Highly absorbent resin and method for producing same

A super-absorbent, polymer technology, used in absorbent pads, medical science, bandages, etc., can solve the problems of reduced absorption, insufficient absorption rate of diapers, etc., to achieve the effect of reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] As a manufacturing apparatus for superabsorbent polymers, a continuous process including a polymerization step, a hydrogel pulverization step, a drying step, a pulverization step, a classification step, a surface crosslinking step, a cooling step, a classification step, and a transportation step connecting the respective steps can be used. manufacturing device.

[0105] (step 1)

[0106] 100 parts by weight of acrylic acid, 0.7 parts by weight (7000ppm) of polyethylene glycol diacrylate (weight average molecular weight: about 500g / mol) as an internal crosslinking agent, 0.015 parts by weight (150ppm) of allylmethyl Acrylate and 0.01 parts by weight of IRGACURE 819 as a photoinitiator were mixed to prepare a monomer solution. Subsequently, while the monomer solution was continuously supplied by a metering pump, 160 parts by weight of a 24% by weight aqueous sodium hydroxide solution was continuously subjected to line mixing to prepare an aqueous monomer solution. At th...

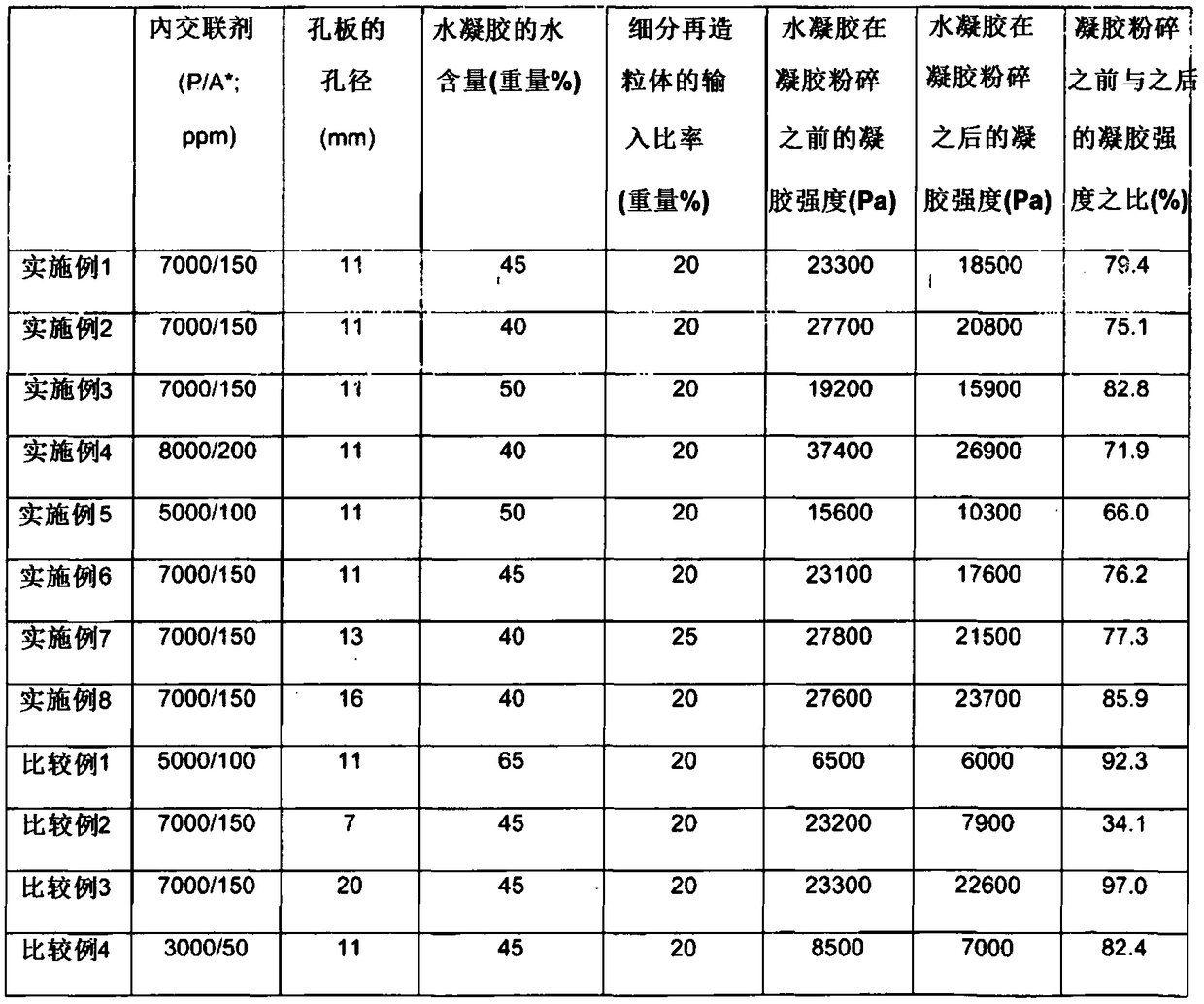

Embodiment 2 to 8 and comparative example 1 to 4

[0116] The superabsorbent polymer was prepared in the same manner as in Example 1, except that the content range of the internal crosslinking agent, the pore diameter of the orifice plate set in the gel pulverizer, the thickness of the hydrogel were changed as shown in Table 1 below. Water content and input ratio of fine powder regranulate.

