An efficient reaction kettle with an improved heat dissipation speed

A technology of heat dissipation speed and reactor, which is applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve the problem of high cost and achieve low cost and good effect , the effect of compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

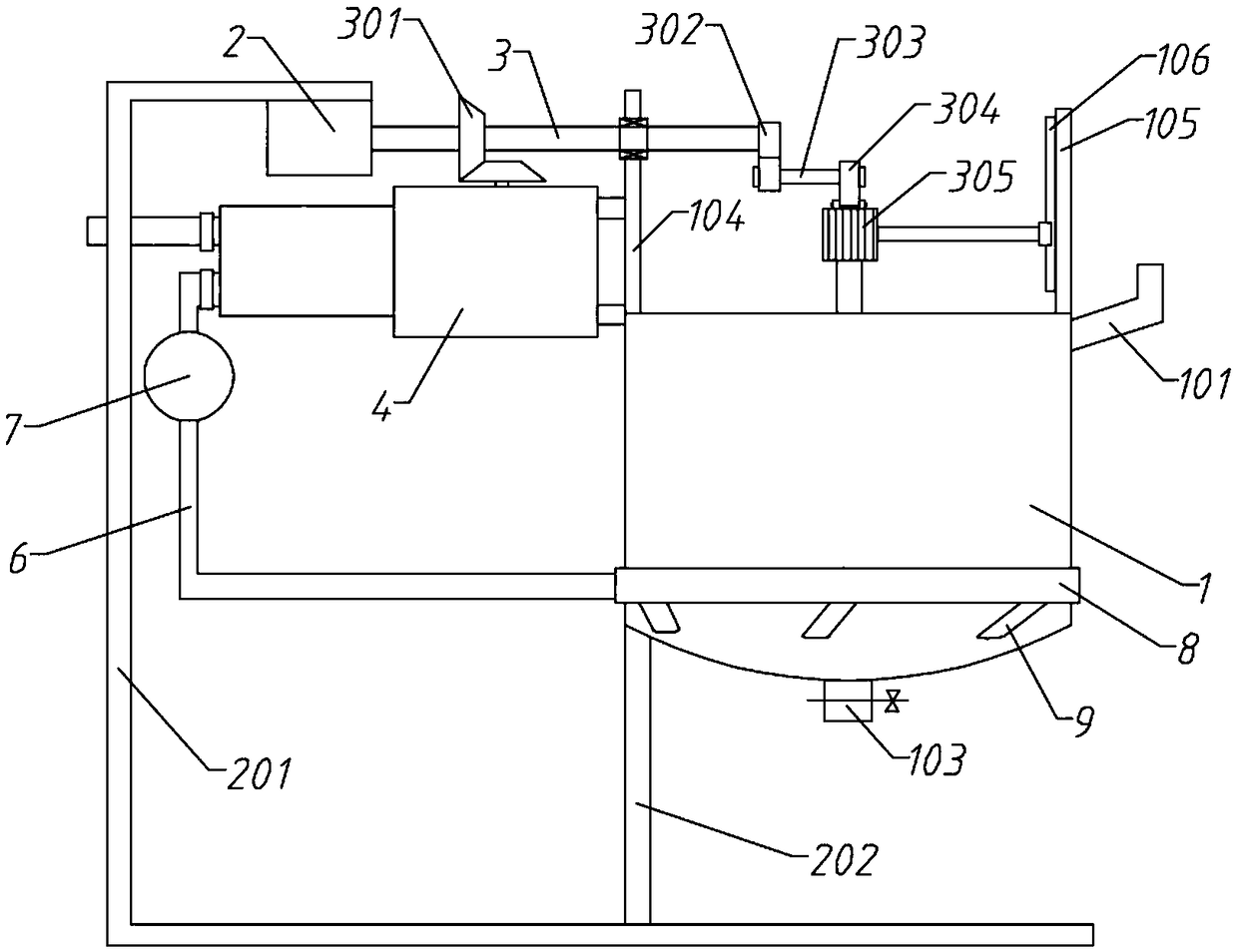

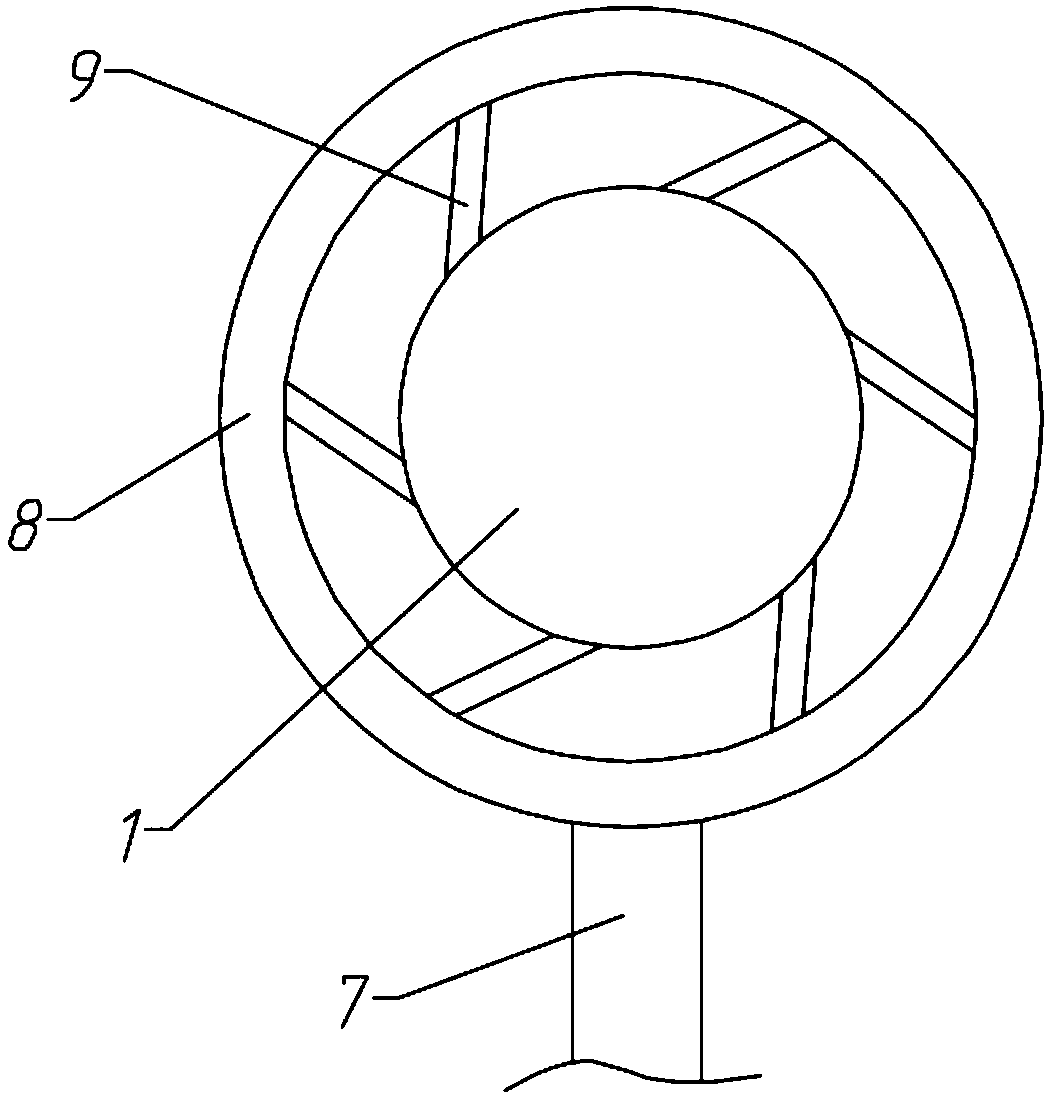

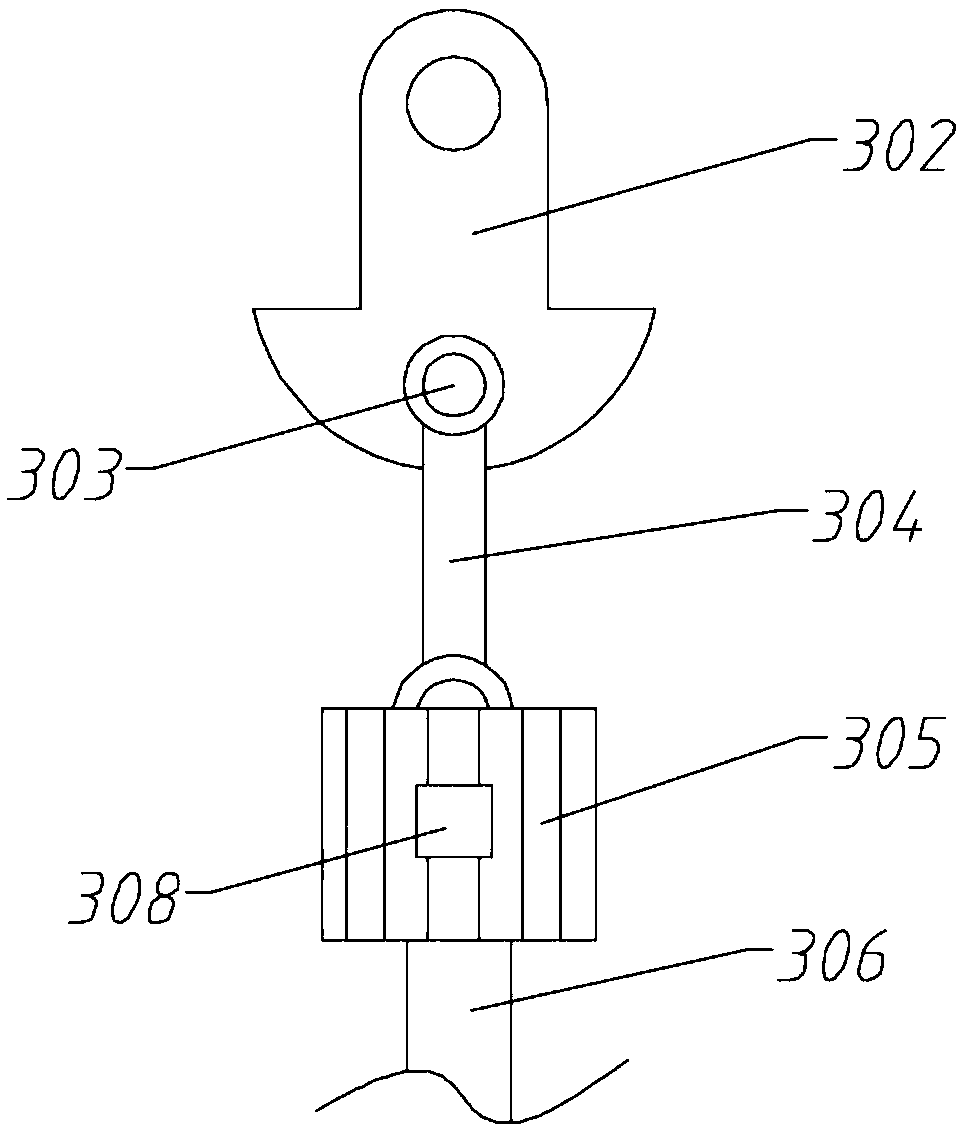

[0041] A high-efficiency reaction kettle for accelerating heat dissipation, including a tank body 1, a mounting frame 201, a lifting component and a suction structure 4;

[0042] The mounting frame 201 is a similar C-shaped plate bent up and down, and the upper end is bent shorter than the lower end; the tank body 1 is arranged on the left side of the mounting frame 201, and the left end of the bottom of the tank body 1 is fixedly connected to the lower end of the mounting frame 201 through a support rod 202; A driving motor 2 is installed on the upper end of the frame 201, and the output end of the driving motor 2 protrudes horizontally to the right and is connected with a driving shaft 3, and the driving shaft 3 is arranged higher than the tank body 1;

