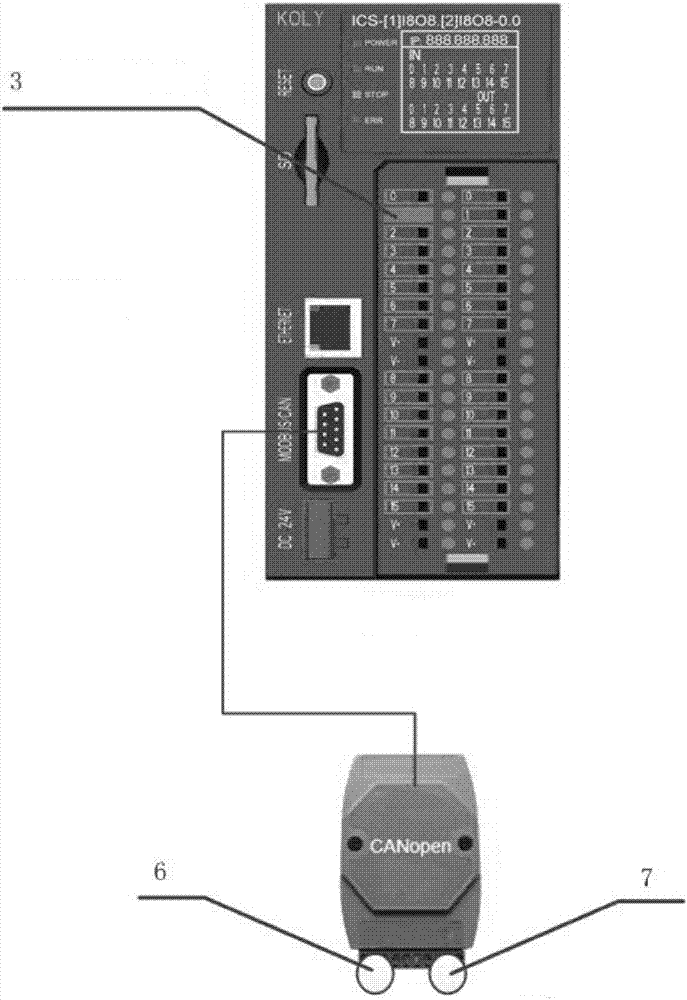

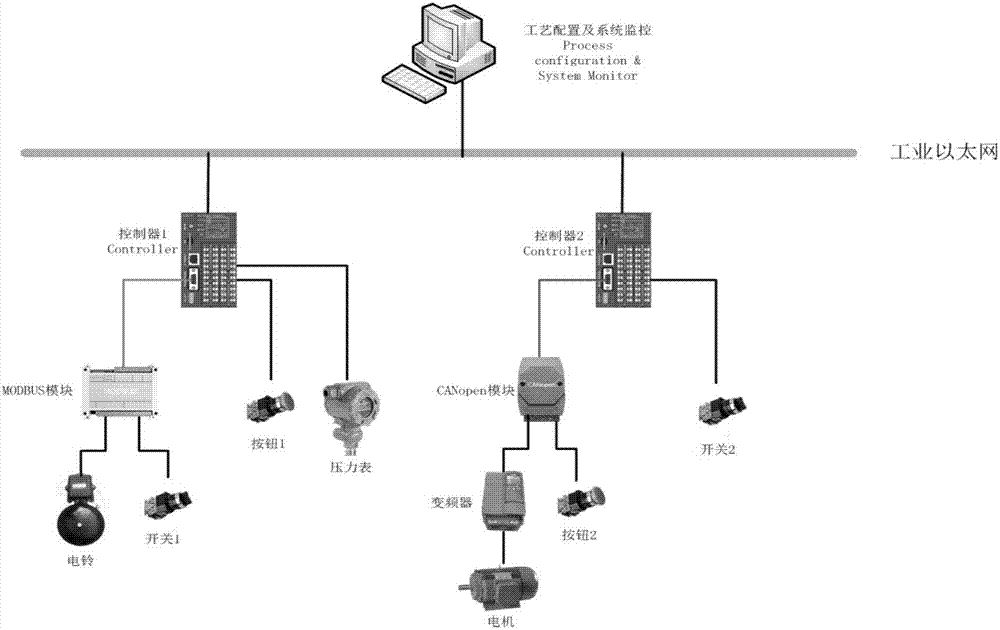

Soft PLC technology-based wireless sensor network control terminal

InactiveCN104317236AImprove applicabilityImprove good performanceProgramme control in sequence/logic controllersWireless mesh networkProcess control block

The present invention discloses a soft PLC technology-based wireless sensor network control terminal. The soft PLC technology-based wireless sensor network control terminal comprises an embedded controller which adopts an embedded system, an I / O module which is used for acquiring input information data and output processing-post information data of a detection area, and a soft PLC system, wherein the soft PLC system includes a soft PLC development system and a soft PLC operating system, wherein the soft PLC operating system includes a soft PLC operating program and a real-time operating kernel, wherein the real-time operating kernel is arranged in the embedded controller, the soft PLC operating program is used for the realizing various kinds of logic control and process control of a wireless sensor network. The soft PLC technology-based wireless sensor network control terminal of the invention can improve the applicability and scalability of a sensor network control system; the visual operation platform of the soft PLC technology-based wireless sensor network control terminal can satisfy requirements of use of different systems; the soft PLC technology-based wireless sensor network control terminal can increase the portability of the system and can assist in avoiding a complex process of a traditional PLC application process programming and simplifying operation.

Owner:SHANGHAI DIANJI UNIV +1

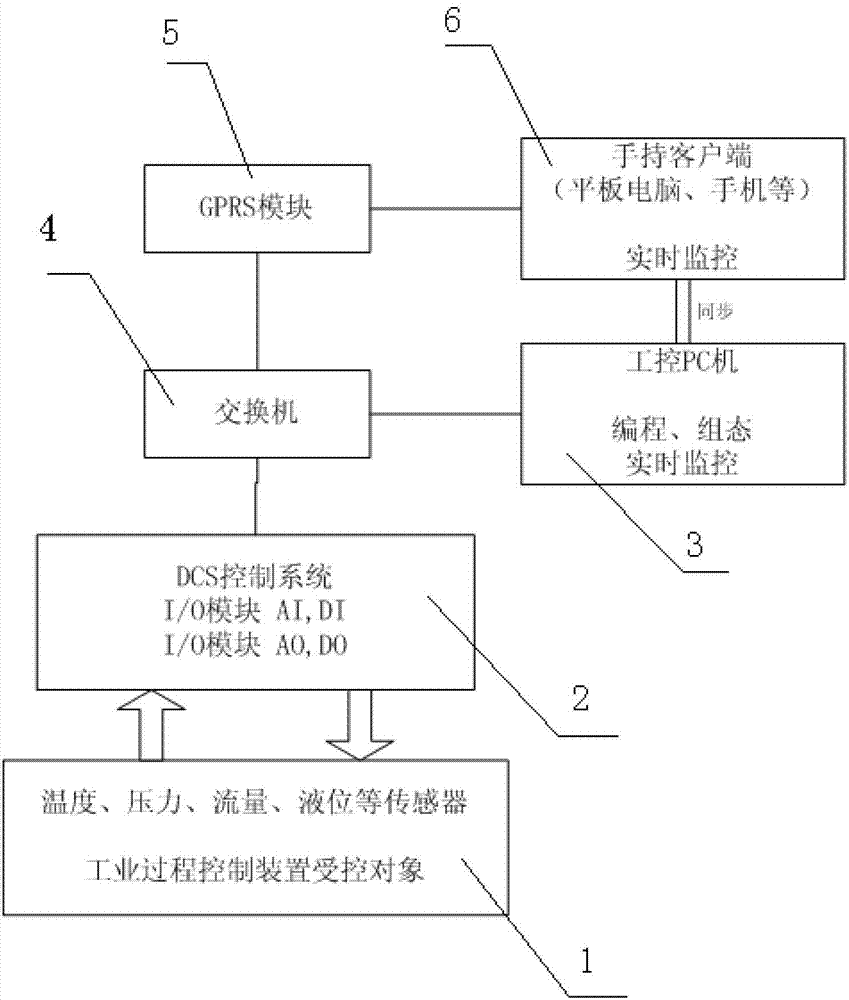

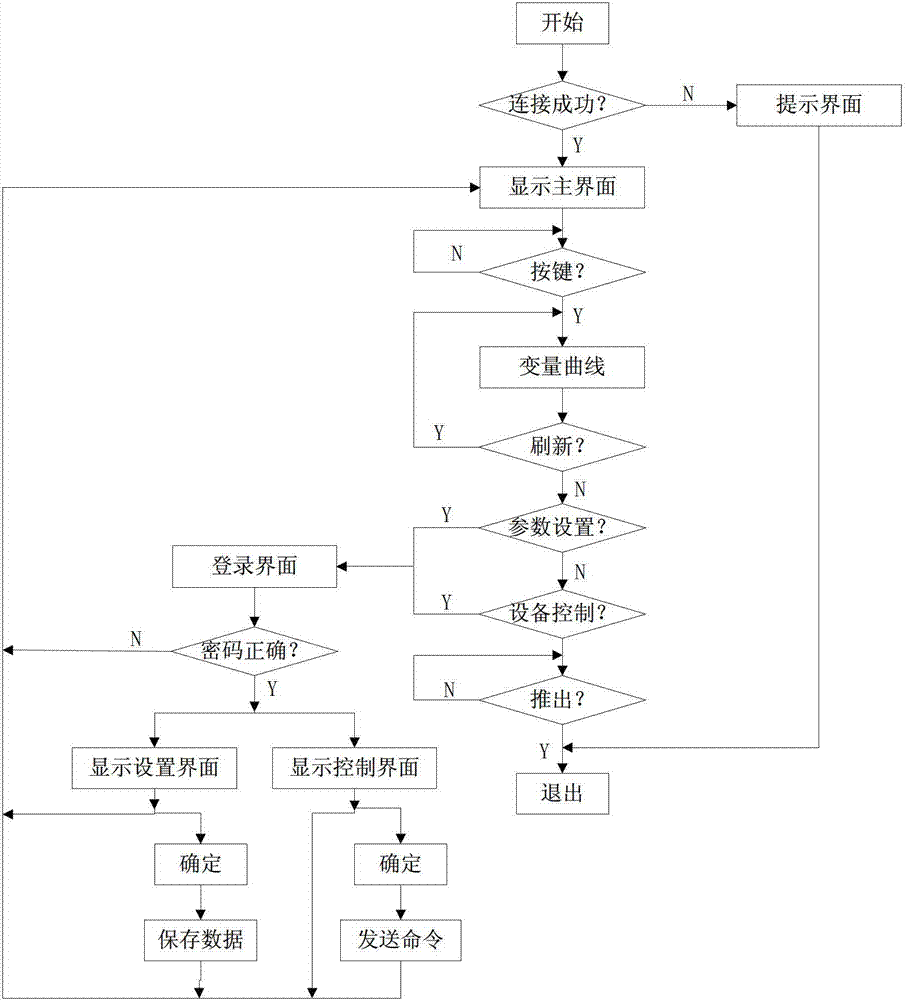

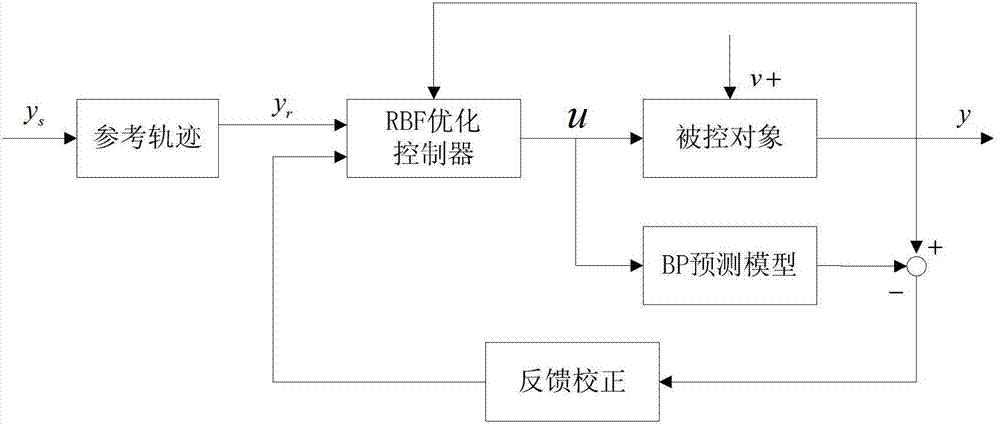

Process control system and method based on neural network predictive control

InactiveCN102830625AQuick responseEasy to trackTotal factory controlAdaptive controlGeneral Packet Radio ServiceDistributed control system

The invention discloses a process control system and a process control method based on neural network predictive control, comprising a physical controlled object, a DCS (distributed control system), an industrial control computer, a switch, a GPRS (general packet radio service) wireless communication module and a handheld client device. The physical controlled object is controlled by the DCS; the switch is connected with the DCS; the industrial control computer and the GPRS wireless communication module are connected with the switch; the handheld client device carries out wireless network communication through the GPRS wireless communication module, synchronizes with the industrial control computer and realizes remote and field monitoring. According to the process control method provided by the invention, the model prediction in predictive control is realized through a BP (back propagation) neutral network, the controller optimization in the predictive control is realized through an RBF (radial basis function) neutral network, and for a process control system with constraint conditions, the constraint conditions are taken into consideration as part of rolling optimization. In application, the process control system and the process control method based on the neural network predictive control has the following advantages: the response speed is high, the tracing performance is good, the robustness is good, and the anti-interference is strong.

