Yeast protein and preparation method and application thereof

A technology of yeast protein and protein, applied in the field of yeast protein and its preparation, to achieve the effects of reducing protein denaturation, good taste and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Wherein, in a preferred embodiment, the present invention provides a method for preparing yeast protein, comprising the steps of:

[0029] 1) Enzymolysis: Yeast powder with a nucleic acid content of 0.1-1.5% is prepared into a solution of 5%-15% (preferably 8%-12%), and the pH is adjusted to 5.0-7.5, and the temperature is 20-70°C (preferably 30- 55°C), adding 0.1%-2% enzyme of yeast powder mass for enzymolysis (preferred enzymolysis time is 2-16h);

[0030] 2) Take the heavy phase by centrifugation, precipitate and disperse with an appropriate amount of water (preferably, the mass fraction of dry matter after dispersion is also 5%-15%);

[0031] 3) Wall breaking: adjust the pH of the above dispersion to 7.0-9.0, and break the wall homogeneously for 1-6 times (preferably 2-4 times) under the pressure of 800-1500 bar.

[0032] 4) Spray-drying or freeze-drying: spray-drying or freeze-drying the above-mentioned broken crude protein liquid to obtain high-purity yeast prote...

Embodiment 1

[0045] Add 10Kg of beer yeast powder and purified water to make a solution of 120Kg, add dilute hydrochloric acid to adjust the pH to 5.0, adjust the temperature to 35°C, add 50g of compound plant hydrolase (Viscozyme L) for enzymolysis for 2 hours, centrifuge at 5000rpm for 20min, and remove the supernatant. Then the precipitate was dispersed with 60Kg of water, and the pH was adjusted to 7.0 with sodium carbonate.

[0046] Homogenize the above liquid for 6 times under the pressure of 800bar, and the homogeneous flow rate is 1m 3 / h.

[0047] The crude protein is freeze-dried to obtain yeast protein powder, and the weight of the prepared yeast protein powder product is weighed to be 5.2Kg.