[0043] A liquid inlet pipe 101 is connected to the top of one side of the tank body 1; a vertical left support plate 104 and a right support plate 105 are fixedly connected to the left and right ends of the top of the tank bo...

Embodiment 2

[0054] A high-efficiency reaction kettle for accelerating heat dissipation, including a tank body 1, a mounting frame 201, a lifting component and a suction structure 4;

[0055] The mounting frame 201 is a similar C-shaped plate bent up and down, and the upper end is bent shorter than the lower end; the tank body 1 is arranged on the left side of the mounting frame 201, and the left end of the bottom of the tank body 1 is fixedly connected to the lower end of the mounting frame 201 through a support rod 202; A driving motor 2 is installed on the upper end of the frame 201, and the output end of the driving motor 2 protrudes horizontally to the right and is connected with a driving shaft 3, and the driving shaft 3 is arranged higher than the tank body 1;

[0056] A liquid inlet pipe 101 is connected to the top of one side of the tank body 1; a vertical left support plate 104 and a right support plate 105 are fixedly connected to the left and right ends of the top of the tank bo...

Embodiment 3

[0065] A high-efficiency reaction kettle for accelerating heat dissipation, including a tank body 1, a mounting frame 201, a lifting component and a suction structure 4;

[0066] The mounting frame 201 is a similar C-shaped plate bent up and down, and the upper end is bent shorter than the lower end; the tank body 1 is arranged on the left side of the mounting frame 201, and the left end of the bottom of the tank body 1 is fixedly connected to the lower end of the mounting frame 201 through a support rod 202; A driving motor 2 is installed on the upper end of the frame 201, and the output end of the driving motor 2 protrudes horizontally to the right and is connected with a driving shaft 3, and the driving shaft 3 is arranged higher than the tank body 1;

[0067] A liquid inlet pipe 101 is connected to the top of one side of the tank body 1; a vertical left support plate 104 and a right support plate 105 are fixedly connected to the left and right ends of the top of the tank bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com