Owner:JIANGSU UNIV OF SCI & TECH

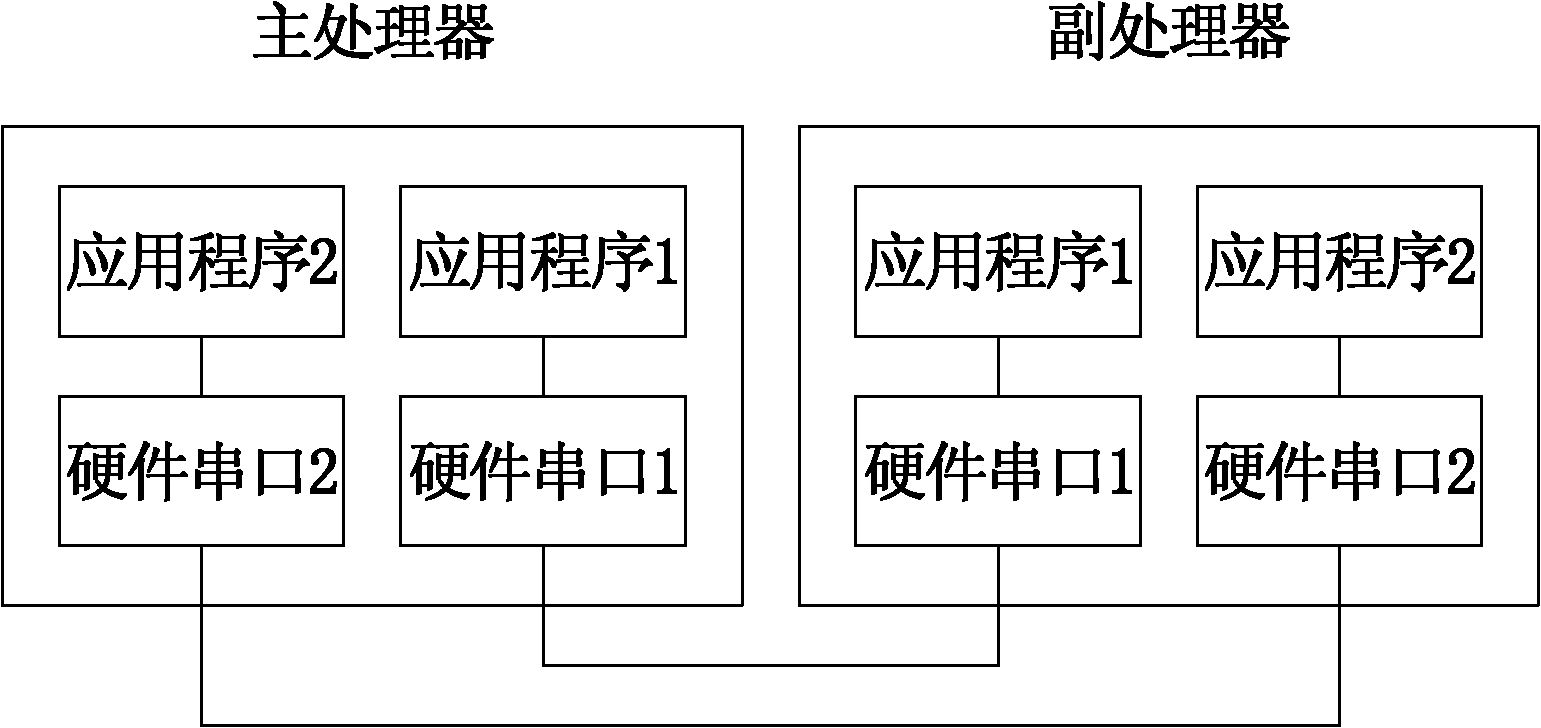

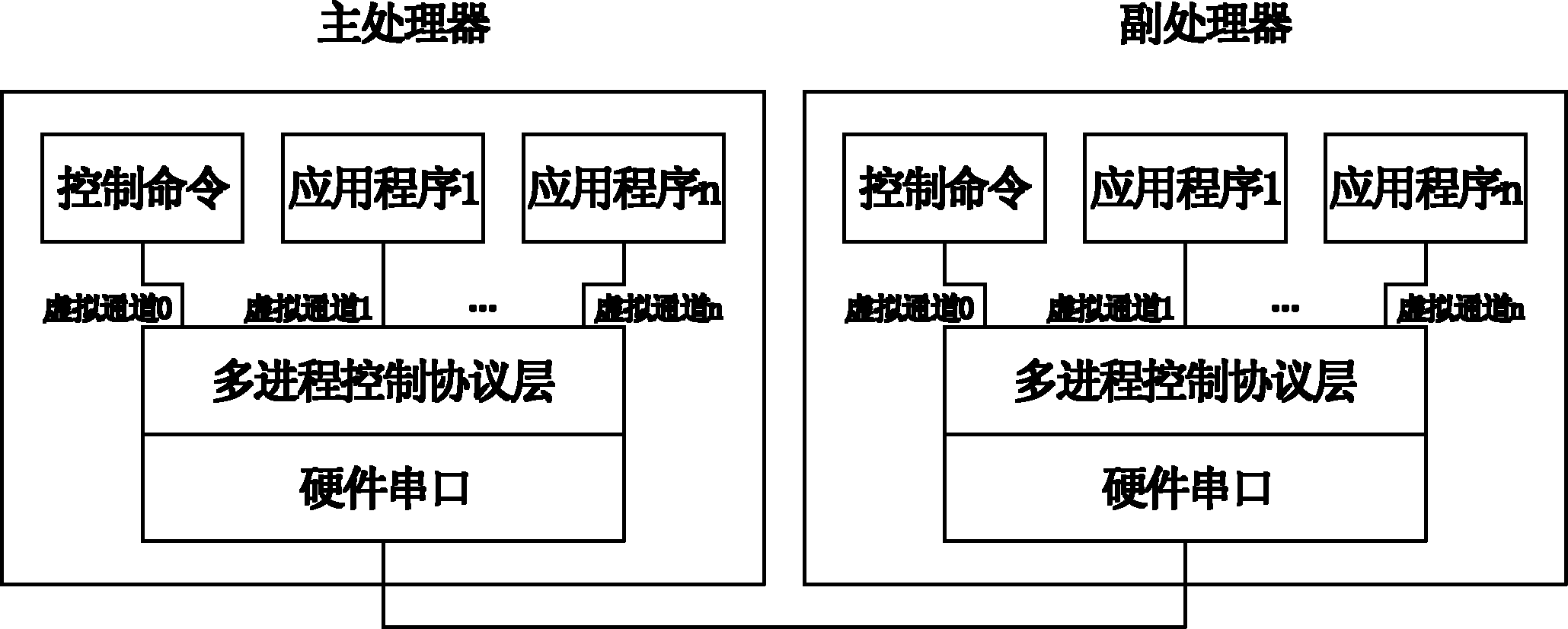

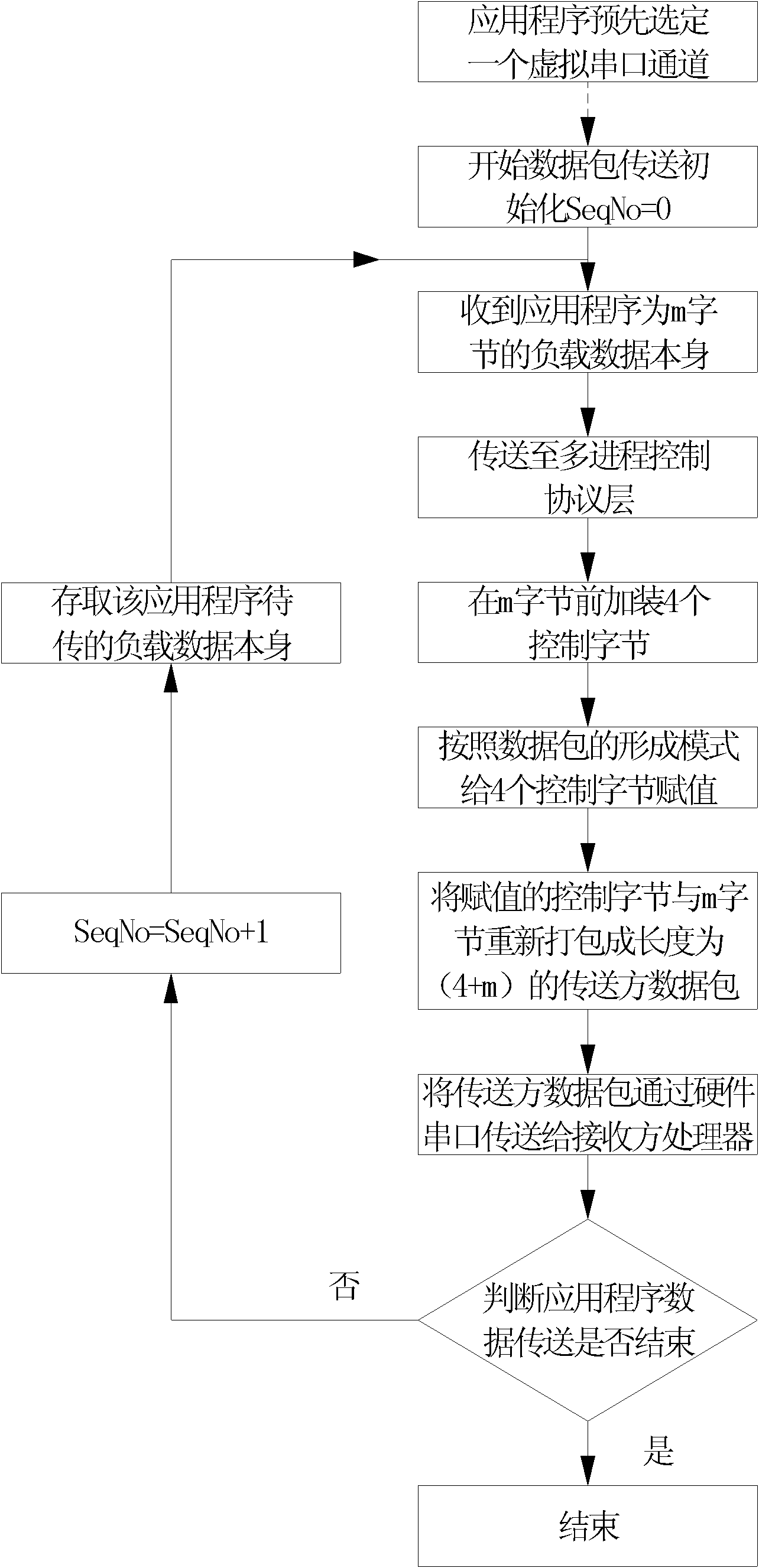

Communication method for implementing multi-process control through single hardware serial port

The invention discloses a communication method for implementing multi-process control through a single hardware serial port, which comprises the steps that: as much as 16 virtual serial port channels are provided on the single hardware serial port, a transmitting party transmits an application data packet to a receiving party on a multi-process control protocol layer according to the generation mode of the data packet, the receiving party unpacks and analyzes the data packet on the peer-to-peer multi-process control protocol layer. The method has the advantages that: multi-process control is offered to application by utilizing one essential hardware serial port, thereby saving the pin of hardware chip which increasingly becomes valuable in product design and being favorable for chip minimization; only 4 bytes are used as the control bytes for the data packet, which greatly improves the transmission speed and efficiency of data on the hardware serial port; and the data packet adopts the simple and effective generation mode which only takes up quite less memory and calculation resource, so the communication method is particularly suitable for high-speed data transmission and portable electronic products.

