Camera module and fixing device of camera module

A camera module and fixing device technology, applied in the field of photography, can solve problems such as difficult to stabilize, easy to loose the fixed position, heavy weight of the lens module, etc., to achieve the effect of not easy to fix, not easy to loose, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

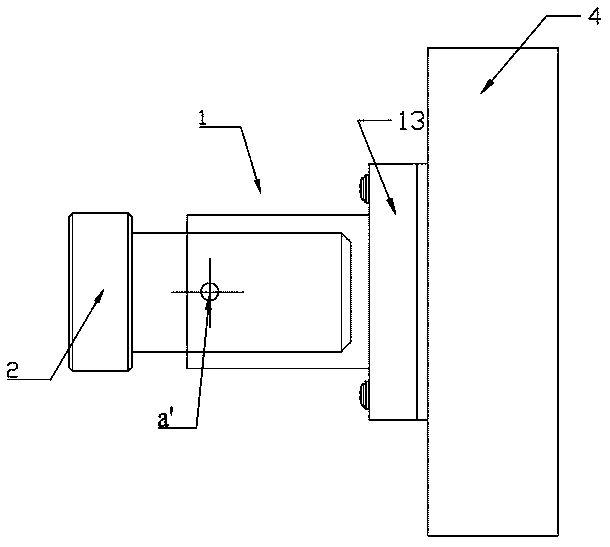

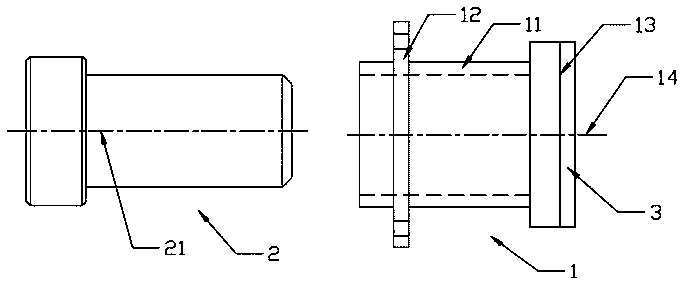

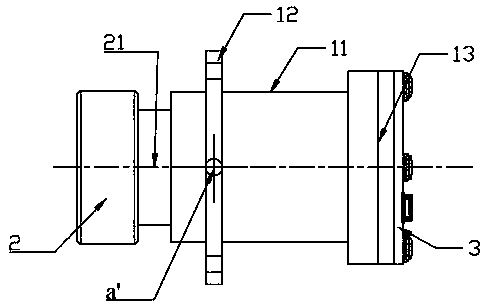

[0035] Such as Figure 2~Figure 3 As shown, a camera module provided by an embodiment of the present invention includes a lens 2 and a lens base 1; the lens 2 has a first axis 21, and the first axis 21 is arranged laterally. The landscape setting can be as figure 2 The setting shown in is parallel to the horizontal line; or in other embodiments, the setting is roughly parallel to the horizontal line, for example, the angle with the horizontal line is within the range of plus 20 degrees and minus 20 degrees.

[0036] The camera module in this embodiment is more specifically a large-size camera module, and the large size is relative to a camera in the communication industry such as a mobile phone product. The length of the lens 2 of the camera module is not less than 20mm, or the weight of the lens 2 is not less than 15G.

[0037] The lens base 1 includes a lens accommodation part 11 and a fixed connection part 12 for fixed connection with the outside; the lens accommodation ...

Embodiment 2

[0052] The present invention also provides a camera module fixing device 4, the camera module is the camera module in the first embodiment above, and the fixing device 4 has a through hole 41 matched with the lens accommodating part 11; After a part of the camera module passes through the through hole 41 , the lens base 1 of the camera module is fixed on the fixing device 4 through the fixed connection part 12 .

[0053] When the fixed connection part 12 is the second solution in the first embodiment, after the hollow shell 11 of the lens base 1 passes through the through hole 41 of the fixing device 4, it is attached to the corresponding surface of the fixing device through the ring structure 121 Make a permanent connection.

[0054] When the fixed connection part 12 is the third scheme or the fourth scheme in the first embodiment, as Figure 5~Figure 7 As shown, the fixing device 4 also has a space 42 matching the fixed connection portion 12 of the lens base 1 and a rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com