[0117] In the following Examples 1 to 8 and Comparative Examples 1 to 4, the gel strength before and after gel pulverization of the hydrogel was measured by the method summarized below, and the measurement results were summarized and shown in the following Table 1 together. .

[0118] *Measurement method of gel strength of hydrogel

[0119] A. Preparation of the sample to be measured:

[0120] First, hydrogel samples to be measured (a hydrogel sheet before gel pulverization and a hydrogel after gel pulverization) were prepared to have a diameter of about 2.5 cm and a thickness of about 2 mm to 5 mm. Load the prepared sample on a microb...

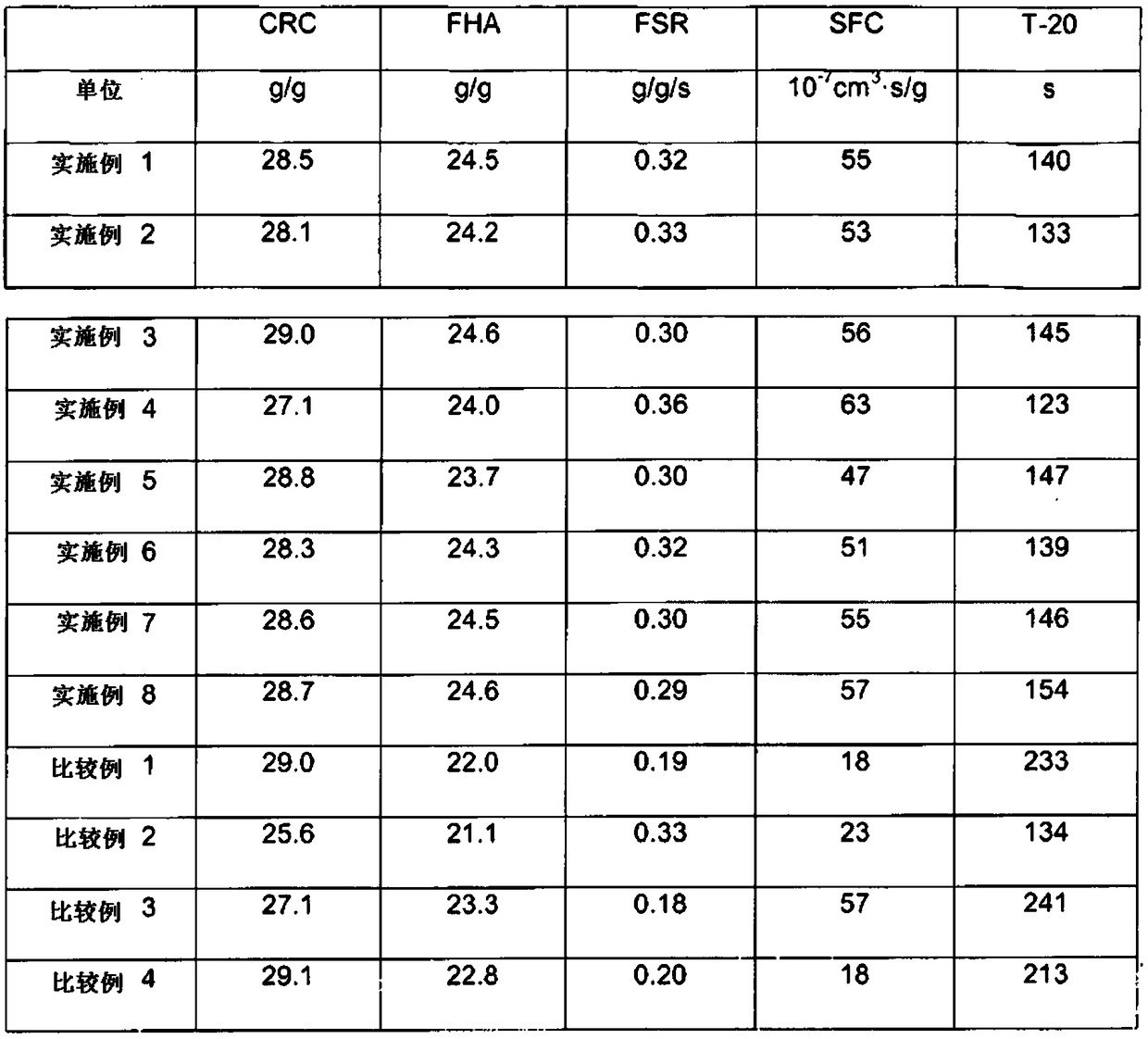

experiment example

[0130] The physical properties of the superabsorbent polymers prepared in Examples and Comparative Examples were measured and evaluated by the following methods.

[0131] (1) Centrifuge retention capacity (CRC)

[0132] For the superabsorbent polymers of Examples and Comparative Examples, it was measured by water absorption capacity under no-load conditions according to the test method No. WSP 241.3 recommended by EDANA (European Disposables and Nonwovens Association, European Disposables and Nonwovens Association) Centrifuge retention capacity (CRC). Will W 0 (g, about 0.2 g) of superabsorbent polymer was uniformly put into a bag made of nonwoven fabric, and then sealed. Then, the bag was immersed in a physiological saline solution consisting of a 0.9% by weight sodium chloride aqueous solution at room temperature. After 30 minutes, water was removed from the bag by centrifugation at 250G for 3 minutes, and the weight of the bag was measured W 2 (g). Furthermore, the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com