Owner:INTEBYTE ZHENJIANG

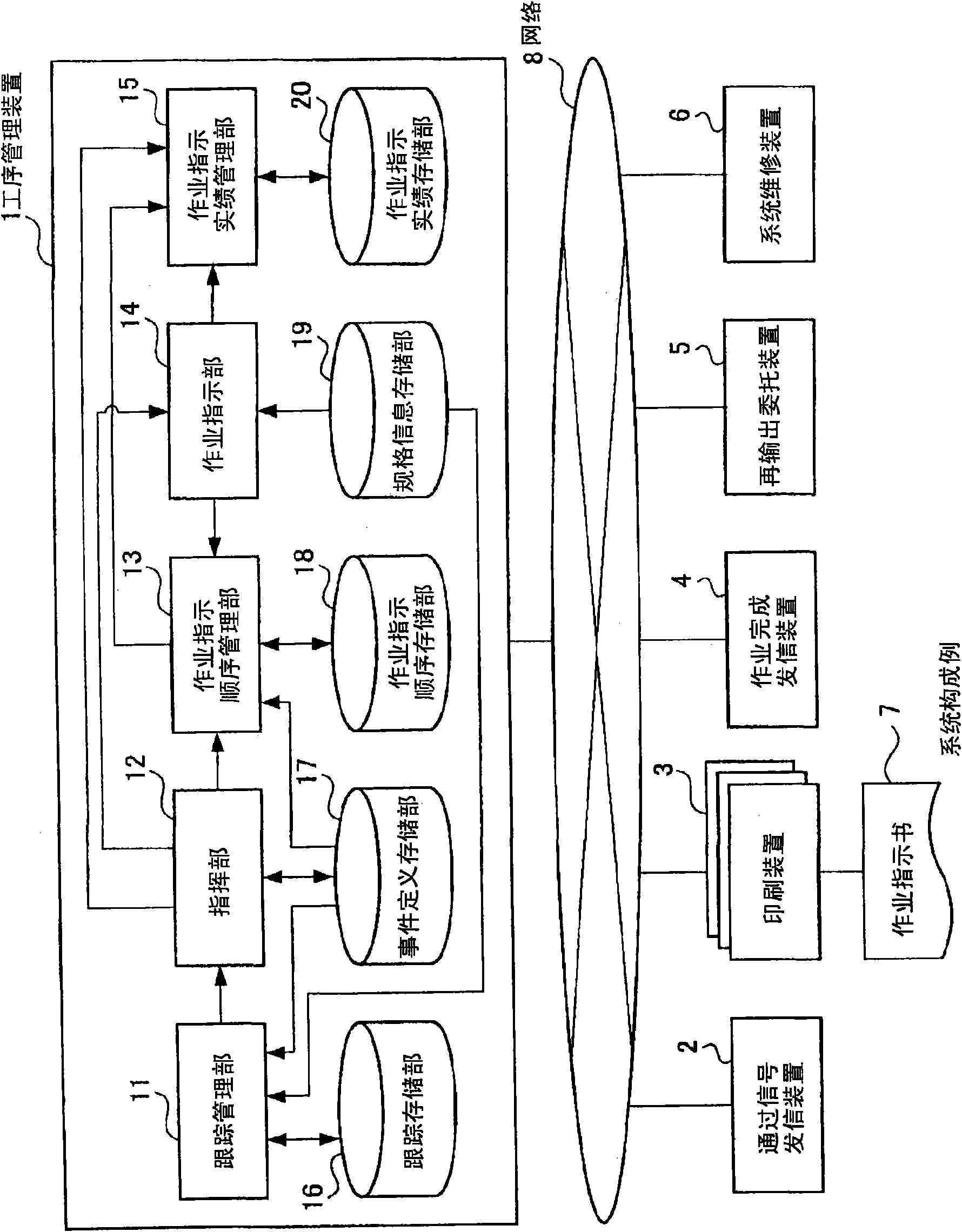

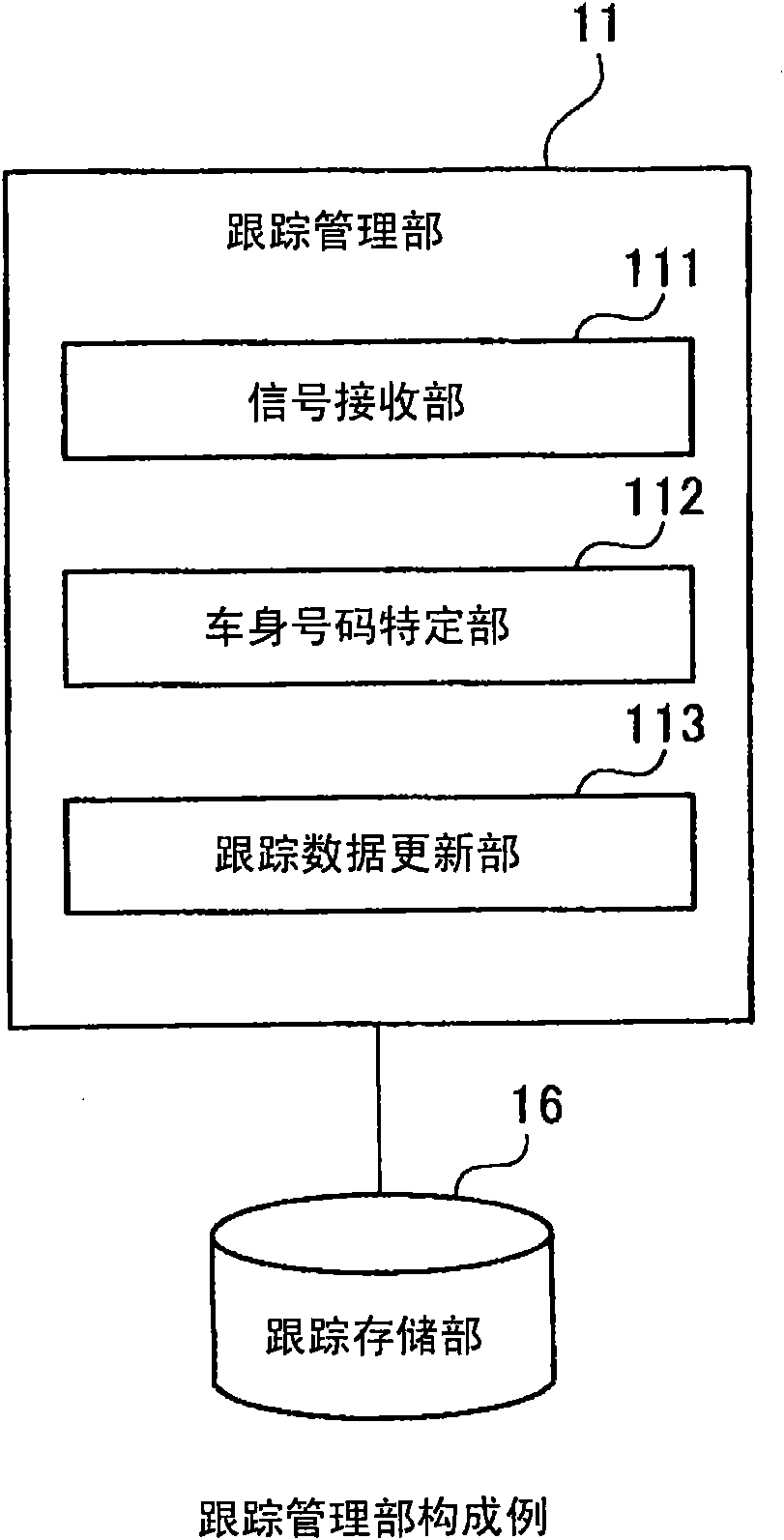

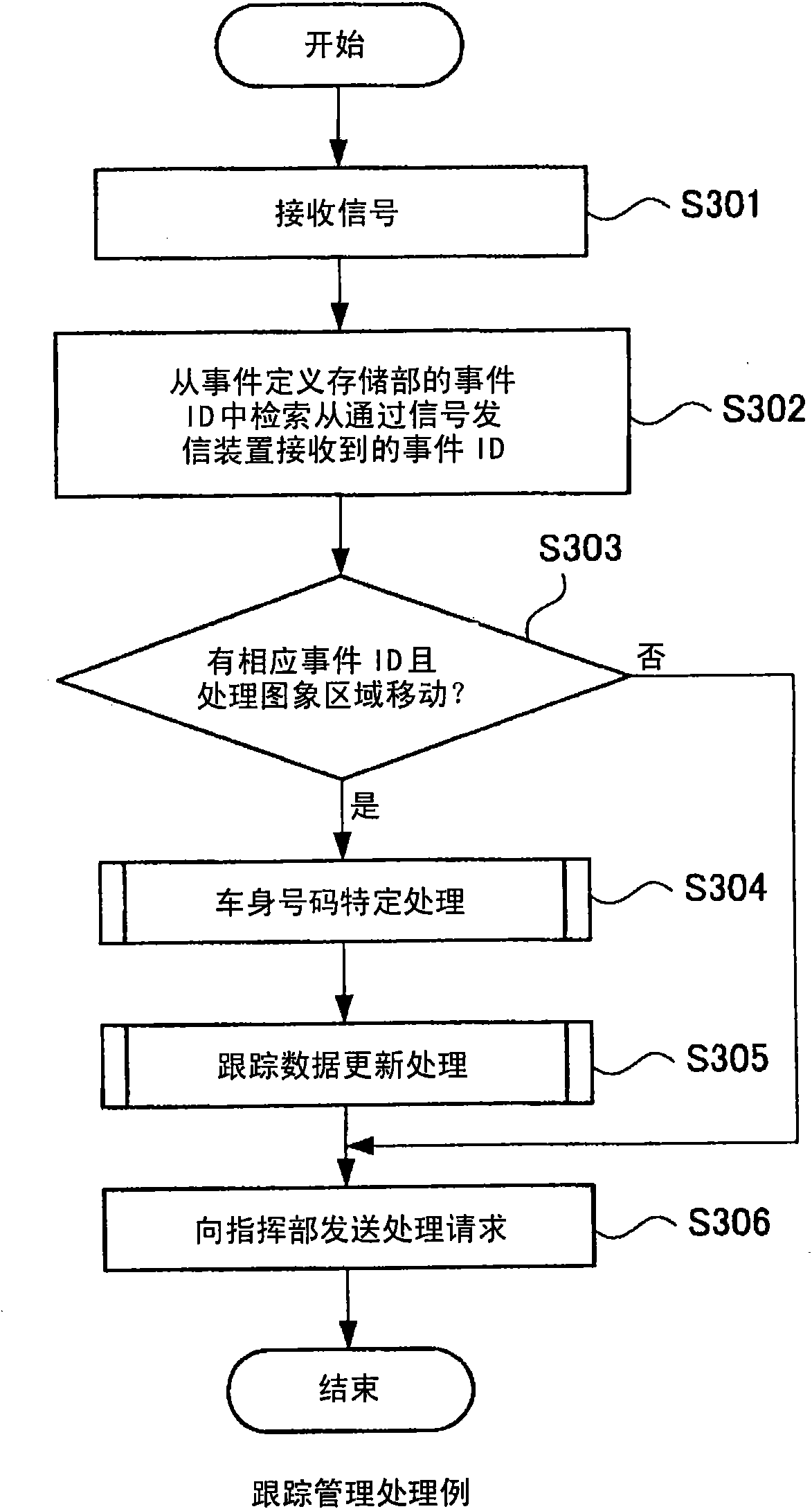

Process control device, process control method, and process control system

ActiveCN101644930AEasy to graspSuppress job stopData processing applicationsTotal factory controlProduction lineOrder control

The invention provide a process control system that can issue a work instruction sheet in the initially planned sequence order in the sub-line production process, even if the sequence order of the product in the main production line is changed. The process control device includes a tracking controller (11) receiving event information indicating that a product pass a predetermined location is received, and controlling the current position and sequence status of the products; a conductor unit (12) for determining a corresponding process based on the event information; and a work instruction unit(14) for issuing a work instruction for the product in the production line in response to the request from the conductor unit. The device further includes a work instruction past record control unit(15) for controlling past record of the work instructions in response to an issue of the work instruction; a work instruction sequence order control unit (13) for controlling a sequence order of the work instructions; and a work instruction sequence order storage (18) for storing information of the sequence order of the work instructions. Thereby, the control to the information of the sequence order of the work instructions in addition to the current location information of the product is realized.