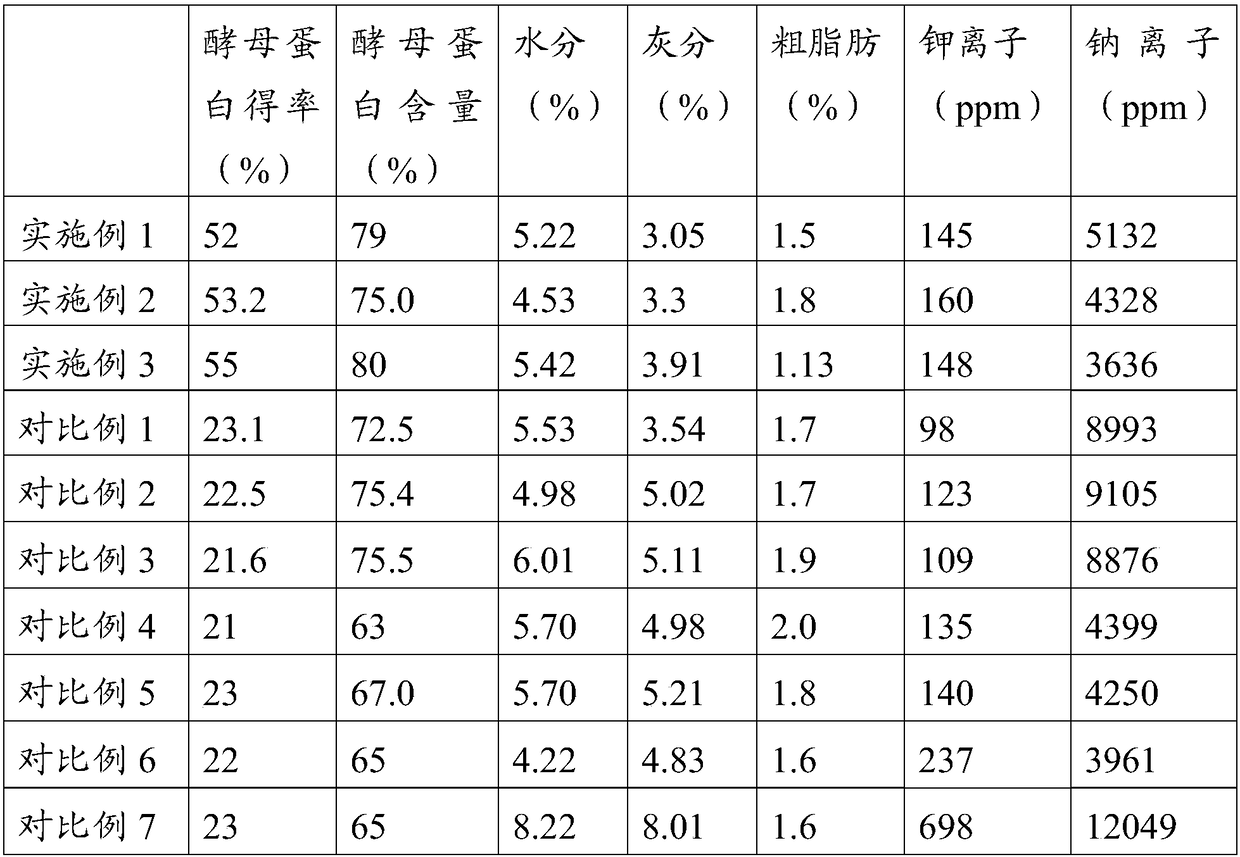

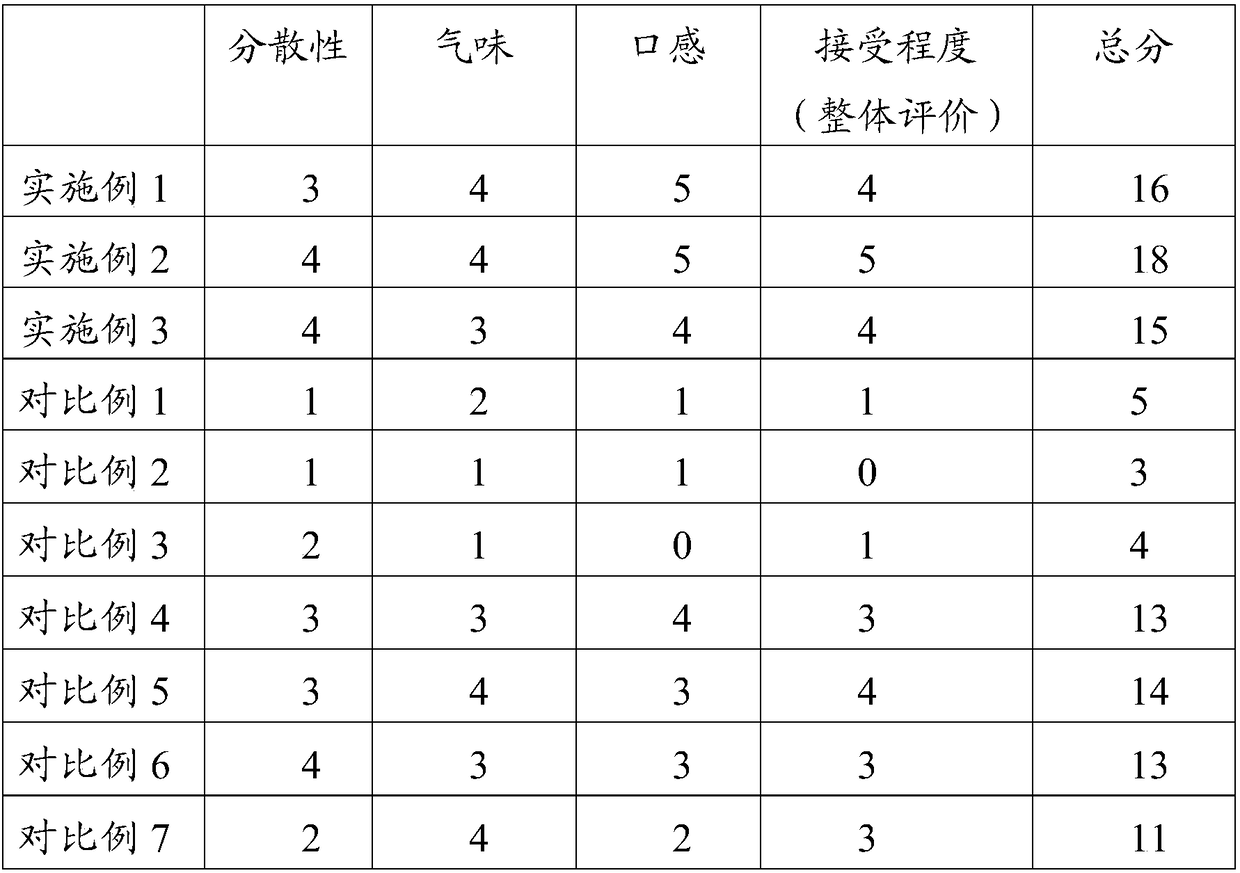

[0048] Calculate the yield of yeast protein powder according to the following formula, and the calculation results are shown in Table 2:

[0049] Yeast protein yield = (yeast protein powder quality ÷ yeast raw material quality) × 100% (formula Ⅰ)

[0050] The content of protein in the ...

Embodiment 2

[0061] Add 10Kg of brewer’s yeast powder and pure water to make a solution of 100Kg, add dilute hydrochloric acid to adjust pH6.0, temperature 55℃, add 100g cellulase for enzymatic hydrolysis for 16h, centrifuge at 5000rpm for 30min, disperse the precipitate with 60Kg water, adjust pH with sodium carbonate to 9.0.

[0062] Under the pressure of 1500bar, homogenize the above liquid once, and the homogeneous flow rate is 2m 3 / h. Then adjust the pH to 7.0 and spray dry to obtain yeast protein powder. The weight of the prepared yeast protein powder product is 5.32Kg.

[0063] According to the same method as in Example 1, the yield of protein was calculated, and the content of protein was determined. The results are shown in Table 2.

[0064] Simultaneously according to the method identical with embodiment 1, measure moisture in the yeast protein that makes, ash content, crude fat, potassium, the content of sodium, measurement result is shown in Table 3.

[0065] At the same t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap