Novel centrifuging machine for pesticide production

A centrifuge and pesticide technology, applied in the field of centrifuges, can solve the problems that affect the stable operation of pesticide production enterprises, cannot reasonably and efficiently prepare pesticides, and the centrifuge does not run.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

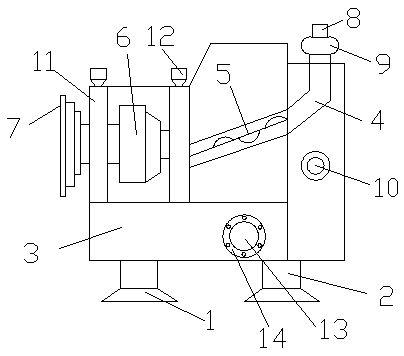

[0016] A new type of centrifuge for pesticide production, comprising a frame 1 and a base 2. A base 2 is riveted on the frame 1, and a body 3 is arranged on the base 2 and on the body 3 An inwardly extending feed tube 4 is provided, and a conveying part 5 is connected to the feed tube 4, and the conveying part 5 is inclined to communicate with the feed tube 4, and on the conveying part 5 A differential 6 is connected, and a differential wheel 7 is arranged outside the differential 6.

[0017] The feed pipe 4 is provided with a feed head 8, the feed head 8 is provided with a contact end, and a cavity 9 is provided at the lower end of the feed head 8. The said cavity 9 has a circular structure, and the cavity 9 and the feed pipe 4 are mutually connected.

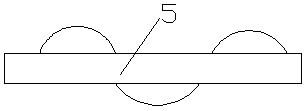

[0018] The conveying component 5 is a screw conveying roller, and a screw blade 9 is provided on the screw conveying roller.

[0019] A washing pipe 10 is provided in the fuselage 3, and the washing pipe 10 is externally connected ...

Embodiment 2

[0024] A new type of centrifuge for pesticide production, comprising a frame 1 and a base 2. A base 2 is riveted on the frame 1, and a body 3 is arranged on the base 2 and on the body 3 An inwardly extending feed tube 4 is provided, and a conveying part 5 is connected to the feed tube 4, and the conveying part 5 is inclined to communicate with the feed tube 4, and on the conveying part 5 A differential 6 is connected, and a differential wheel 7 is arranged outside the differential 6.

[0025] The feed pipe 4 is provided with a feed head 8, the feed head 8 is provided with a contact end, and a cavity 9 is provided at the lower end of the feed head 8. The said cavity 9 has a circular structure, and the cavity 9 and the feed pipe 4 are mutually connected.

[0026] The conveying component 5 is a screw conveying roller, and a screw blade 9 is provided on the screw conveying roller.

[0027] A washing pipe 10 is provided in the fuselage 3, and the washing pipe 10 is externally connected ...

Embodiment 3

[0033] A new type of centrifuge for pesticide production, comprising a frame 1 and a base 2. A base 2 is riveted on the frame 1, and a body 3 is arranged on the base 2 and on the body 3 An inwardly extending feed tube 4 is provided, and a conveying part 5 is connected to the feed tube 4, and the conveying part 5 is inclined to communicate with the feed tube 4, and on the conveying part 5 A differential 6 is connected, and a differential wheel 7 is arranged outside the differential 6.

[0034] The feed pipe 4 is provided with a feed head 8, the feed head 8 is provided with a contact end, and a cavity 9 is provided at the lower end of the feed head 8. The said cavity 9 has a circular structure, and the cavity 9 and the feed pipe 4 are mutually connected.

[0035] The conveying component 5 is a screw conveying roller, and a screw blade 9 is provided on the screw conveying roller.

[0036] A washing pipe 10 is provided in the fuselage 3, and the washing pipe 10 is externally connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com