Owner:HITACHI INFORMATION & CONTROL SOLUTIONS LTD

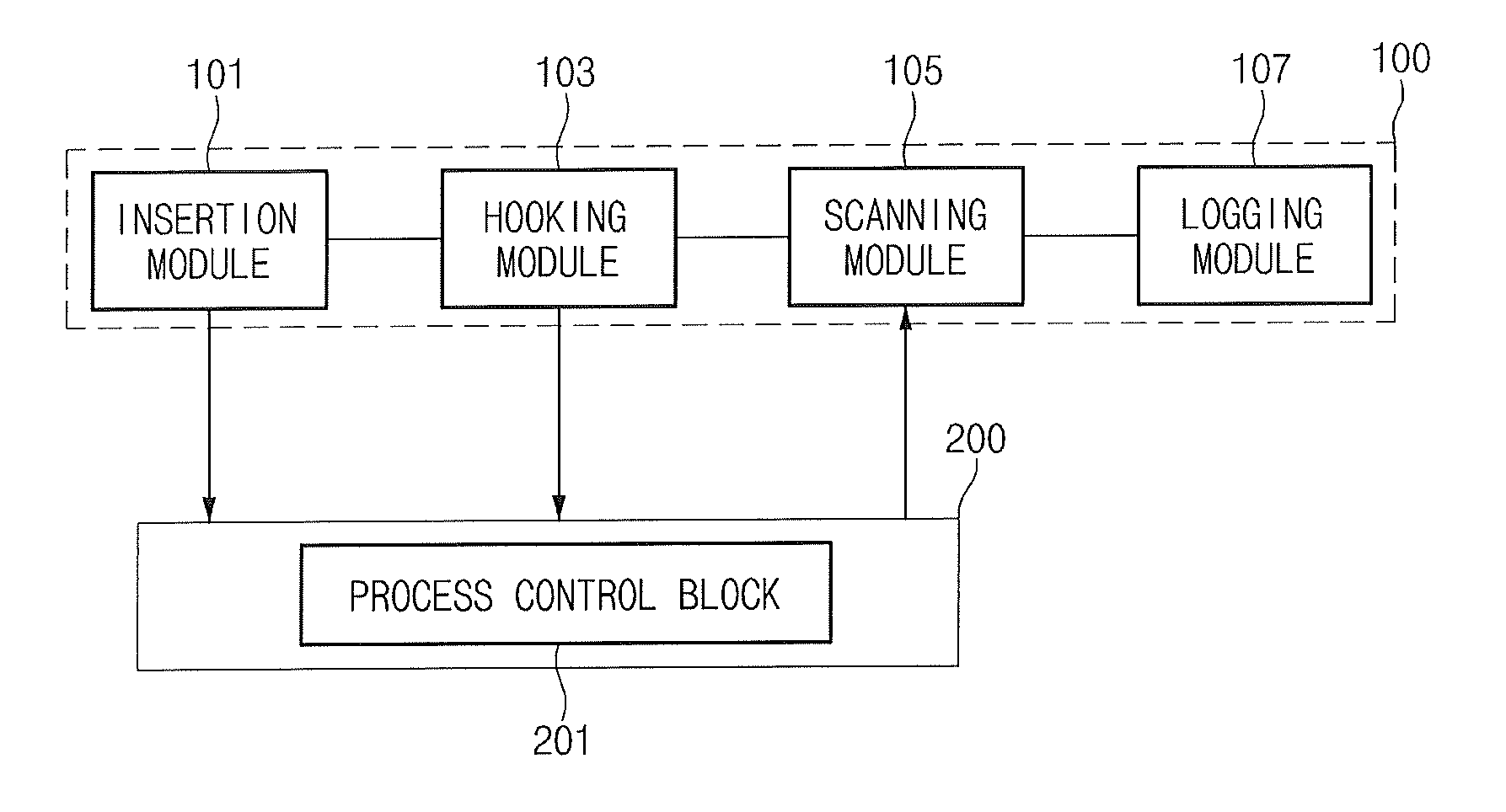

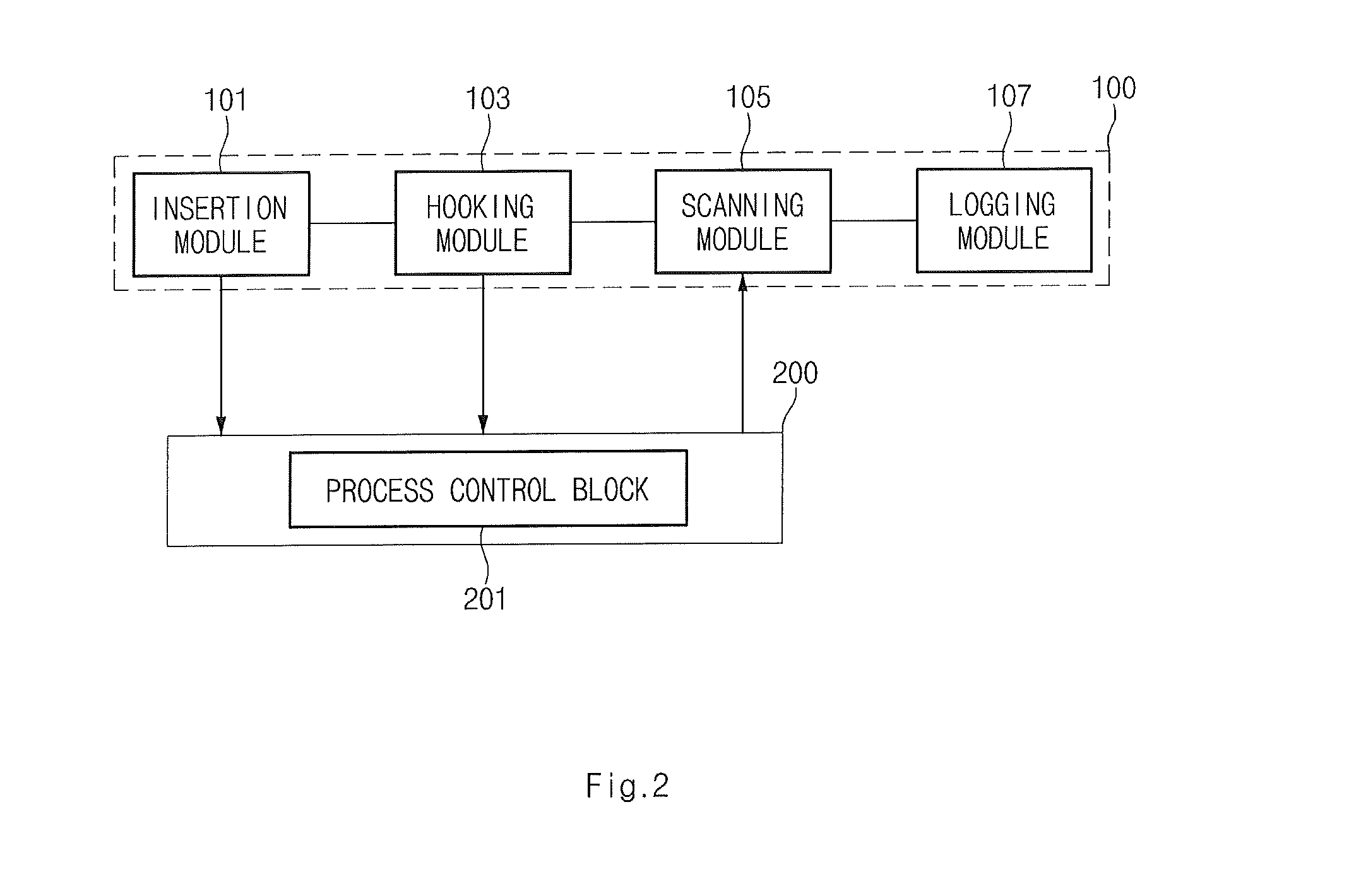

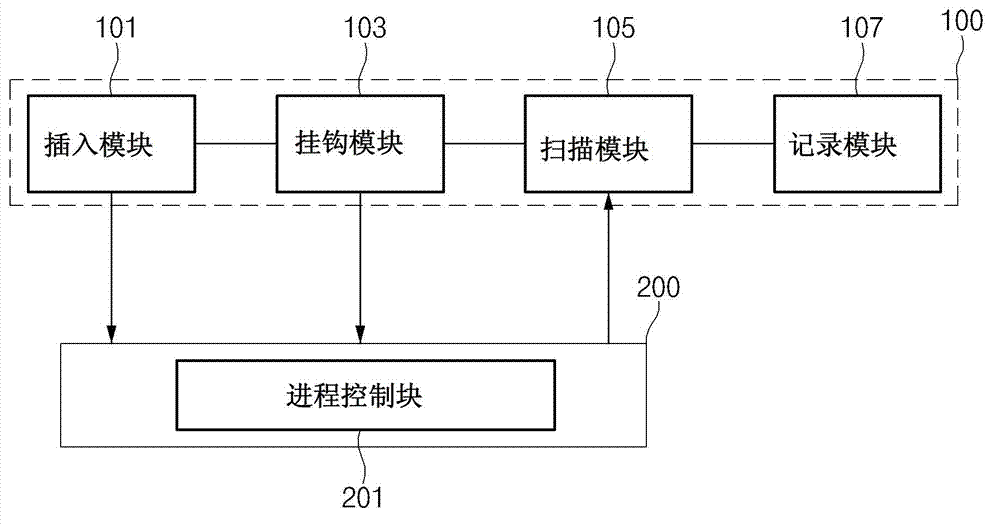

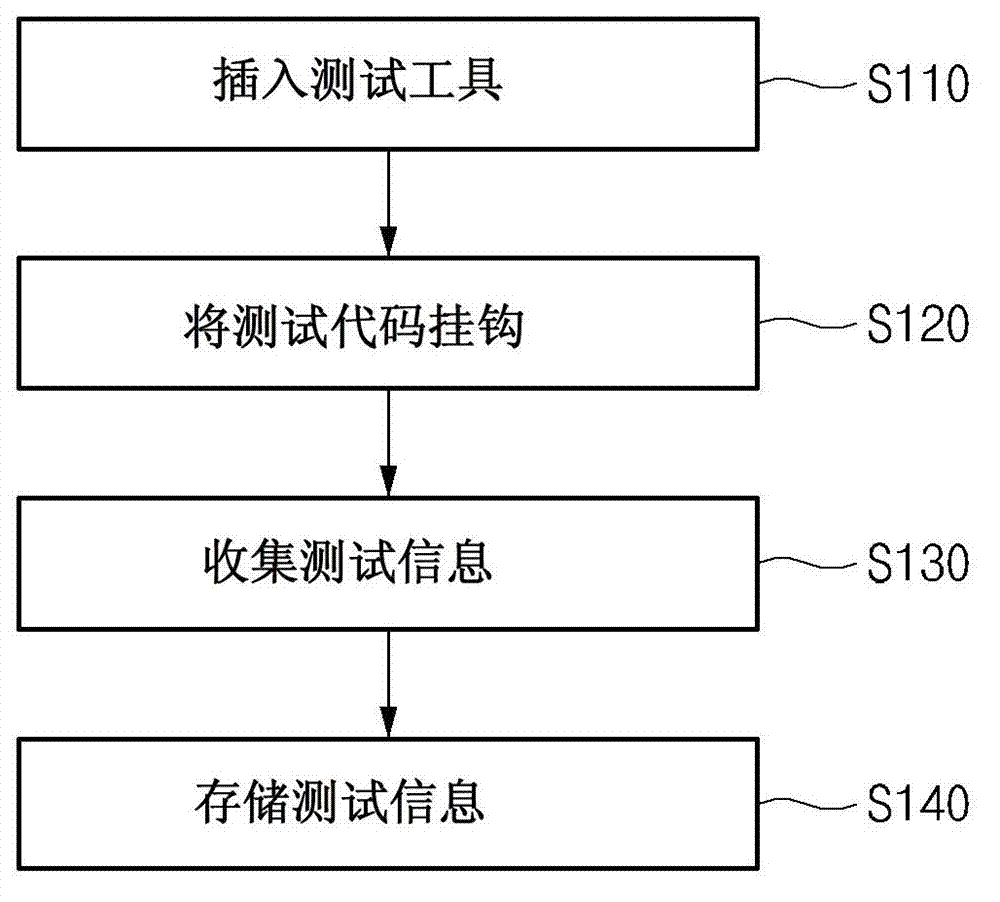

System test apparatus

The present invention relates to a system test apparatus. The system test apparatus includes an insertion module configured to insert a test agent into a process control block, a hooking module configured to hook a test target to a test code using the test agent when an event related to the test target occurs, a scanning module configured to collect pieces of test information about a process in which the event related to the test target has occurred when the test target is hooked, and a logging module configured to store the pieces of test information collected by the scanning module.

Owner:HYUNDAI MOTOR CO LTD +2

Method for controlling file access in operation system according to user's action history

ActiveCN1936915AAvoid visitingInappropriate accessPlatform integrity maintainanceOperational systemProcess control block

The method includes steps: setting up access control list (ACL) for files needed to protect; arranging access control item with attribute being as 'having executed' for each program needed to guard against in ACL; specific access right is prescribed in ACE, and ID of access is setup as program file name needed to guard against; when a process requests to access a file, operation system checks through each access control item of ACL of the file in sequence. For access control item with attribute being as 'having executed', operation system determines whether current process is executing ACE specified programs by looking at program names provided by 'process control block' in current process. Advantages are: ACL mechanism investigates behavior history of user in order to prevent baleful users from accessing target file inadequately through network so as to raise safety of operation system.

Owner:毛德操 +1

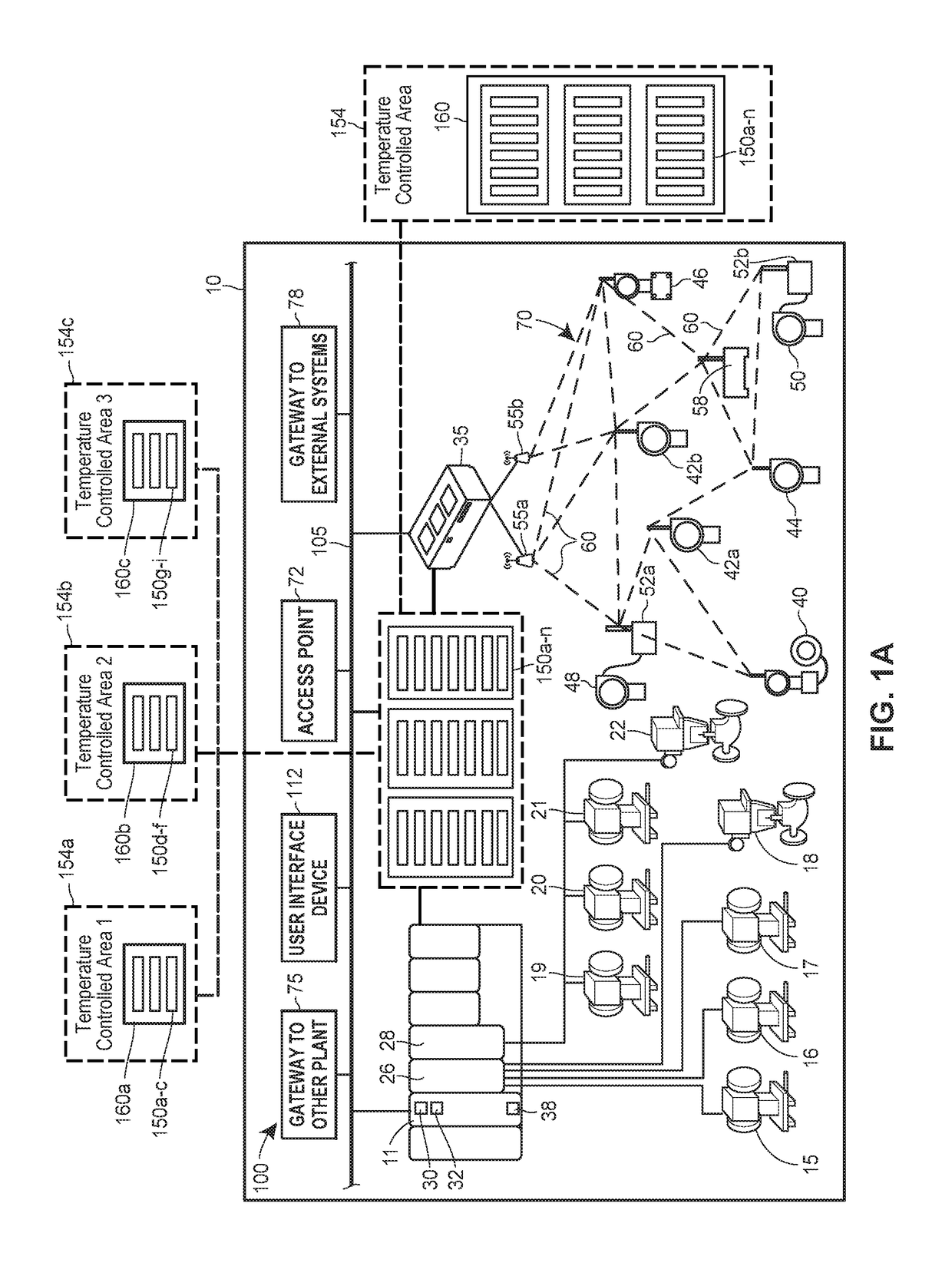

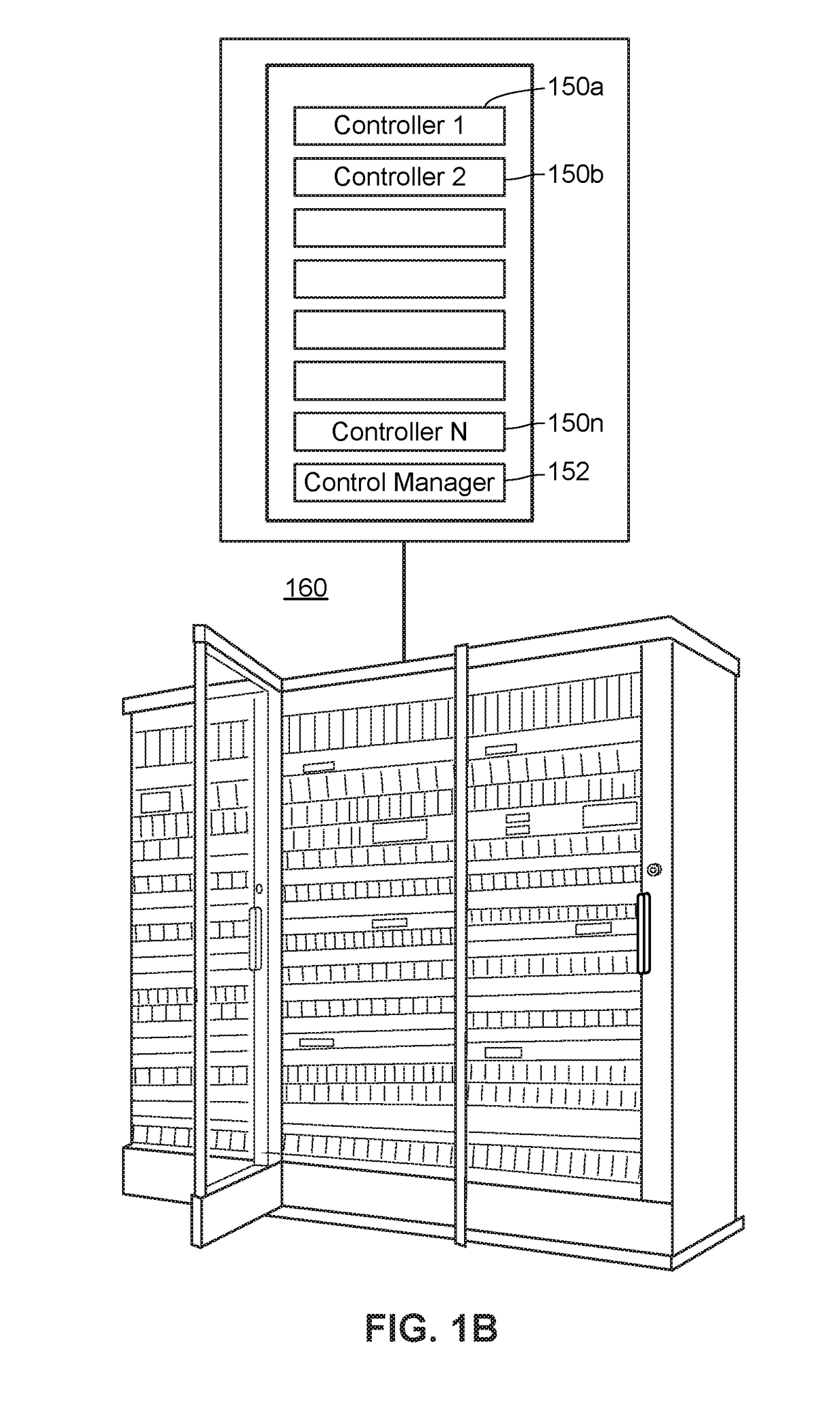

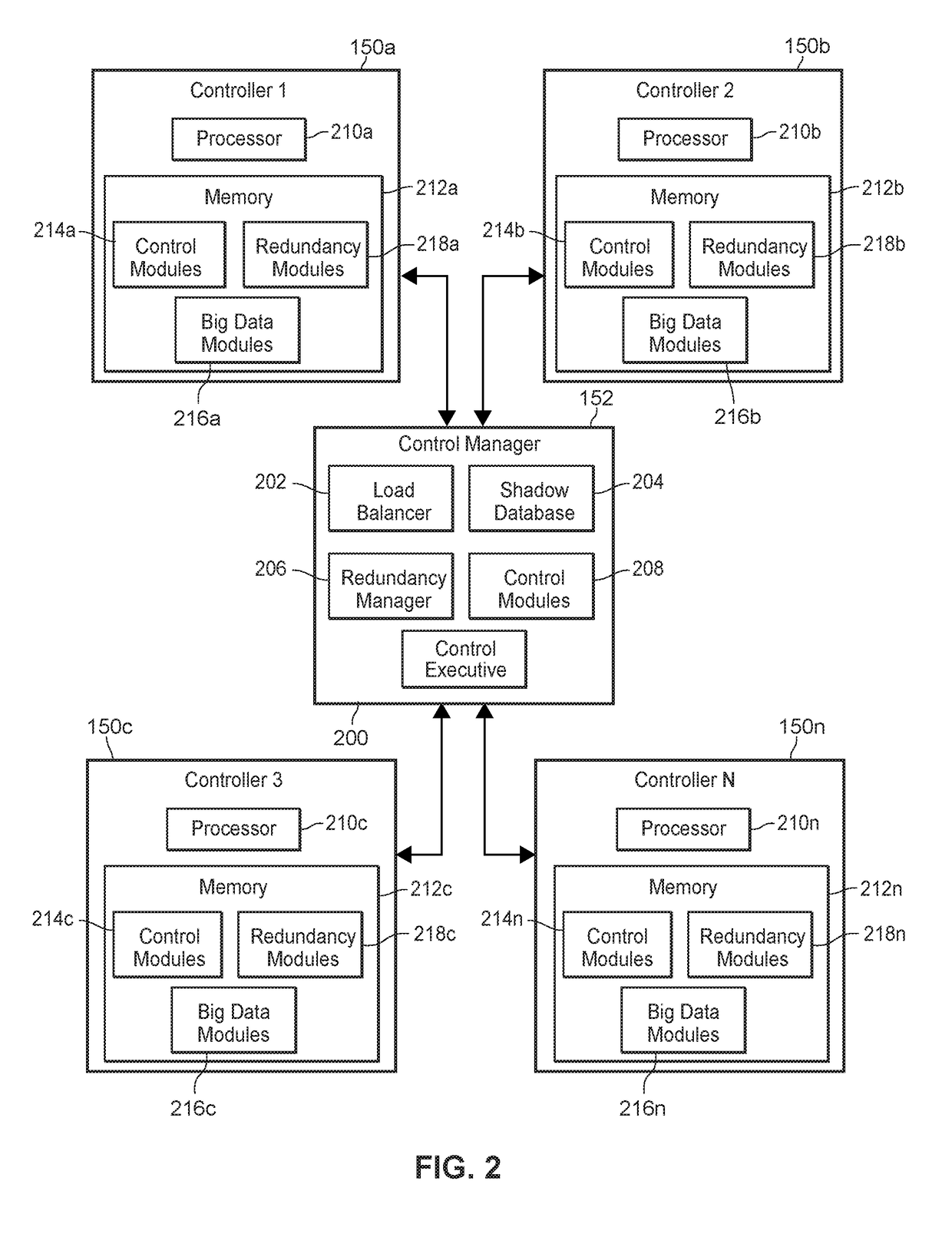

High performance control server system

ActiveUS20190056719A1Increase flexibilitySafety arrangmentsProgram controlTemperature controlControl system

Techniques for controlling the operation of a process plant or several process plants within a process control system using a centralized or distributed controller farm allow for increased flexibility in the process control system. Any of the controllers in the controller farm may be utilized to execute modules corresponding to any of the field devices in one or several process plants. Control modules or other operations may be allocated amongst the controllers distributing the load so that one controller is not performing several operations while others are inactive. Additionally, the controller farm may be located in a temperature controlled room or area in an offsite location from the process plants. In some scenarios, load balancing techniques are performed to distribute the load for the modules equally or at least similarly amongst the controllers.

Owner:FISHER-ROSEMOUNT SYST INC

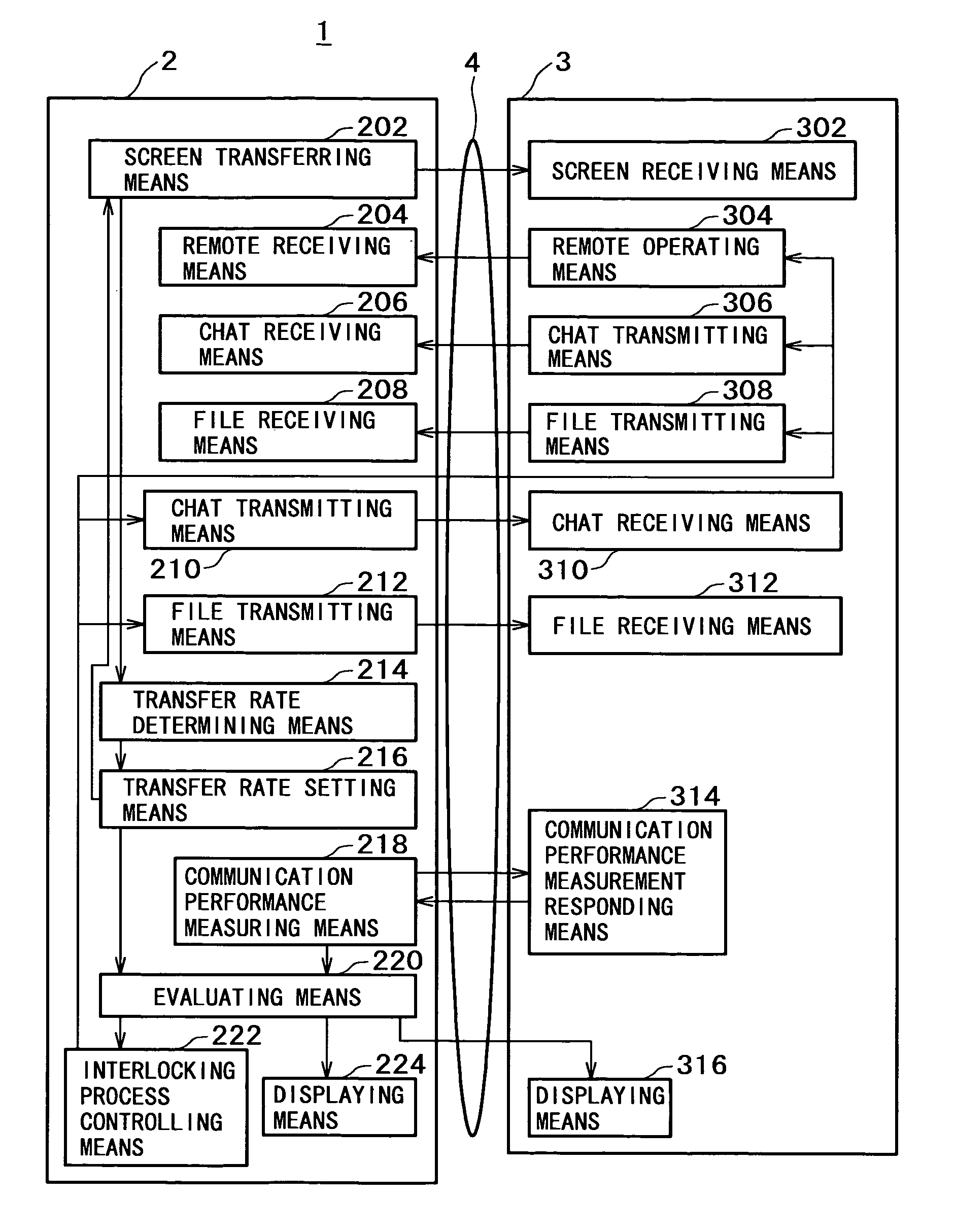

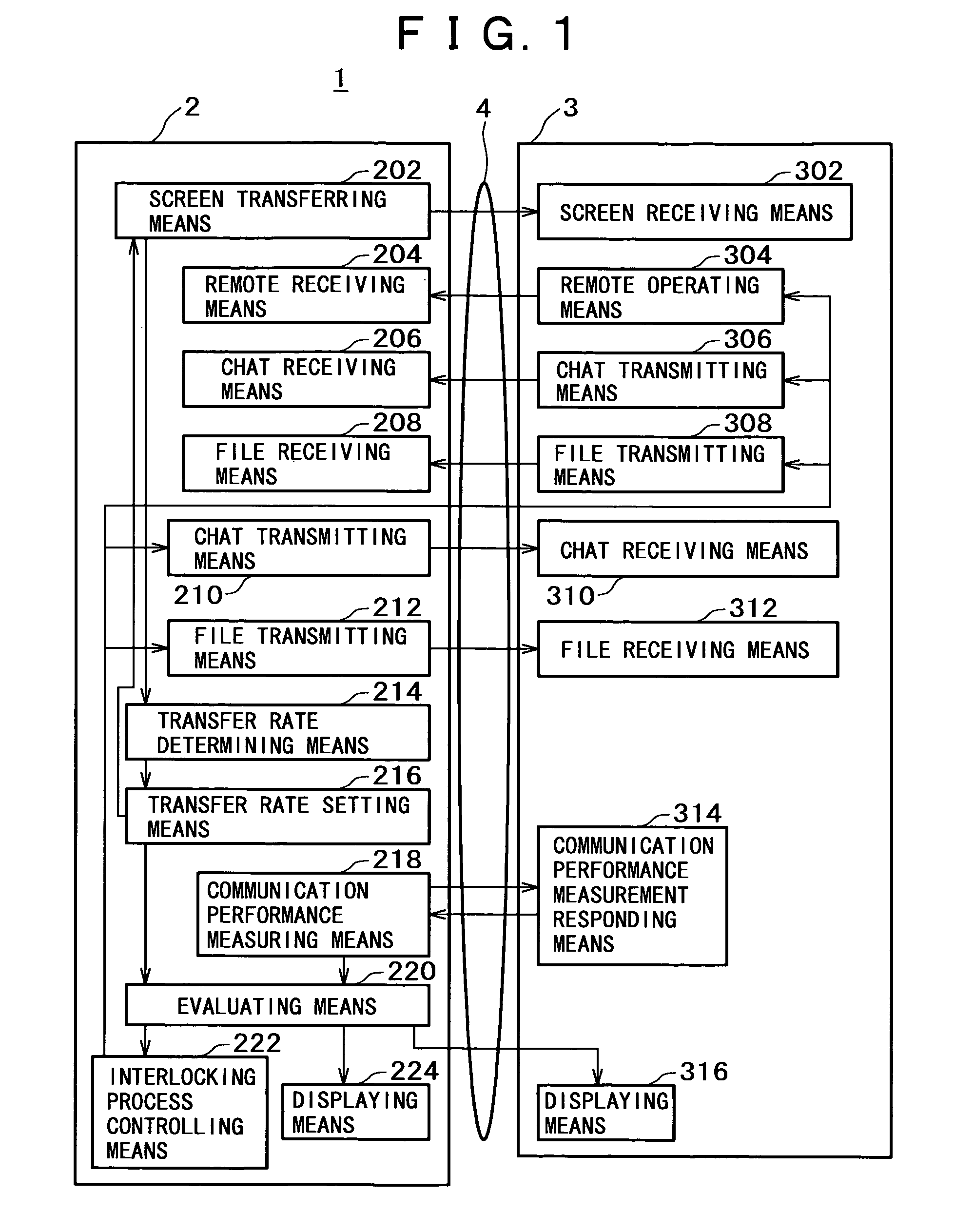

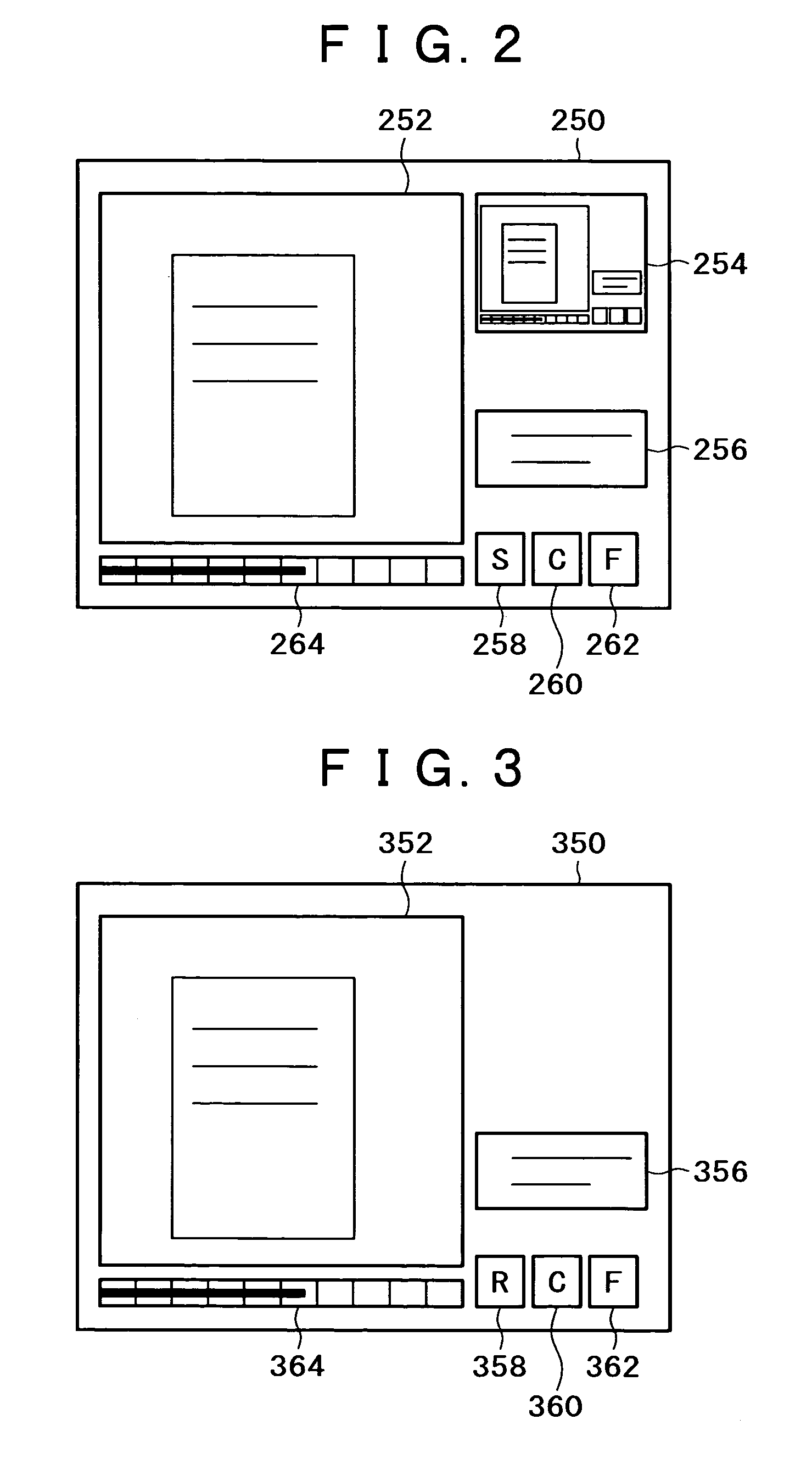

Data sharing system, transmitting terminal apparatus, transmitting terminal apparatus controlling method, receiving terminal apparatus, receiving terminal apparatus controlling method, and recording medium

InactiveUS7443882B2Easy to controlAvoid wastingError preventionTransmission systemsTerminal equipmentComputer terminal

A data sharing system is disclosed together with a transmitting terminal apparatus and a receiving terminal apparatus interconnected and controlled so as to effect efficient data transfers and concomitant interlocking processes therebetween in keeping with network communication status. The transmitting terminal apparatus illustratively includes a transfer rate setting block for setting a transfer rate based on how fast display screen data were transferred previously to the receiving terminal apparatus, a communication performance measuring block for measuring communication performance parameters representative of network communication performance between the transmitting terminal apparatus and the receiving terminal apparatus, an evaluating block for calculating evaluation parameters for evaluating the network communication status using at least the transfer rate and the communication performance parameters, and an interlocking process controlling block for controlling an interlocking process between the transmitting terminal apparatus and the receiving terminal apparatus by use of the evaluation parameters.

Owner:SONY CORP

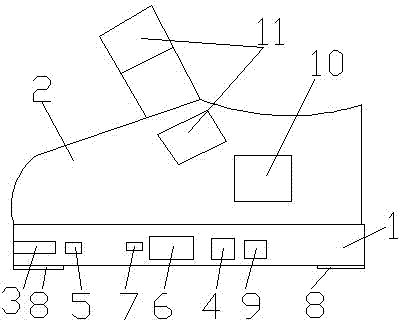

Baby shoe

A baby shoe comprises a sole, an upper, a light-emitting device, a sound production device and a body weight measuring device. The light-emitting device comprises a diode, a power supply and a switch, the diode is arranged in the sole corresponding to toes, the tail end of the switch extends out of the sole, and the diode is respectively electrically connected with the power supply and the switch. The sound production device comprises an intelligent voice chip, the power supply and a switch, wherein the intelligent voice chip is arranged in the sole corresponding to a foot arch, the tail end of the switch extends out of the sole, and the intelligent voice chip is respectively electrically connected with the power supply and the switch. The body weight measuring device comprises the power supply, weighing sensors, a process control block and a display window, wherein the weighing sensors are respectively arranged at the bottom of the sole corresponding to a foot sole and a heel, the display window is arranged on the upper, the process control block is arranged in the middle of the sole, and the weighing sensors are respectively electrically connected with the power supply, the process control block and the display window. The light-emitting device, the sound production device and the body weight measuring device share the same power supply. The shoe can emit light, produce music and measure the body weight, and is rich in function, practical, convenient, compact in structure and light in weight.

