Cold strip steel leveling unit process control method

A process control, cold-rolled strip steel technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of the specific method system and the first-level and third-level communication methods that are not introduced in the function realization, To achieve the effect of facilitating transplantation and promotion, convenient program management, and clear function division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

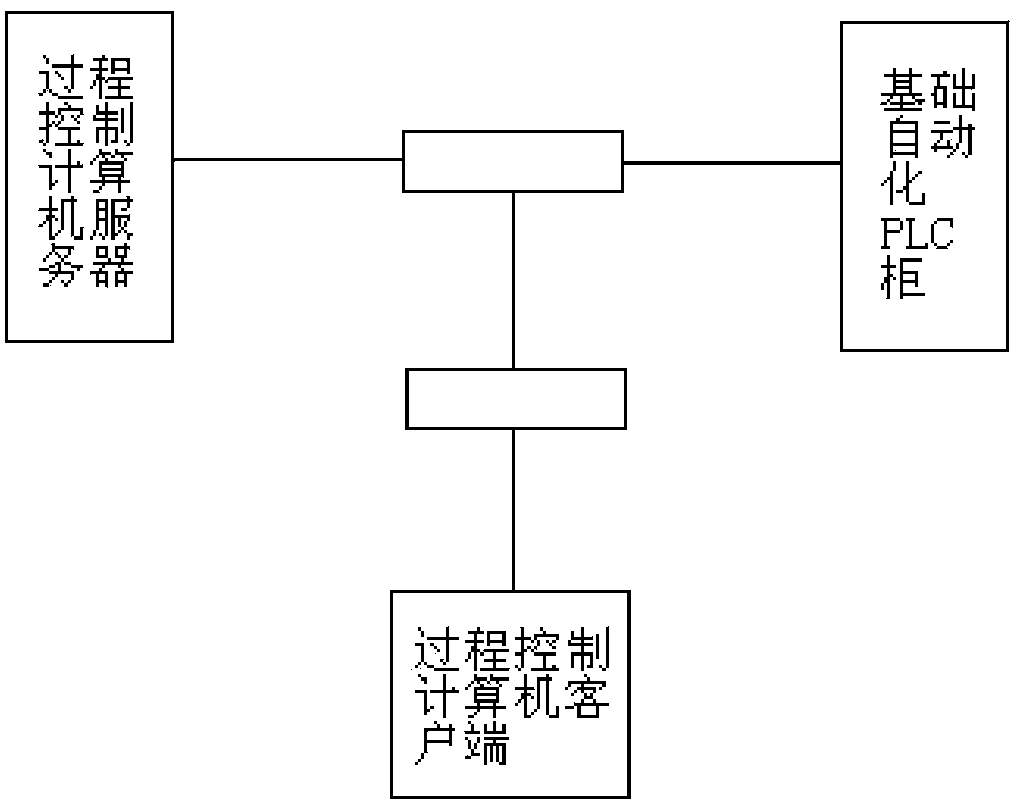

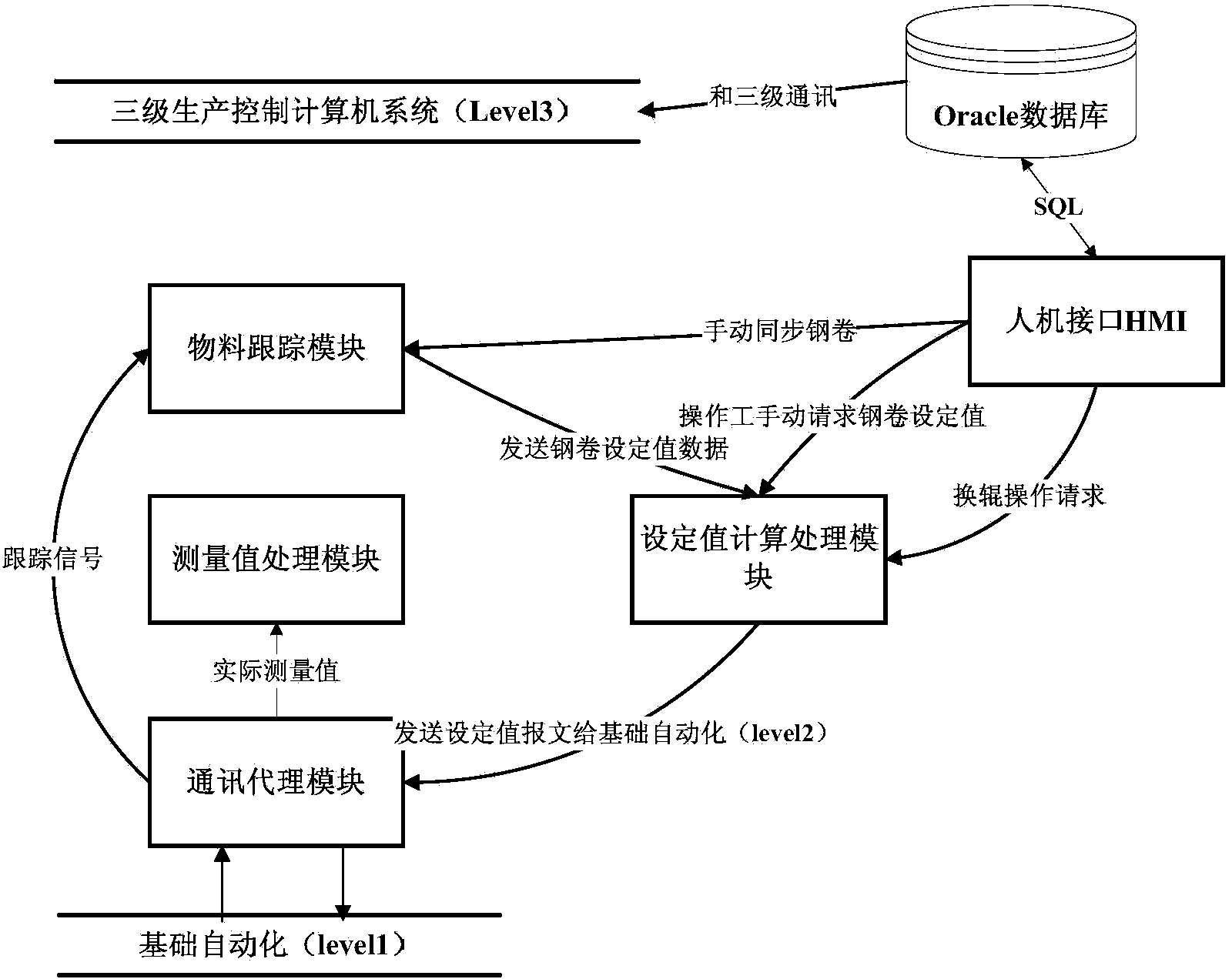

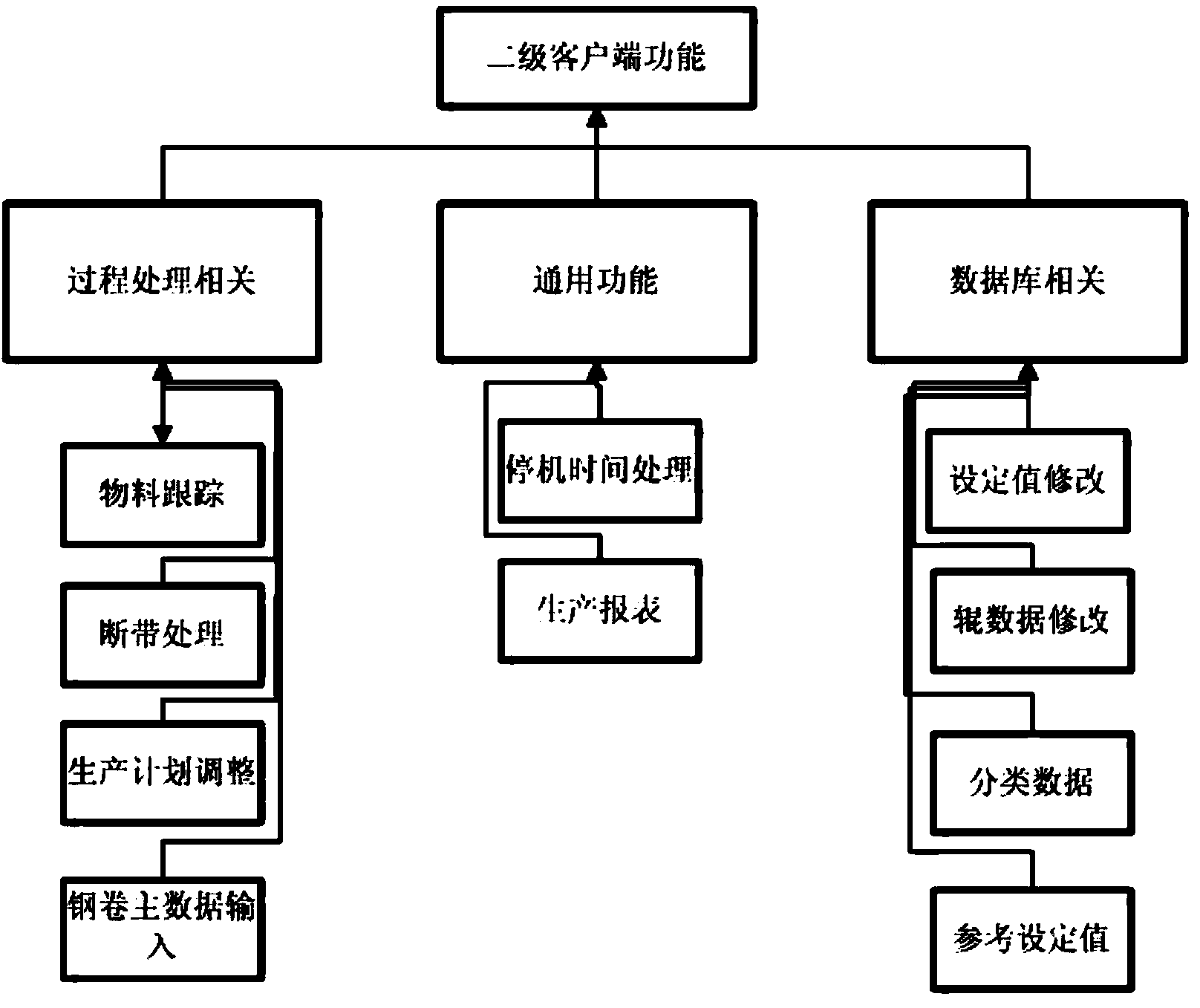

[0037] 1. The whole process control system adopts VB6.0 version programming. The process control computer server and client are respectively Chinese Windows2000Server and Windows2000professional operating systems, with an open programming environment. The database of the process control system is Oracle9i and is installed on the process control computer server together with the process control system. The server and client adopt C / S structure. The server is placed in the main power room of the unit, and the client is placed in the field operation console The communication between them is connected by two switches, and the two switches are connected by multi-mode optical fiber. The communication between the process control system and the basic automation PLC utilizes industrial Ethernet and uses TCP / IP protocol for communication. The entire syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com