Owner:蒋宏伟

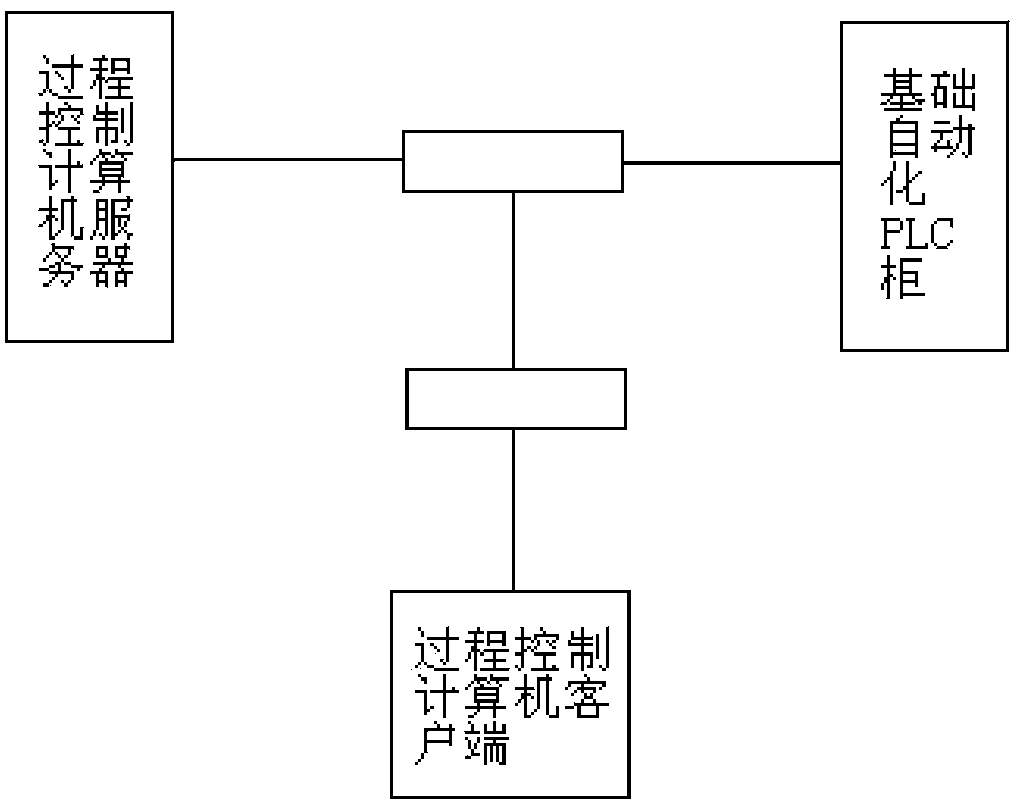

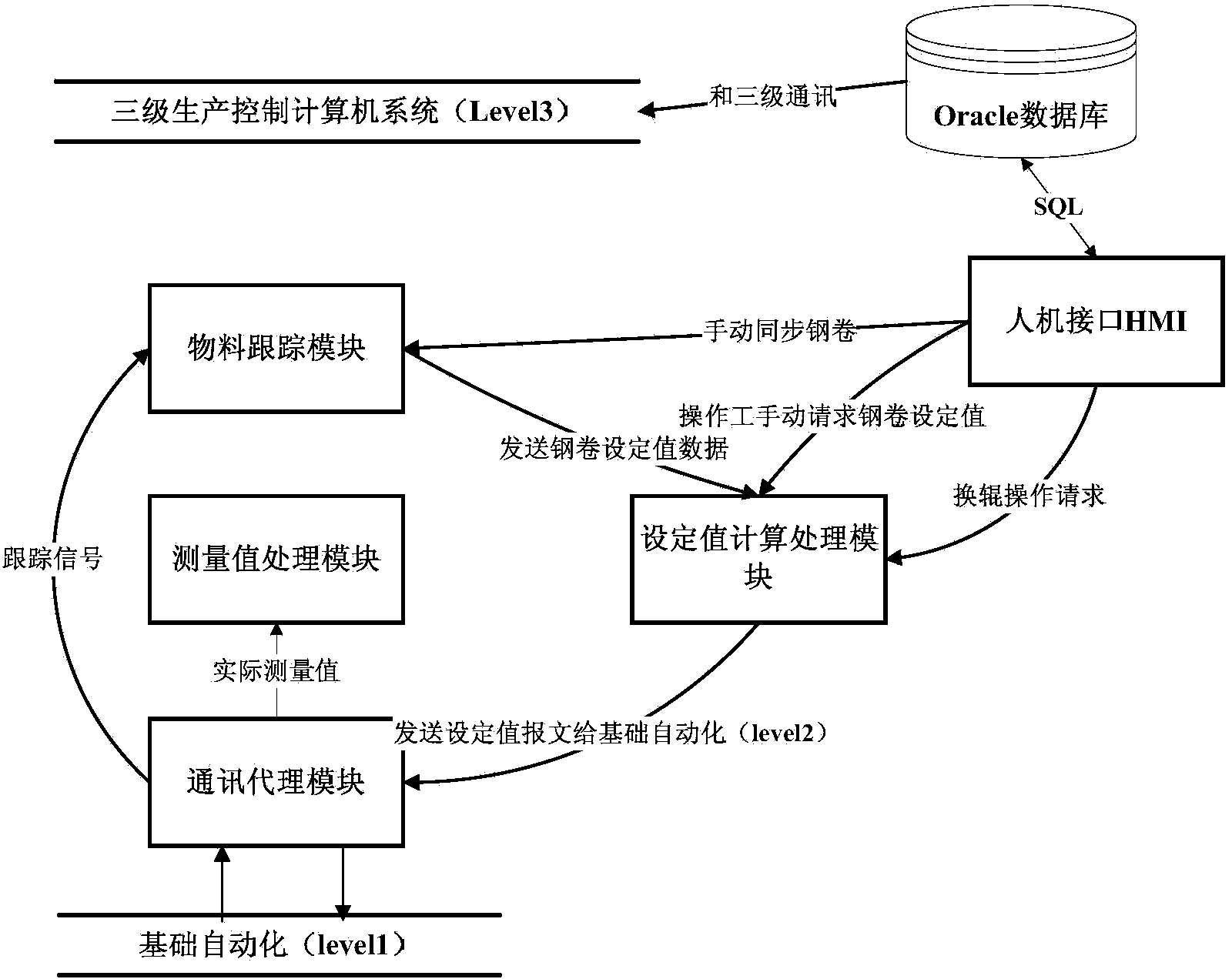

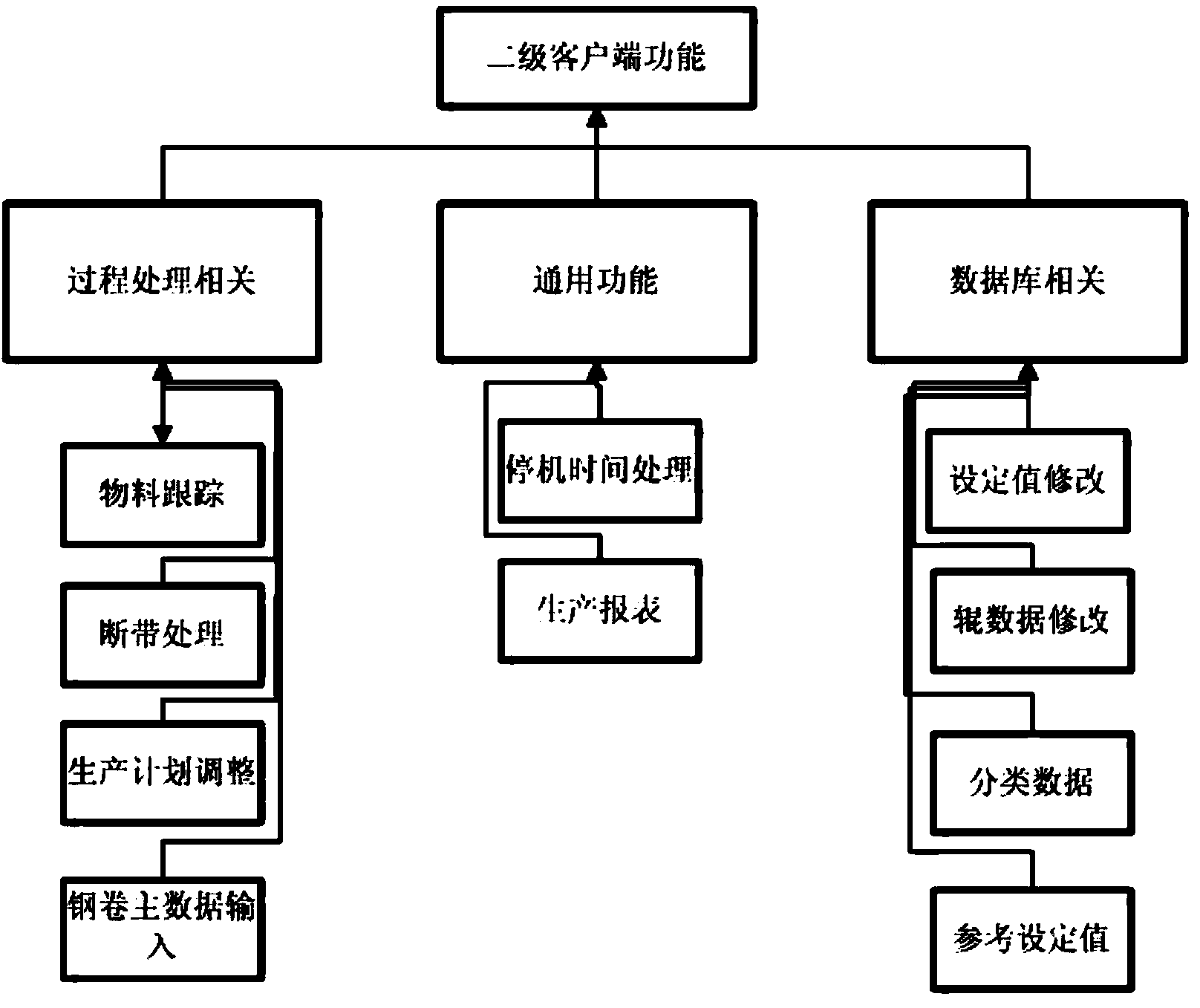

Cold strip steel leveling unit process control method

InactiveCN103760856AFunctional division is clearEasy to transplantTechnology managementTotal factory controlMessage structureProcess control block

The invention provides a cold strip steel leveling unit process control method. The method comprises the steps that the VB6.0 version programme is adopted, and a server and a client side are of a C / S structure; the communication method of a process control system and a basic automation PLC, a message processing method, a message structure and message content are established, the functions and the solution of functional modules of the process control system and the function achieving technical condition of the process control system are established, and therefore an operator can conveniently manage a steel coil plan, set values, technological parameters, finished product data, downtime and a team and group through a customized HMI; various accurate data are provided for an ERP system. The whole process control system is clear in functional partitioning, capable of being transplanted and popularized conveniently and suitable for the process control of a cold rolled leveling unit.

Owner:ANGANG STEEL CO LTD

System test apparatus

The present invention relates to a system test apparatus, which comprises: an insertion module which inserts a test agent into a process control block; a hooking module which hooks a test object with a test code using the test agent when a test object-related event is generated; a scanning module which collects test information on a process in which the test object-related event is generated when the test object is hooked; and a logging module which stores the test information collected by the scanning module.

Owner:HYUNDAI MOTOR CO LTD +2

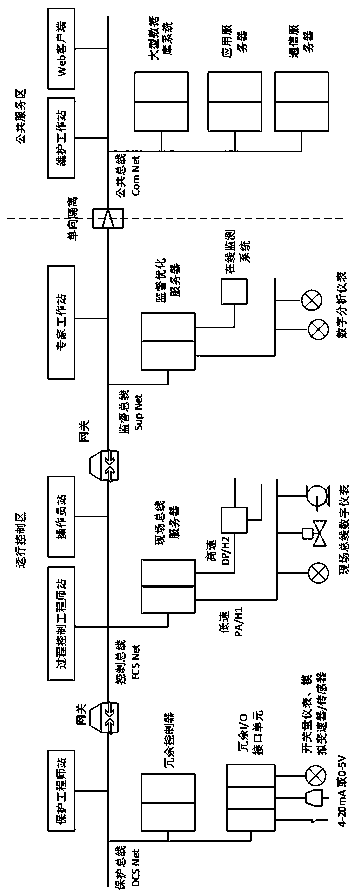

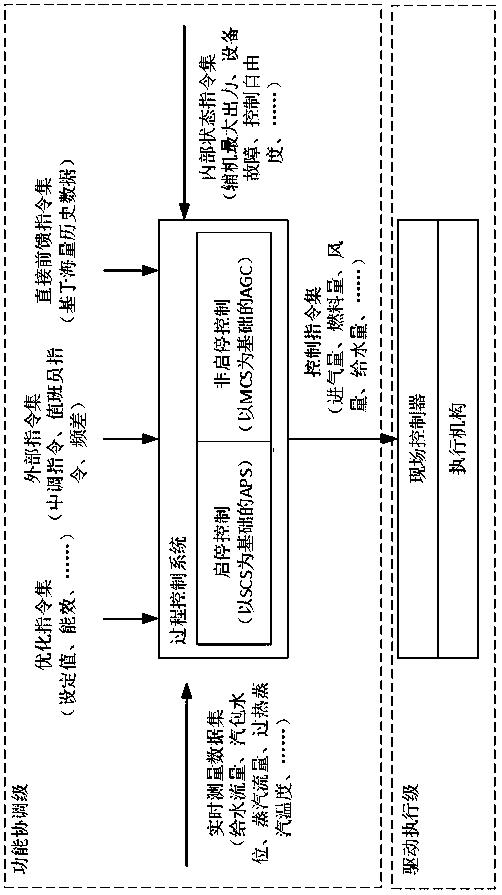

Overall structure of thermal automation system of thermal power plant

ActiveCN109189022ARealize production supervisionRealize APSTotal factory controlProgramme total factory controlData setData platform

The invention discloses an overall structure of a thermal automation system of a thermal power plant, composed of four parts as follows: measurement communication, protection, process control and supervision optimization, wherein the measurement communication consists of a field sensor, a transmitter, an actuator, and a communication network; the communication network includes protection, control,supervision, and a common bus; the protection includes equipment protection and protection management; the process control includes a two-level mode consisting of a function coordination level and adrive execution level; the function coordination level includes performing start-stop and non-start-stop control, accepting an optimized instruction set, an external instruction set, a direct feed-forward instruction set, a real-time measurement data set, and an internal state instruction set as input signals, and establishing a parallel control system that simultaneously faces the entire power generation production process; and the supervision optimization realizes the online monitoring for the integrated data platform and thermal process optimization and equipment in the operational controlzone. The overall structure of a thermal automation system of a thermal power plant respectively provides an implementation manner of a capital construction and a production plant, which provides a reference for the construction of a smart power plant.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

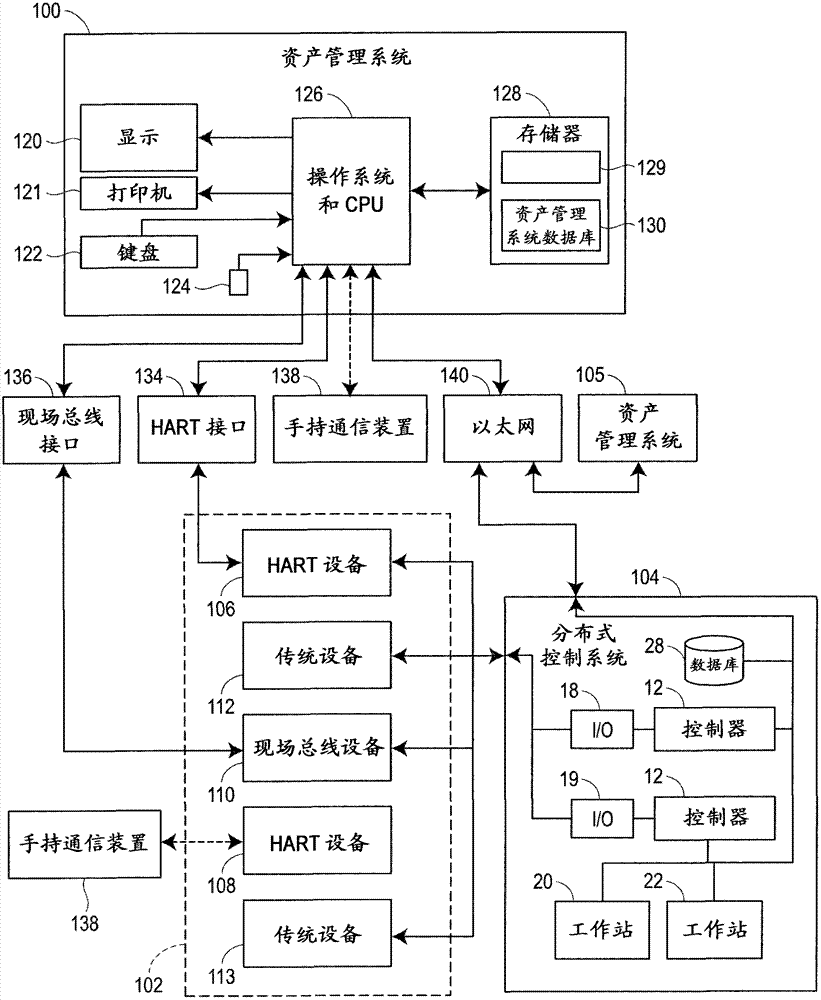

Software lockout coordination between a process control system and an asset management system

A process control system coordinates with an associated asset management system to implement a plant safety mechanism and, in particular, to prevent unintended changes to, or otherwise undesired operation of, one or more process control equipment resources in a process plant. A maintenance technician uses the asset management system to request access to one or more of the process control equipment resources. A process operator receives the request via the process control system and grants or denies the request. Process control equipment resources for which a process operator grants a request are inoperable, in part or in whole, by the process control system. Upon completion of the maintenance task, the maintenance technician requests to return control of the process control equipment resource to the process operator. The return is complete when the process operator acknowledges the return of the resource to the process control system.

Owner:FISHER-ROSEMOUNT SYST INC

Process guidance system for industrial process control

ActiveCN107037795AEasy to buildBuild simplicityTotal factory controlProgramme total factory controlDecompositionControl system

The invention discloses a process guidance system for industrial process control. The system comprises a process guidance module, a data acquisition and monitoring control system, a process analysis module and an interface drive module, wherein the process guidance module is used for performing action decomposition and attribute configuration on a controlled element, and performing simple imaging and drag operation on the process of a user to generate intelligent guidance data that can be recognized by the system; the data acquisition and monitoring control system is used for monitoring the running state of the process control system and adjusting parameters; the process analysis module is used for analyzing the data generated by the process guidance module via a controller, and implementing process control on the user process; and the interface drive module is used for driving peripheral interface equipment according to the analysis result of the process analysis module. The system does not need to concern the specific detail and network topology structure of the controlled element, the user process control program is completely replaced by intelligent data via data drive thought, the controller user process program is free from being compiled, and the process control of the user becomes simple, transparent, direct and flexible.

Owner:唐志

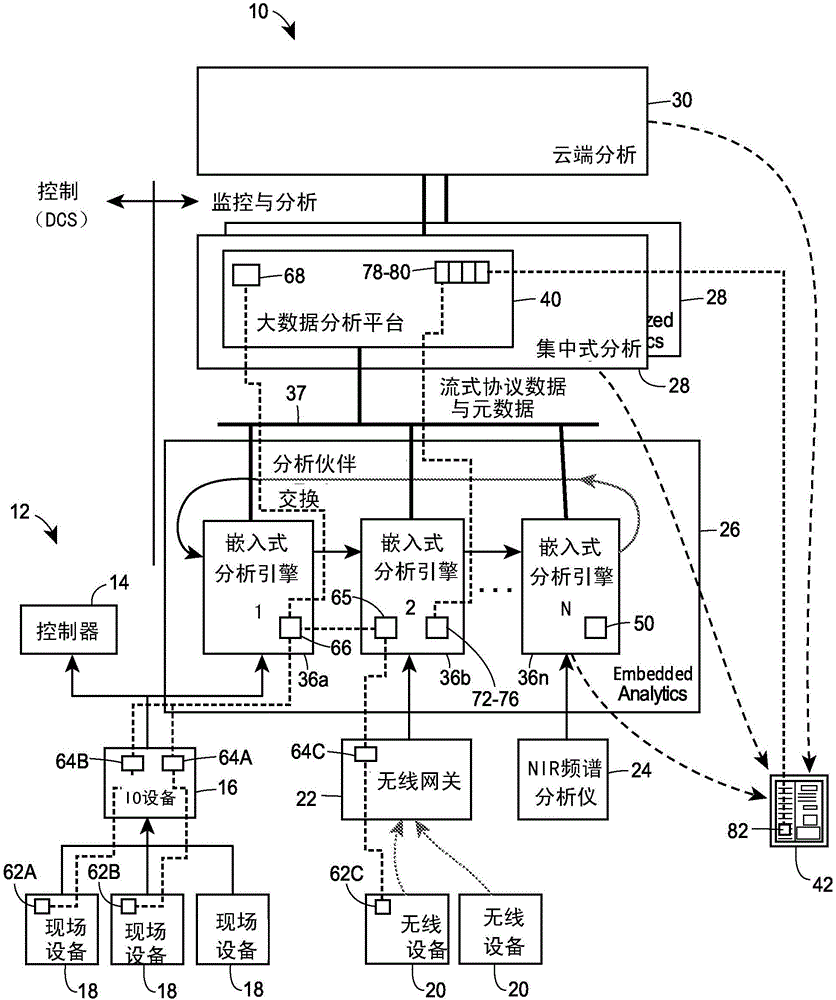

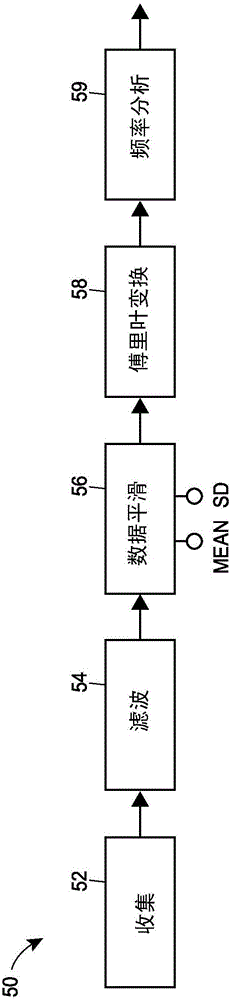

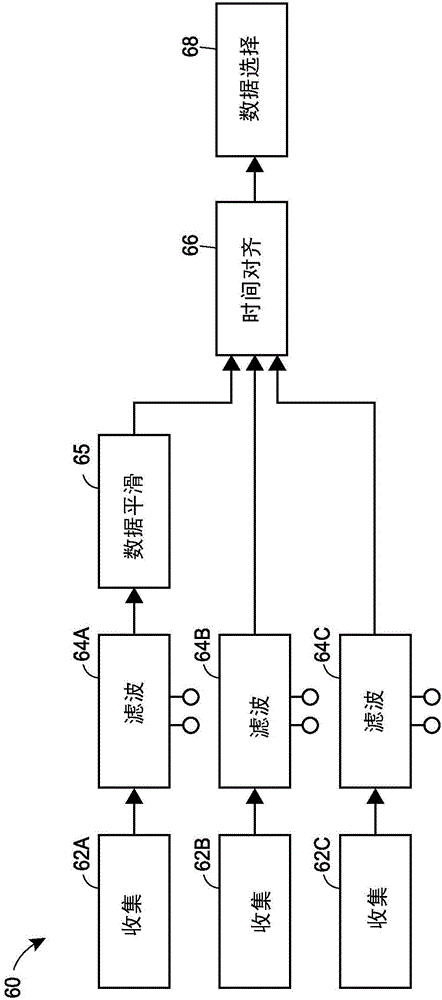

Data pipeline for process control system anaytics

A data pipeline is used as a fundamental processing element for implementing techniques that automatically or autonomously perform signal processing-based learning in a process plant or monitoring system. Each data pipeline includes a set of communicatively interconnected data processing blocks that perform processing on one or more sources of data in a predetermined order to, for example, clean the data, filter the data, select data for further processing, perform supervised or unsupervised learning on the data, etc. The individual processing blocks or modules within a data pipeline may be stored and executed at different devices in a plant network to perform distributed data processing. Moreover, each data pipeline can be integrated into one or more higher level analytic modules that perform higher level analytics, such as quality prediction, fault detection, etc. on the processed data. The use of data pipelines within a plant network enables data collected within a plant control or monitoring system to be processed automatically and used in various higher level analytic modules within the plant during ongoing operation of the plant.

Owner:FISHER-ROSEMOUNT SYST INC

Online device test block integrated into process control safety system

Owner:FISHER-ROSEMOUNT SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com